Preparation method for 3D-SiC/Al composite material of 3D interpenetrating structure

A technology of interpenetrating structure and composite material, which is applied in the field of pressureless infiltration preparation of three-dimensional interpenetrating structure 3D-SiC/Al composite material, can solve the problems of high cost and complicated process, improve wettability and reduce interface heat. The effect of resistance and low expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

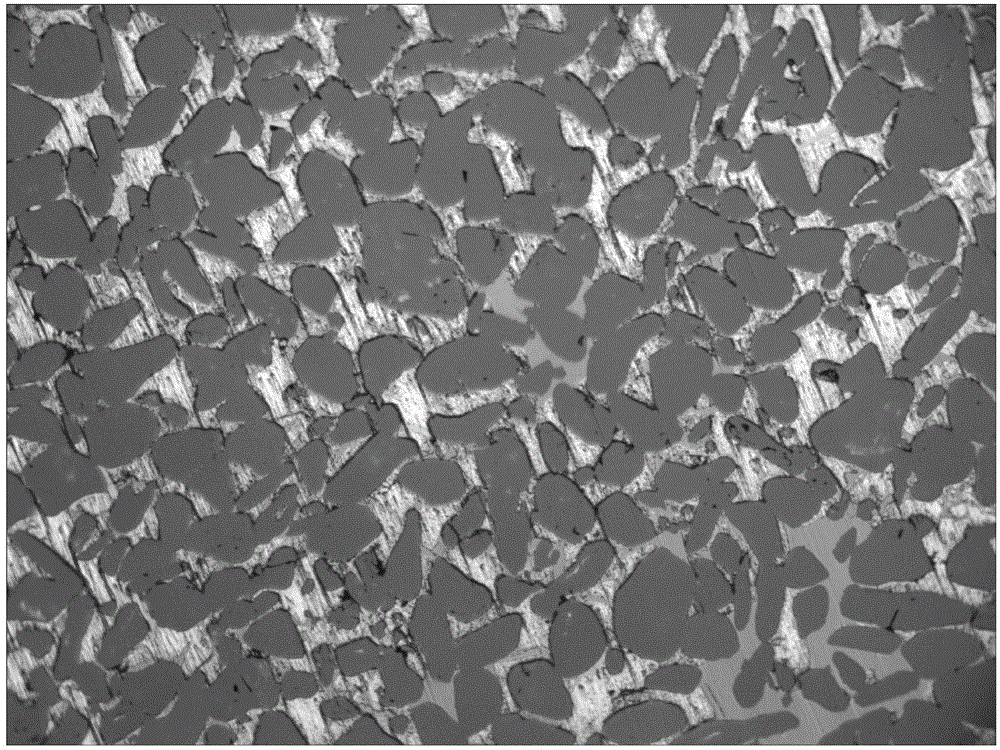

[0029] In this embodiment, the 3D-SiC / Al composite material is made by using SiC powder and aluminum alloy (Al-15Si-10Mg) as main raw materials, and using polycarbosilane as a binder and a sintering aid.

[0030] In this example, the 3D-SiC / Al composite material is prepared according to the following method:

[0031] a. F220 (D50=47μm) SiC micropowder and poly The xylene solution of carbosilane (PCS) is mixed and stirred evenly, wherein the mass of PCS accounts for 8% of the sum of the mass of PCS and SiC micropowder, and silicon carbide powder coated with PCS can be obtained after the xylene volatilizes. Then press it into a SiC biscuit with a pressure of 260MPa on a ceramic tablet press;

[0032] b. Place the SiC biscuit prepared in step a in a tubular atmosphere furnace under the protection of nitrogen and slowly raise the temperature (heating rate 2°C / min) to 700°C for 2 hours, and take samples after cooling to room temperature with the furnace;

[0033] c. Place the SiC b...

Embodiment 2

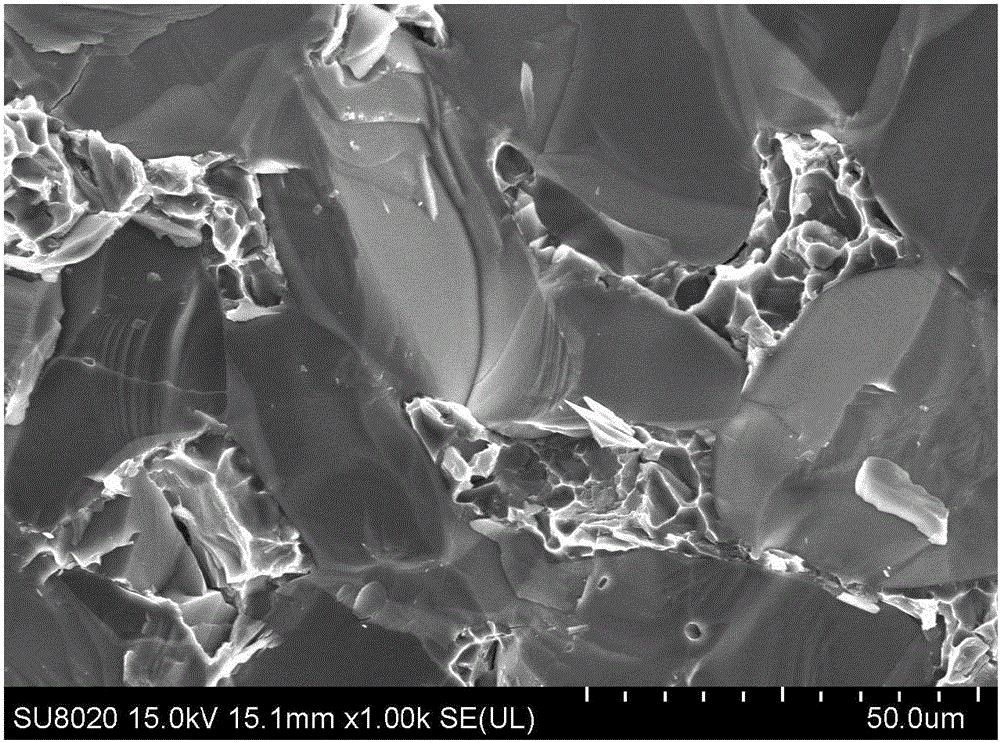

[0037] In this embodiment, the 3D-SiC / Al composite material is made of SiC powder and aluminum alloy (Al-15Si-10Mg) as the main raw materials, and polycarbosilane as the adhesive and sintering aid.

[0038] In this example, the 3D-SiC / Al composite material is prepared according to the following method:

[0039] a. Mix and stir the pretreated F220 (D50=47 μm) SiC powder, F800 (D50=7.2 μm) SiC powder and polycarbosilane (PCS) xylene solution evenly, wherein the mass of PCS accounts for the mass of PCS and SiC powder and the percentage of 5%. SiC powder coated with PCS can be obtained after xylene volatilizes. Then press it into a SiC biscuit with a pressure of 200MPa on a ceramic tablet press;

[0040] b. Place the SiC biscuit prepared in step a in a tubular atmosphere furnace under the protection of nitrogen and slowly raise the temperature (heating rate 2°C / min) to 1100°C for 1 hour, and take samples after cooling to room temperature with the furnace;

[0041] c. Place the ...

Embodiment 3

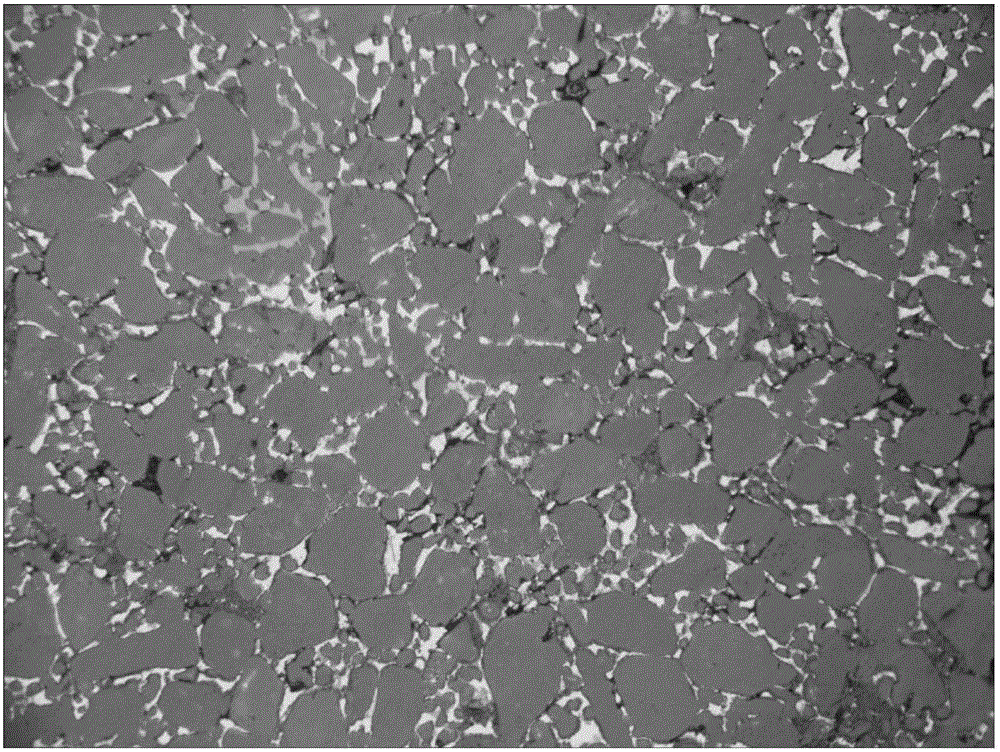

[0045] In this embodiment, the 3D-SiC / Al composite material is made by using SiC powder and aluminum alloy (Al-6Si-8Mg) as main raw materials, and using polycarbosilane as a binder and a sintering aid.

[0046] In this example, the 3D-SiC / Al composite material is prepared according to the following method:

[0047] a. Mix and stir the pretreated F220 (D50=47 μm) SiC micropowder and polycarbosilane (PCS) xylene solution according to the designed ratio, wherein the mass of PCS accounts for 5% of the sum of the mass of PCS and SiC micropowder. After xylene volatilizes, silicon carbide powder coated with PCS micropowder can be obtained. Then press it into a SiC biscuit with a pressure of 220MPa on a ceramic tablet press;

[0048] b. Place the SiC biscuit prepared in step a in a tubular atmosphere furnace under the protection of nitrogen and slowly raise the temperature (heating rate 2°C / min) to 600°C for 2 hours, and take samples after cooling to room temperature with the furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com