Dry-type connected fabricated concrete guardrail

A prefabricated, concrete technology, used in road safety devices, bridge parts, roads, etc., can solve the problem of no high protection level, and achieve the effect of solving the problem of hole positioning, improving stability, and facilitating disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

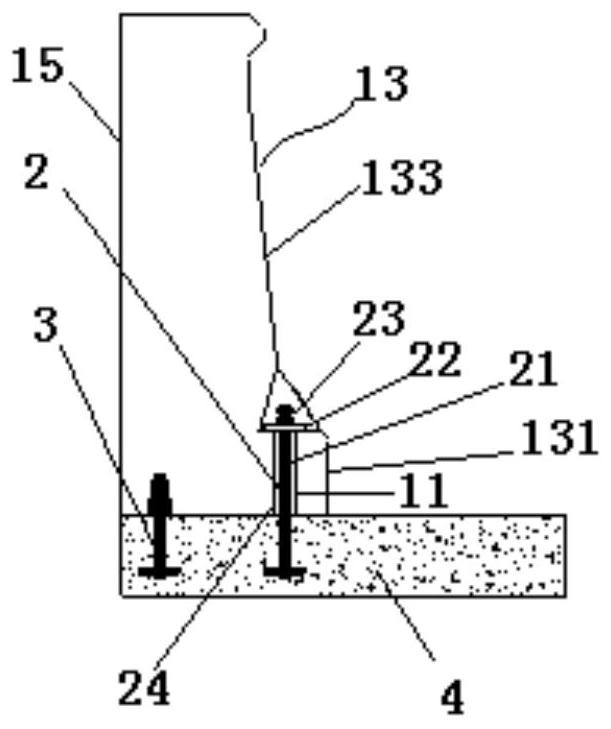

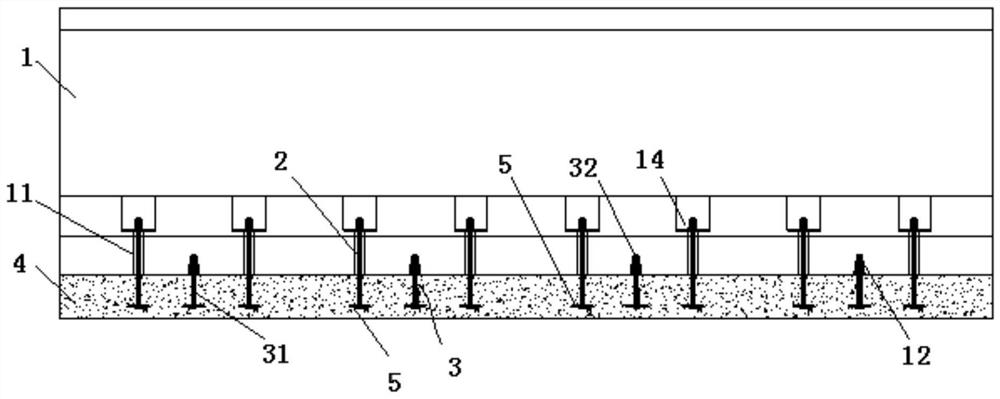

[0032] In order to facilitate the understanding of the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that "inner" in the present invention refers to a direction close to the axis of the bridge or road, and "outer" refers to a direction away from the axis of the bridge or road.

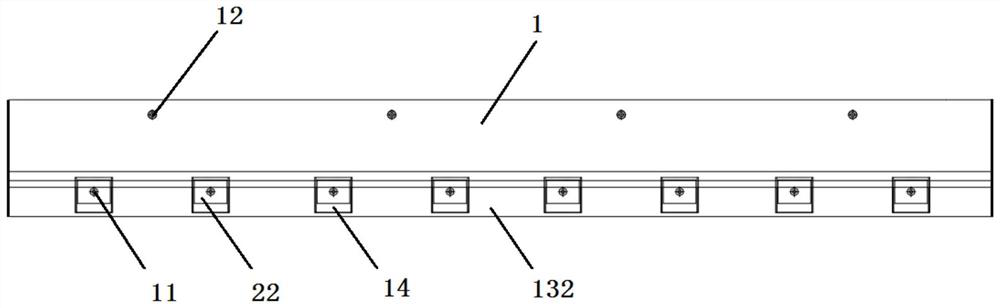

[0033] A dry-connected fabricated concrete barrier such as Figure 1-3As shown, including the guardrail body 1, along the direction of the guardrail, the bottom of the guardrail body 1 is provided with a plurality of bending bolt holes 11 and several shear bolt holes 12 arranged in a staggered manner; and the bending bolt holes 11 are close to the The inner side of the guardrail body is set, and the shear bolt holes 12 are set close to the outer side of the guardrail body, forming a triangular staggered arrangement of anchor hole groups, which can withstand vehicle collision load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com