Molded rare-earth magnet and process for producing same

A technology of rare earth magnets and manufacturing methods, which is applied in the directions of inductor/transformer/magnet manufacturing, magnetic objects, magnetic materials, etc., and can solve problems such as increasing magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] As the raw material magnetic powder, powder of Nd—Fe—B based anisotropic magnet prepared by HDDR method was used. The specific preparation steps are as follows.

[0118] First, an ingot having a composition of "Nd: 12.6%, Co: 17.4%, B: 6.5%, Ga: 0.3%, Al: 0.5%, Zr: 0.1%, Fe: remainder (mass %)" is prepared , The ingot was kept at 1120° C. for 20 hours for homogenization. Furthermore, the homogenized ingot was heated from room temperature to 500° C. and held in a hydrogen atmosphere, and further heated to 850° C. and held.

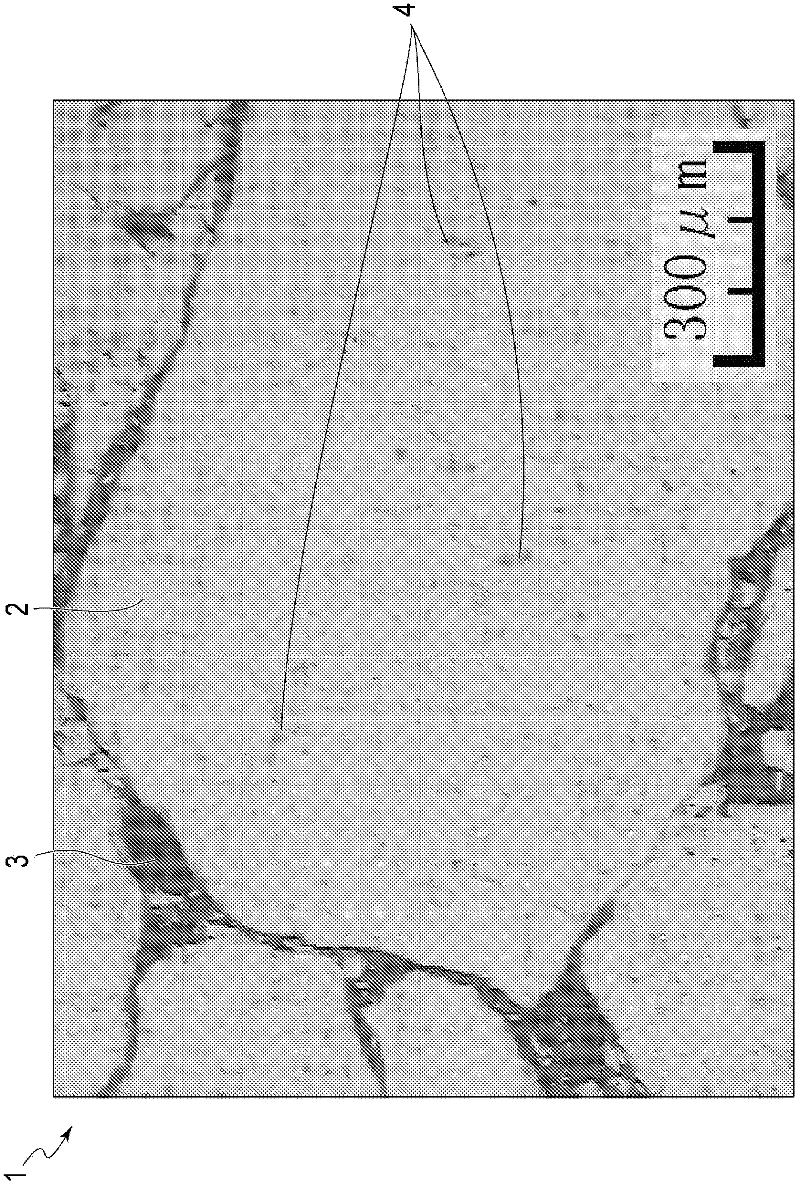

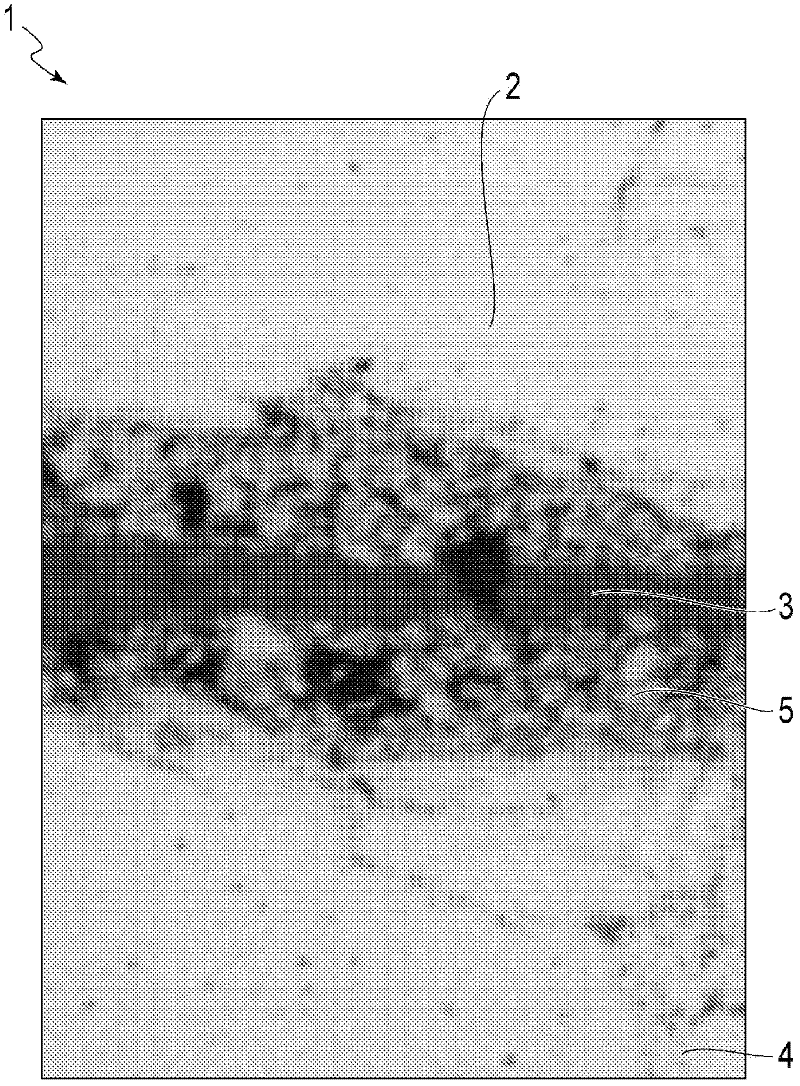

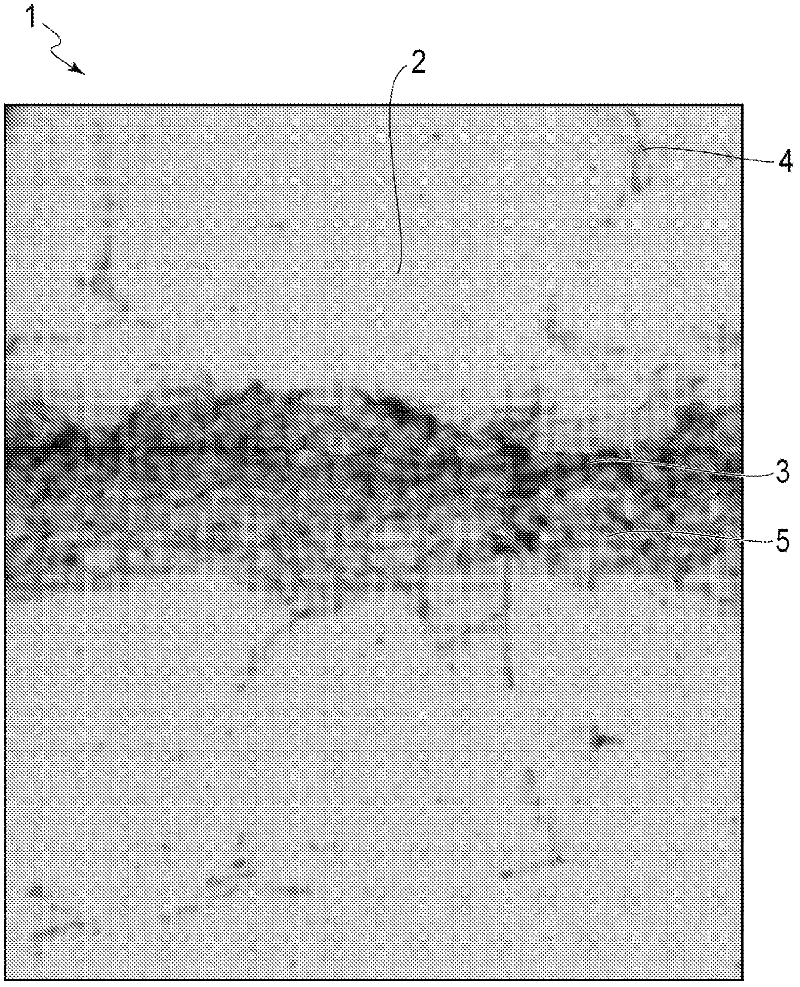

[0119] Next, after holding in a vacuum at 850° C., it was cooled to obtain an alloy having a recrystallized structure of a fine ferromagnetic phase. The alloy was pulverized under an argon atmosphere using a jaw crusher and a Braun mill to obtain rare earth magnet raw material magnetic powder having an average particle diameter of 300 μm. In addition, particles with a particle size of less than 25 μm and particles with a particle size of 525 μm or...

Embodiment 2

[0136] As the rare earth alkoxide, praseodymium triisopropoxide was used instead of dysprosium triisopropoxide to form an insulating phase composed of Pr oxide, and a rare earth magnet molded body was obtained by the same method as in Example 1 above. In addition, the Pr concentration of the praseodymium surface treatment liquid was analyzed by ICP, and the coating amount of the solution was adjusted so that the total coating amount was 40 mg per 10 g of magnet particles.

Embodiment 3

[0138] A rare earth magnet molded body was obtained in the same manner as in Example 1 above except that the raw material magnetic powder for sintered magnets was used instead of the raw material magnetic powder produced by the HDDR method as the raw material magnetic powder. In addition, the raw material magnetic powder was prepared by the following method.

[0139] An alloy compounded to have a composition of Nd: 31.8, B: 0.97, Co: 0.92, Cu: 0.1: Al: 0.24, remainder: Fe (mass %) is processed to a thickness of 0.2 to 0.2 by a strip cast method. 0.3mm thin alloy strip. Next, the alloy ribbon was filled in a container and accommodated in a hydrogen processing apparatus. Furthermore, by filling the hydrogen treatment device with a hydrogen atmosphere at a pressure of 500 kPa, hydrogen is stored in the alloy ribbon at room temperature, and then replaced with argon, and the pressure is further reduced to 10 -5 Pa, release hydrogen. By performing this hydrogen treatment, the all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com