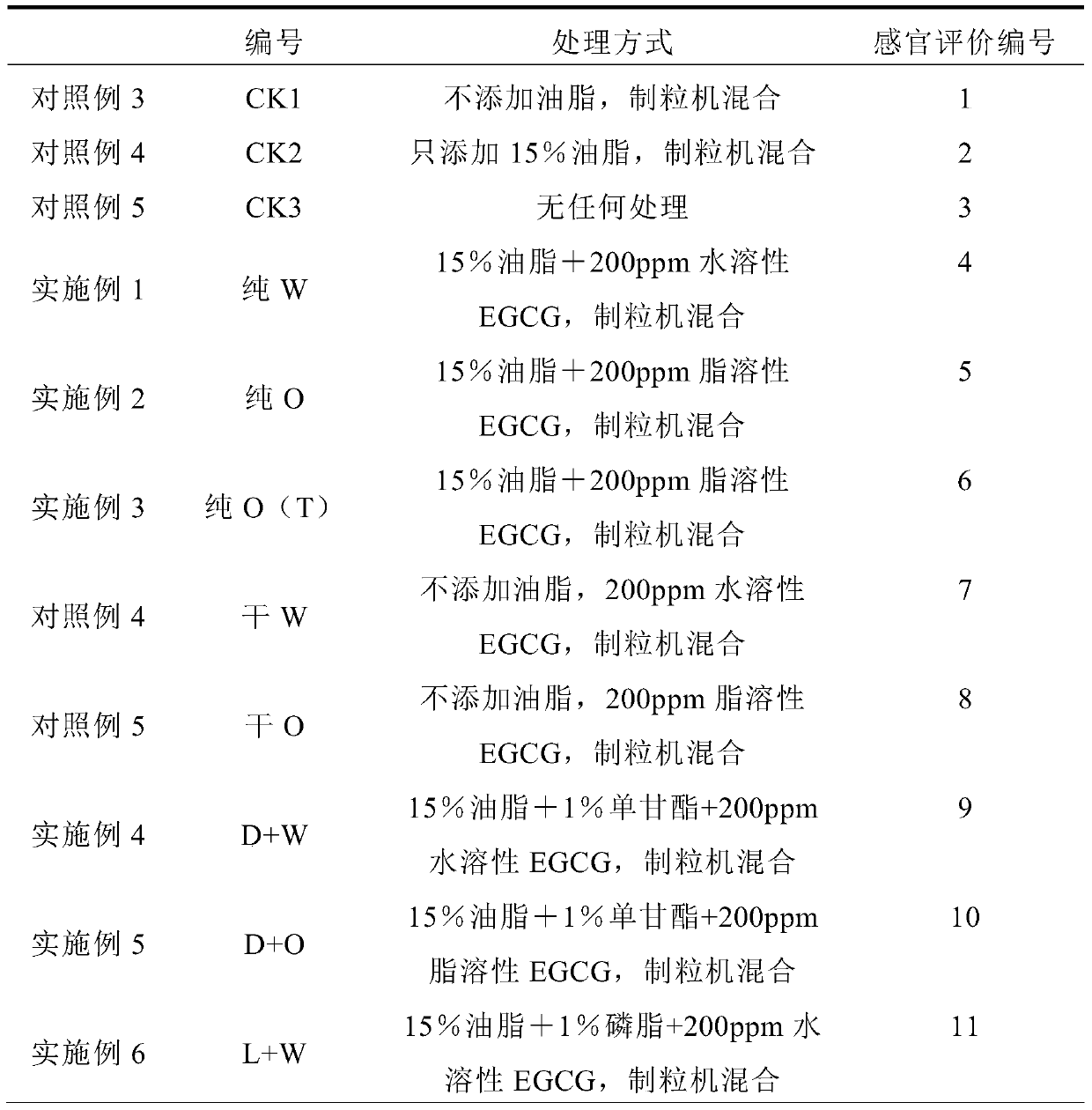

Patents

Literature

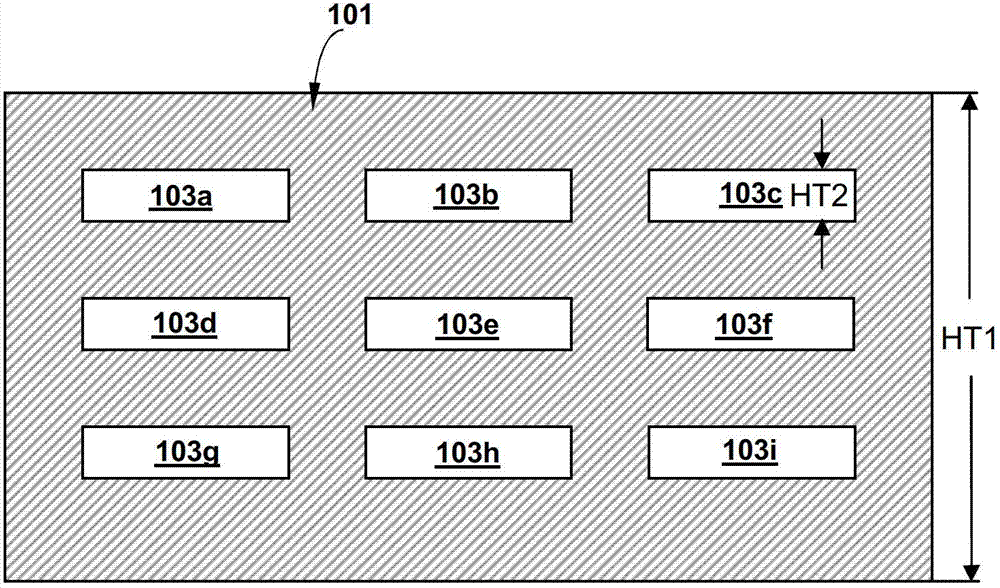

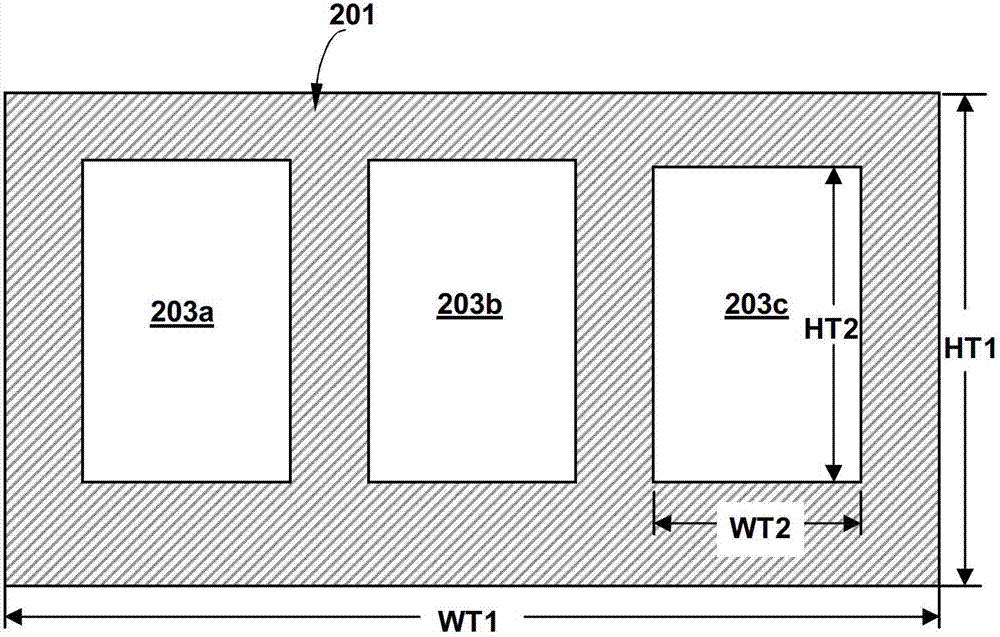

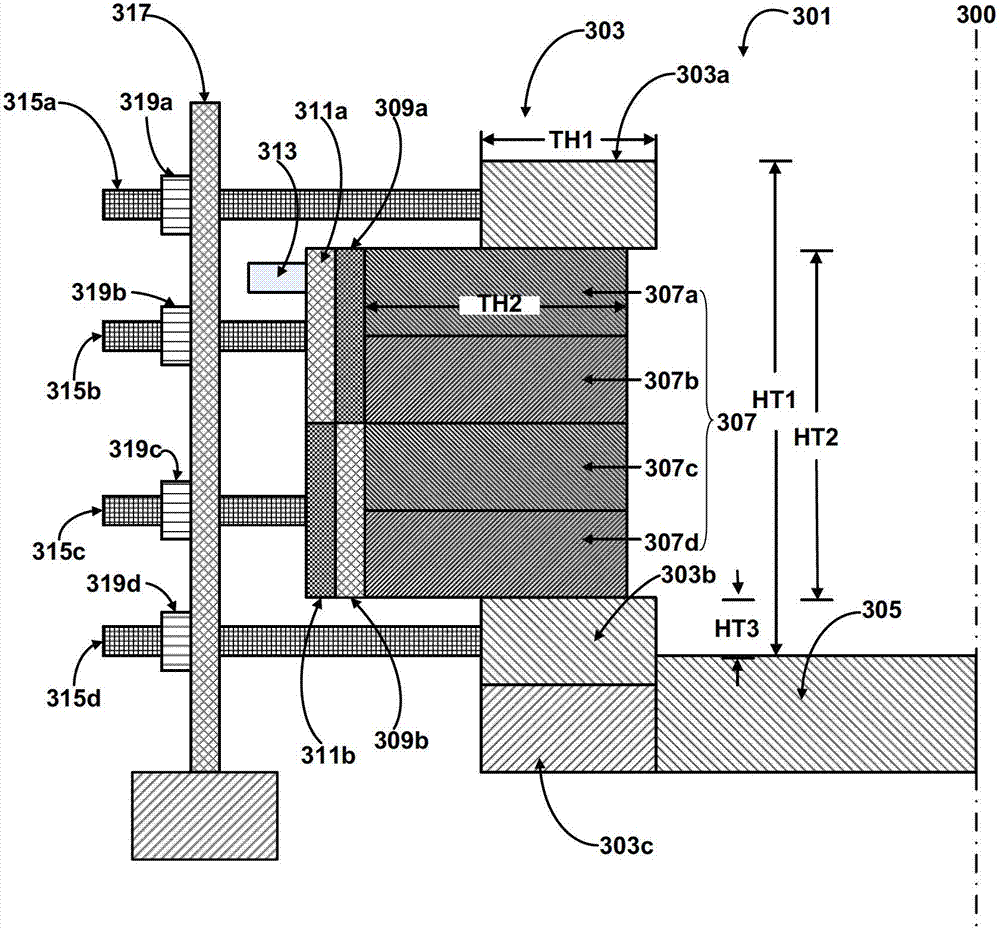

57results about How to "Reduce interface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

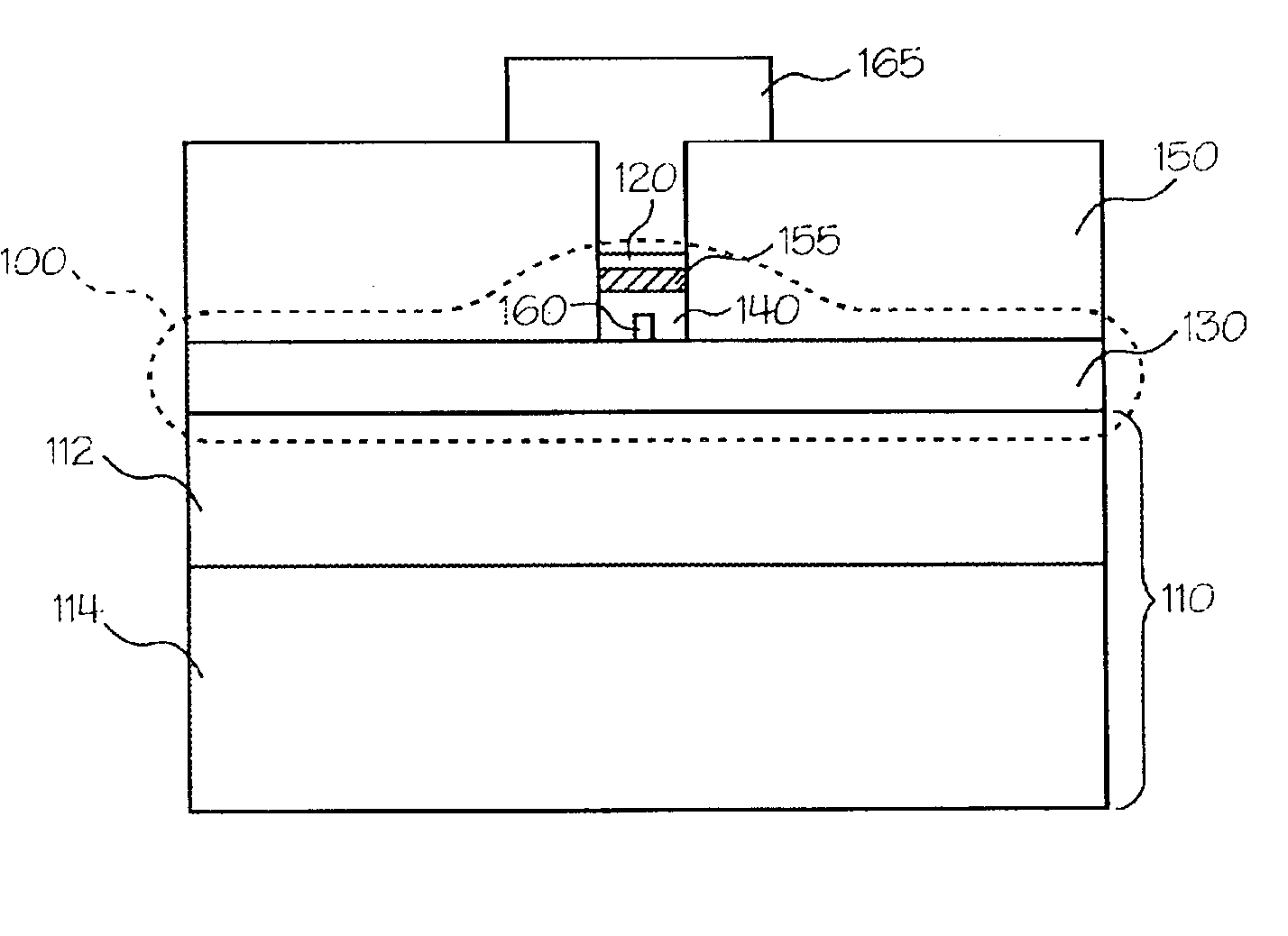

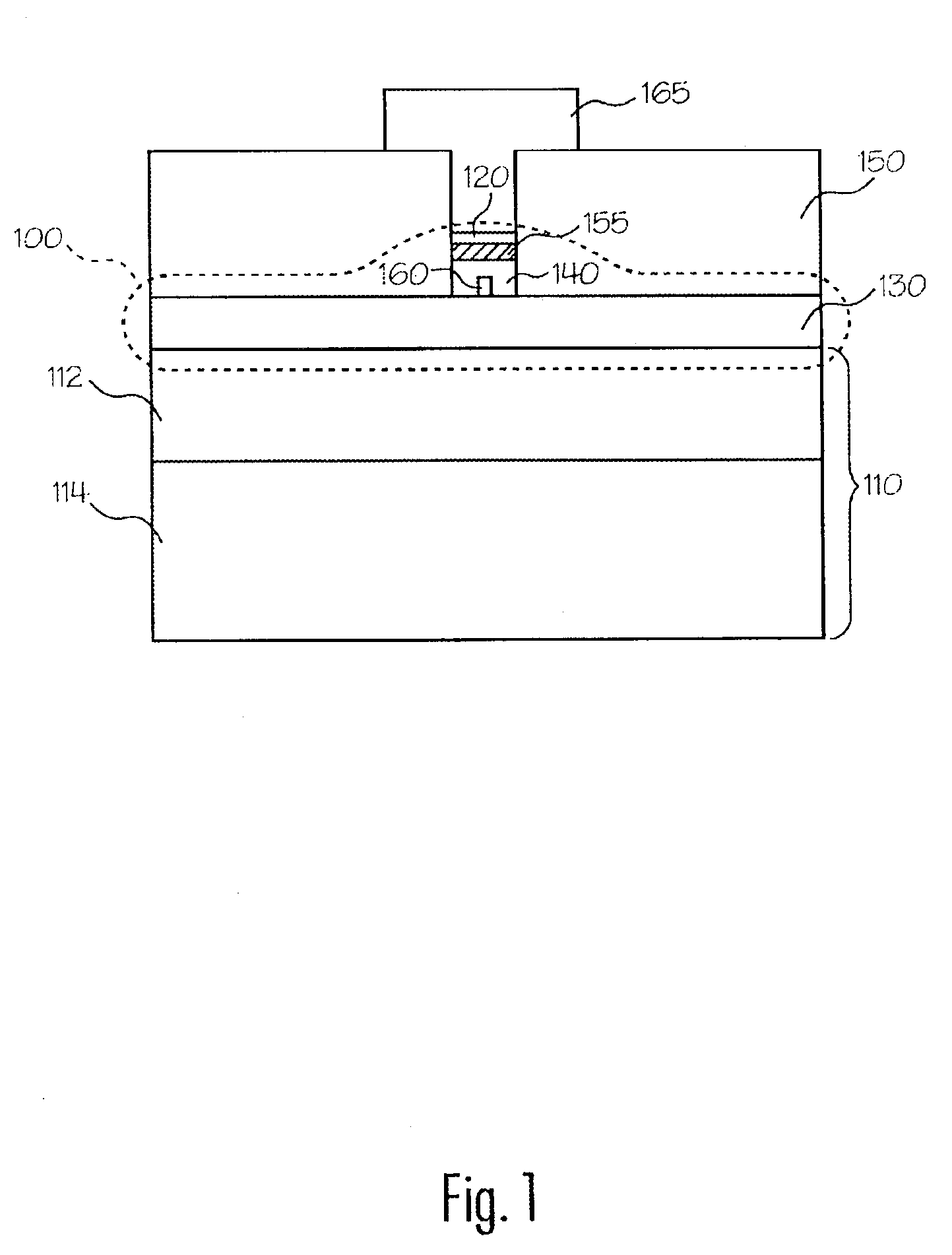

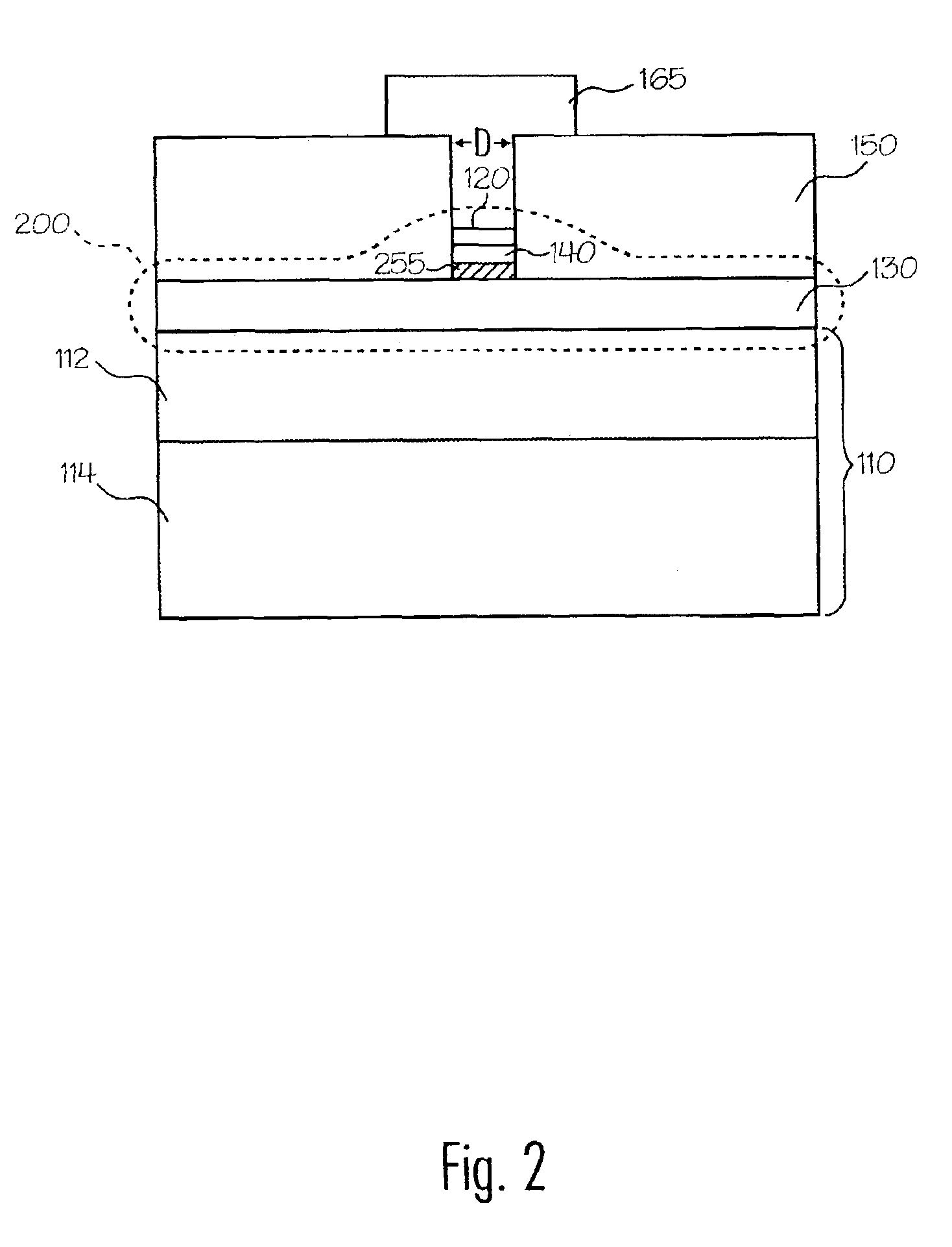

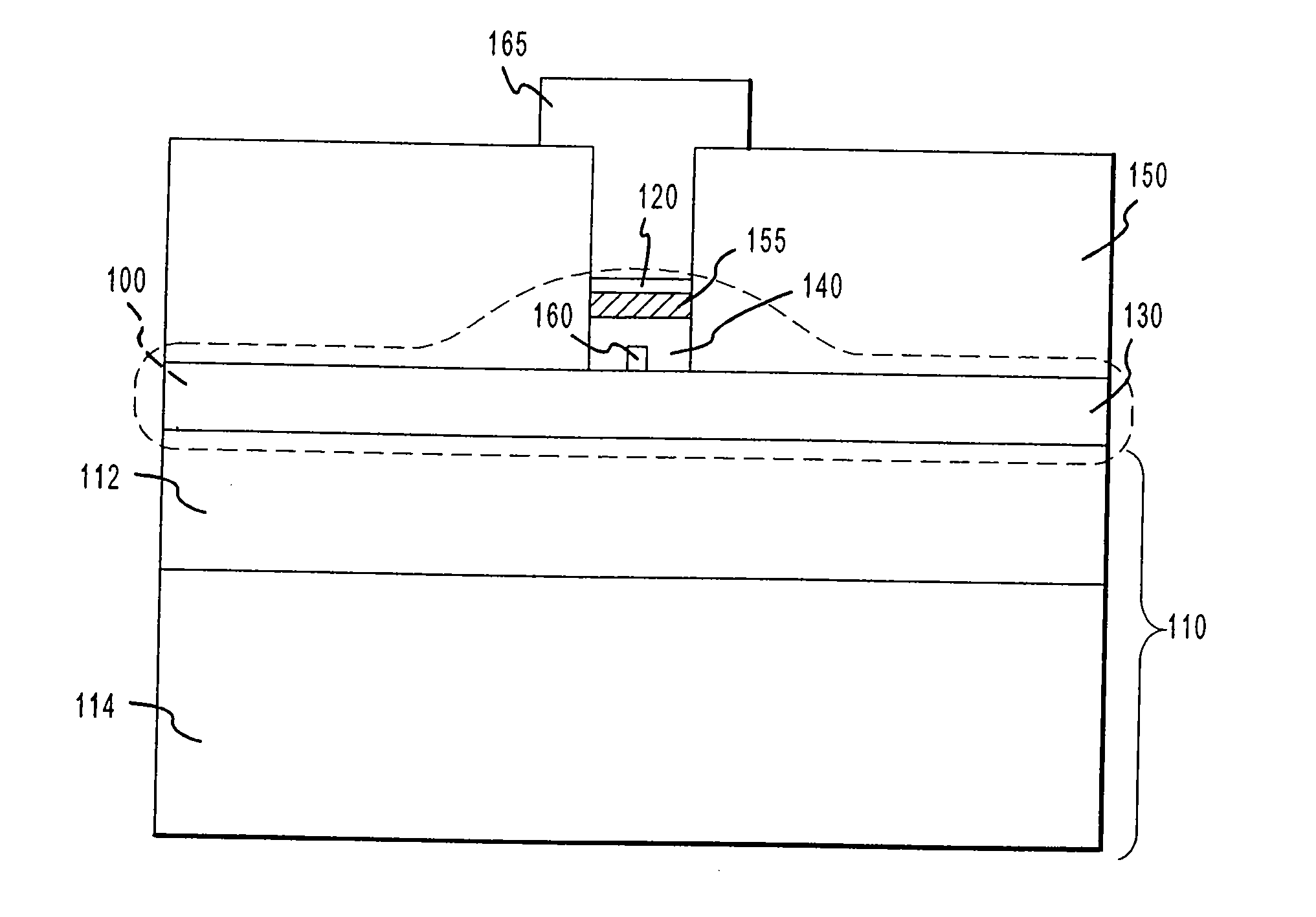

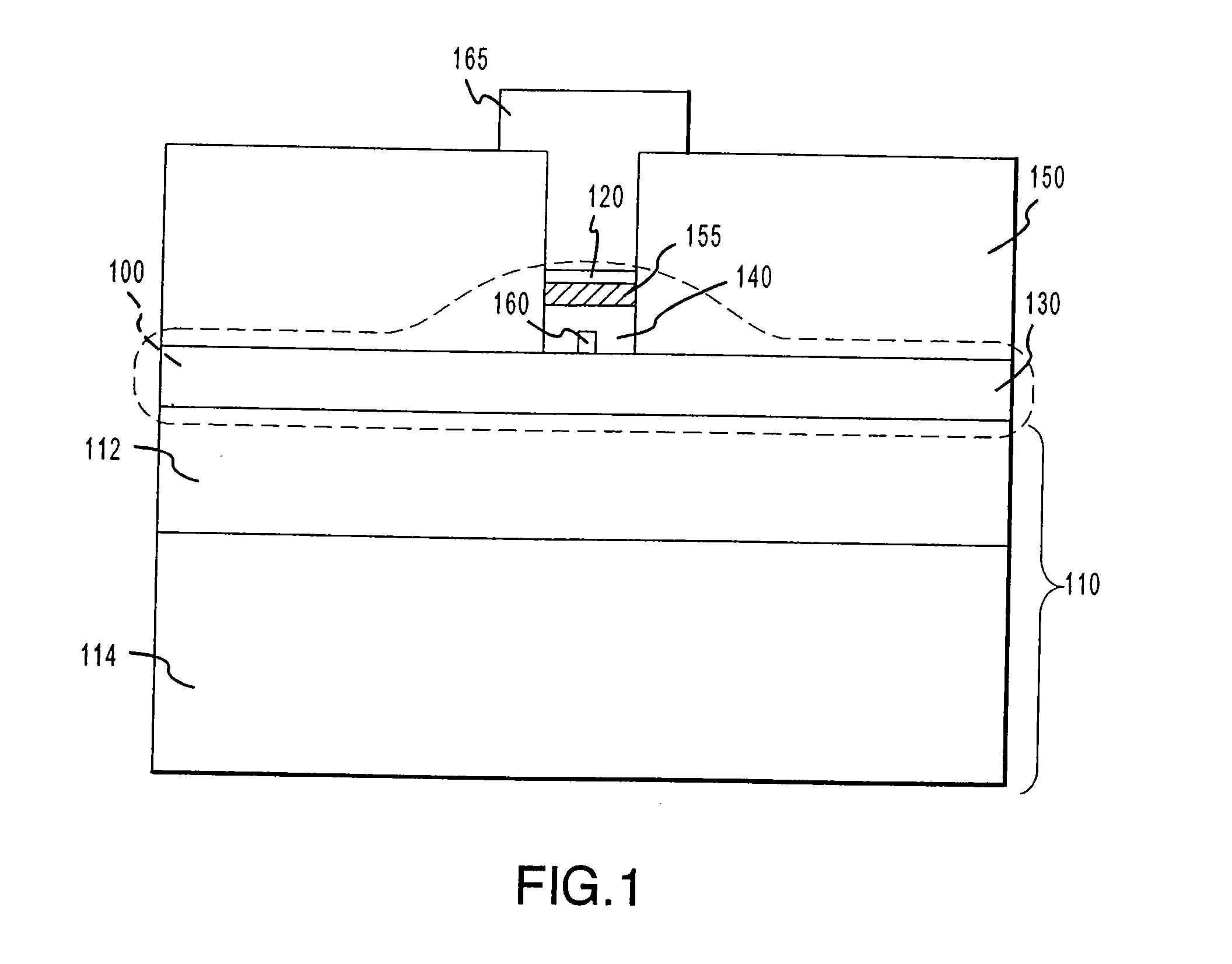

Programmable microelectronic device, structure, and system and method of forming the same

InactiveUS6985378B2Easy and inexpensive to manufactureVariably programmedTransistorNanoinformaticsElectrical conductorProgrammable logic device

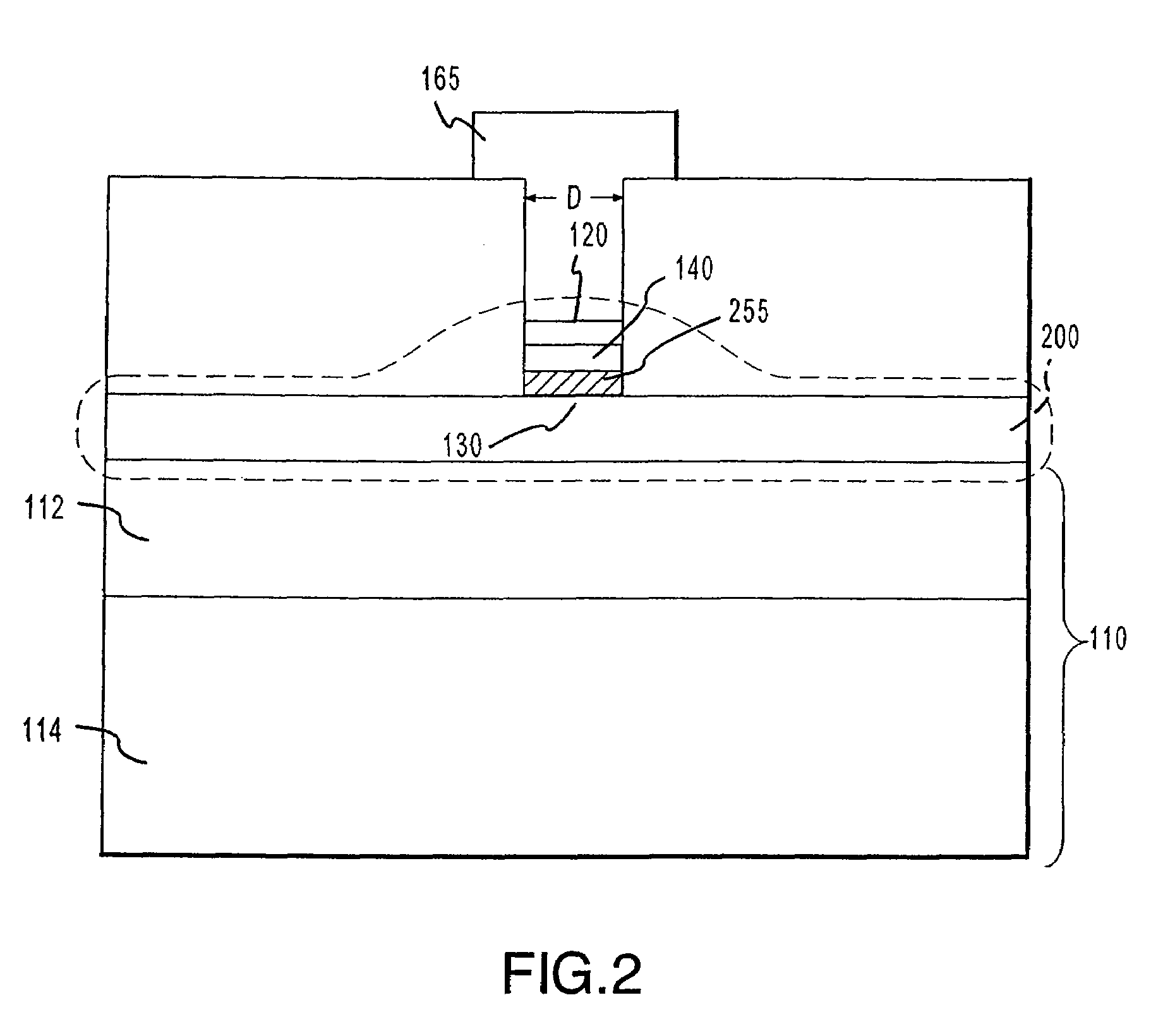

A microelectronic programmable structure suitable for storing information and a method of forming and programming the structure are disclosed. The programmable structure generally includes an ion conductor and a plurality of electrodes. Electrical properties of the structure may be altered by applying energy to the structure, and thus information may be stored using the structure.

Owner:AXON TECH

Microelectronic programmable device and methods of forming and programming the same

InactiveUS6998312B2Easy and inexpensive to manufactureEasy programmingSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorEngineering

A microelectronic programmable structure and methods of forming and programming the structure are disclosed. The programmable structure generally include an ion conductor and a plurality of electrodes. Electrical properties of the structure may be altered by applying a bias across the electrodes, and thus information may be stored using the structure.

Owner:AXON TECH

Microelectric programmable device and methods of forming and programming the same

InactiveUS7675766B2Easy and inexpensive to manufactureEasy programmingTransistorNanotechElectrical conductorEngineering

A microelectronic programmable structure and methods of forming and programming the structure are disclosed. The programmable structure generally include an ion conductor and a plurality of electrodes. Electrical properties of the structure may be altered by applying a bias across the electrodes, and thus information may be stored using the structure.

Owner:AXON TECH

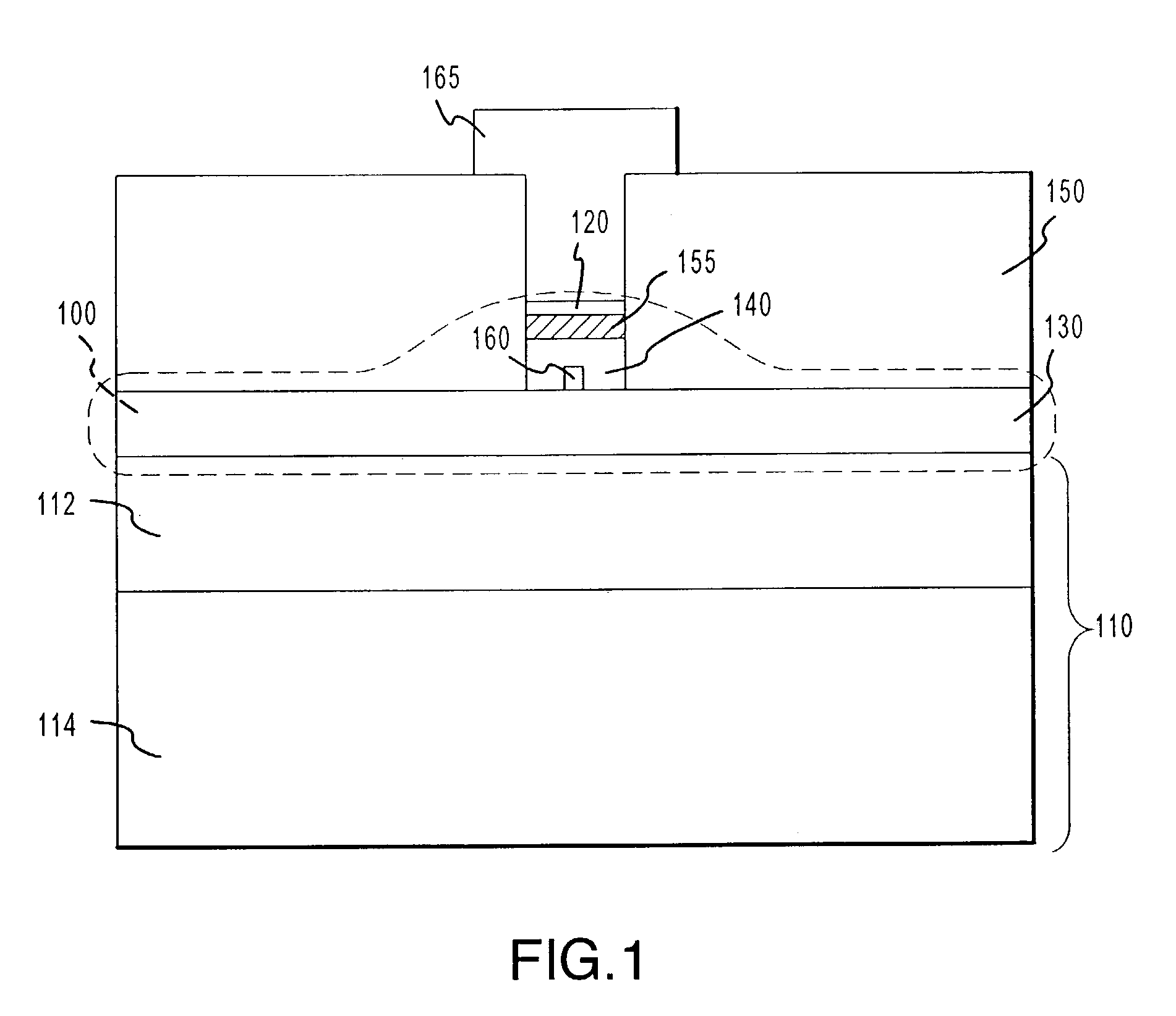

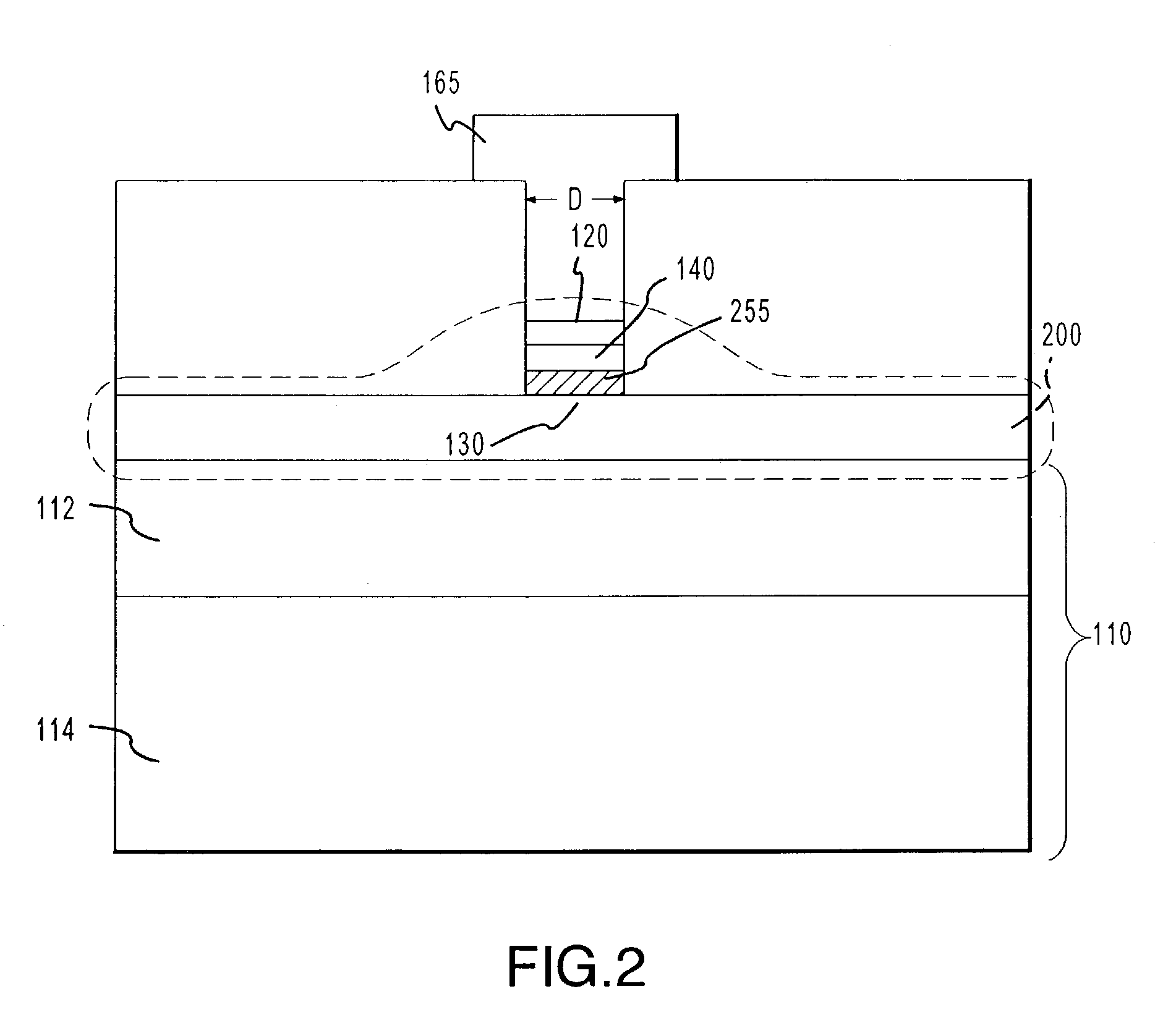

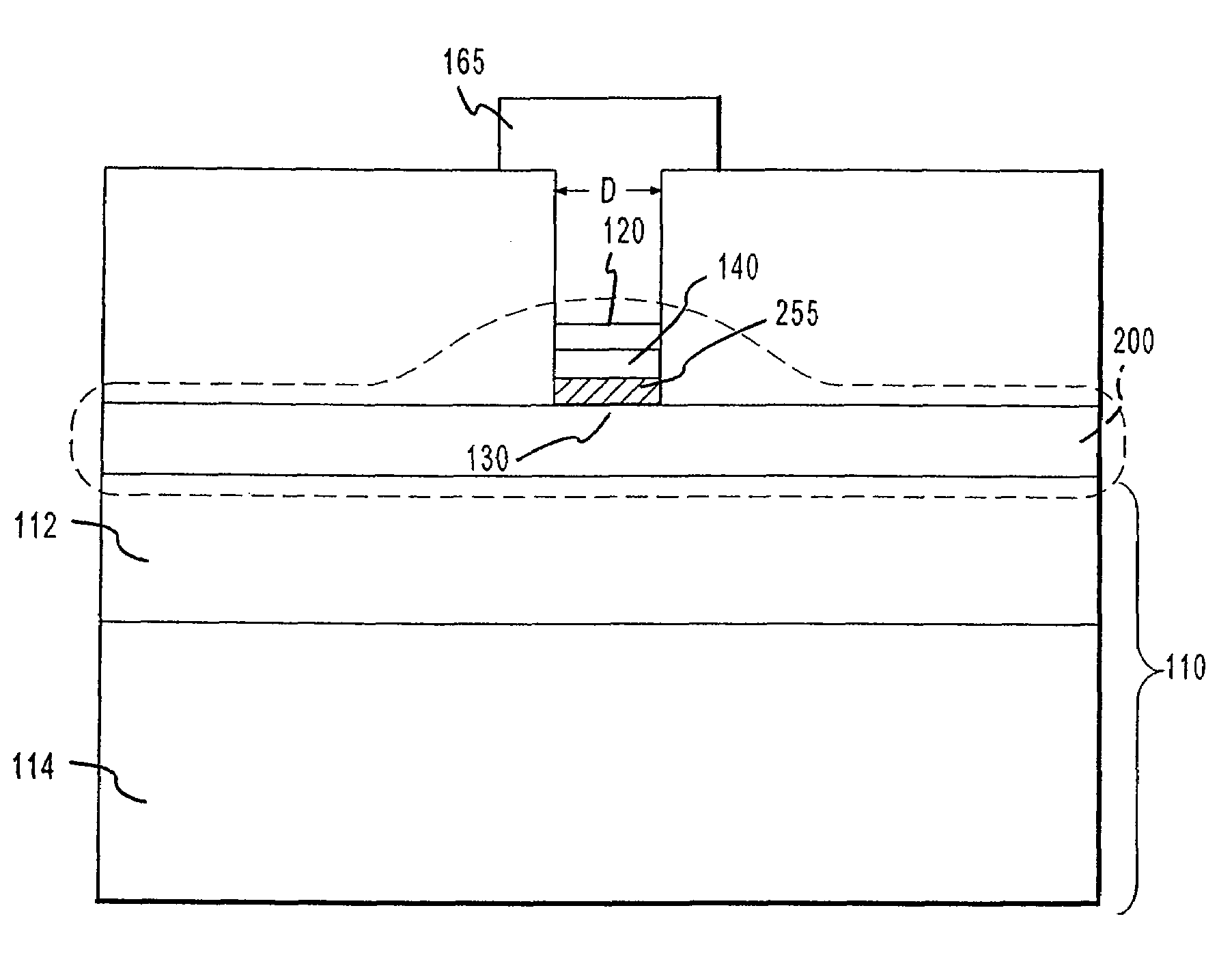

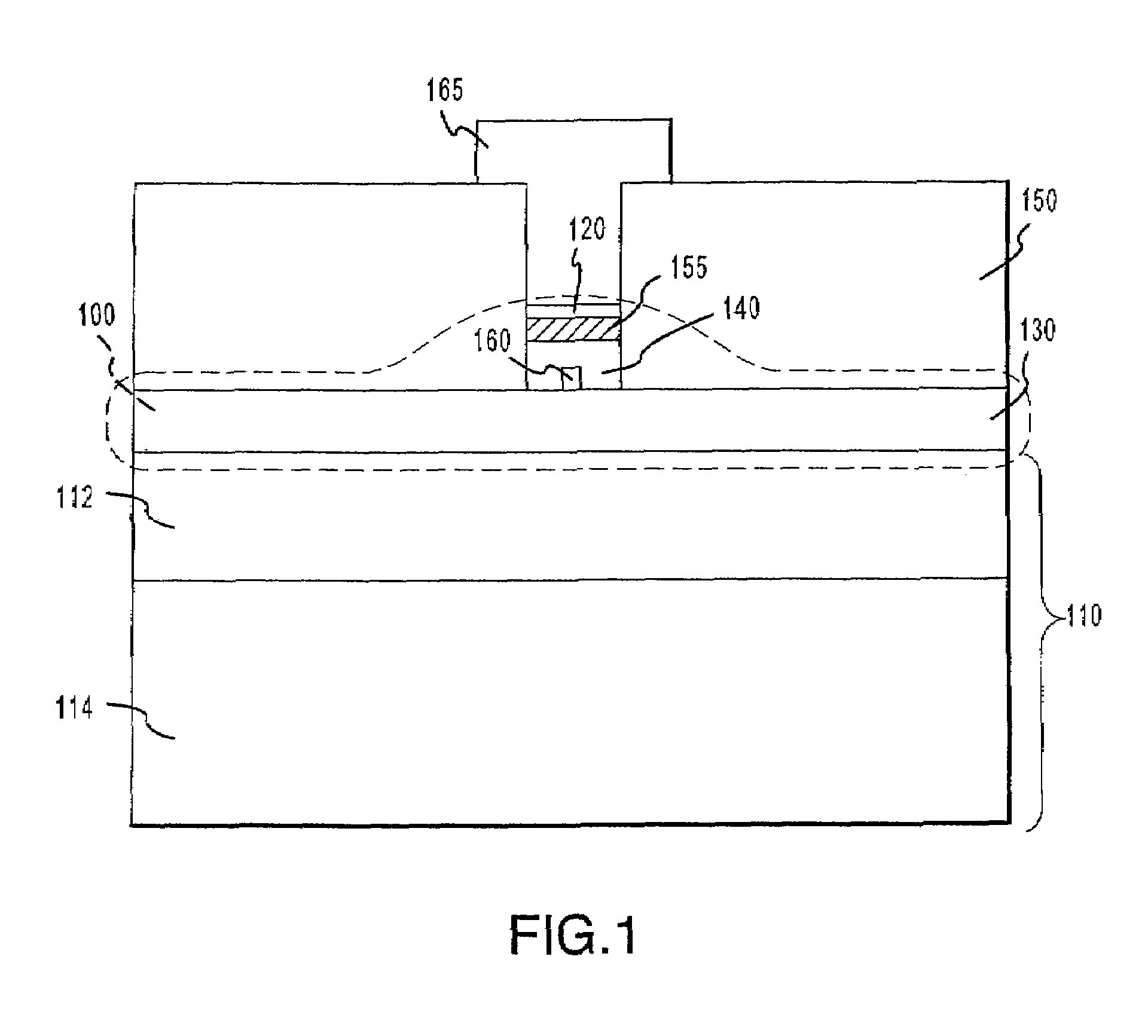

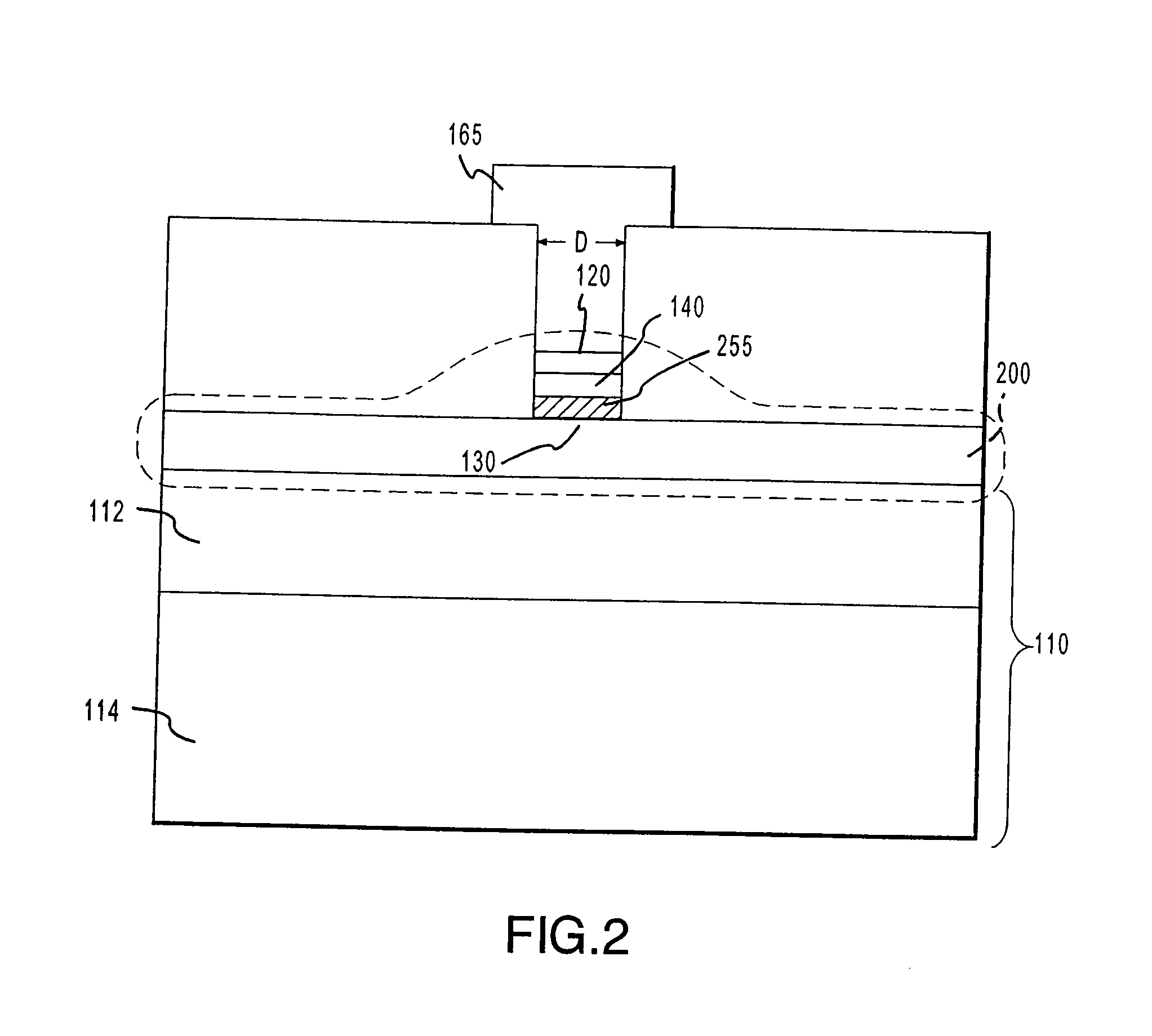

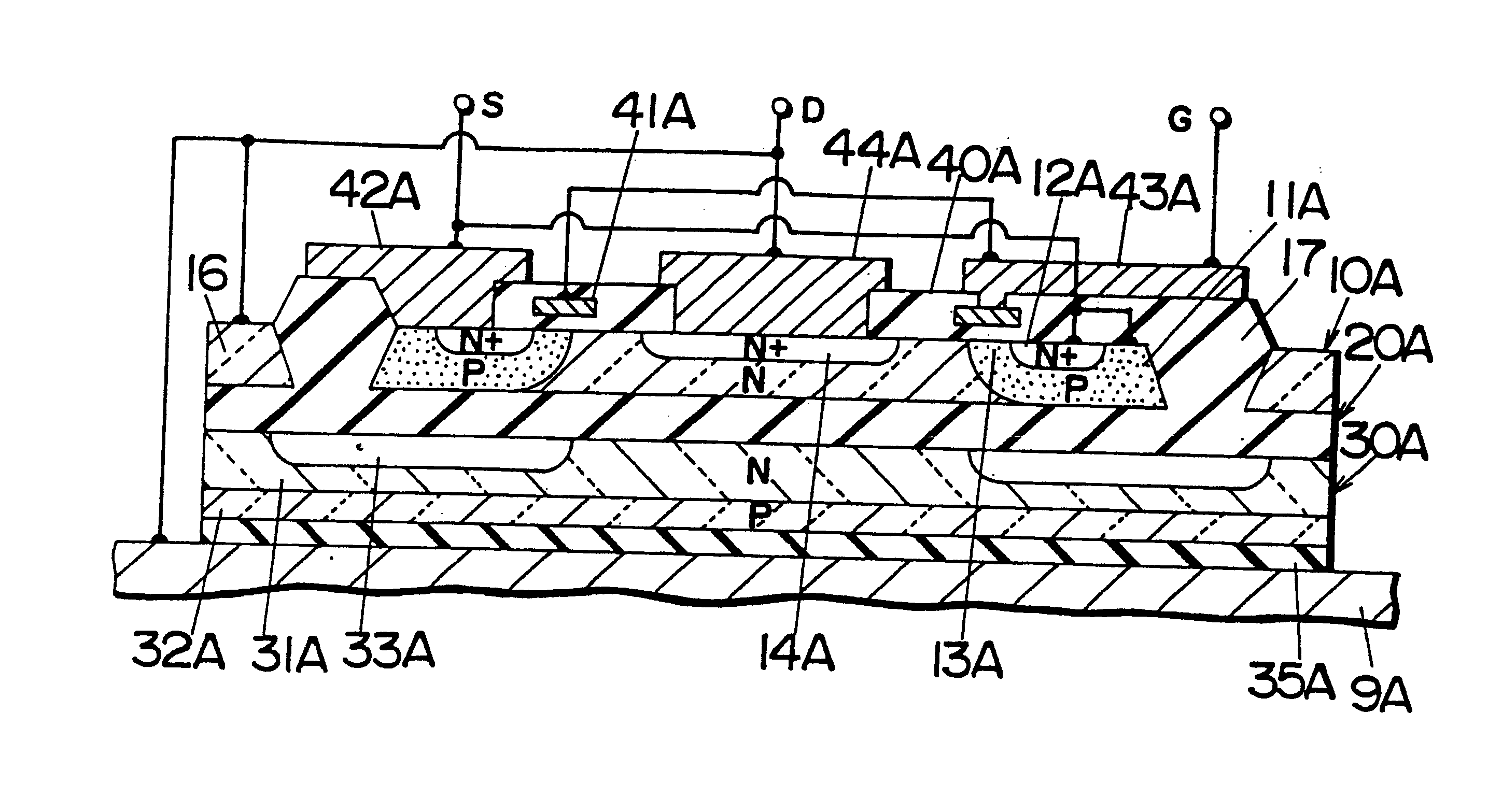

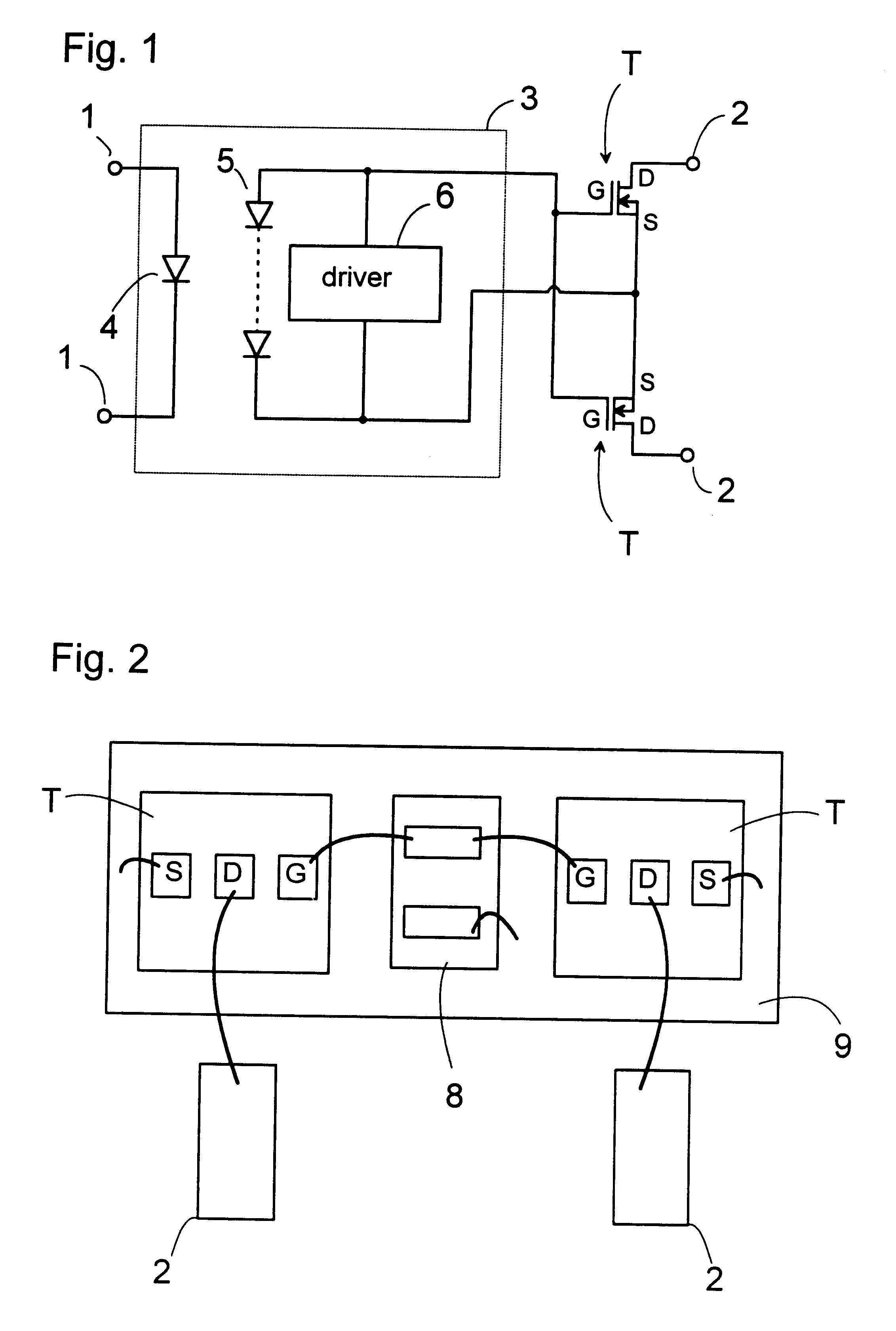

Solid-state relay

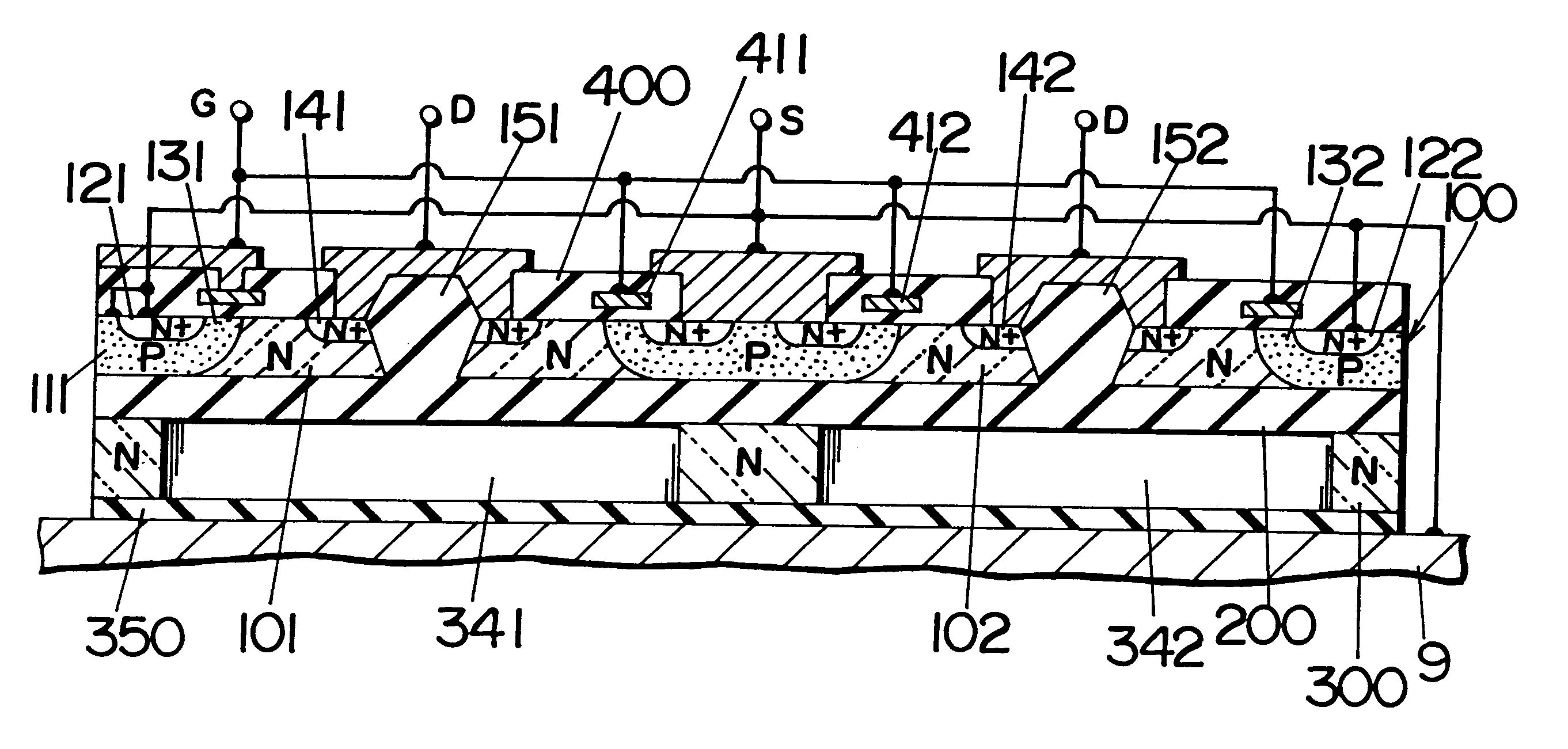

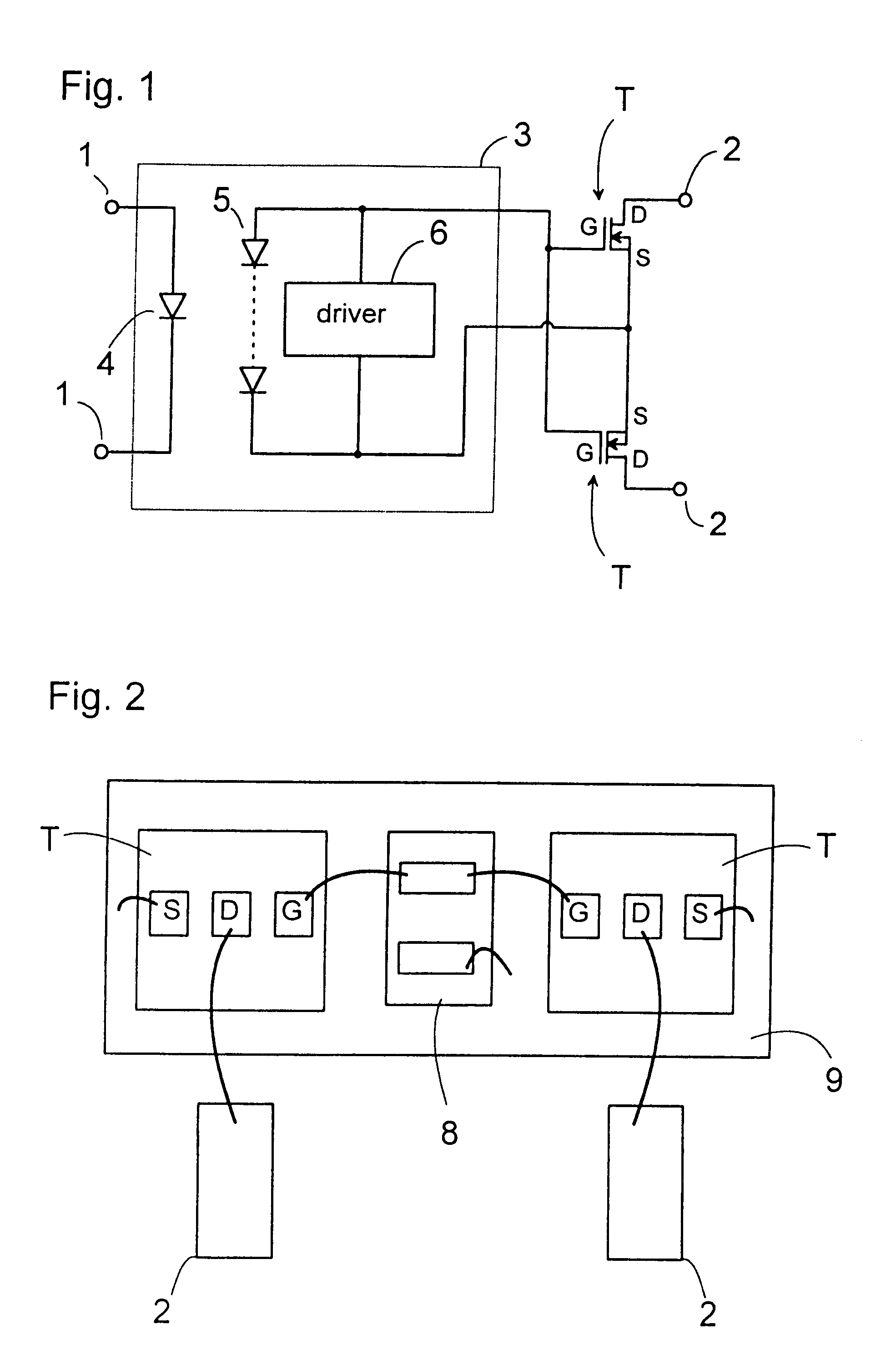

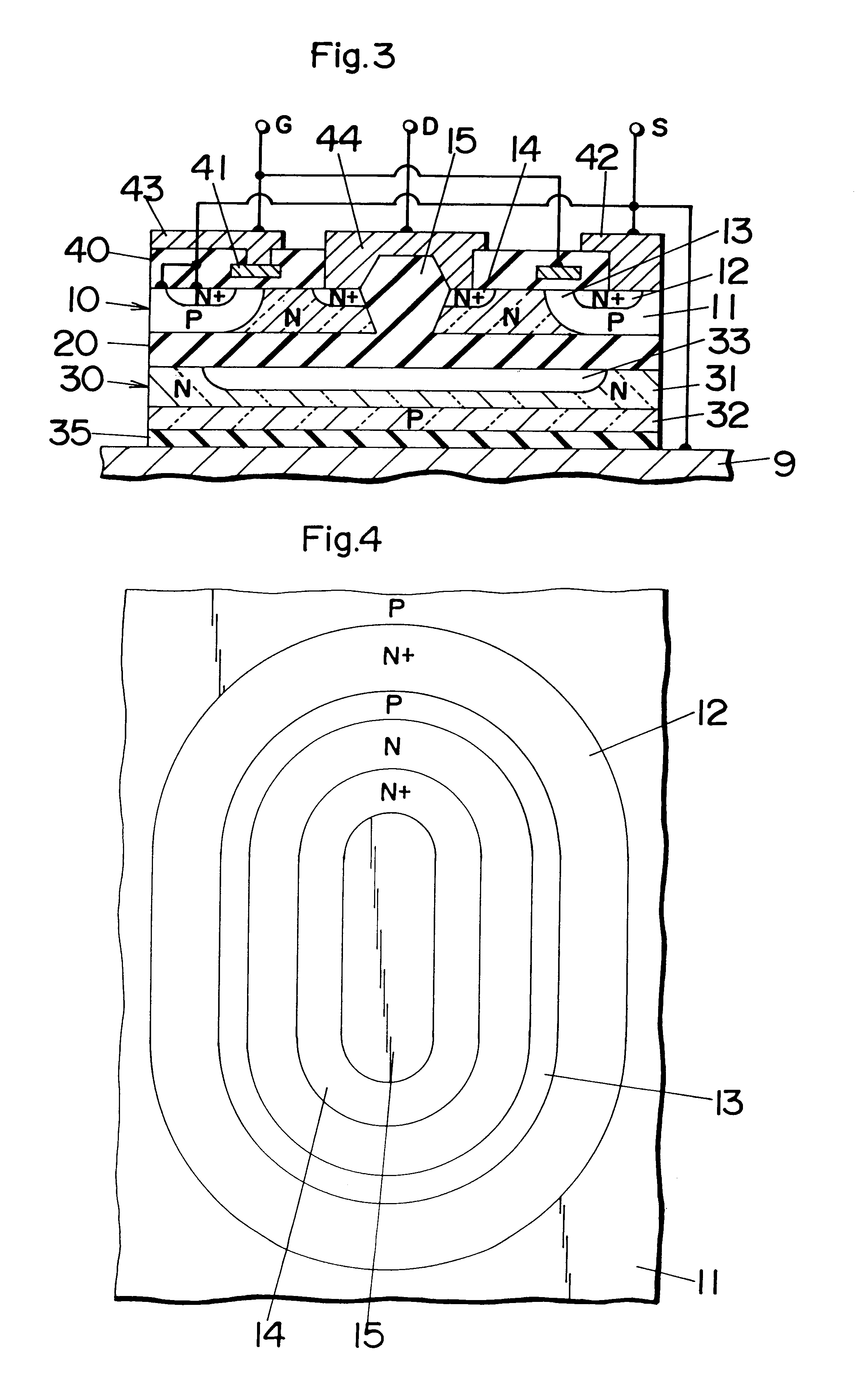

InactiveUS6211551B1Sufficient flexibilityReduce interfaceTransistorSemiconductor/solid-state device detailsCapacitanceInductance

A solid state relay composed of a series connected pair of LDMOSFETs has a minimized output capacitance. Each LDMOSFET is configured to have a silicon layer of a first conductive type, a drain region of the first conductive type diffused in the top surface of the silicon layer, a well region of a second conductive type diffused in the silicon layer in a laterally spaced relation from the drain region, and a source region of the first conductive type diffused within the well region to define a channel extending between the source region and a confronting edge of the well region along the top surface of the silicon layer. Each LDMOSFET is of an SOI (Silicon-On-Insulator) structure composed of a silicon substrate placed on a supporting plate, a buried oxide layer on the silicon substrate, and the silicon layer on the buried oxide layer. The well region is diffused over the full depth of the silicon layer to have its bottom in contact with the buried oxide layer, so that the well region forms with the silicon layer a P-N interface only at a small area adjacent the channel. Because of this reduced P-N interface and also because of the buried oxide layer exhibiting a much lower inductive capacitance than the silicon layer, it is possible to greatly reduce a drain-source capacitance for minimizing the output capacitance of the relay in the non-conductive condition.

Owner:CORNELL RES FOUNDATION INC

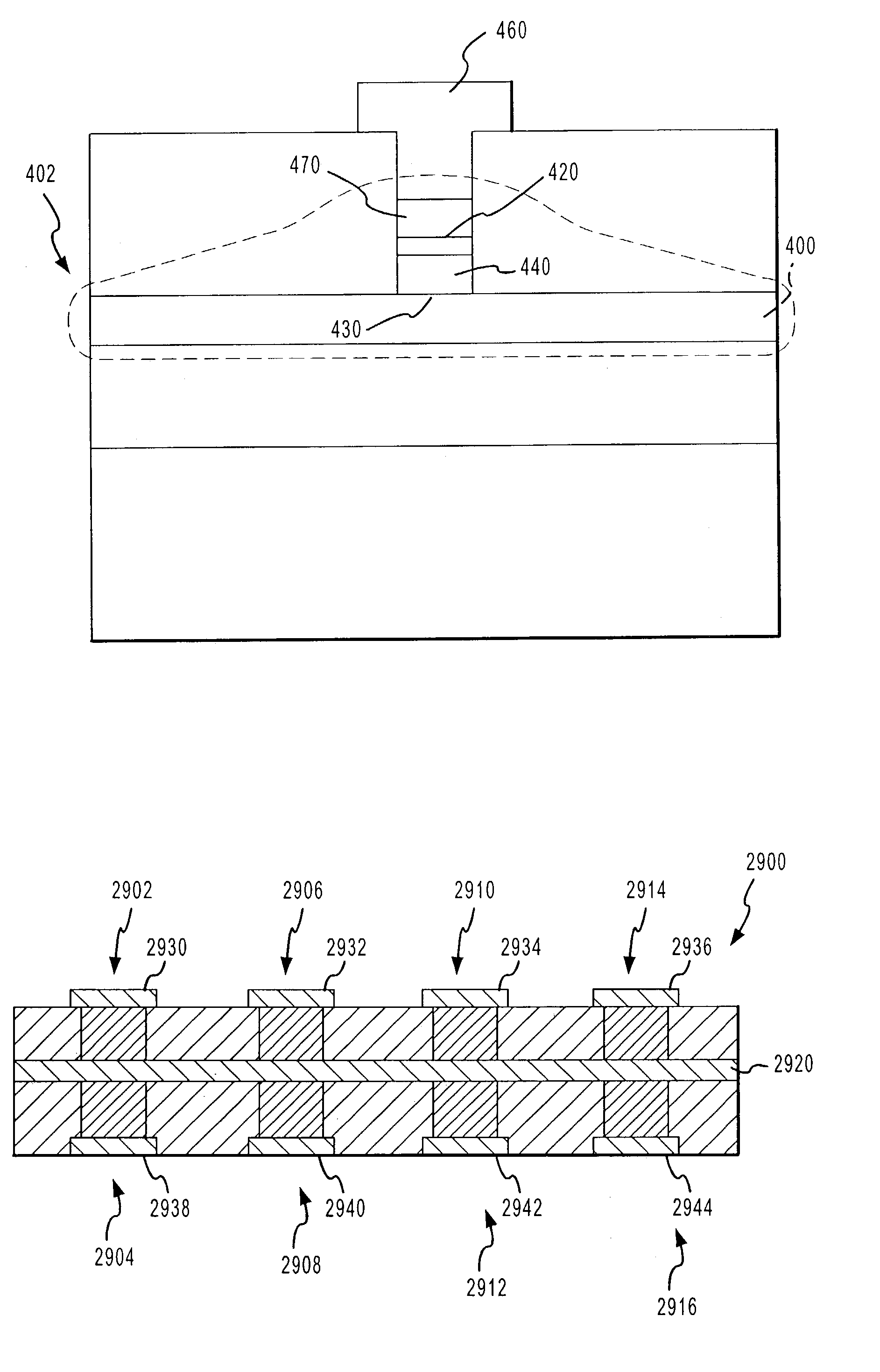

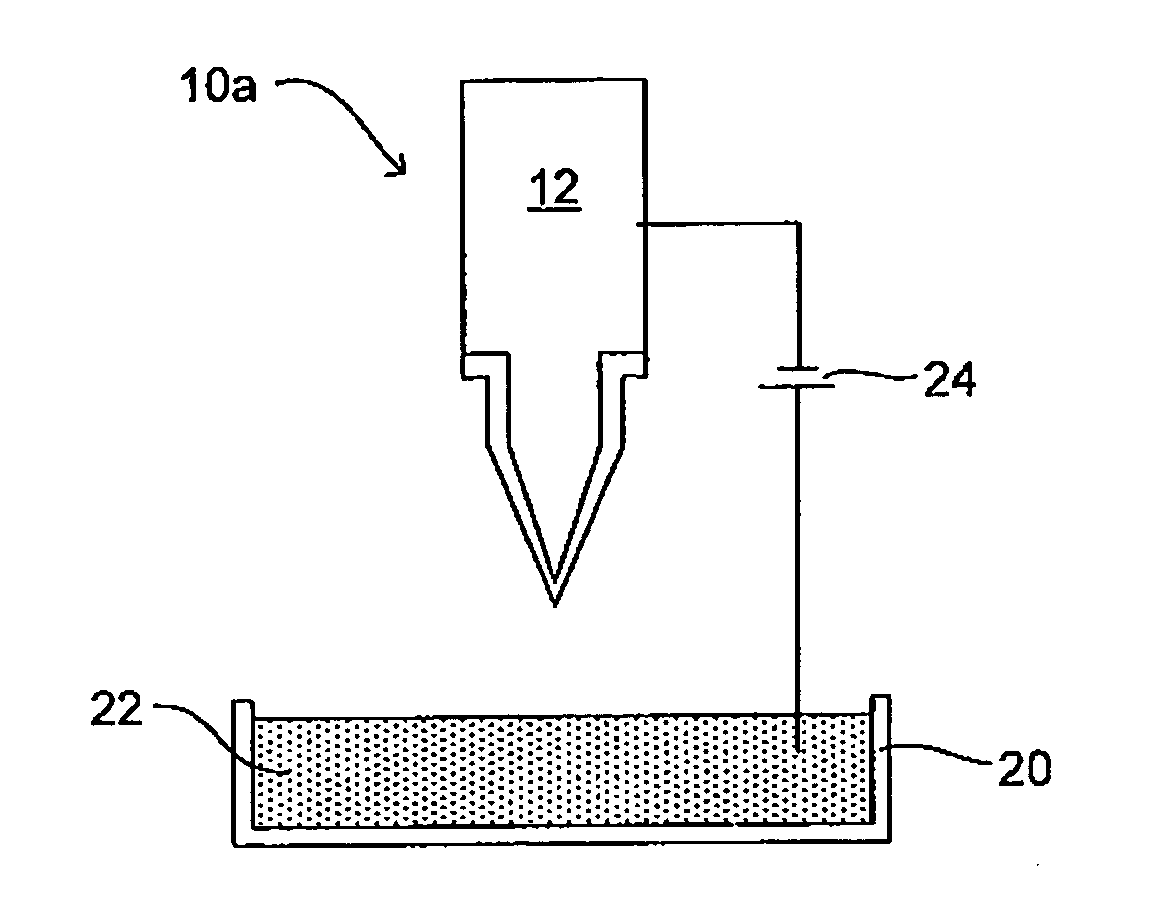

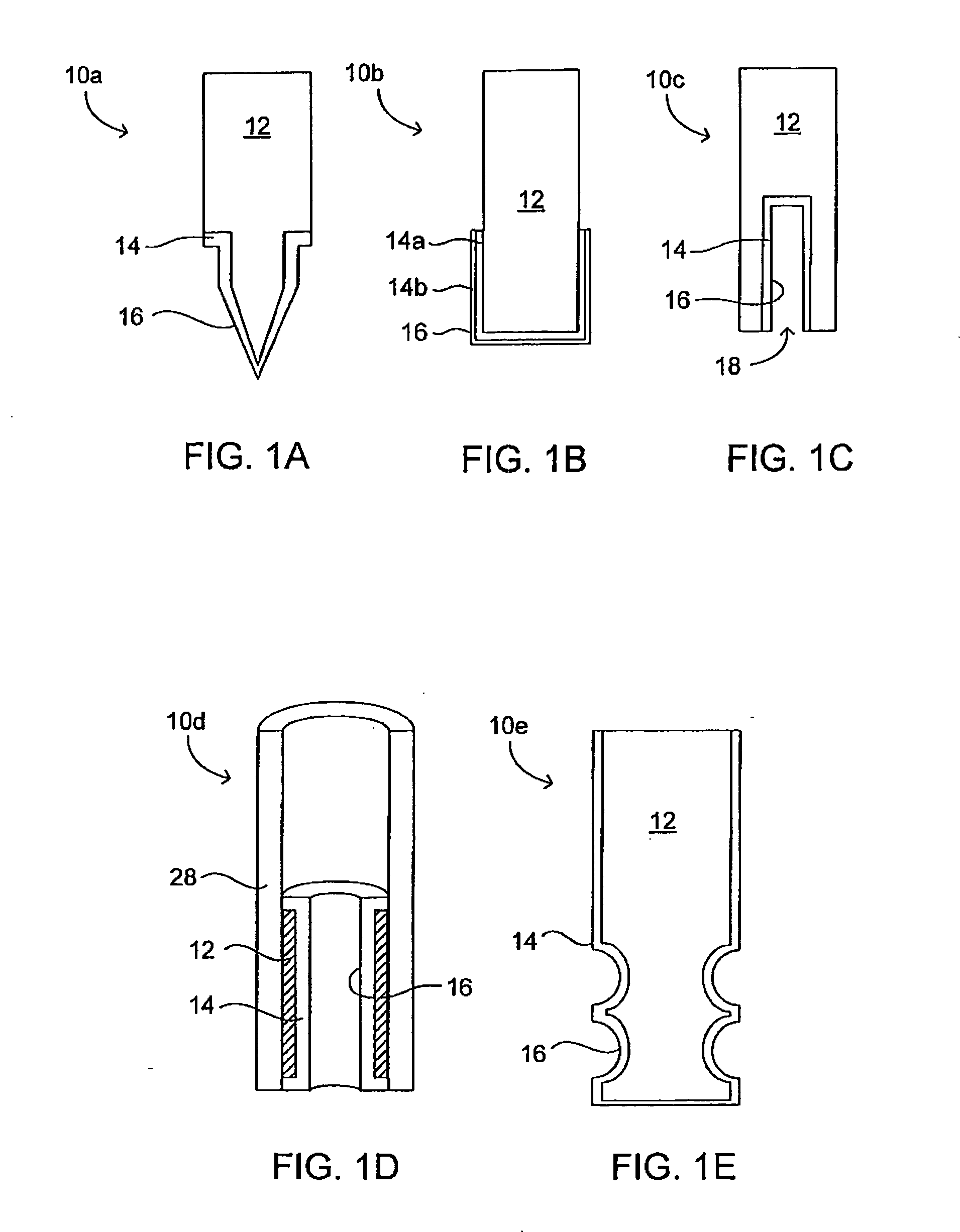

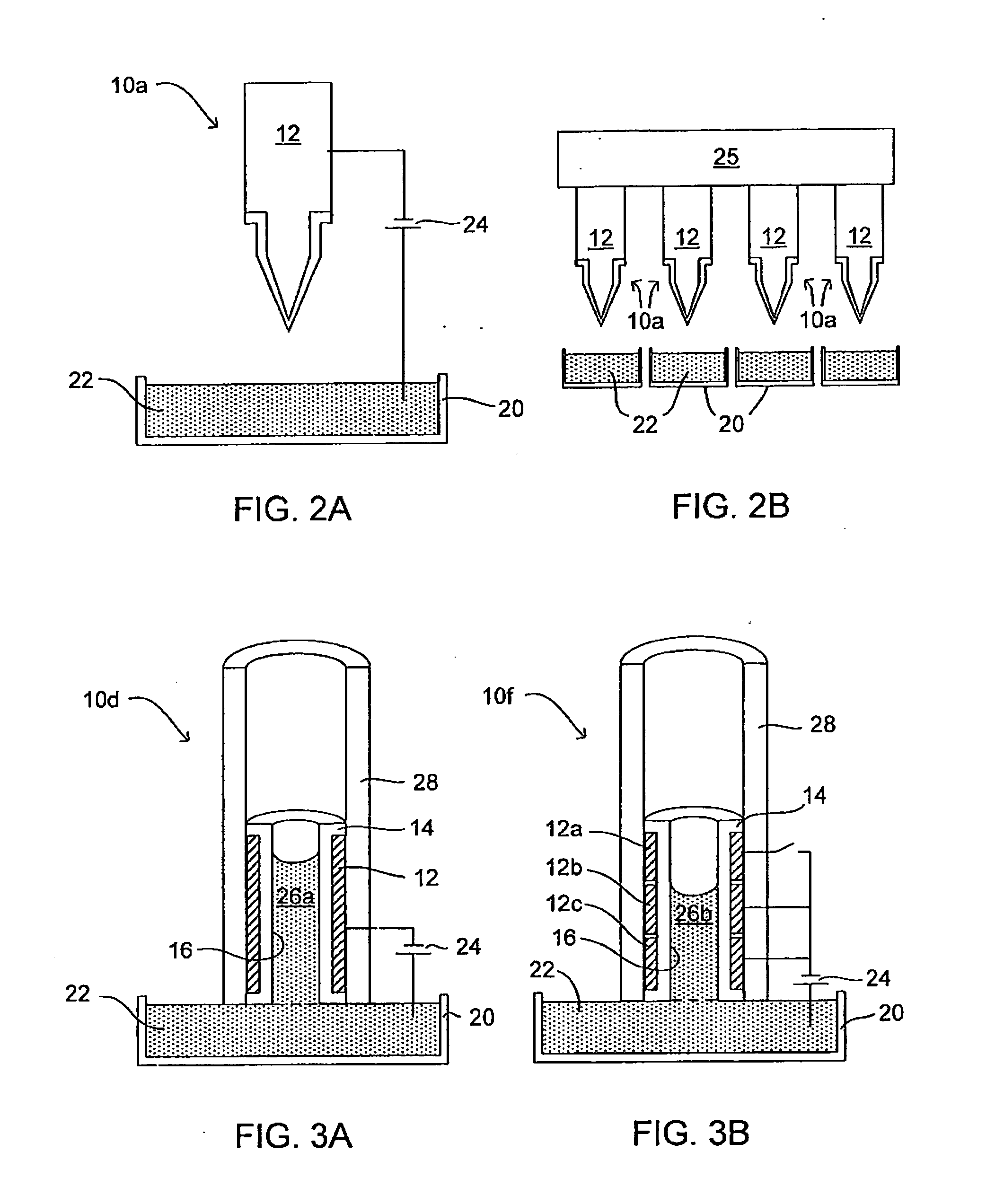

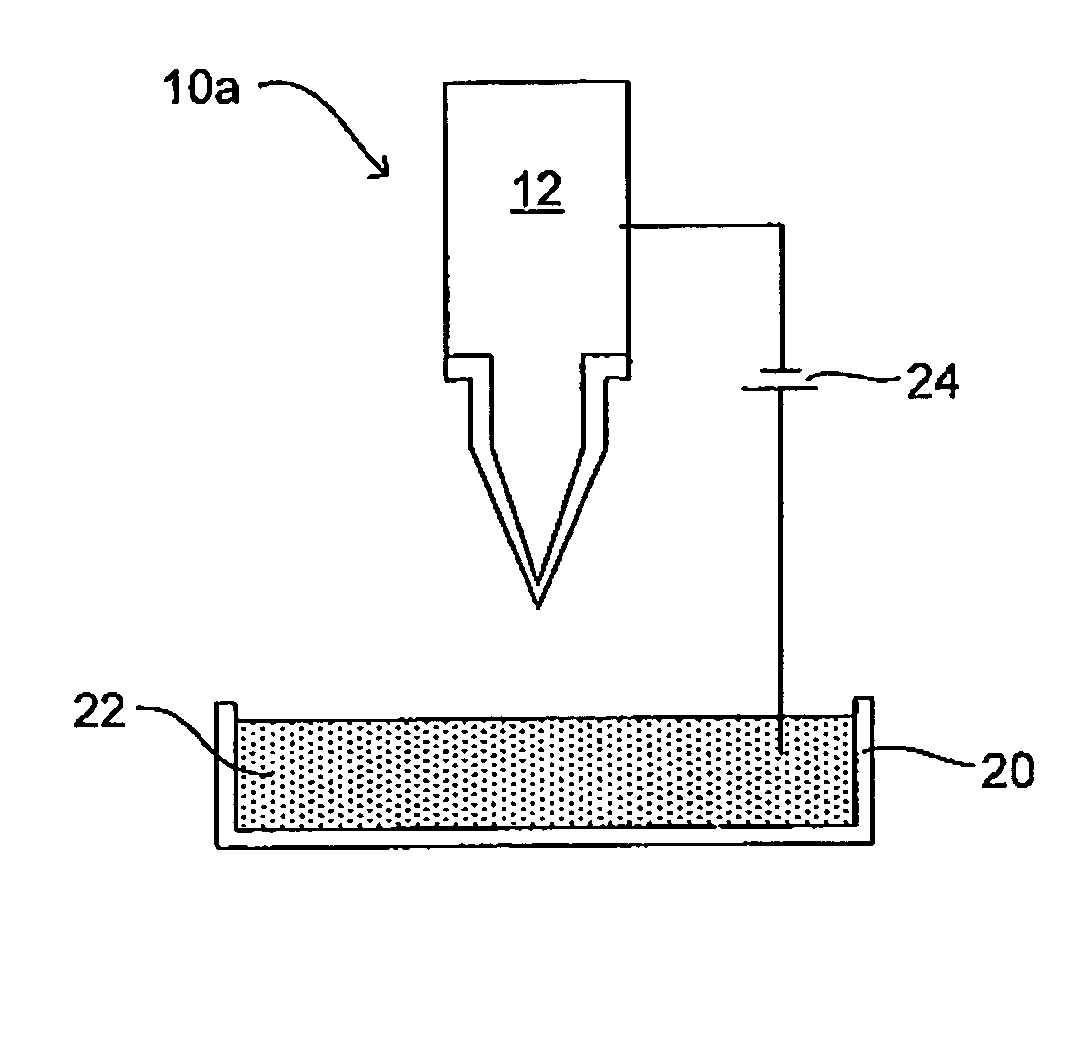

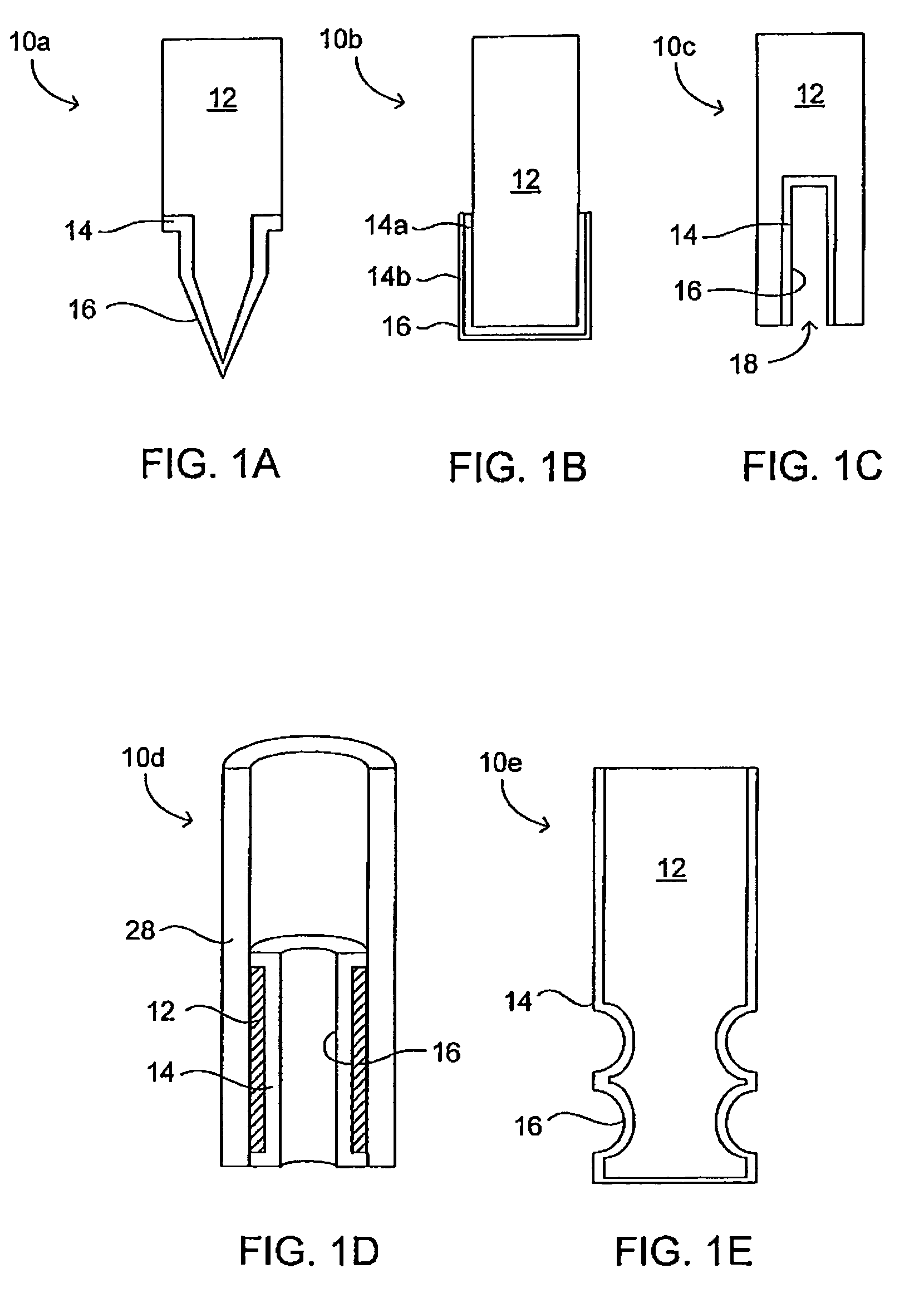

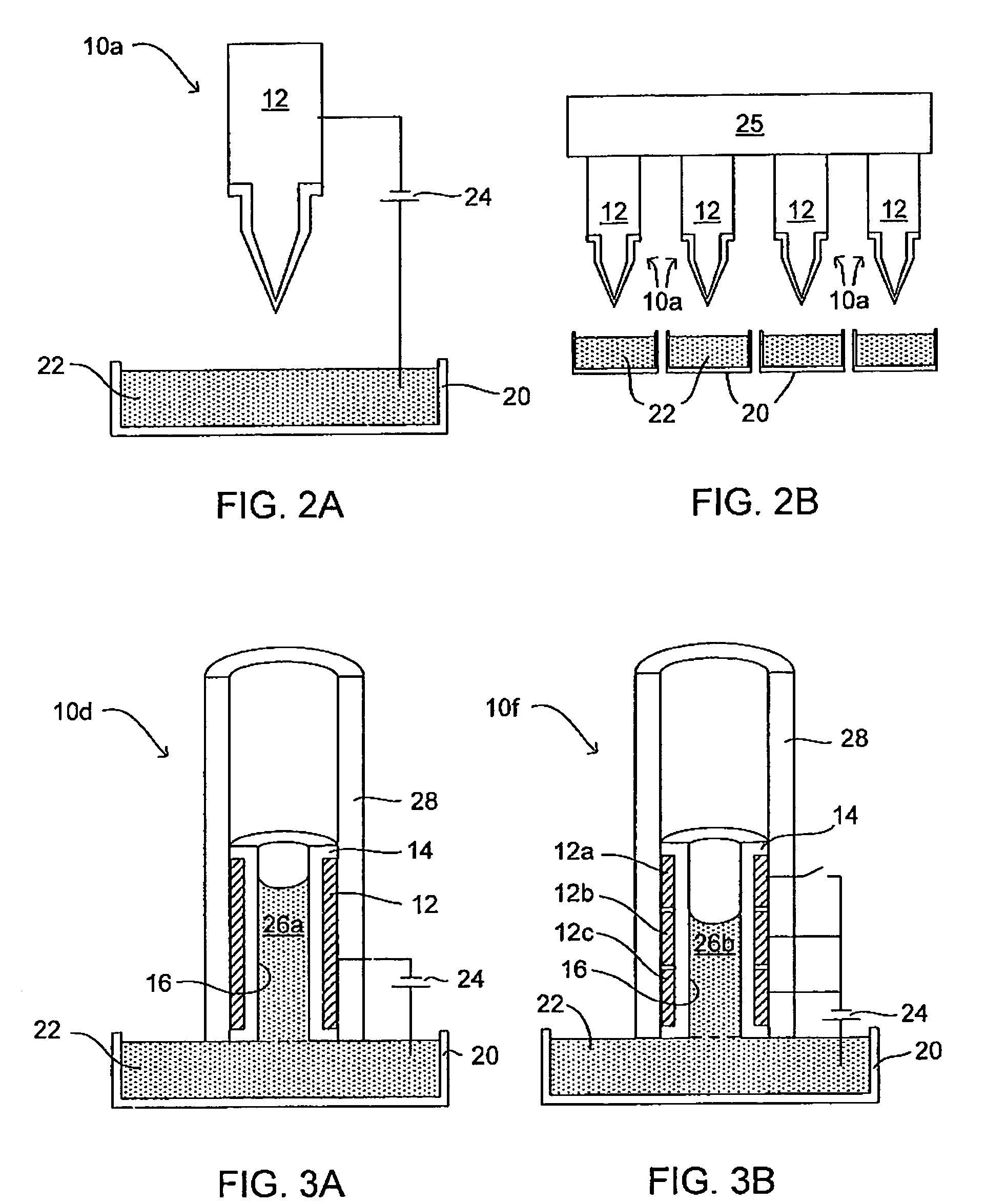

Electro-wetting on dielectric for pin-style fluid delivery

InactiveUS20060081643A1Reduce interfacial surface tensionReduce interface areaSludge treatmentVolume/mass flow measurementDielectricEngineering

A method of delivering fluid can include using electro-wetting effects to pick-up, transport, and / or deliver discrete volumes of fluid. Voltage can be applied across a fluid contact area having a conductive substrate and a dielectric material with an outer surface. The outer surface can have a native interfacial surface tension state and a voltage induced second state having a reduction in interfacial surface tension. A fluid can be contacted such that a volume of fluid adheres to the outer surface of the fluid contact area when the voltage is applied. Subsequently, the voltage can be adjusted such that at least a portion of the volume of fluid is delivered to a receiving location.

Owner:HEWLETT PACKARD DEV CO LP

Microelectronic programmable device and methods of forming and programming the same

InactiveUS20060118848A1Easy and inexpensive to manufactureEasy programmingTransistorSolid-state devicesElectrical conductorEngineering

A microelectronic programmable structure and methods of forming and programming the structure are disclosed. The programmable structure generally include an ion conductor and a plurality of electrodes. Electrical properties of the structure may be altered by applying a bias across the electrodes, and thus information may be stored using the structure.

Owner:AXON TECH

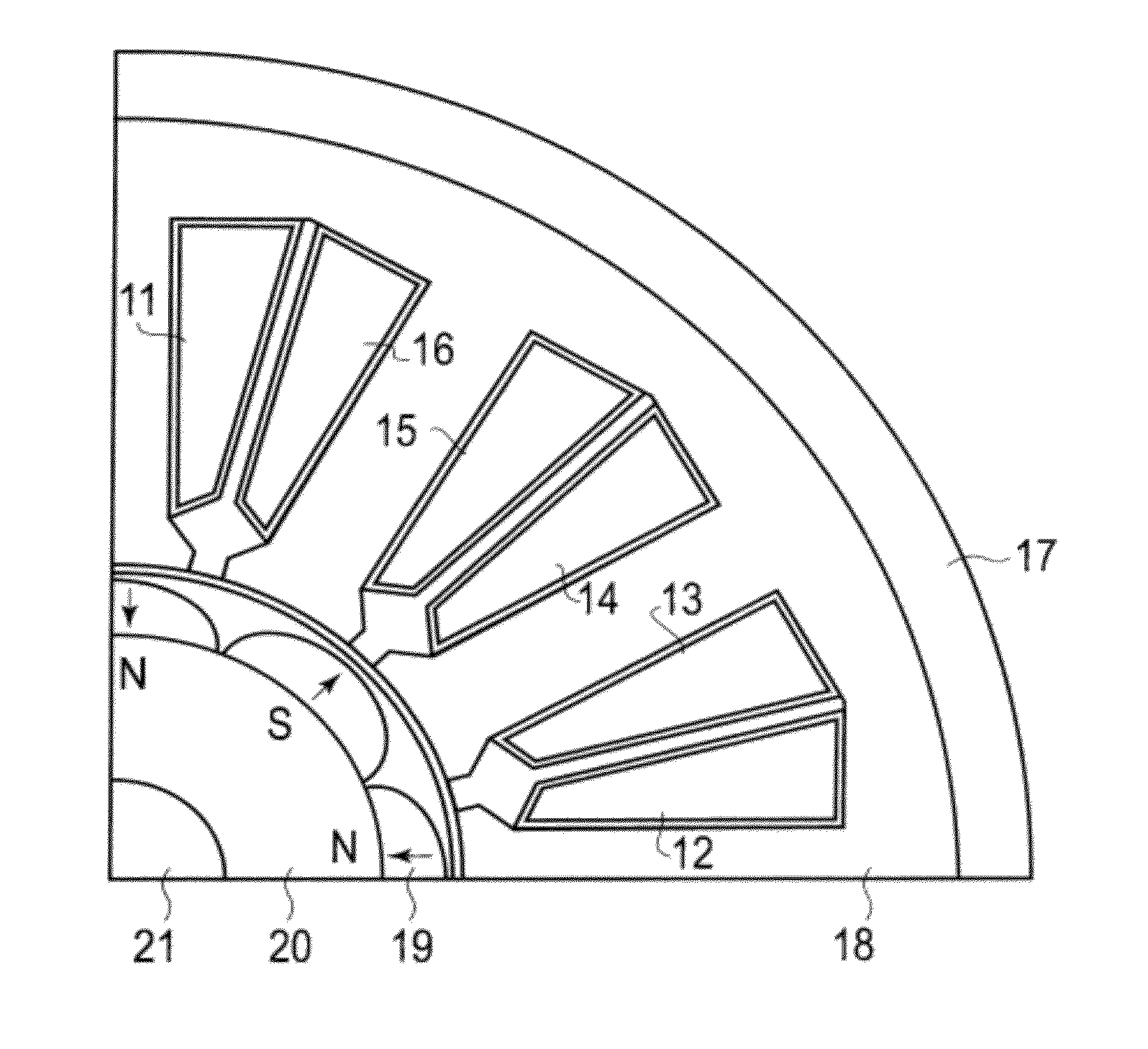

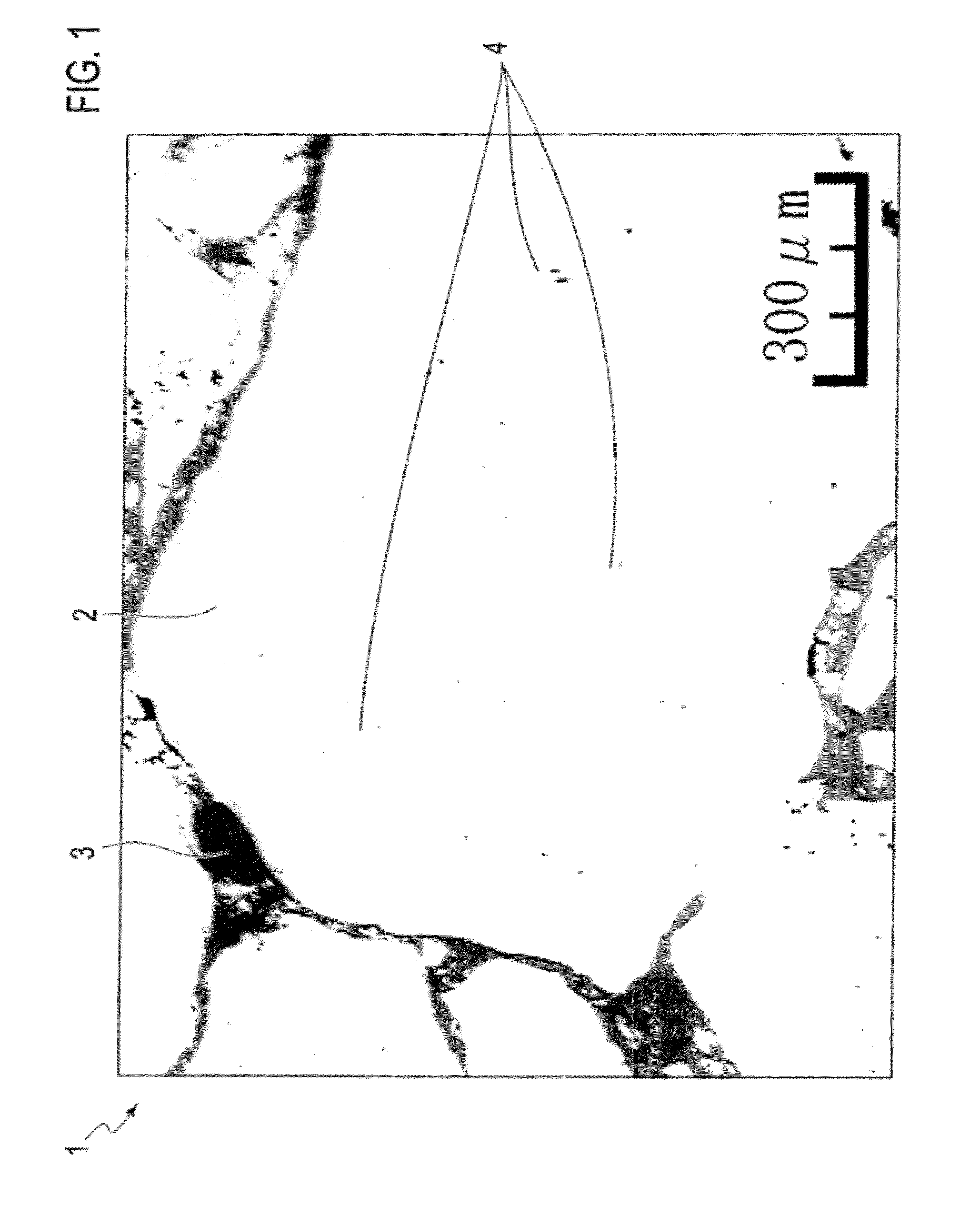

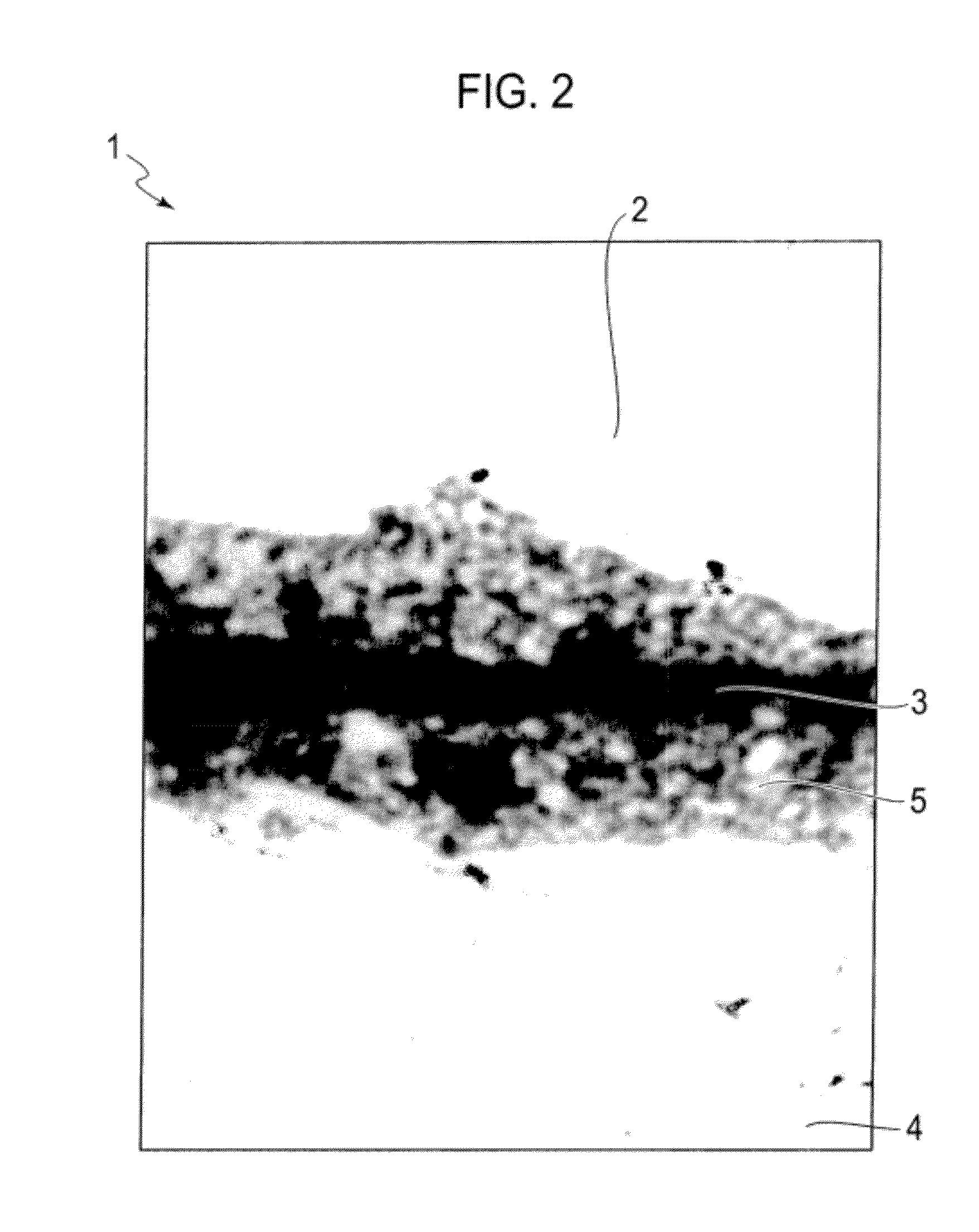

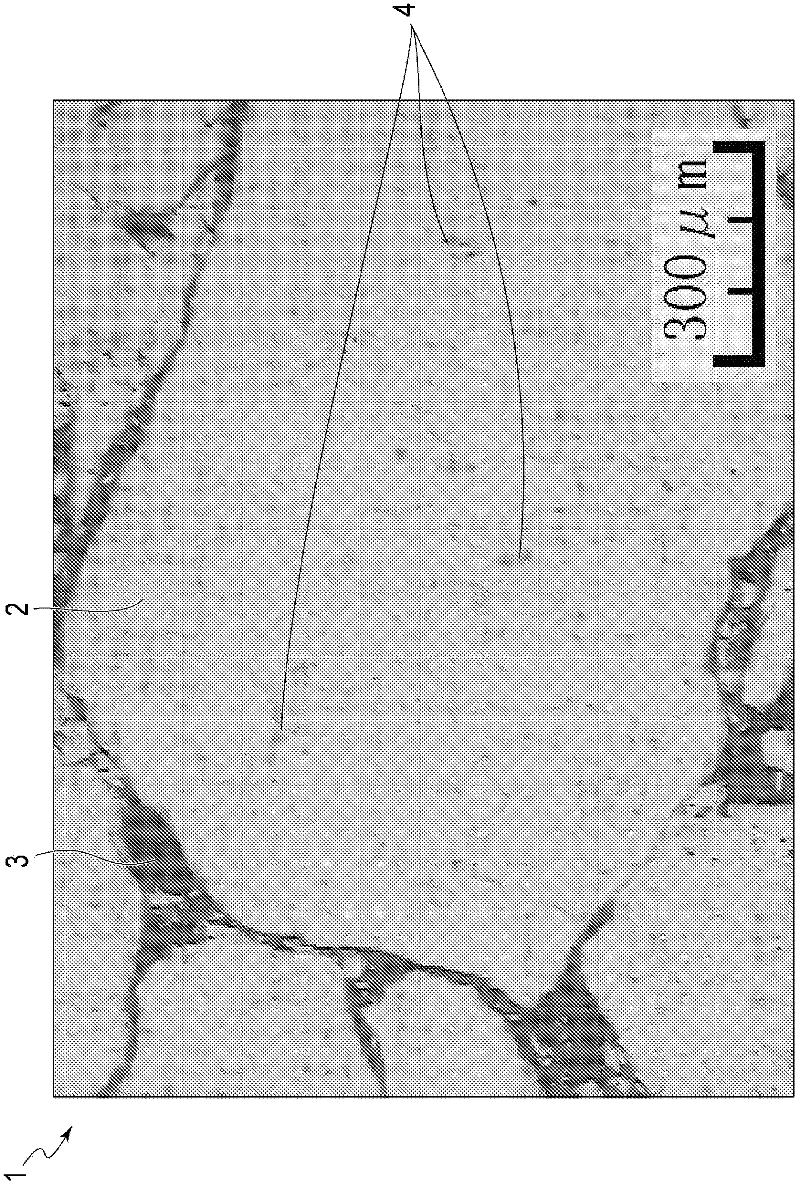

Rare earth magnet molding and method for manufacturing the same

InactiveUS20120153759A1Reduce interface areaReduce impactTransportation and packagingMetal-working apparatusElectric machineRare-earth magnet

A rare earth magnet molding (1) of the present invention includes rare earth magnet particles (2), and an insulating phase (3) present among the rare earth magnet particles. Segregation regions (4) in which at least one element selected from the group consisting of Dy, Tb, Pr and Ho is segregated are distributed in the rare earth magnet particles (2). Accordingly, the rare earth magnet molding that has excellent resistance to heat in motor environments or the like while maintaining high magnetic characteristics (coercive force) is provided.

Owner:NISSAN MOTOR CO LTD

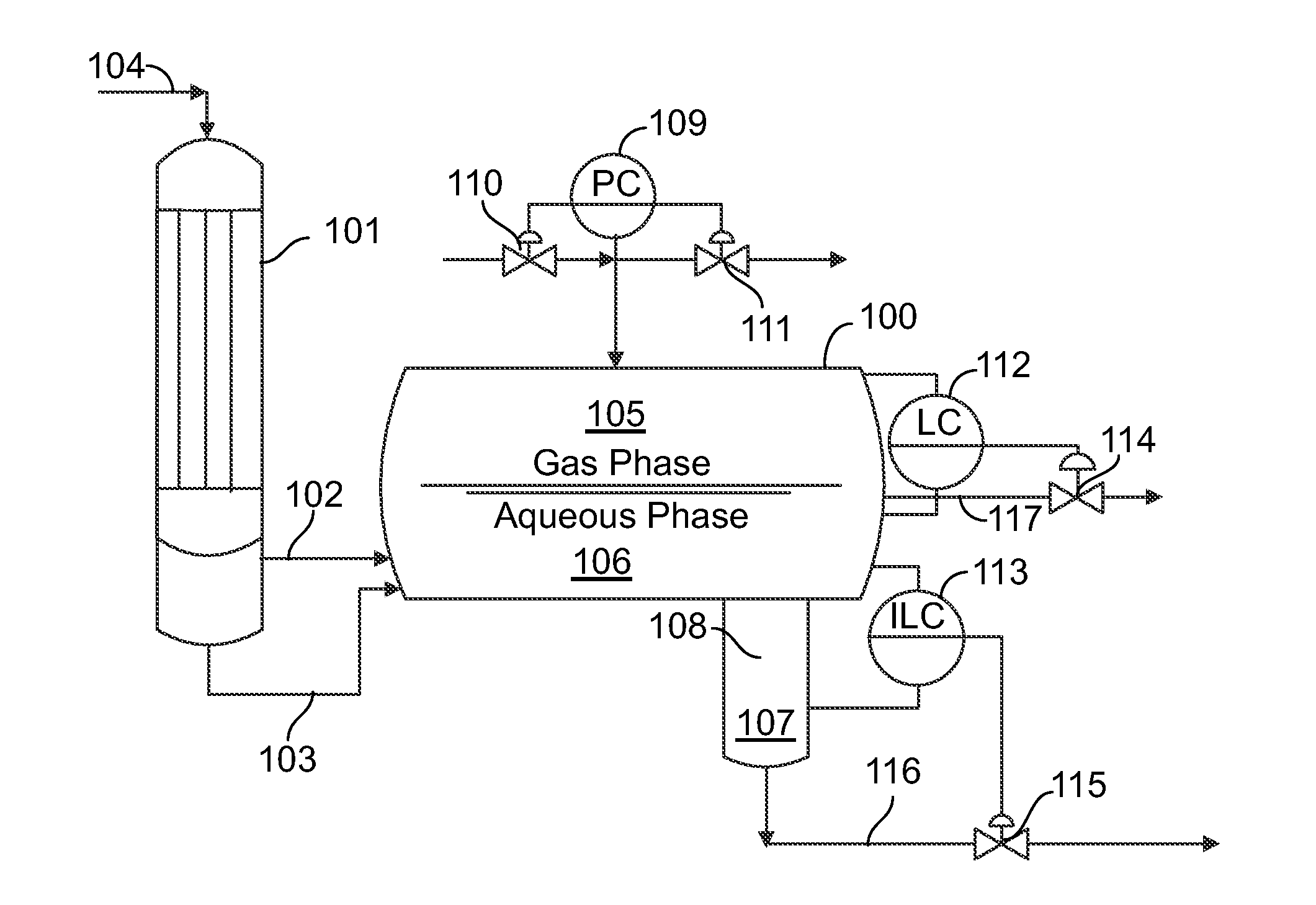

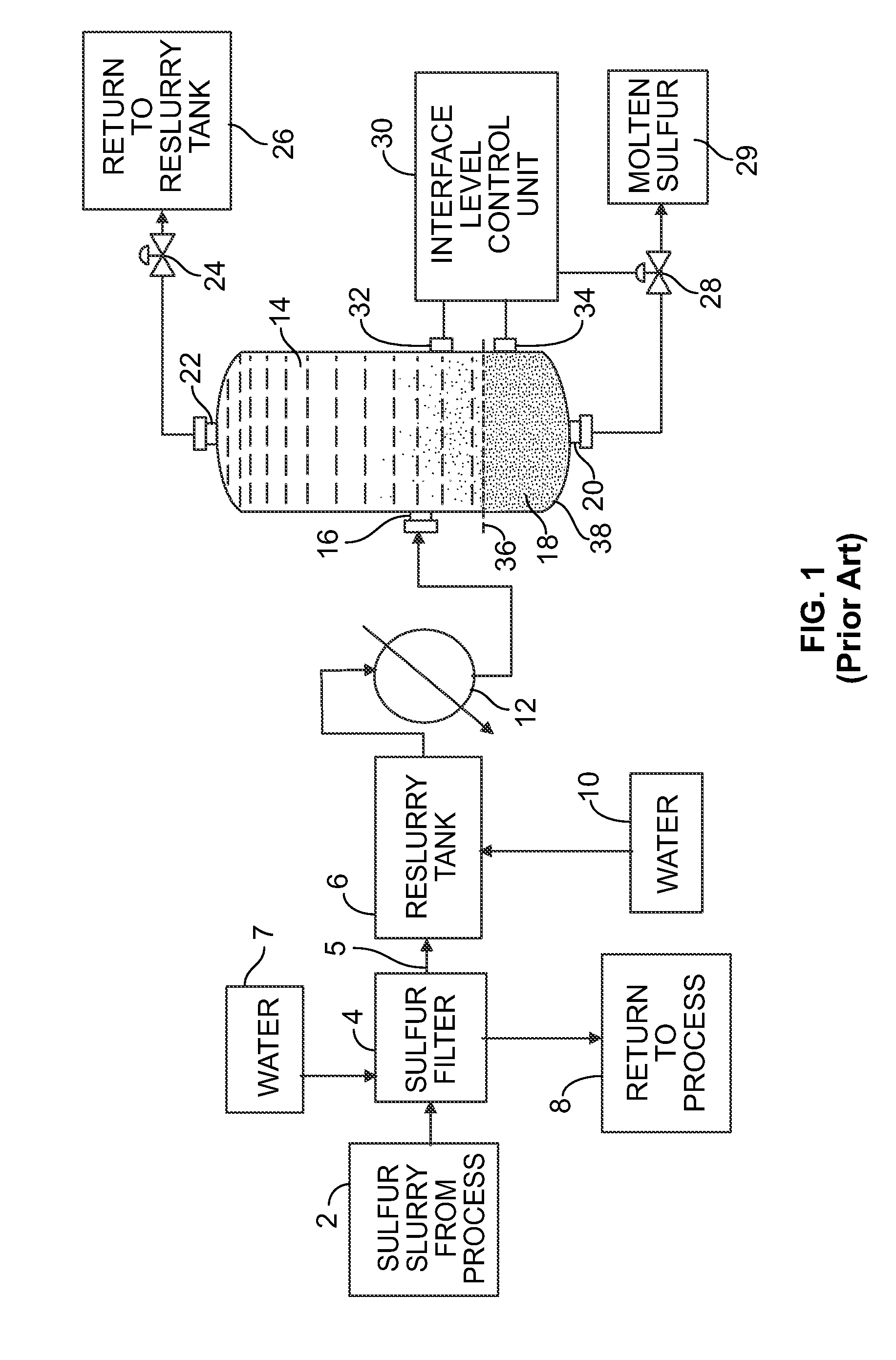

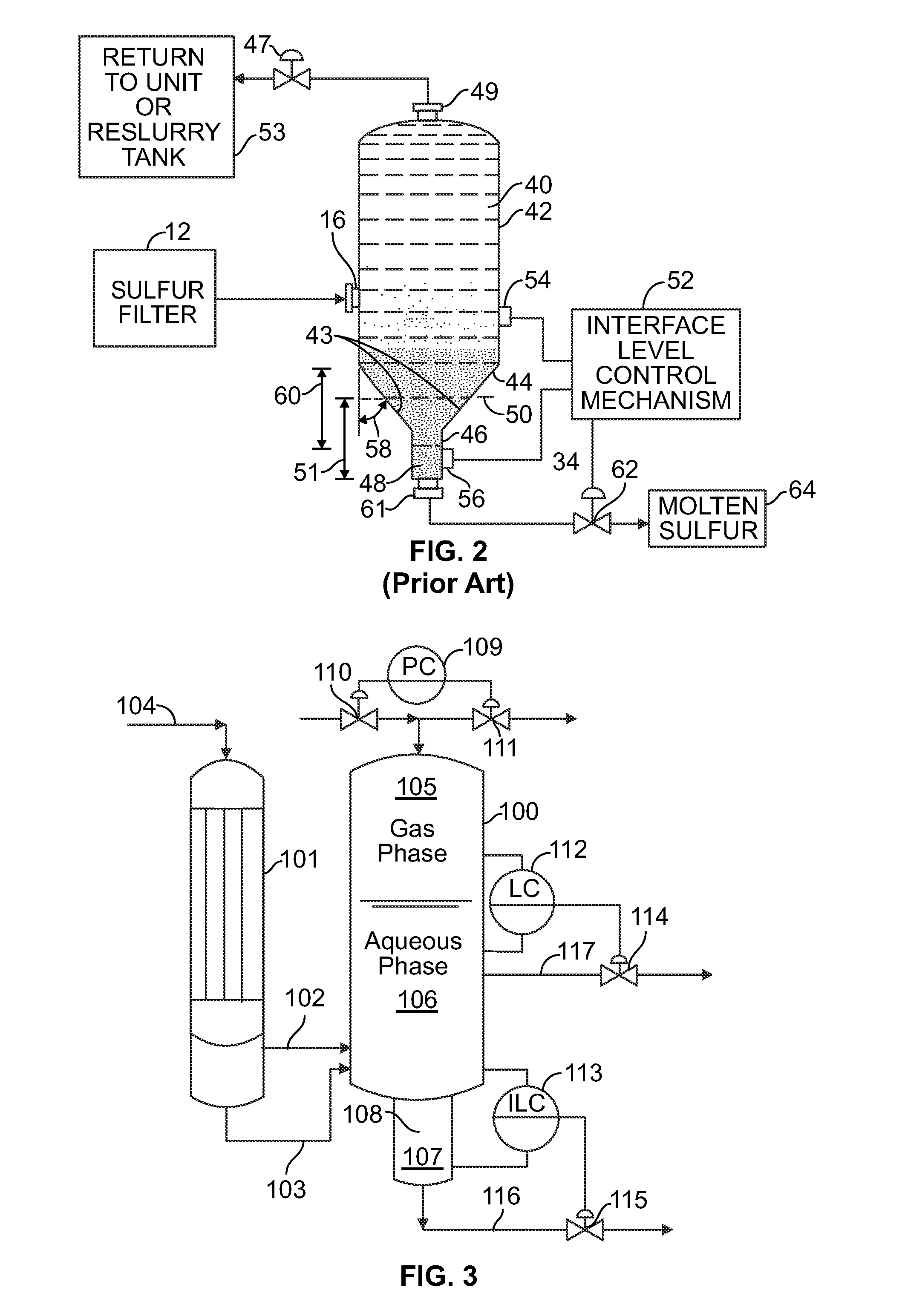

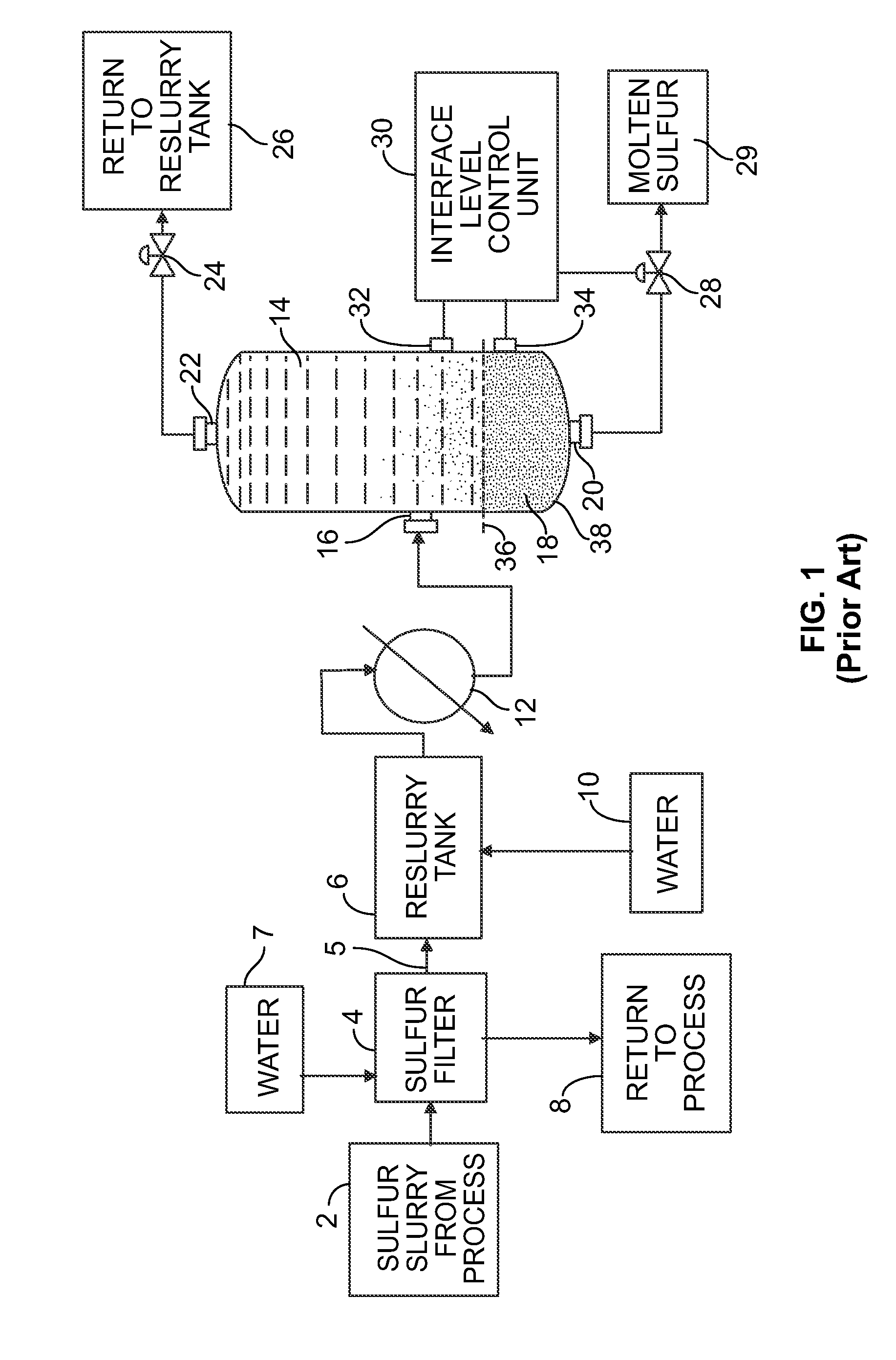

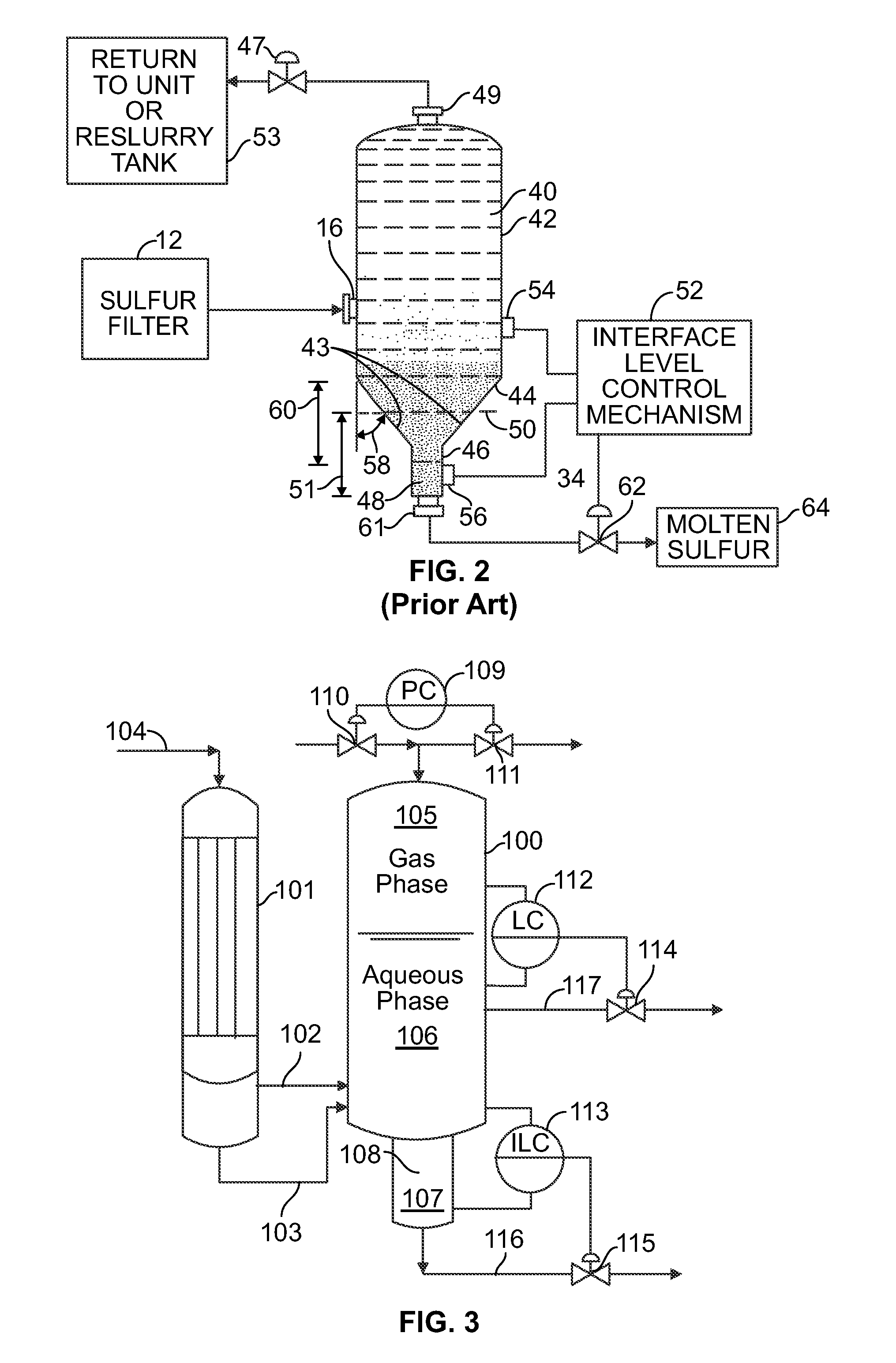

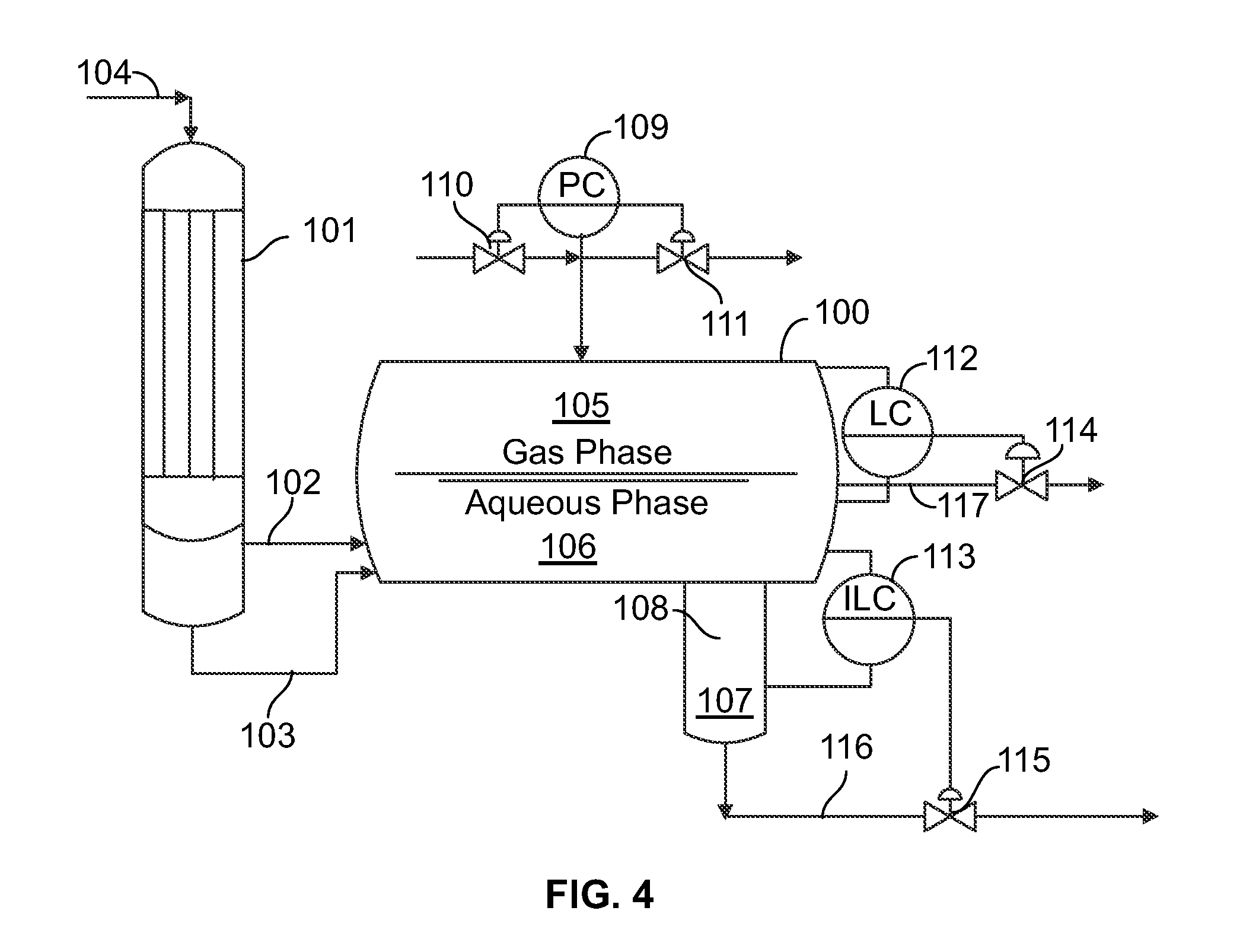

Three phase sulfur separation system with interface control

ActiveUS20110142747A1Quality improvementPrecise interface level controlLevel controlCrystallization separationGas phaseSulfur

A liquid separator system having a gas phase zone, an aqueous phase zone and a denser liquid zone is used to separate mixtures of fluids. The separator can be used for separating molten sulfur from liquid redox solution or reslurry water. The system includes a vessel with a top part and a bottom part. The vessel has a larger diameter at the top part than at the bottom part. The system also includes an inlet for introducing a redox solution or reslurry water and molten sulfur, which is denser than redox solution or reslurry water, into the vessel. An outlet near the bottom part of the vessel allows a flow of the molten sulfur from the vessel. An interface control structure senses an interface level between the redox solution or reslurry water and the molten sulfur, and the interface control structure controls the flow of molten sulfur from the outlet. The interface control structure is adjusted to optimally alter the vertical height of the interface level within the vessel so that the residence time of the molten sulfur in the vessel does not decrease as the sulfur production throughput decreases, and so that the interface area of the molten sulfur and the redox solution is reduced as the sulfur throughput decreases. A pressure controller monitors the pressure in the vessel and adds or removes gas from a gas phase zone in the vessel to maintain a predetermined pressure regardless of the vertical height of the interface.

Owner:MERICHEM CO

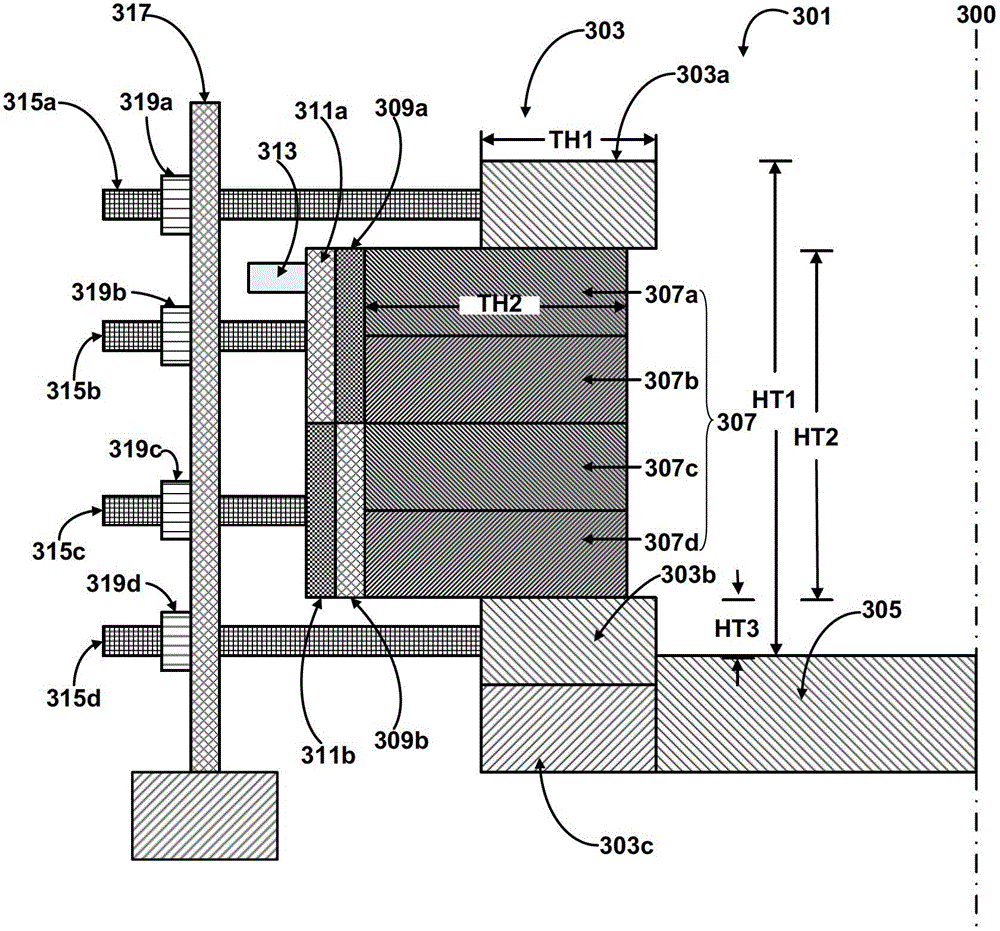

Glass melt handling equipment and method

ActiveCN102807307AExtend your lifeReduce erosionForehearthsOhmic-resistance electrodesGlass meltingElectrode material

A glass melt handling vessel, such as a glass melting furnace, comprising a side-wall monolithic electrode having a stack of multiple pieces of blocks of electrode material, or a pushable electrode, and a method of making a glass material using such vessel. The pushability and / or the use of stacked monolithic electrode prolong vessel life and improves glass melt quality during life cycle of the vessel.

Owner:CORNING INC

Nano compound pour point depressant and preparation method thereof

InactiveCN105969433ABroaden the crystallization temperature rangeCompact arrangementLiquid carbonaceous fuelsFuel additivesMontmorilloniteCold filter plugging point

The invention discloses a nano compound pour point depressant and a preparation method thereof. The nano compound pour point depressant disclosed by the invention is compounded from a nano material and a polymer pour point depressant by a melting and blending method. A montmorillonite nano material modified by cetyl trimethylammonium bromide is compounded with the polymer pour point depressant in a certain mass ratio by adopting the melting and blending method so as to obtain the nano compound pour point depressant. The pour point depression effect of the nano compound pour point depressant is further enhanced on the basis of pour point depression of the original pour point depressant. When the nano compound pour point depressant is applied to 0# diesel oil, the pour point depression effect is superior to that of a commercially available pour point depressant, and the cold filter plugging point and the condensation point are respectively reduced by 12-20 DEG C and 18-26 DEG C.

Owner:SHANGHAI INST OF TECH

Molded rare-earth magnet and process for producing same

InactiveCN102483991AImprove insulation performanceStrong magnetic forceTransportation and packagingMetal-working apparatusHeat resistanceRare-earth magnet

Disclosed is a molded rare-earth magnet (1) which comprises rare-earth magnet particles (2) and an insulating phase (3) present among the rare-earth magnet particles (2). The rare-earth magnet particles (2) have, dispersed therein, segregation regions (4) in which at least one element selected from a group consisting of Dy, Tb, Pr, and Ho has segregated. As a result, the molded magnet can retain high magnetic properties (coercive force) and have excellent heat resistance required for use in motors, etc.

Owner:NISSAN MOTOR CO LTD

Electro-wetting on dielectric for pin-style fluid delivery

InactiveUS7780830B2Reduce interface areaSludge treatmentVolume/mass flow measurementDielectricBiomedical engineering

A method of delivering fluid can include using electro-wetting effects to pick-up, transport, and / or deliver discrete volumes of fluid. Voltage can be applied across a fluid contact area having a conductive substrate and a dielectric material with an outer surface. The outer surface can have a native interfacial surface tension state and a voltage induced second state having a reduction in interfacial surface tension. A fluid can be contacted such that a volume of fluid adheres to the outer surface of the fluid contact area when the voltage is applied. Subsequently, the voltage can be adjusted such that at least a portion of the volume of fluid is delivered to a receiving location.

Owner:HEWLETT PACKARD DEV CO LP

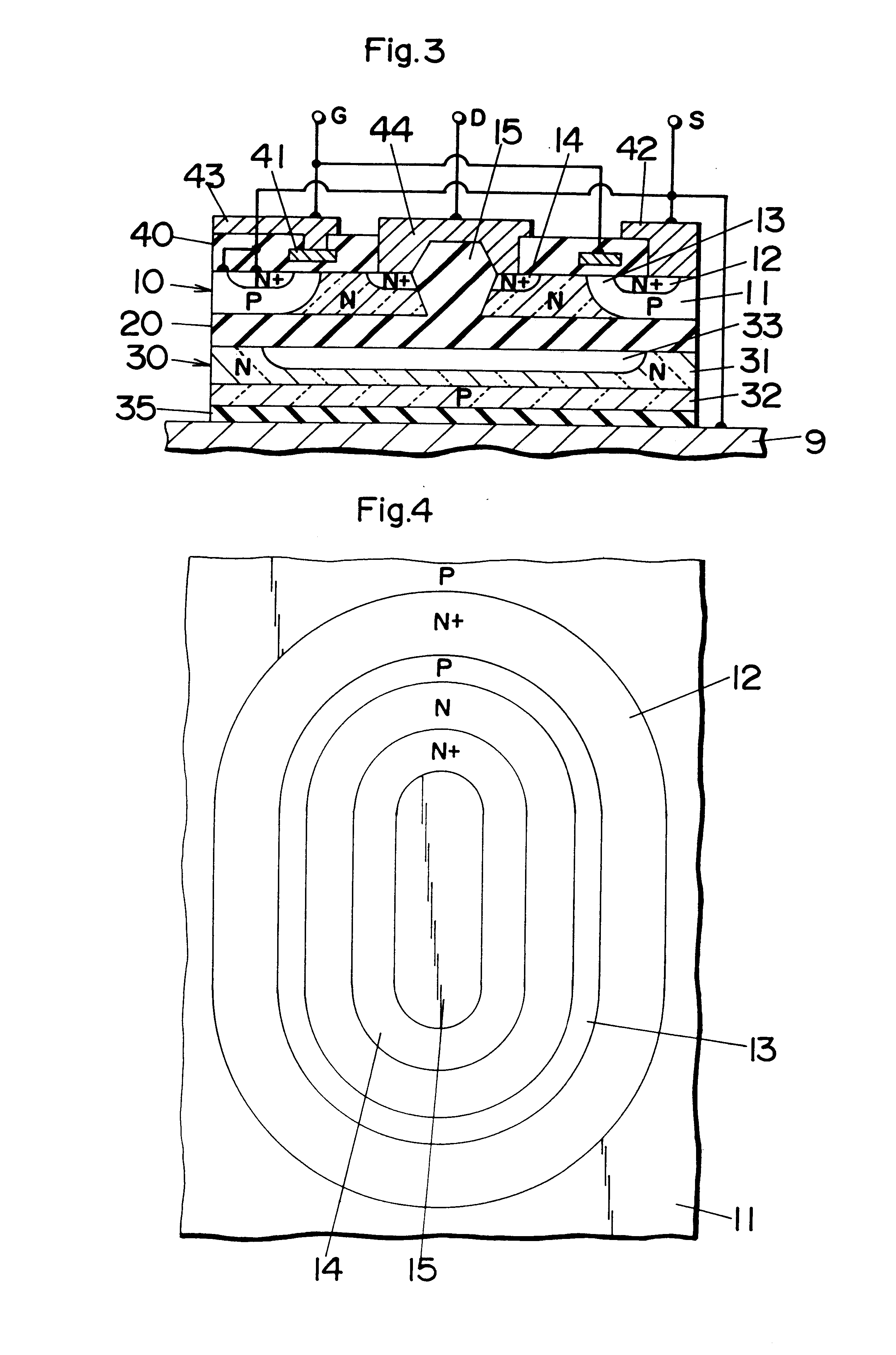

Solid-state relay

InactiveUS6373101B1Sufficient flexibilityReduce interfaceTransistorSemiconductor/solid-state device detailsCapacitanceInductance

A solid state relay composed of a series connected pair of LDMOSFETs has a minimized output capacitance. Each LDMOSFET is configured to have a silicon layer of a first conductive type, a drain region of the first conductive type diffused in the top surface of the silicon layer, a well region of a second conductive type diffused in the silicon layer in a laterally spaced relation from the drain region, and a source region of the first conductive type diffused within the well region to define a channel extending between the source region and a confronting edge of the well region along the top surface of the silicon layer. Each LDMOSFET is of an SOI (Silicon-On-Insulator) structure composed of a silicon substrate placed on a supporting plate, a buried oxide layer on the silicon substrate, and the silicon layer on the buried oxide layer. The well region is diffused over the full depth of the silicon layer to have its bottom in contact with the buried oxide layer, so that the well region forms with the silicon layer a P-N interface only at a small area adjacent the channel. Because of this reduced P-N interface and also because of the buried oxide layer exhibiting a much lower inductive capacitance than the silicon layer, it is possible to greatly reduce a drain-source capacitance for minimizing the output capacitance of the relay in the non-conductive condition.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Control method for internal condensation structures of gear steel rectangular blanks

The invention discloses a control method for internal condensation structures of gear steel rectangular blanks. The control method comprises specific steps of low-pulling-speed casting, medium-strength secondary cooling control of a fan-shaped section, weakening of an electric stirring effect of a crystallizer and strengthening of the electric stirring effect of a terminal. The control method forthe internal condensation structures of the gear steel rectangular blanks can effectively enlarge internal columnar crystal areas of casting blanks to reduce center isometric crystal areas; and the internal columnar crystal areas of the casting blanks are not smaller than 70%, so that the intersecting areas between the columnar crystal areas and the center isometric crystal areas are reduced, andthe influence on the product quality by component segregation and inclusion collection in the intersecting places between the columnar crystal areas and the center isometric crystal areas is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

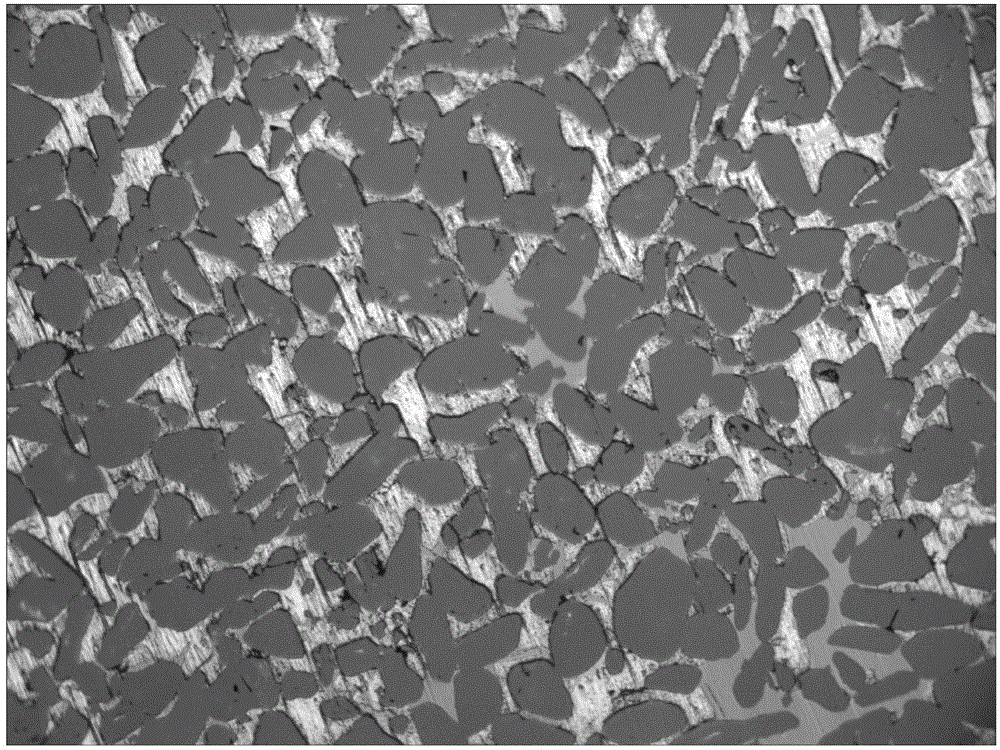

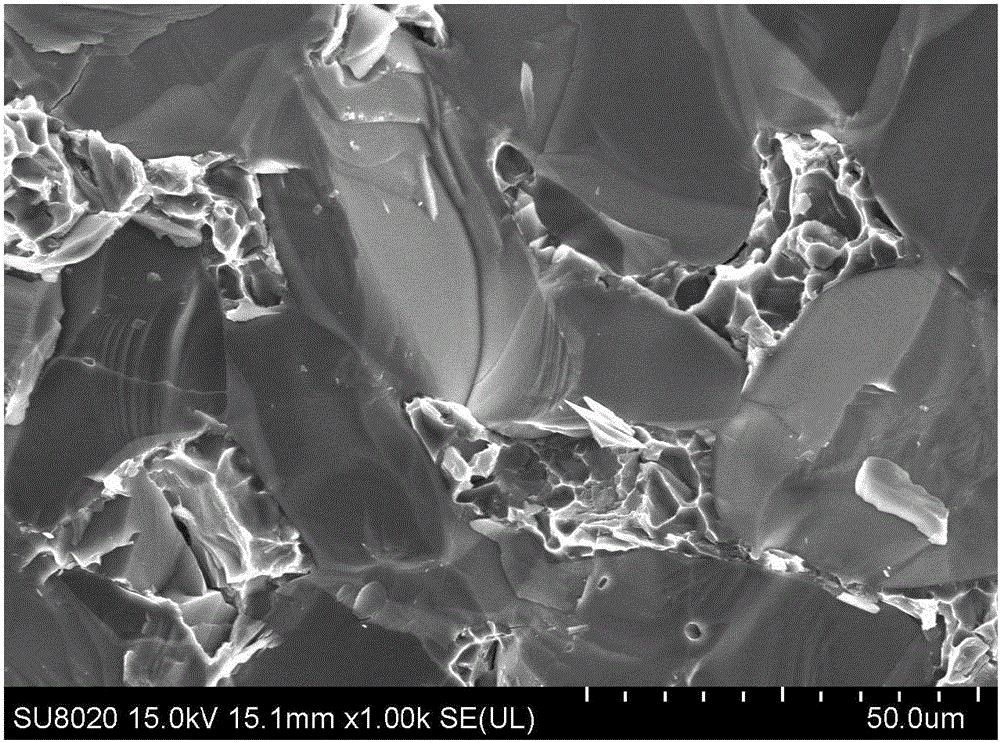

Preparation method for 3D-SiC/Al composite material of 3D interpenetrating structure

The invention relates to a preparation method for a 3D-SiC / Al composite material of a 3D interpenetrating structure. The preparation method for the 3D-SiC / Al composite material of the 3D interpenetrating structure comprises a preparation process of a 3D-SiC prefabricated member and a subsequent pressureless melt infiltration preparation process of the 3D-SiC / Al composite material. When applied to the subsequent pressureless melt infiltration 3D-SiC composite material, the 3D-SiC prefabricated member can be or not be subjected to oxidation pretreatment according to the used aluminum alloy compositions. The content of SiC in the composite material is 50-73 vol%, the density of the composite material can reach up to 2.90-3.1 g / cm<2>, the heat conductivity can reach up to 232 W / (m.DEG C), the coefficient of thermal expansion is as low as 5.72*10<-6> / DEG C, and the bending strength can reach up to 330 Mpa. The overall performance can meet the technical performance requirements, such as a low expansion factor, high heat conductivity and sufficient bending strength, which must be met by electronic packaging materials.

Owner:HEFEI UNIV OF TECH

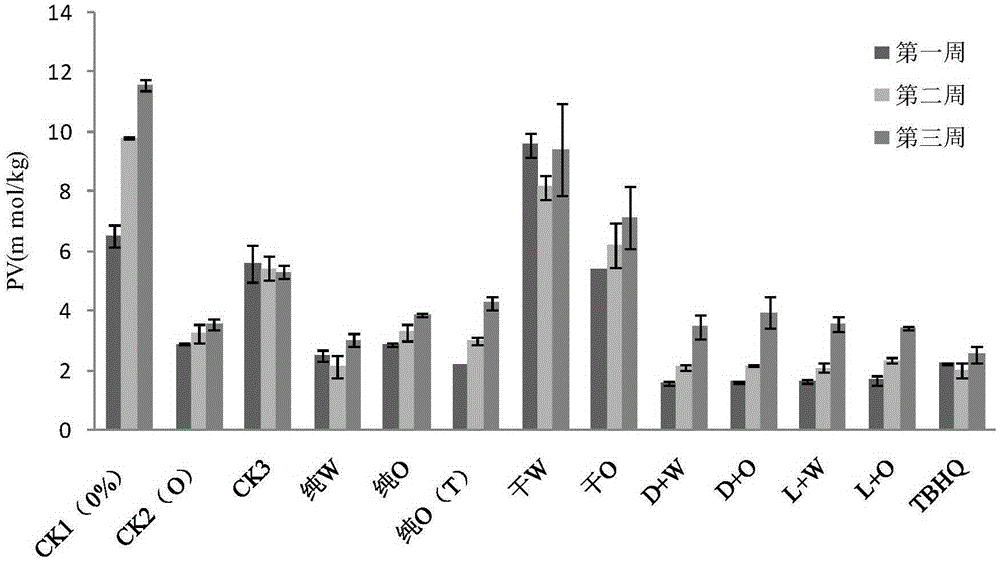

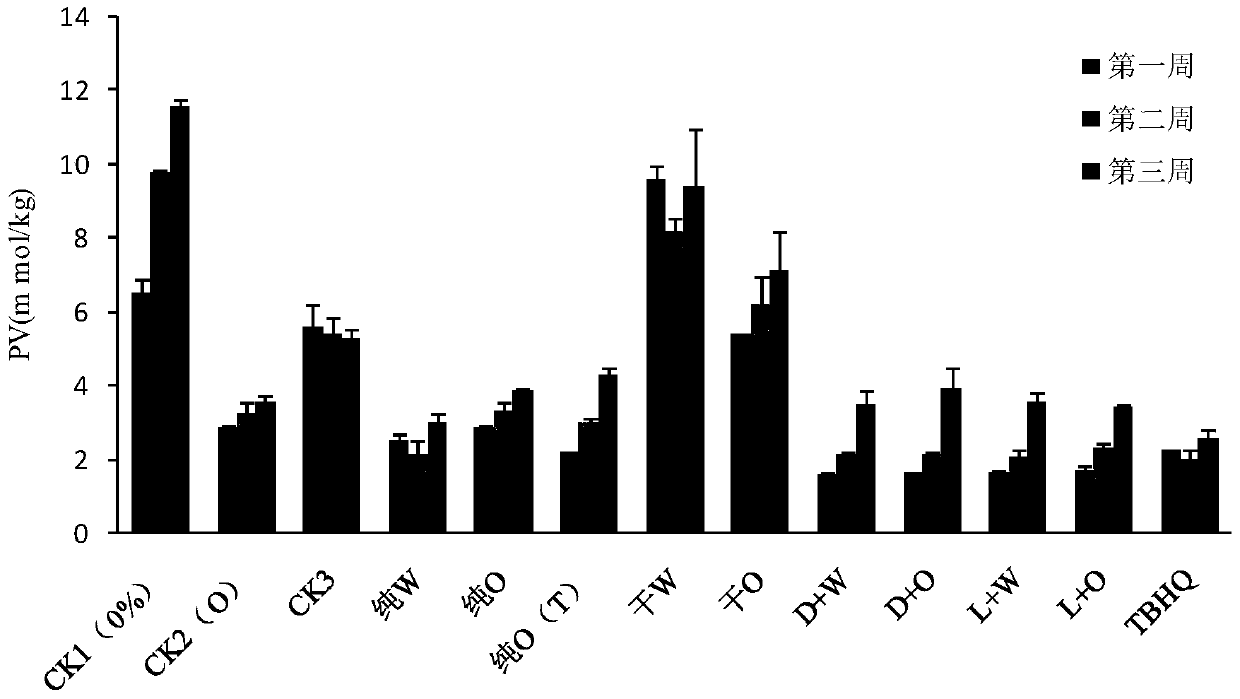

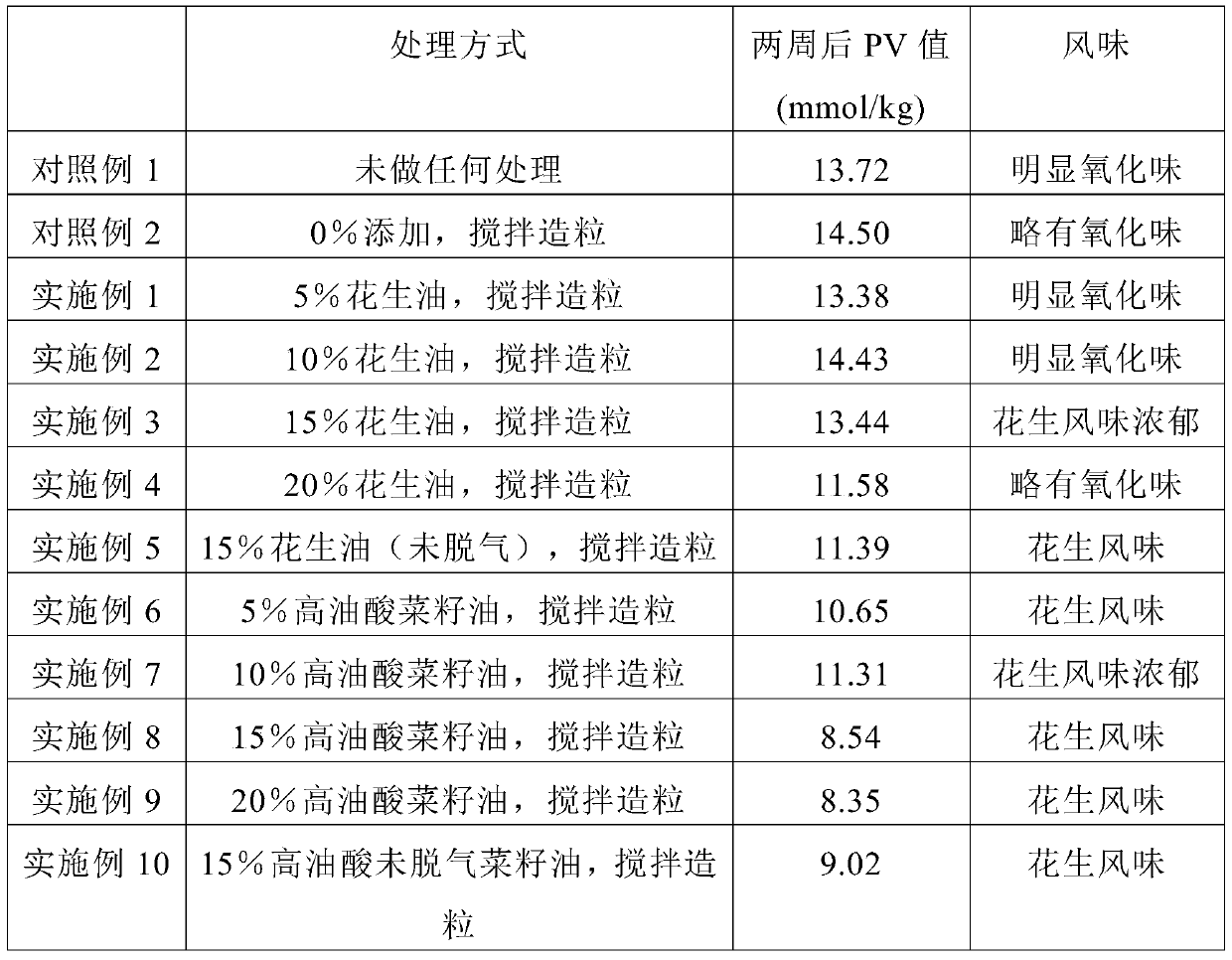

Rich-flavor and long-shelf life peanut powder and preparation process thereof

ActiveCN106666609AStrong aromaLong lasting fragranceFood ingredient as antioxidantBiotechnologyPeanut meal

The present invention relates to rich-flavor and long-shelf life peanut powder and a preparation process thereof, and particularly provides a peanut powder product and a preparation method thereof, and a food containing the peanut powder product. According to the present invention, the peanut powder product contains peanut powder, added grease and an optional antioxidant, and has characteristics of enhanced flavor, delayed peanut powder oxidation rate, and lasting flavor.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

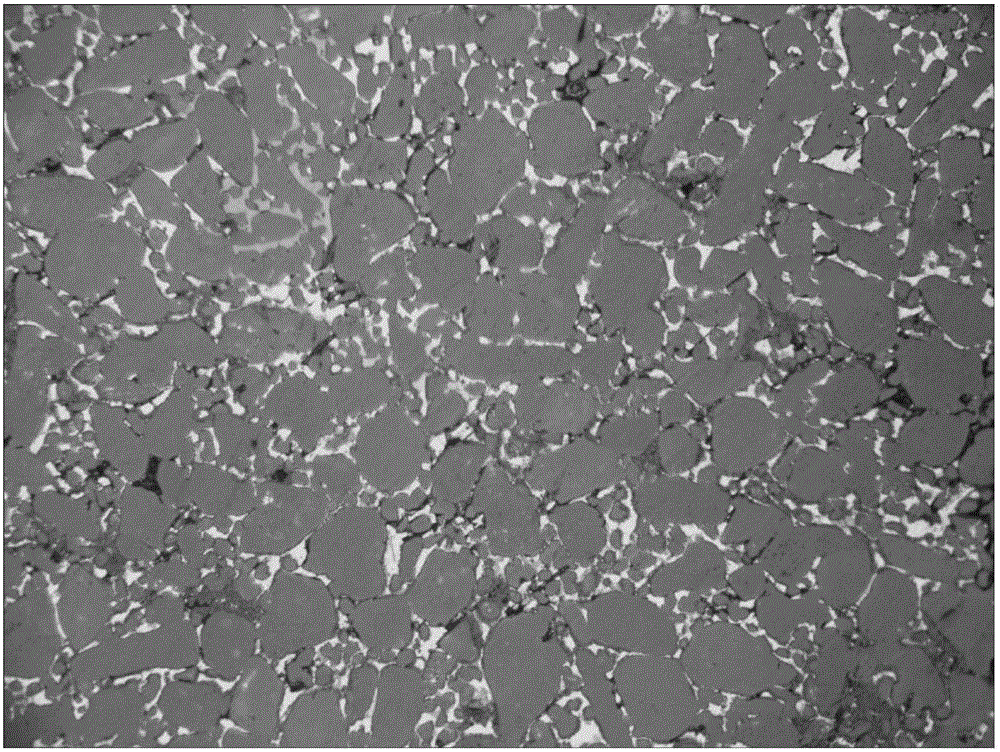

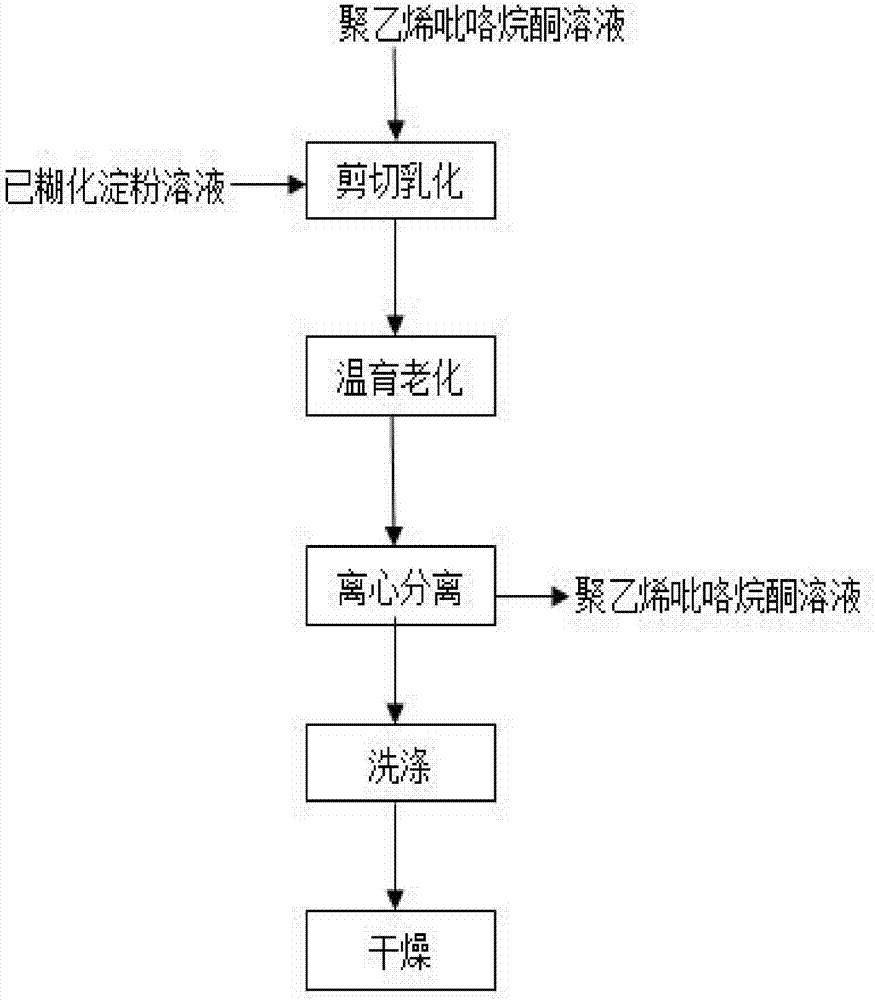

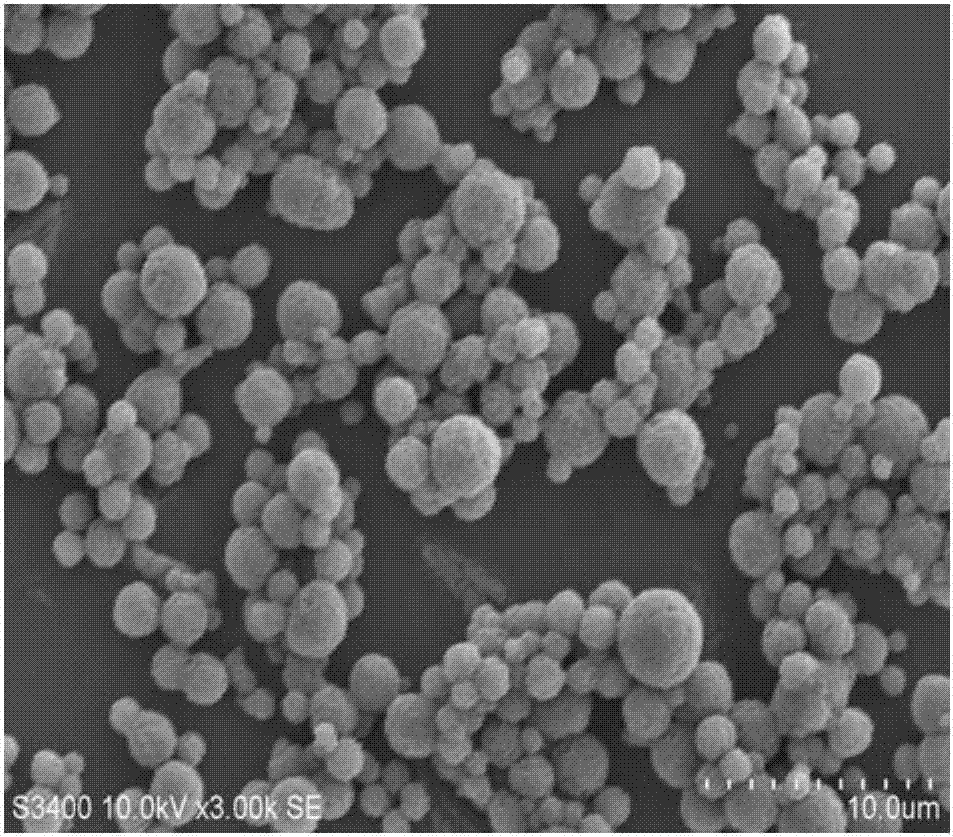

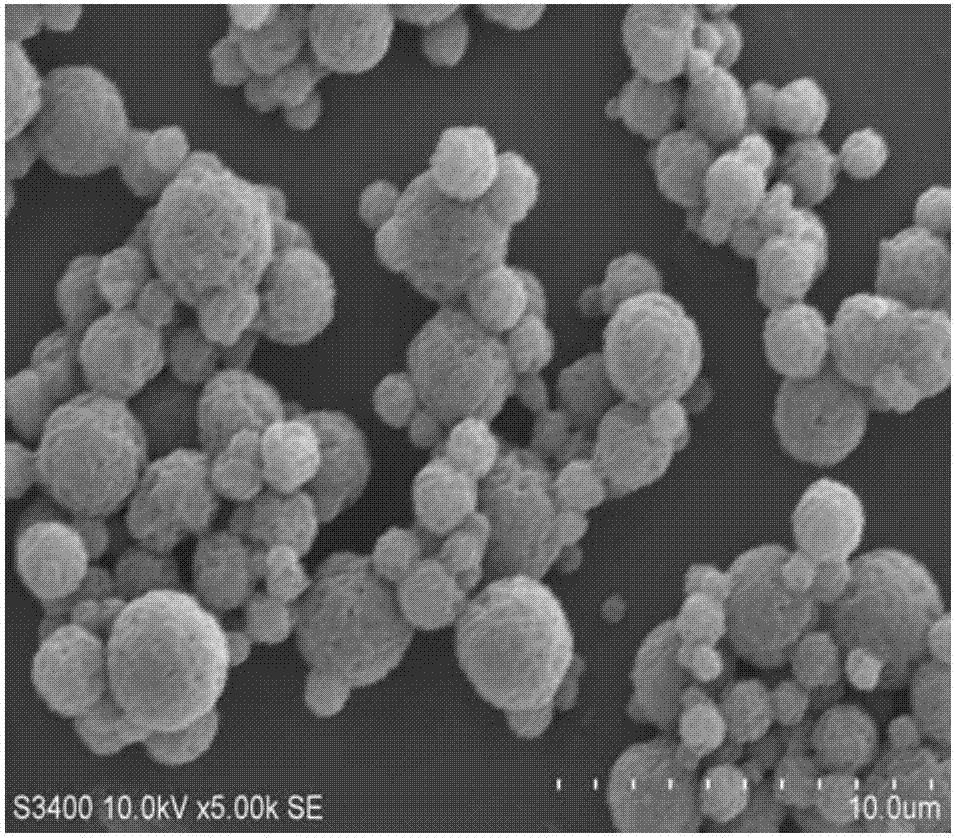

Preparation method of starch microspheres with small particle sizes

ActiveCN106902716AAvoid reunionSmall particle sizeMicroballoon preparationMicrocapsule preparationFree energiesEmulsion

The invention discloses a preparation method of starch microspheres with small particle sizes. The preparation method comprises steps as follows: (1) preparation of a starch solution; (2) preparation of a polyvinylpyrrolidone solution; (3) forming of an aqueous two-phase emulsion through high-speed shearing and emulsification performed after the polyvinylpyrrolidone solution is added to the starch solution; (4) balling through retrogradation and solidification, separation and washing: the emulsified aqueous two-phase emulsion is put in an environment at the temperature of 4-30 DEG C to be retrograded for 24 h, then taken out and subjected to centrifugal separation for 10-15 min, a substrate in a centrifuge tube is washed and then dried for 12 h, and the starch microspheres with the average particle sizes smaller than 10 mu m are obtained. The prepared starch microspheres have the characteristic of being small in particle size, the phenomenon that starch microspheres aggregate due to the fact that the interfacial area between the two phases of the aqueous two-phase emulsion is substantially increased, the interfacial free energy is substantially increased and liquid drops aggregate to reduce the interfacial free energy in the preparation process of the starch microspheres can be avoided, and the preparation method has great application value.

Owner:GUANGXI ACAD OF SCI

Three phase sulfur separation system with interface control

ActiveUS8367009B2Reduce interface areaConstant operationLevel controlCrystallization separationGas phaseSulfur

A liquid separator system having a gas phase zone, an aqueous phase zone and a denser liquid zone is used to separate mixtures of fluids. The separator can be used for separating molten sulfur from liquid redox solution or reslurry water. The system includes a vessel with a top part and a bottom part. The vessel has a larger diameter at the top part than at the bottom part. The system also includes an inlet for introducing a redox solution or reslurry water and molten sulfur, which is denser than redox solution or reslurry water, into the vessel. An outlet near the bottom part of the vessel allows a flow of the molten sulfur from the vessel. An interface control structure senses an interface level between the redox solution or reslurry water and the molten sulfur, and the interface control structure controls the flow of molten sulfur from the outlet. The interface control structure is adjusted to optimally alter the vertical height of the interface level within the vessel so that the residence time of the molten sulfur in the vessel does not decrease as the sulfur production throughput decreases, and so that the interface area of the molten sulfur and the redox solution is reduced as the sulfur throughput decreases. A pressure controller monitors the pressure in the vessel and adds or removes gas from a gas phase zone in the vessel to maintain a predetermined pressure regardless of the vertical height of the interface.

Owner:MERICHEM CO

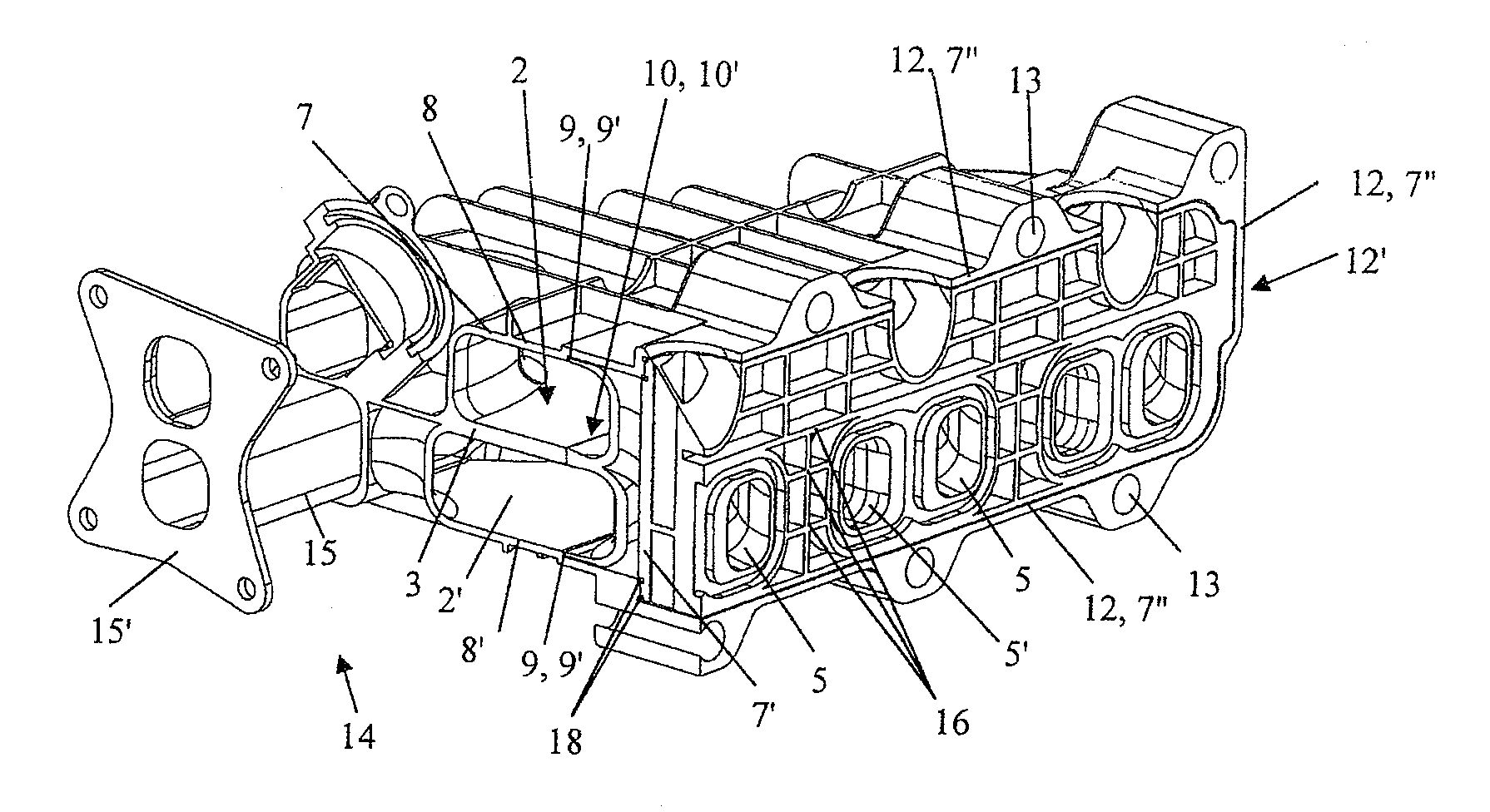

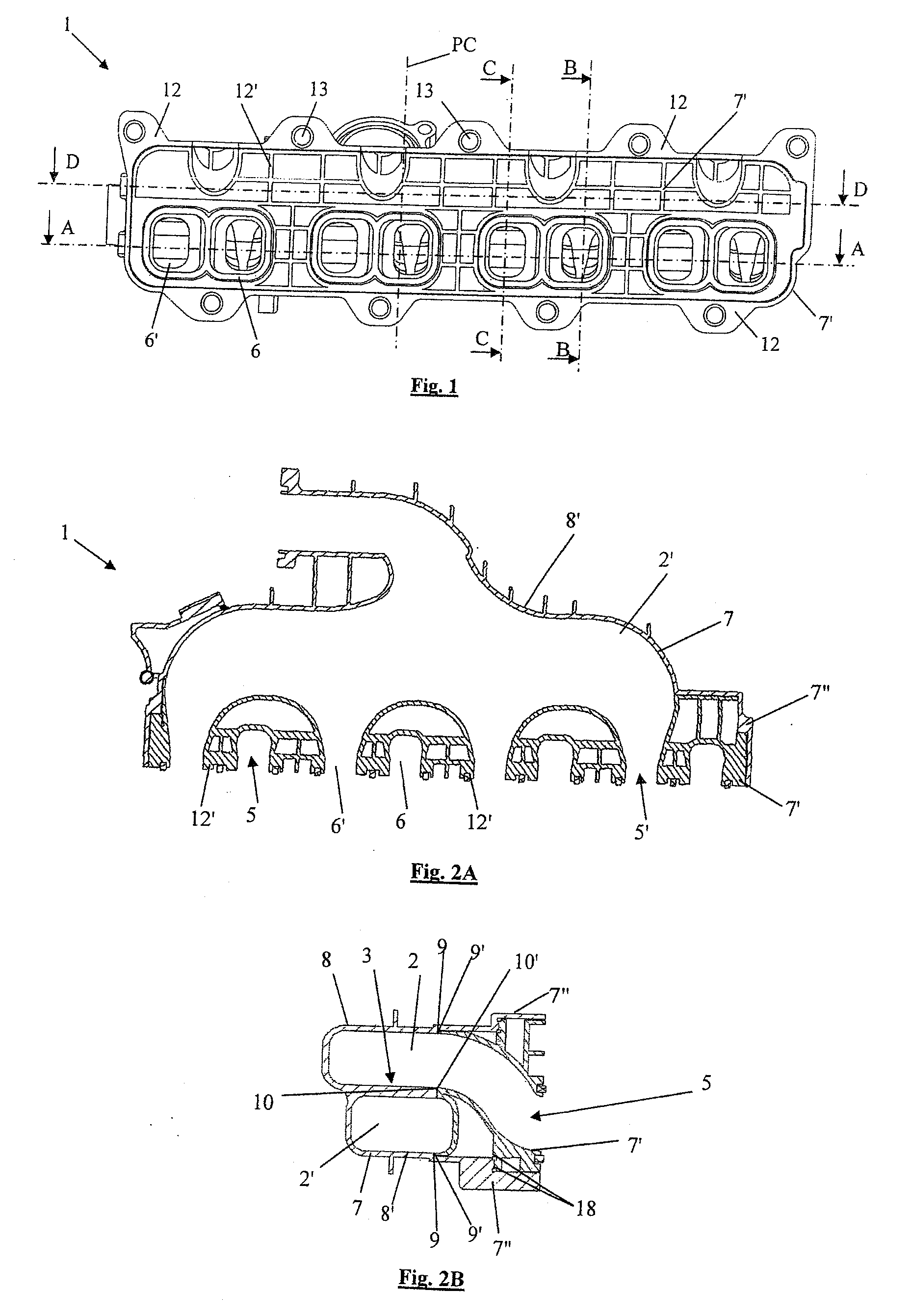

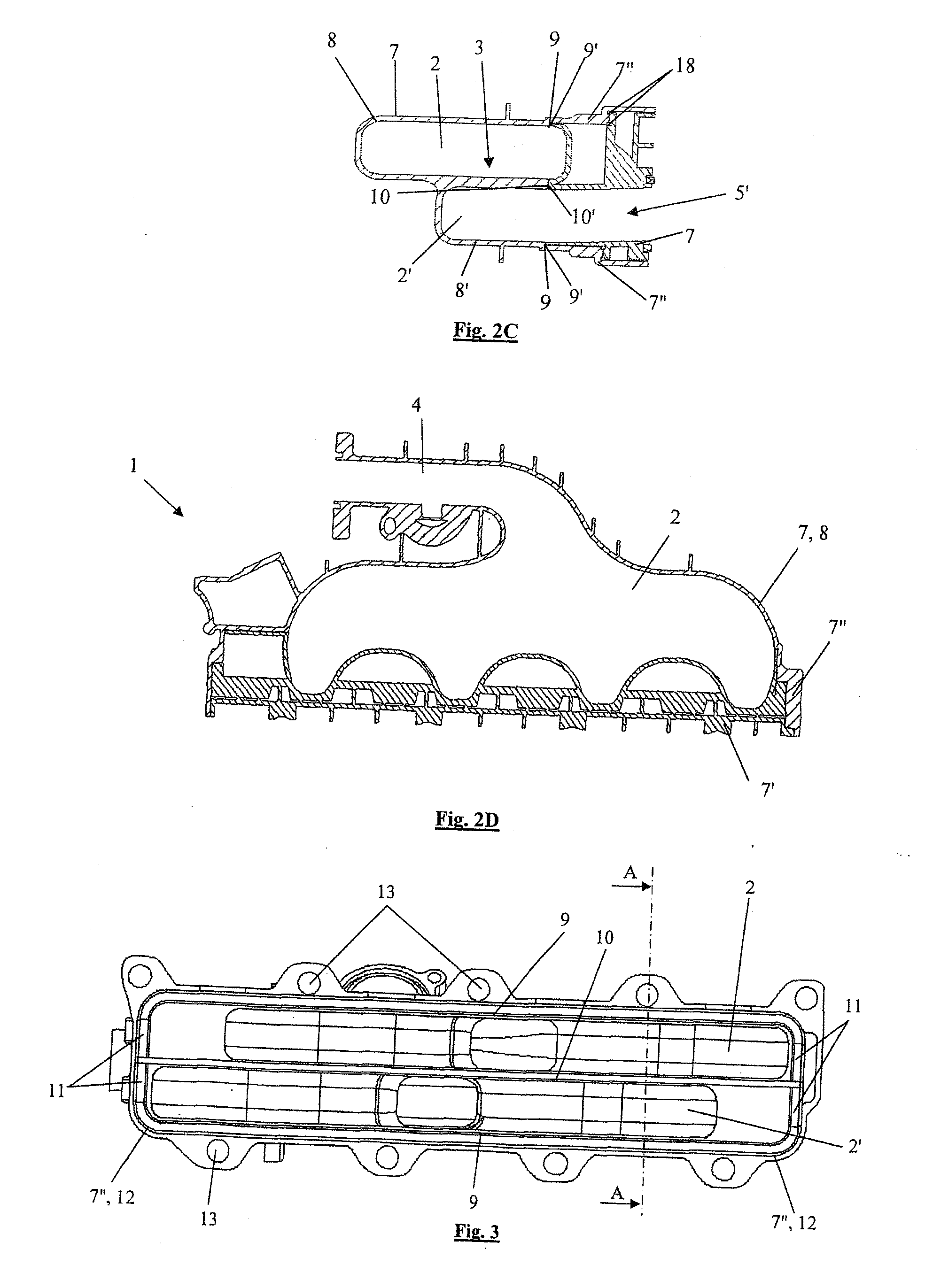

Double-plenum inlet manifold and vehicle incorporating such a manifold

ActiveUS20090071430A1Production cost be reduceReduce interface areaInternal combustion piston enginesNon-fuel substance addition to fuelStructural unitFlow diverter

This invention relates to a double-plenum or double-chamber inlet manifold or splitter, made up of a structural unit comprising two distinct coupled plenums with a common wall, an inlet opening for each of the two plenums and several pipes through each of the said plenums, the said superimposed plenums having substantially flattened general structures and forming, with their respectively connected inlet openings and pipes, two independent circulation circuits running from the entrance at the inlet openings to the outlet at the external openings of the pipes, the said external or outlet openings of the pipes being grouped in pairs, with each pair having an opening of each of the two types of pipes; the manifold comprises two one-piece parts assembled together, in a gas-tight manner, at the continuous assembly areas, a first part incorporating at least the two inlet openings and first portions of the walls of the two plenums, contiguous to the said openings and the second part incorporating the pipes and second portions of the walls of the two plenums, contiguous to the said pipes and complementary to the above-mentioned first portions.

Owner:SYST MOTEURS

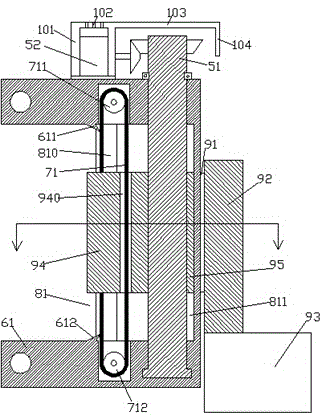

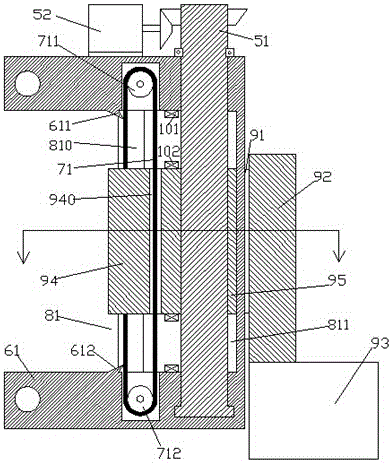

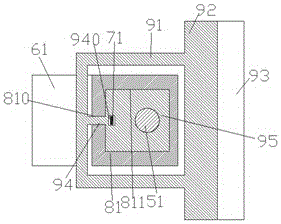

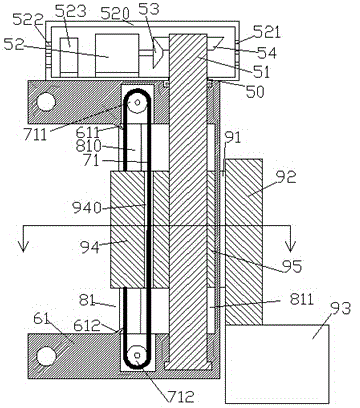

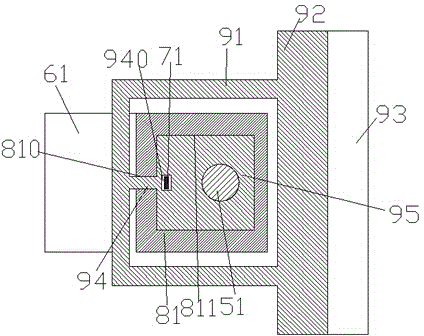

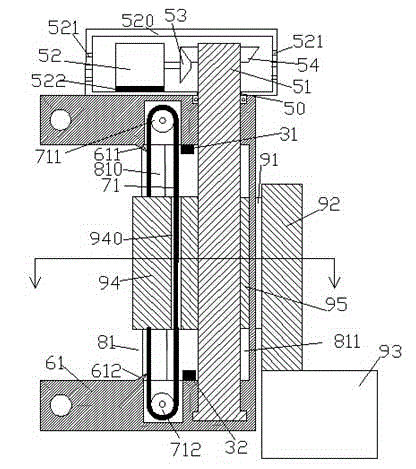

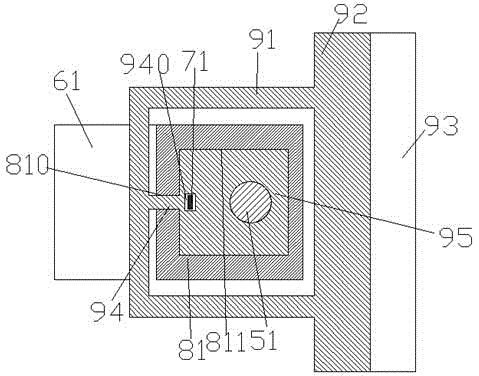

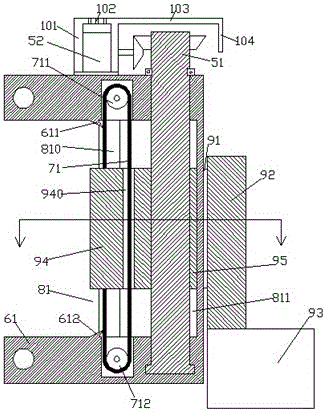

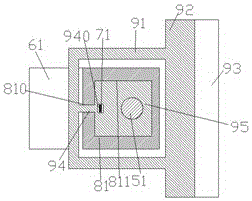

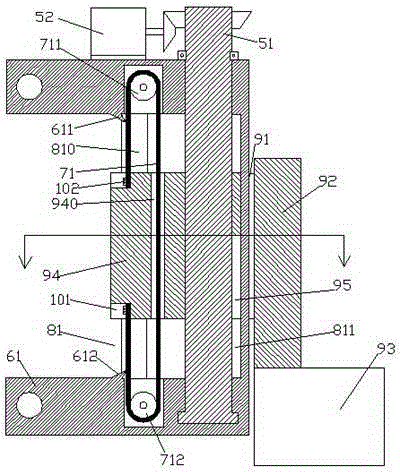

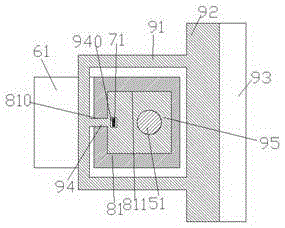

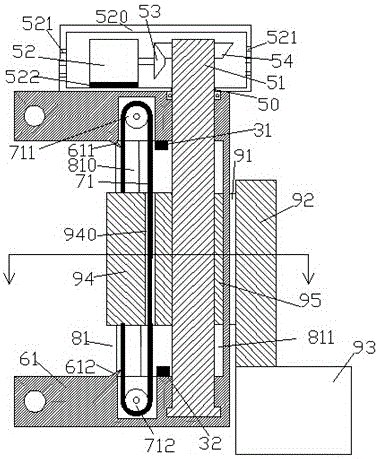

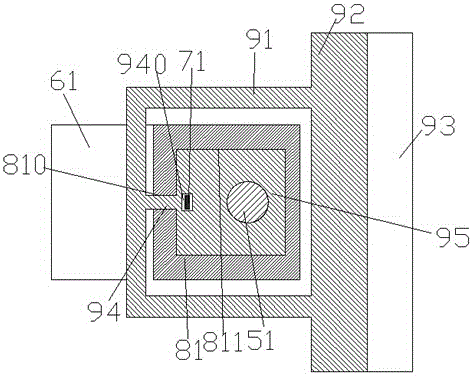

Rice planting device with protective cover

The invention provides a rice planting device with a protective cover. The rice planting device comprises a bearing frame body (92), a rice seedling transplantation executing mechanism (93) installed at the lower end of the bearing frame body (92) and a fixed connection frame connected with a drive vehicle. The fixed connection frame comprises an upper connecting portion (61), a lower connecting portion (61) and a sliding travel portion (81) fixedly arranged between the upper connecting portion (61) and the lower connecting portion (61). An inner cavity (811) and a middle slot (810) communicated with the inner cavity (811) are formed in the sliding travel portion (81). A threaded sliding block (95) is arranged in the inner cavity (811) in a sliding mode, wherein a threaded hole is formed in the middle of the threaded sliding block (95).

Owner:叶雨玲

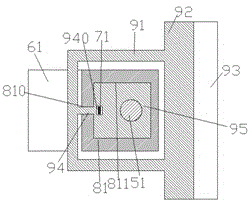

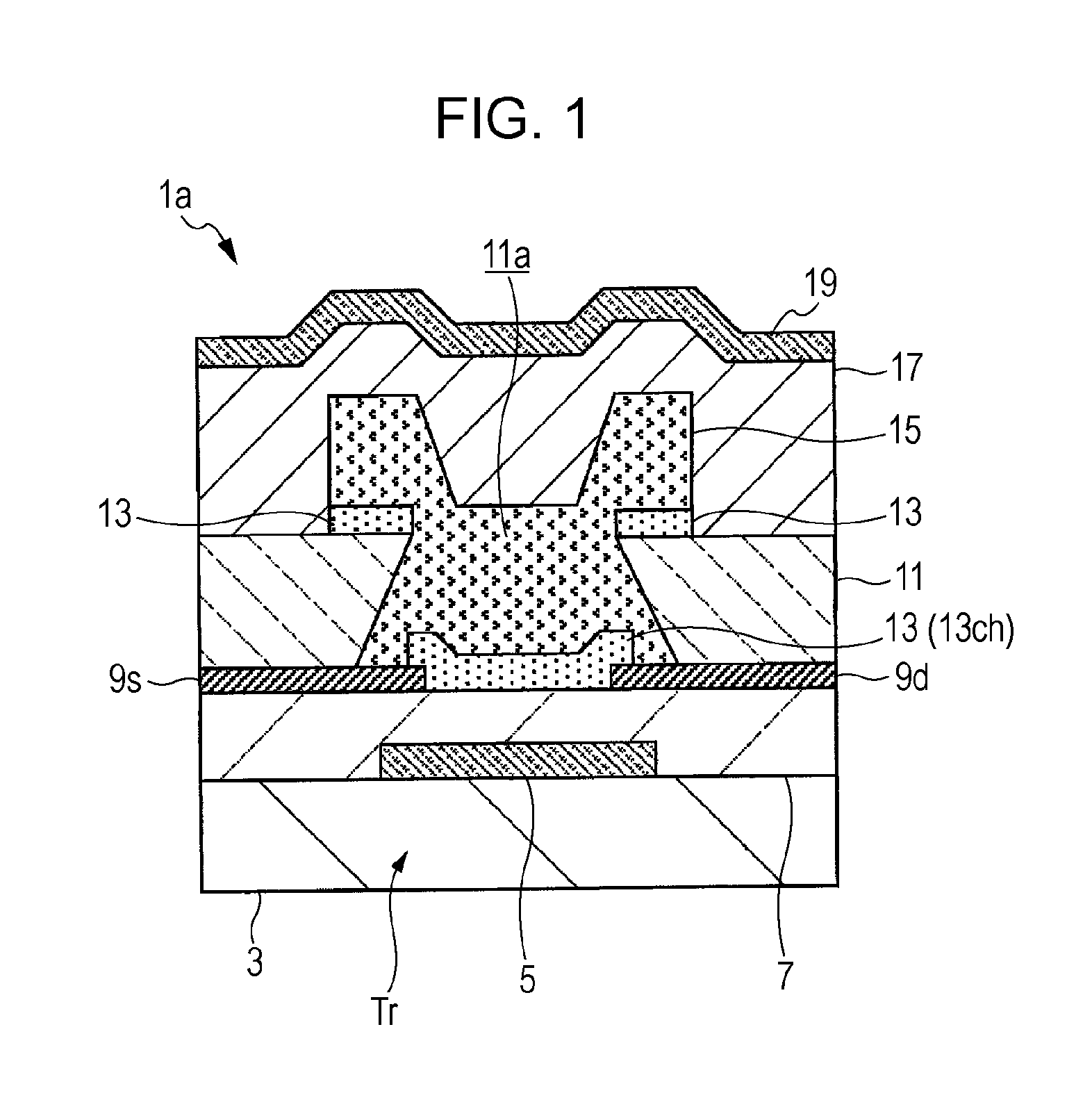

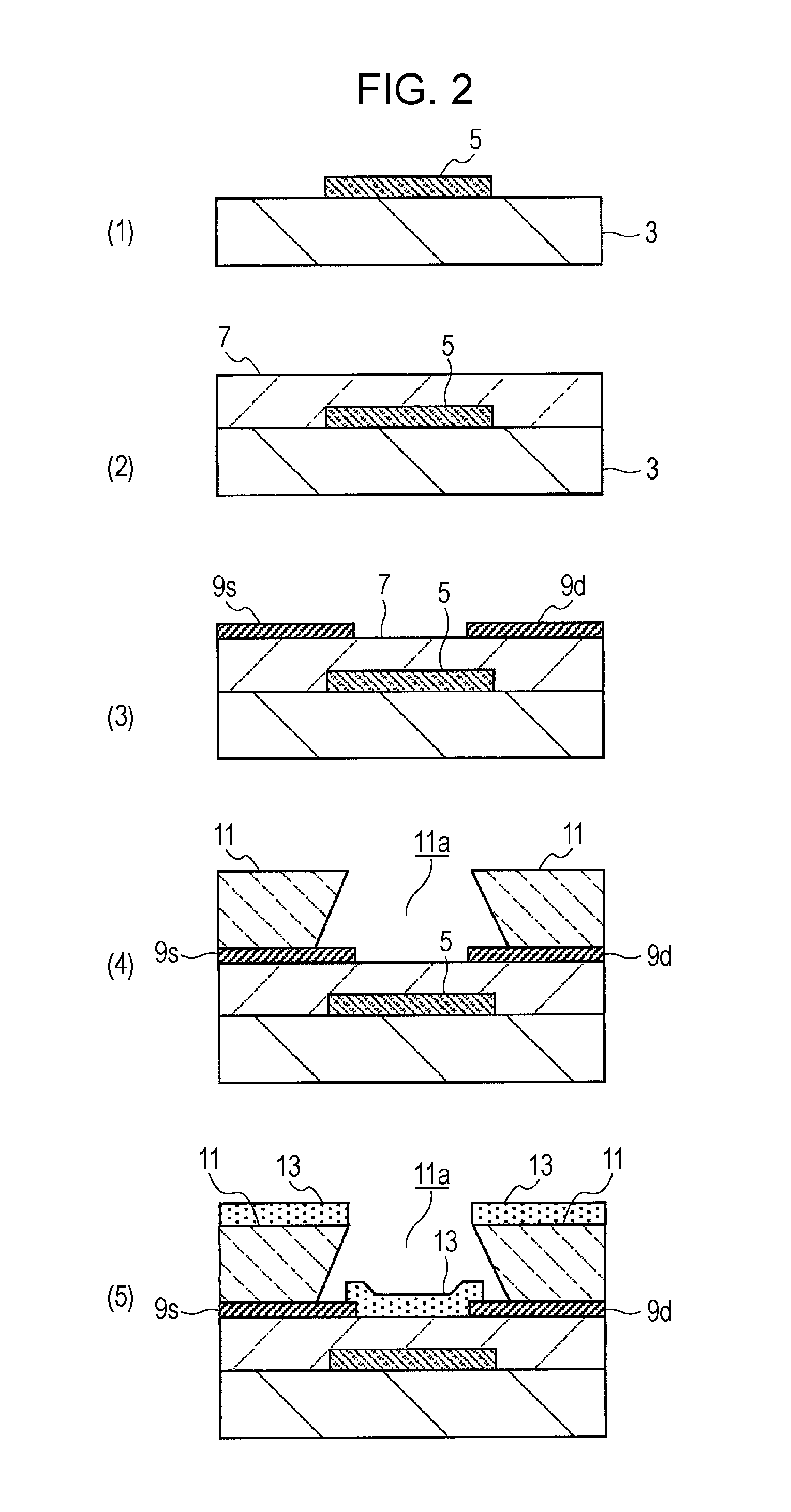

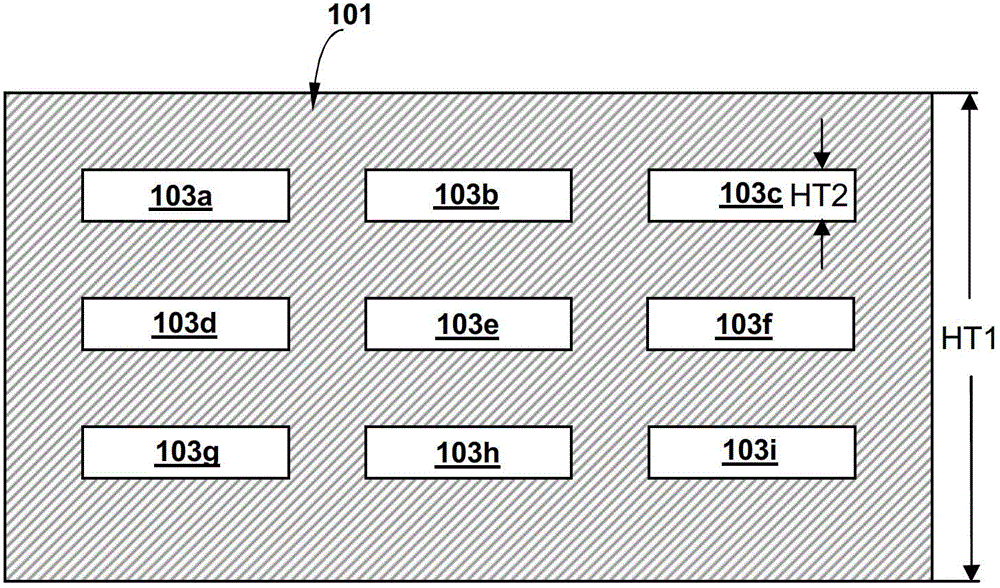

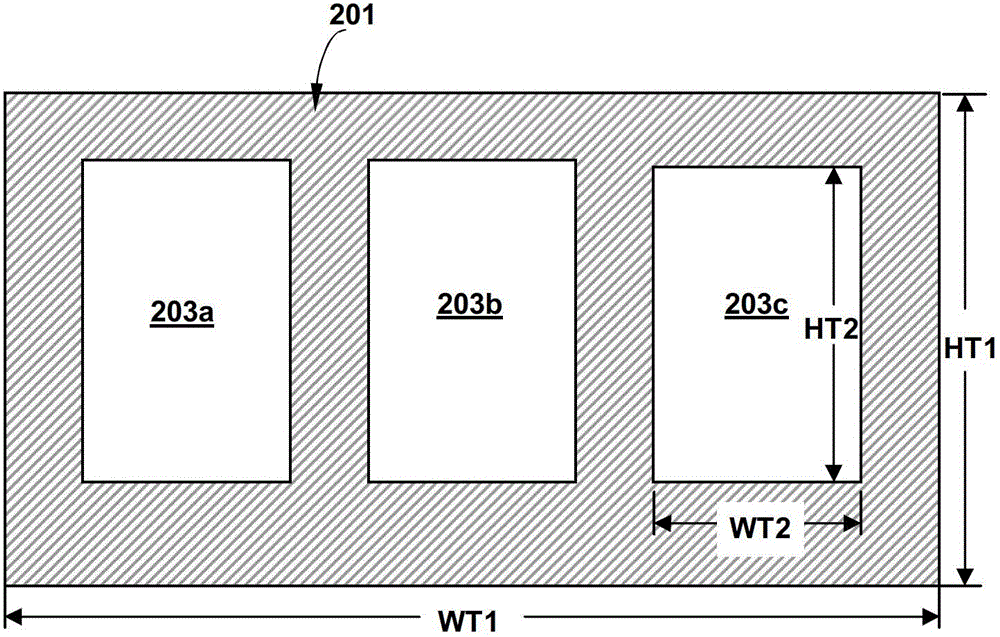

Semiconductor device and display apparatus

InactiveUS8569745B2Avoid layeringImprove featuresSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialEngineering

A semiconductor device includes an organic semiconductor layer, and a protective film. The protective film covers a side wall of the organic semiconductor layer. An insulating partition wall is disposed on the substrate. The partition wall includes an opening. The organic semiconductor layer includes a first portion that is disposed within the opening of the partition wall. The protective film fills the inside of the opening of the partition wall.

Owner:SONY CORP

A kind of peanut powder with strong flavor and long shelf life and its preparation process

ActiveCN106666609BStrong aromaLong lasting fragranceFood ingredient as antioxidantBiotechnologyPeanut meal

The present invention relates to rich-flavor and long-shelf life peanut powder and a preparation process thereof, and particularly provides a peanut powder product and a preparation method thereof, and a food containing the peanut powder product. According to the present invention, the peanut powder product contains peanut powder, added grease and an optional antioxidant, and has characteristics of enhanced flavor, delayed peanut powder oxidation rate, and lasting flavor.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

An anti-overtravel rice planting device

Disclosed is an overtravel-resistant paddy rice planting device. The paddy rice planting device comprises a support frame body (92), a transplanting actuator (93) installed below the support frame body (92), and a fixed connection support connected to a driving vehicle. The fixed connection support comprises two of upper and lower connection portions (61) and a sliding stroke portion (81) fixedly arranged between the two connection portions (61). The sliding stroke portion (81) is internally provided with an inner chamber (811) and a central groove gap (810) communicating the inner chamber (811), wherein the inner chamber (811) is internally slidingly provided with a thread sliding block (95), the center of which is provided with a screw hole.

Owner:重庆雅攀农业开发有限责任公司

Rice seedling transplanting device good in heat dissipation performance

A rice seedling transplanting device good in heat dissipation performance comprises a bearing frame body (92), a rice seedling transplanting execution mechanism (93) arranged at the lower end of the bearing frame body (92), and a fixed connection frame connected with a drive vehicle. The fixed connection frame comprises an upper connection part (61), a lower connection part (61) and a sliding stroke part (81) fixedly arranged between the upper connection part (61) and the lower connection part (61). The sliding stroke part (81) is internally provided with an inner cavity (811) and a middle groove seam (810) communicated with the inner cavity (811). A threaded slide block (95) with a screwed hole in the middle is arranged in the inner cavity (811) in a sliding mode.

Owner:俞升洋

Automatic rice transplanting device

The invention provides an automatic rice transplanting device. The automatic rice transplanting device comprises a bearing frame body (92), a rice transplanting executing mechanism (93) which is installed at the lower end of the bearing frame body (92) and a fixed connecting frame which is connected with a driving vehicle, wherein the fixed connecting frame comprises connecting parts (61) which are arranged in an up-and-down mode and a sliding strode part (81) which is fixedly arranged between the up and down connecting parts (61), the sliding strode part (81) is internally provided with an inner chamber (811) and a middle groove seam (810) which is communicated with the inner chamber (811), and the inner chamber (811) is provided with a threaded sliding block (95) with a screw hole formed in the middle in a sliding mode.

Owner:绥棱县科田机械制造有限公司

A rice planting device with a protective cover

The invention provides a rice planting device with a protective cover. The rice planting device comprises a bearing frame body (92), a rice seedling transplantation executing mechanism (93) installed at the lower end of the bearing frame body (92) and a fixed connection frame connected with a drive vehicle. The fixed connection frame comprises an upper connecting portion (61), a lower connecting portion (61) and a sliding travel portion (81) fixedly arranged between the upper connecting portion (61) and the lower connecting portion (61). An inner cavity (811) and a middle slot (810) communicated with the inner cavity (811) are formed in the sliding travel portion (81). A threaded sliding block (95) is arranged in the inner cavity (811) in a sliding mode, wherein a threaded hole is formed in the middle of the threaded sliding block (95).

Owner:叶雨玲

Easy-maintenance rice planting apparatus

The invention relates to an easy-maintenance rice planting apparatus, which comprises a bearing frame body (92), a rice seedling transplant performing mechanism (93) arranged on the lower end of the bearing frame body (92), and a fixation connection frame connected to a drive vehicle, wherein the fixation connection frame comprises two coupling parts (61) in an upper-lower manner and a sliding stroke part (81) fixedly arranged between the two coupling parts (61), an inner chamber (811) and a middle portion groove seam (810) communicated to the inner chamber (811) are arranged inside the sliding stroke part (81), and a threaded sliding block (95) with threads on the middle portion is slidably arranged inside the inner chamber (811).

Owner:孙旭东

An automatic rice transplanting device

ActiveCN104938117BEffective isolationReduce interface areaTransplantingEngineeringMechanical engineering

The invention provides an automatic rice transplanting device. The automatic rice transplanting device comprises a bearing frame body (92), a rice transplanting executing mechanism (93) which is installed at the lower end of the bearing frame body (92) and a fixed connecting frame which is connected with a driving vehicle, wherein the fixed connecting frame comprises connecting parts (61) which are arranged in an up-and-down mode and a sliding strode part (81) which is fixedly arranged between the up and down connecting parts (61), the sliding strode part (81) is internally provided with an inner chamber (811) and a middle groove seam (810) which is communicated with the inner chamber (811), and the inner chamber (811) is provided with a threaded sliding block (95) with a screw hole formed in the middle in a sliding mode.

Owner:绥棱县科田机械制造有限公司

Glass melt processing equipment and method

ActiveCN102807307BExtend your lifeReduce erosionForehearthsOhmic-resistance electrodesGlass meltingElectrode material

Owner:CORNING INC

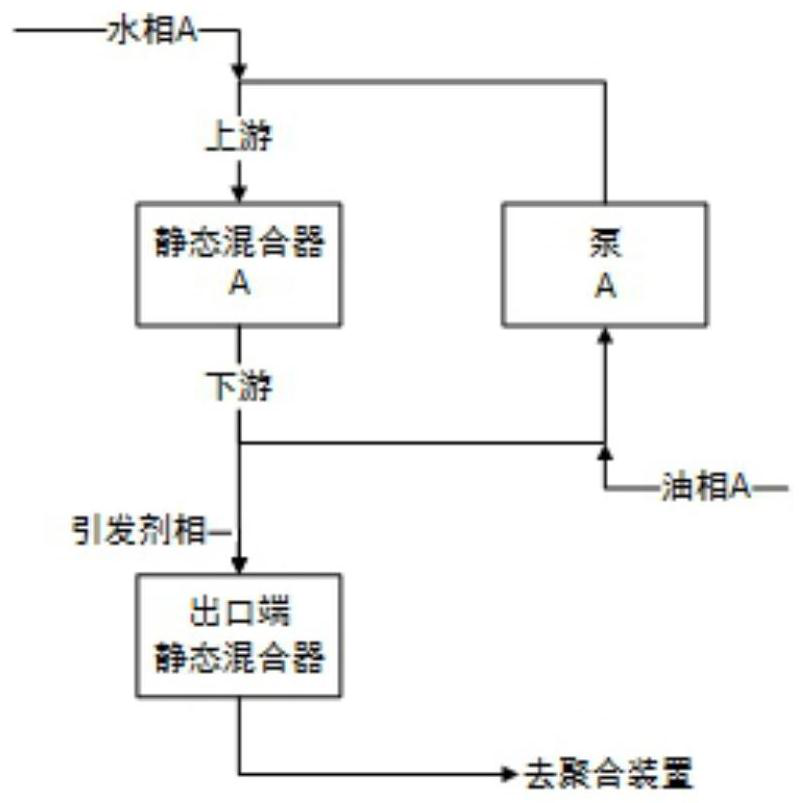

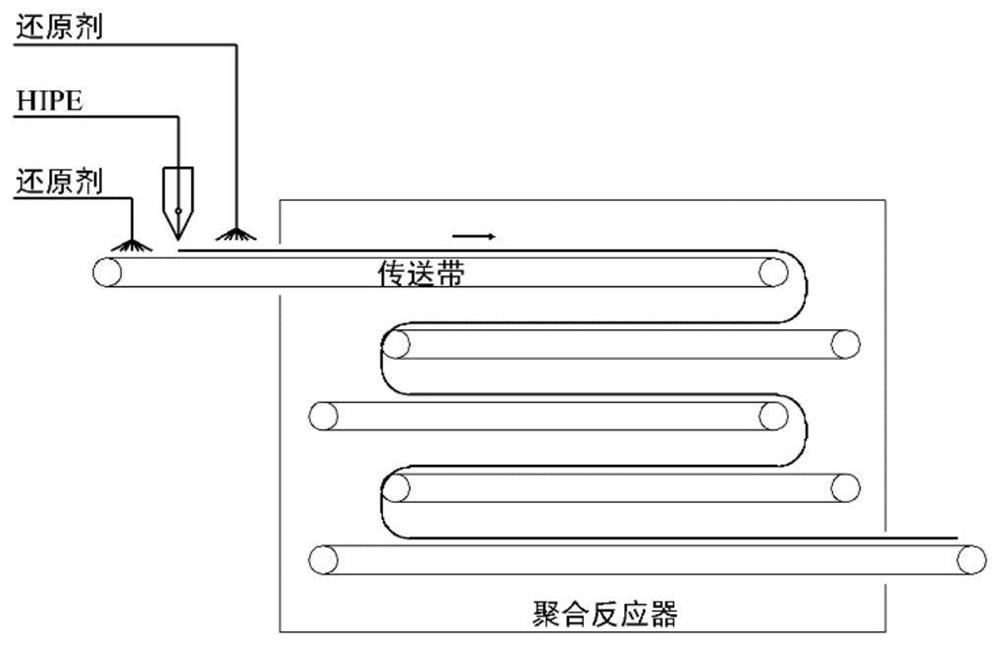

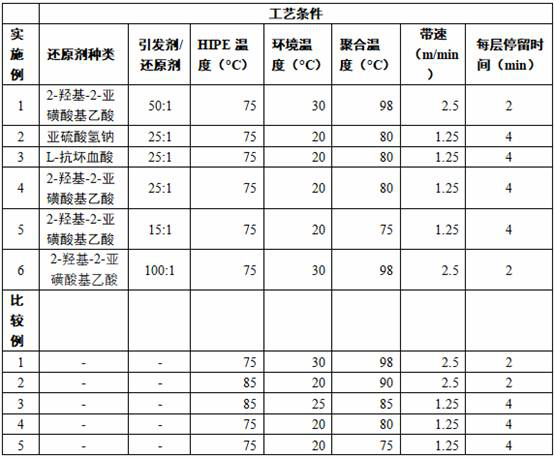

Method for reducing surface fusion and surface adhesion of high internal phase emulsion in polymerization process

The invention relates to a method for reducing surface fusion and surface adhesion of HIPE (high internal phase emulsion) in a polymerization process during production of HIPE foam by a continuous method, which comprises the following steps: depositing HIPE on conveying equipment, and simultaneously applying a water phase containing a reducing agent before and after the HIPE deposition position; and then polymerization is carried out, so that HIPE surface fusion and surface adhesion are prevented. For the lower surface of the HIPE in the prior art, the temperature of the high internal phase emulsion is higher than that of a deposition area conveyor belt, so that the temperature of the lower surface of the high internal phase emulsion after deposition is rapidly reduced, the polymerization rate of the lower surface of the HIPE is greatly reduced, and the internal phase is fused to different degrees in a polymerization curing furnace, so that the problems are solved for the first time. The surface fusion and the surface adhesion of the HIPE in the polymerization process are reduced.

Owner:苏州星日化学有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com