A double-layer structure inclined bed of a turning center and its manufacturing method

A double-layer structure and turning center technology, which is applied in the field of machine tools, can solve the problems that the bed affects the machining accuracy and the bed is easy to deform, and achieves the effect of stable overall structure, strong rigidity, good bending and torsional rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

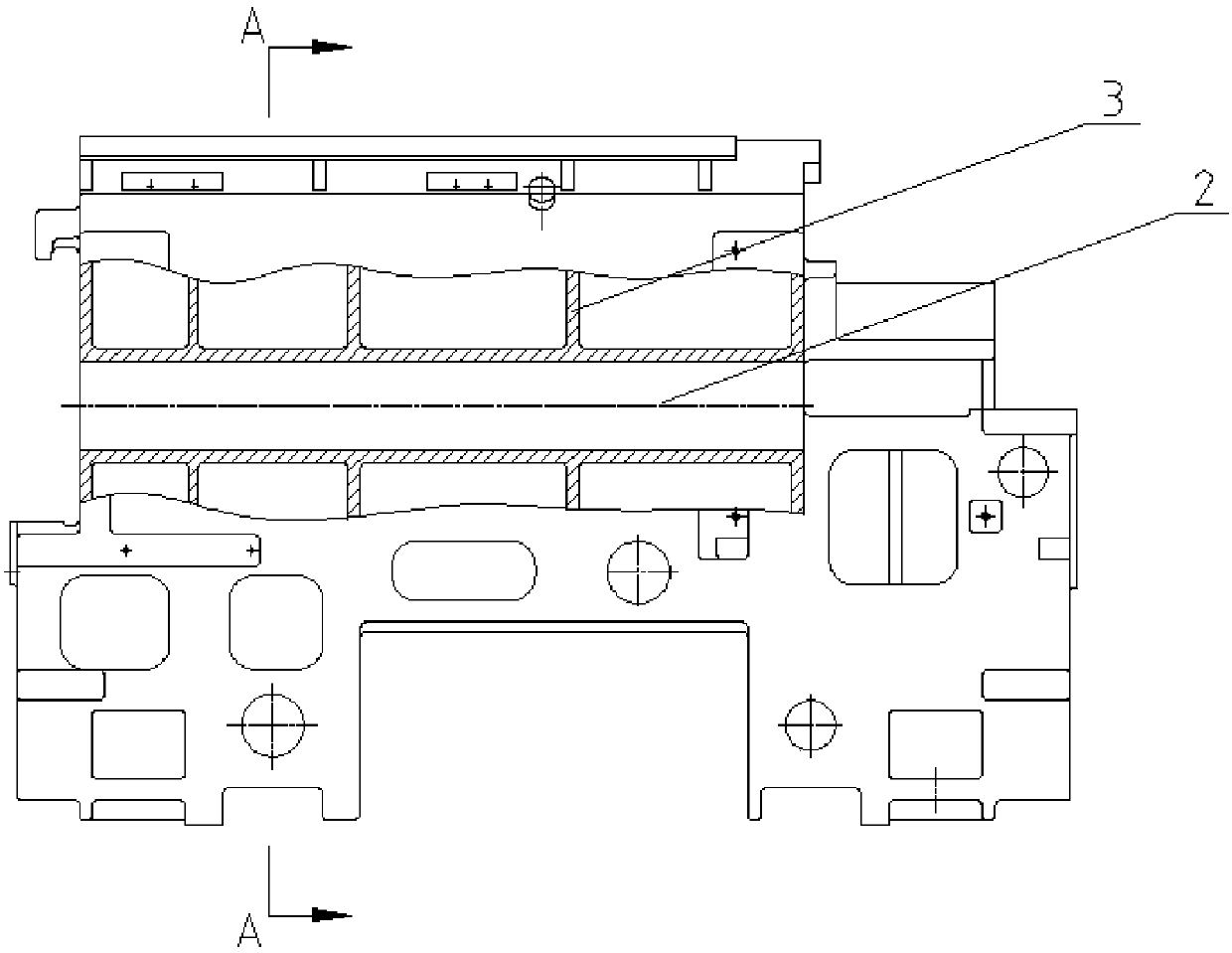

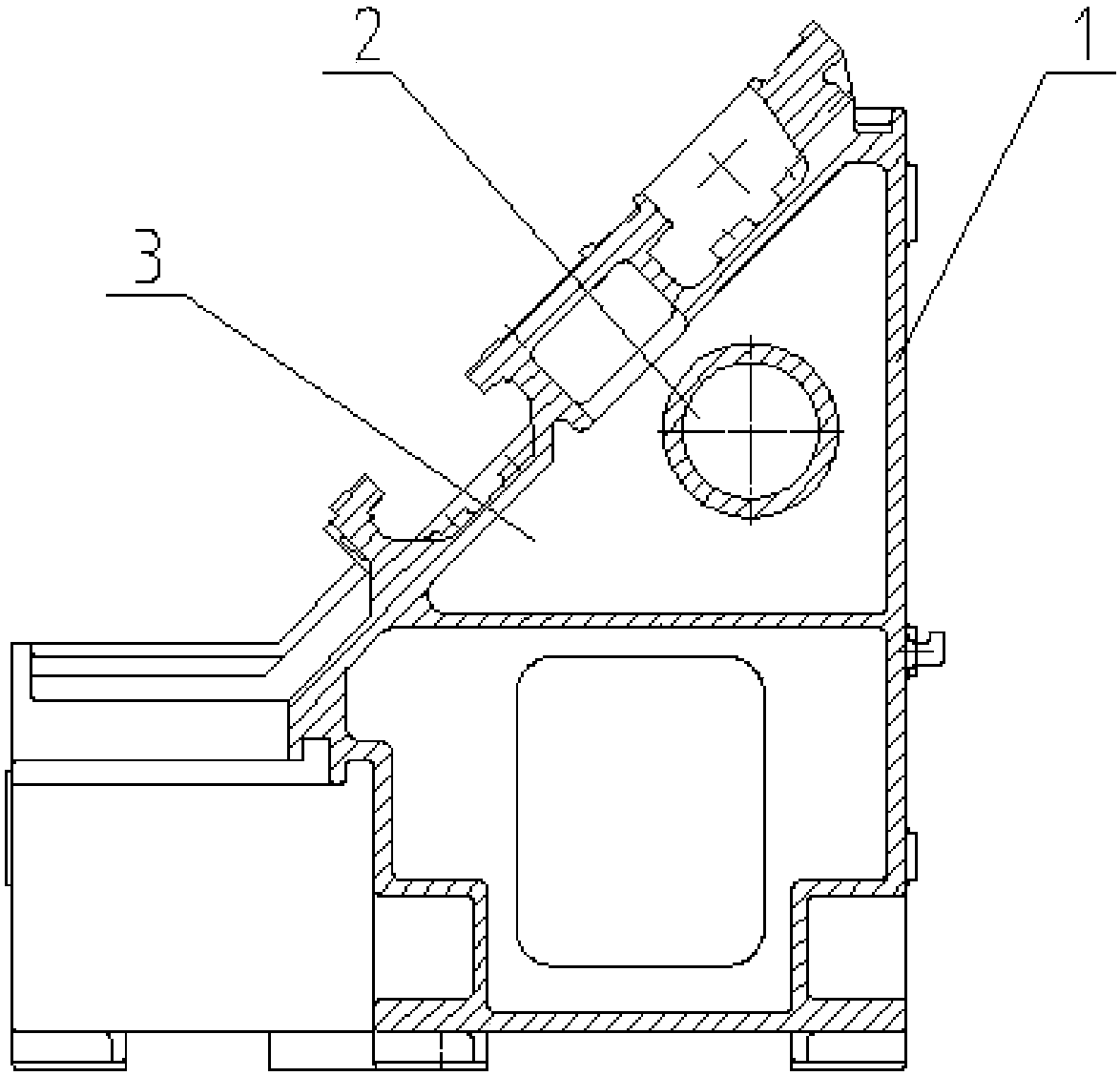

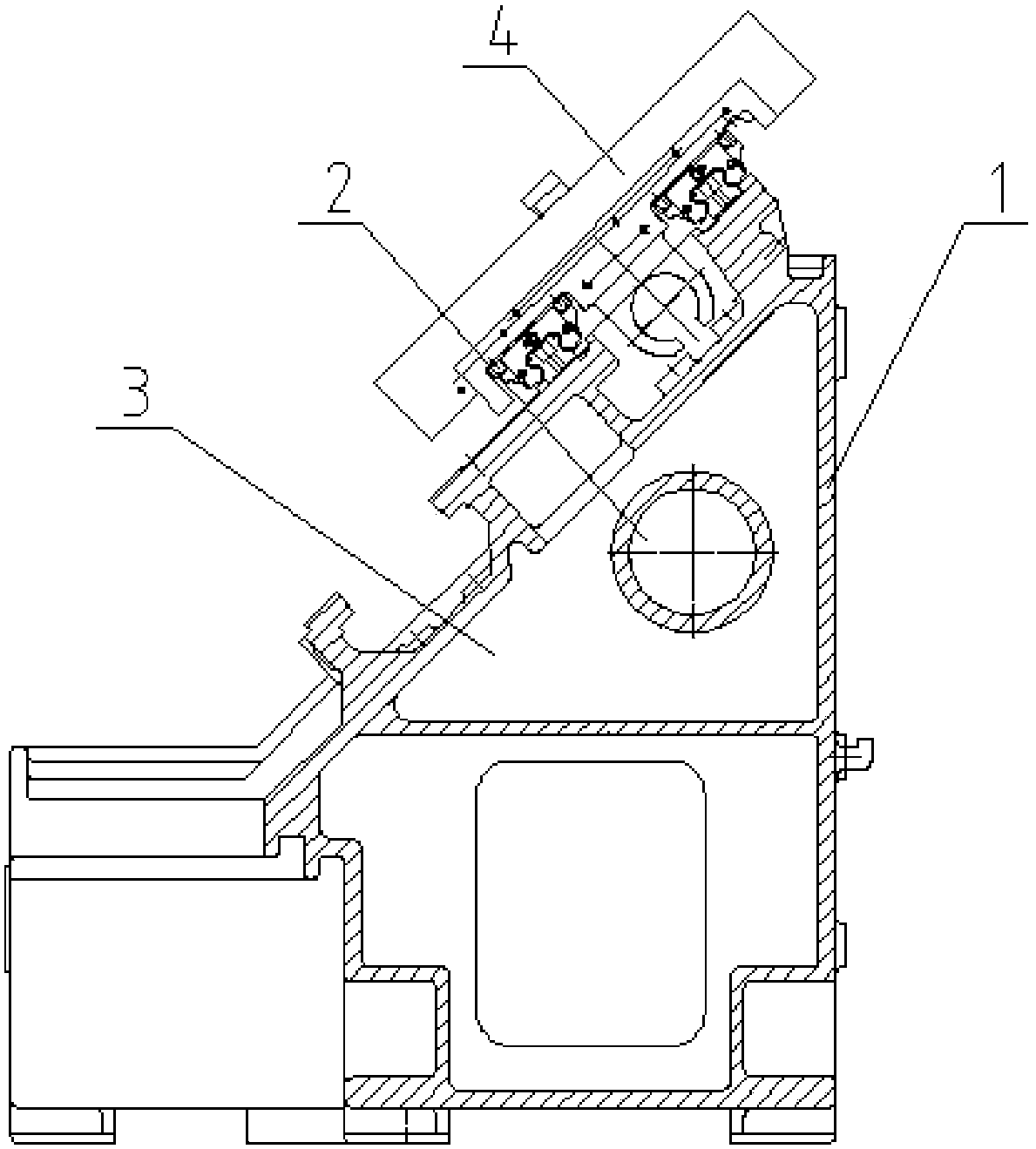

[0045] Such as figure 1 and figure 2As shown, a double-layer structure inclined bed of a turning center includes an upper bed and a lower bed. The upper bed is an inclined bed, and the inclined bed includes an outer frame 1, a cylinder 2 and a transverse partition 3; The cross section of 1 is an isosceles right triangle; the cylinder 2 is arranged inside the outer frame 1; the central axis of the cylinder 2 passes through the center of gravity of the cross section triangle of the outer frame 1; the outer diameter of the cylinder 2 is D t ,D t The size satisfies the following relationship:

[0046]

[0047] Where: D t is the outer diameter of the cylinder, T is the torque generated by the cutting force, ρ is the ratio of the inner and outer diameters of the cylinder 2 section, [τ] is the allowable shear stress of the cylinder section; [τ]=(0.8~1.0 )〔σ〕;〔σ〕is the allowable tensile stress of the material; the material of the inclined bed (including the cylinder and the pa...

Embodiment 2

[0069] Same as Embodiment 1, the difference is: In order to further improve the overall rigidity of the bed and reduce the cutting force generated by the moving saddle to the inclined bed, in this embodiment the distance between the transverse partitions 3 is set to be the distance between the moving saddle 4, which ensures that there are always at least two transverse partition rib structures at the bottom of the mobile saddle, providing support for the mobile saddle bearing the cutting force, decomposing the cutting force, and further reducing the cutting force. Distortion of machine tool contours due to torsional deformation of large parts.

Embodiment 3

[0071] Same as Embodiment 2, except that the projected area of the lower part of the bed is larger than and covers the projected area of the upper spindle of the bed.

[0072] On the one hand, this setting considers that it is more convenient for the staff to load and unload the workpiece. On the other hand, when the machine tool spindle as the force point falls within the lower part of the bed as the support surface, no overturning force will be generated when the external force is applied. , the overall structure is more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com