Novel fore shaft pipe

A lock pipe, a new type of technology, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problem of not being able to adapt to different reinforcement cage edge shapes, the diameter cannot change with the width of the continuous wall, and it is not easy to accurately grasp the timing of extubation, etc. To achieve the effect of convenient and quick dismantling, increasing the degree of freedom of construction, and reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

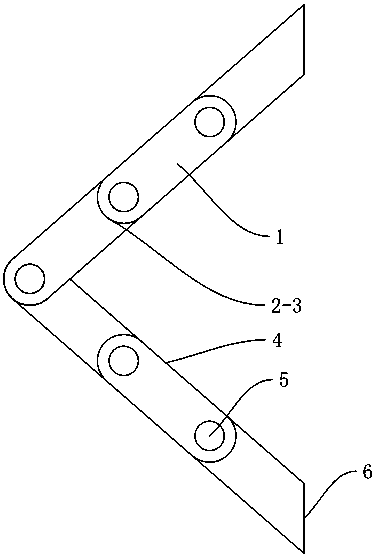

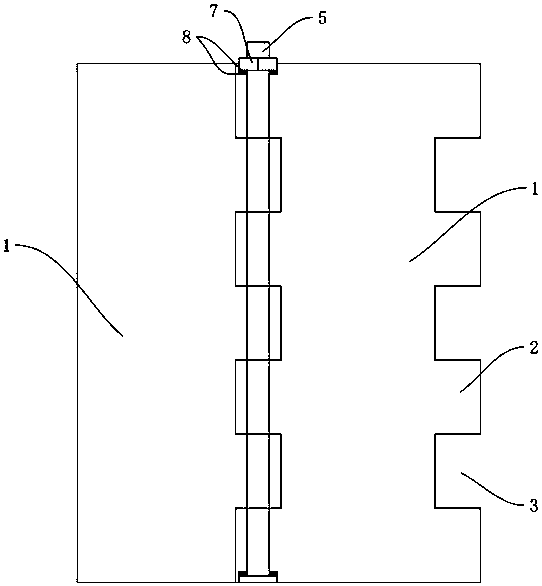

[0033] Embodiment 1: a kind of novel locking pipe (see figure 1 image 3 ), the whole is a foldable structure in which a plurality of rectangular slats 1 are hinged to each other through high-strength connecting shafts 5. There are 6 slats in this embodiment, and four of them have connecting structures on both sides , two of them have only one side with a connecting structure, and the other side is a straight edge 6, and the two strips are located on both sides of the lock pipe. The slats are hinged by the connecting shaft and then locked by the locking device to form a shape suitable for the end face of the wall section. The slats have a contact plane 4 . The straight edge and the contact plane are non-perpendicular, and the straight edge and the contact plane form an angle of 45°.

[0034]The slats are integrally structured along the length direction, the length of the slats is equal to the length of the lock pipe, the sides of the slats are respectively provided with conc...

Embodiment 2

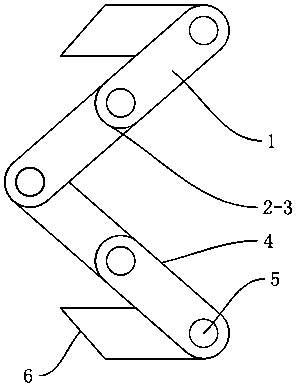

[0037] Embodiment 2: a kind of novel locking pipe (referring to figure 2 ), the difference from Example 1 is that when adjusting the width of the locking tube, the outermost slats can be rotated around the connecting shaft to form an M-shaped structure, which also maintains a suitable clip between the two contact planes corners, and the height of the protruding sharp corner at the end of the wall segment will not be very high. Refer to Example 1 for all the other structures.

Embodiment 3

[0038] Embodiment 3: a kind of novel locking pipe (referring to Figure 7 ), the difference from Example 1 is that the lock pipe is formed as a whole in a trapezoidal shape, the middle two of the six slats are on the same plane, and the two panels on both sides are on the same plane respectively, and the remaining structures refer to the embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com