Automatic rice transplanting device

A sliding plate and driving motor technology, applied in the field of agricultural machinery, can solve the problems of reduced operation reliability, polluted internal environment, deteriorated lubrication or sliding operating conditions, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

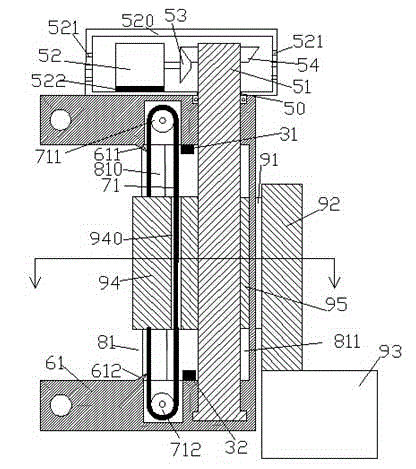

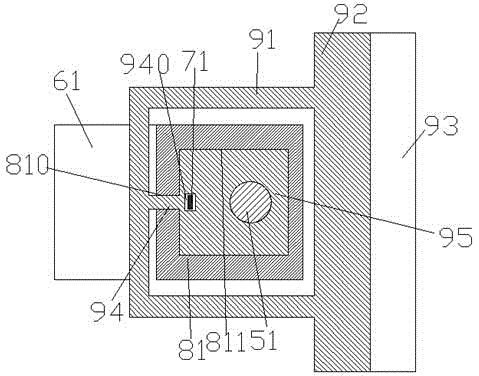

[0009] Combine below Figure 1-2 The present invention will be described in more detail.

[0010] According to an embodiment, an automatic rice transplanting device includes a carrier body 92, a rice transplanting actuator 93 installed at the lower end of the carrier body 92, and a fixed connection frame connected to a driving vehicle. The fixed connection frame includes two upper and lower connections. part 61 and a sliding stroke part 81 fixedly arranged between the upper and lower coupling parts 61, the sliding stroke part 81 is provided with an inner cavity 811 and a middle slot 810 communicating with the inner cavity 811, the A threaded slider 95 with a screw hole in the middle is slidably disposed in the inner cavity 811, a sliding plate 94 fixedly connected to the threaded slider 95 is slidably disposed in the middle slot 810, and the upper end of the carrier body 92 passes through The connecting arms 91 located on both sides of the sliding stroke portion 81 are fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com