Patents

Literature

63results about How to "Enough grip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

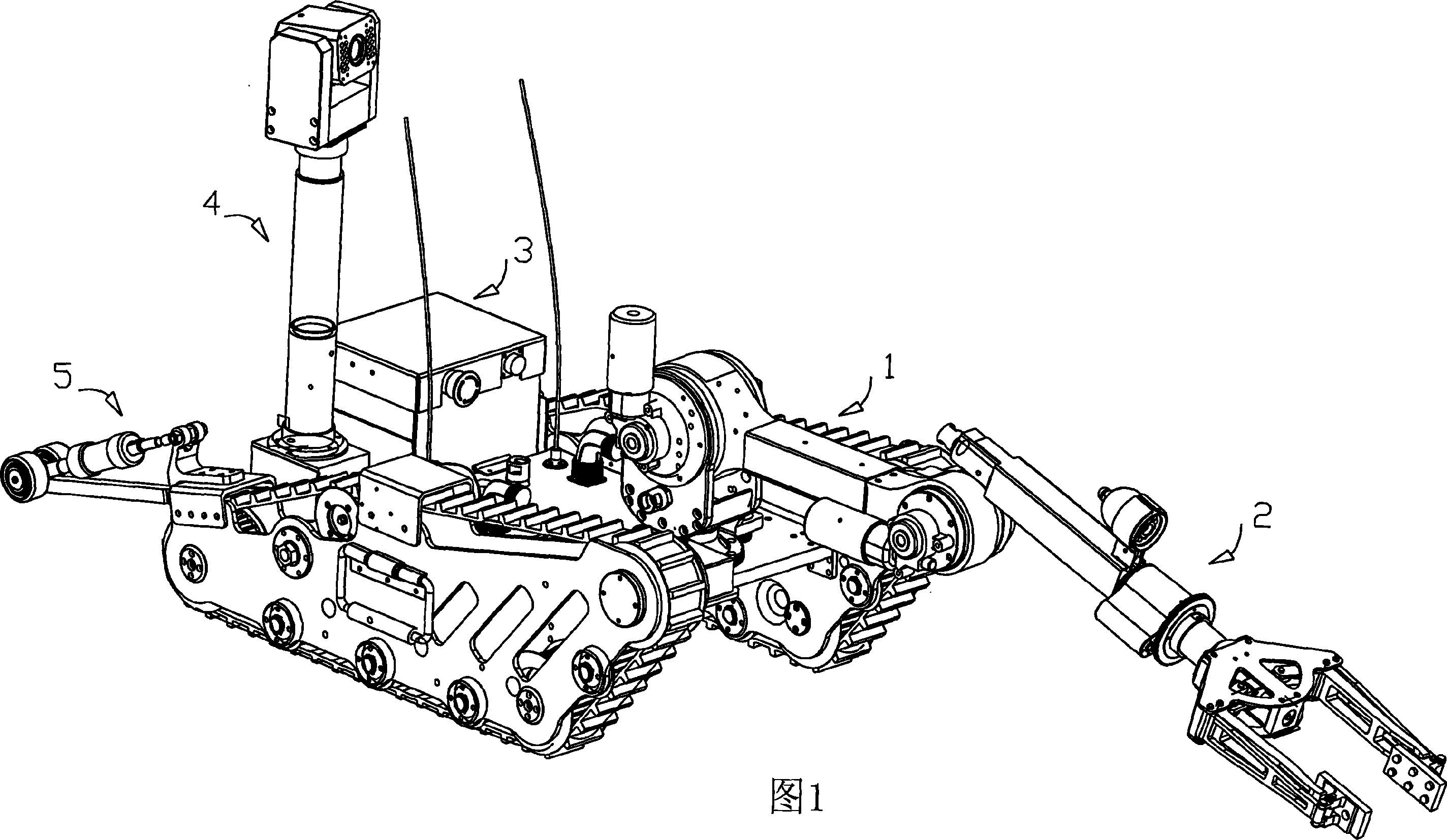

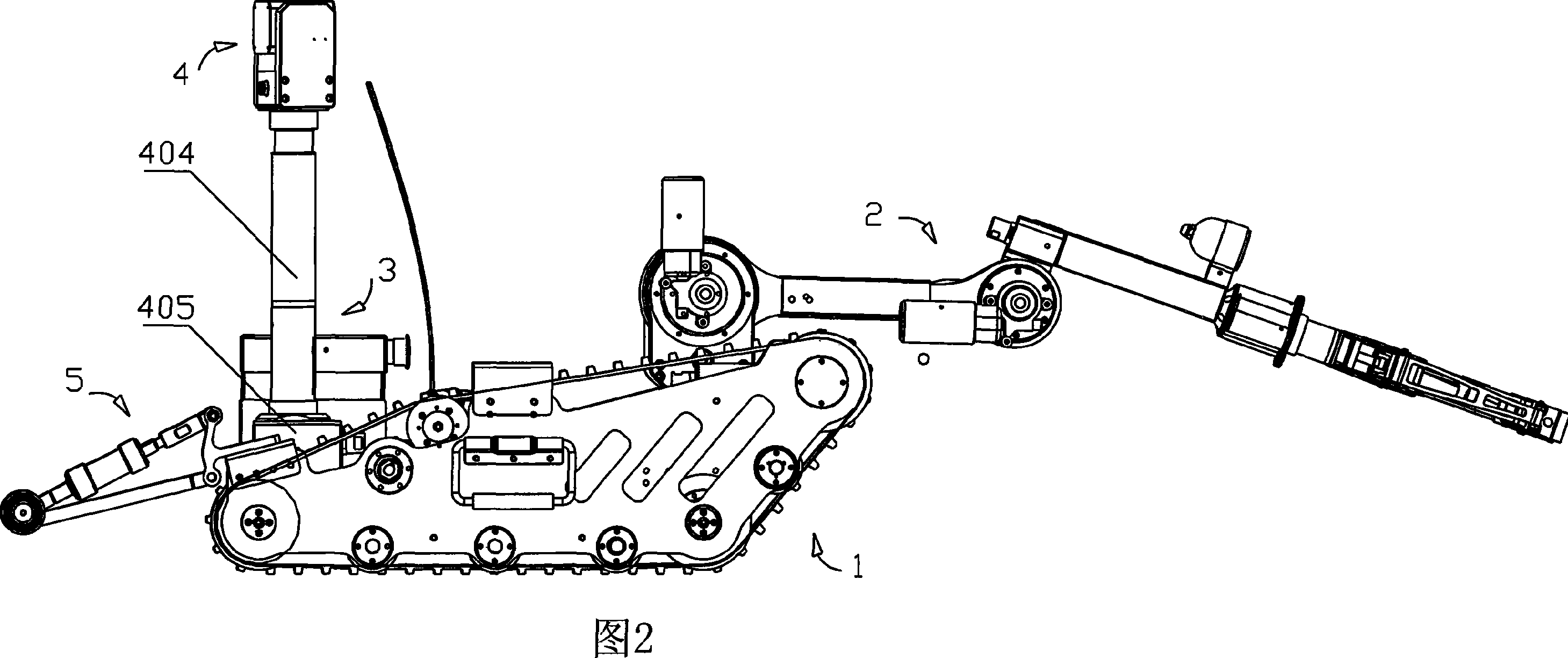

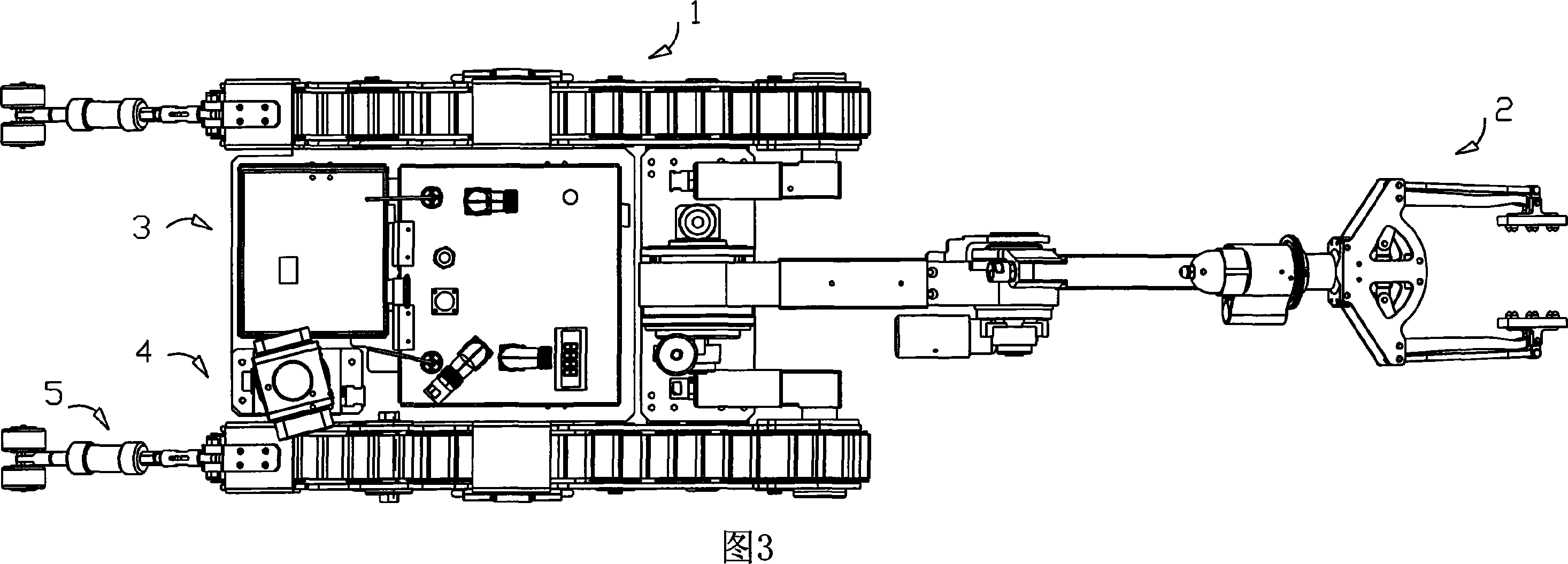

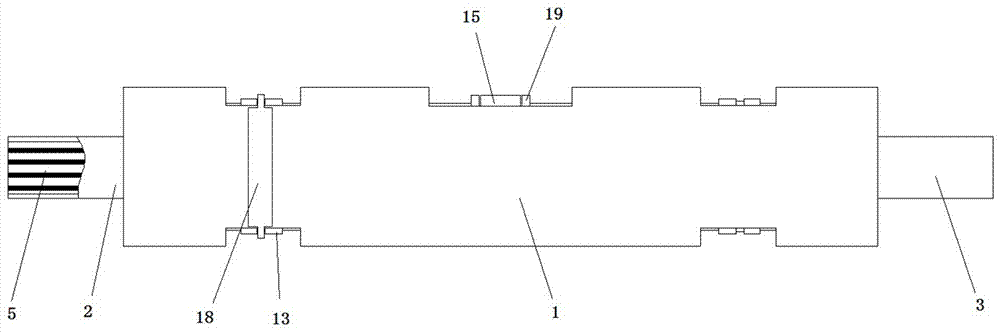

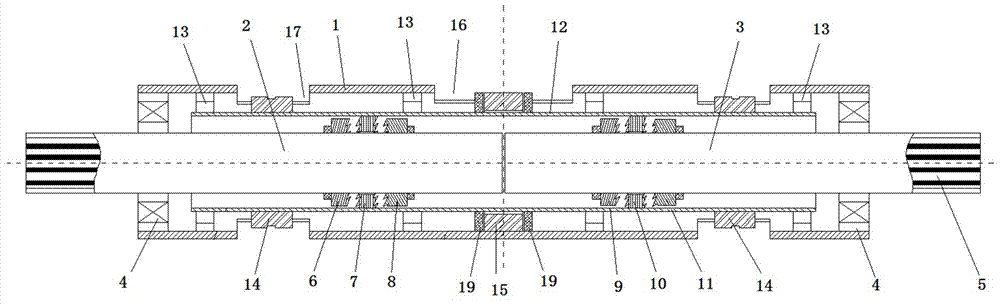

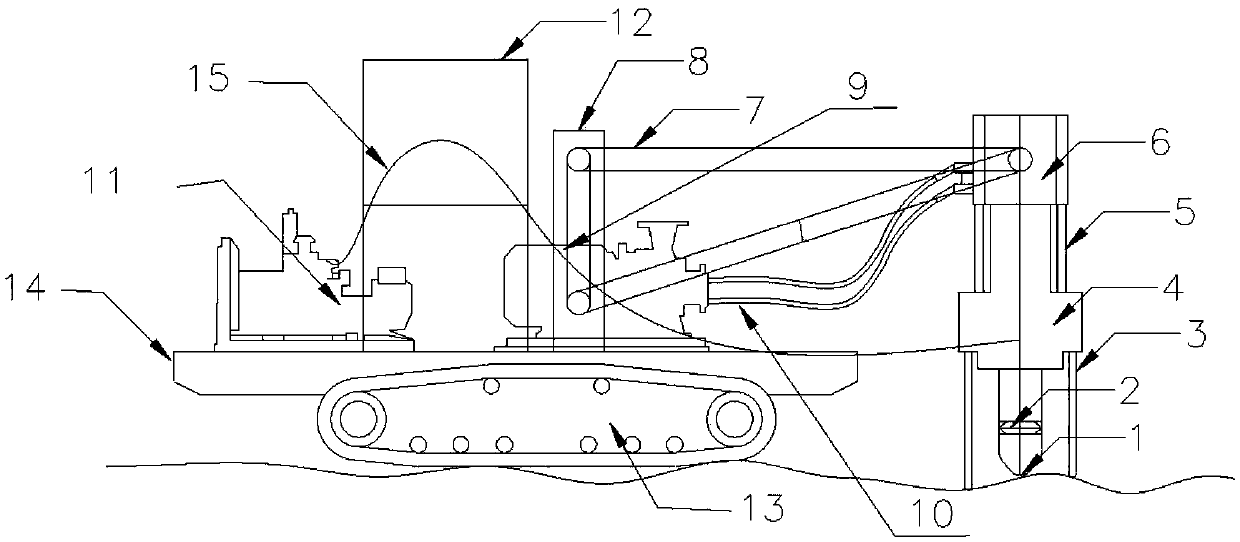

Robot for eliminating exploding and danger

The present invention relates to one kind of small explosive eliminating and hazardous article eliminating robot, which includes one running part, one manipulator part, one body part, one cradle part and one control part. The equipment compartment and battery compartment of the body part and the cradle part are set on the back chassis, the running part including one right part and one left part is connected symmetrically on two sides of the front chassis and the back chassis in the body part and has two tail supports, and the manipulator part set on the front chassis of the body part has multiple freedoms for sufficient grasping capacity and high capacity of passing through narrow space. The small explosive eliminating and hazardous article eliminating robot has functions similar to that of large robot, great topographic adaptability and high obstacle surmounting capacity, and may be applied directly for eliminating explosive and hazardous article.

Owner:BEIJING UNIVERSAL PIONEERING TECH

RE-containing prealloy powder

ActiveCN1986116AGood composition uniformitySufficient sintering reactivityRare-earth elementScanning electron microscope

The present invention relates to a kind of pre-alloyed powder and its application in making diamond tool. The pre-alloyed powder consists of at least two selected from Fe, Co, Cu and Ni as basic components, one or several of Mn, Ti, Sn, Mo, W and WC, and one or two of RE, such as La and Ce. It contains at most 80 % of Fe, at most 40 % of Co, at most 80 % of Cu, at most 40 % of Ni, at most 8 % of M and 0-5 % of RE, where, M is one or several of Mn, Ti, Sn, Mo, W and WC and RE is La and / or Ce. The pre-alloyed powder has also inevitable impurity. Scanning electronic microscope measurement shows that the pre-alloyed powder has basic particle size smaller than 15 micron and oxygen content not more than 2 %. The pre-alloyed powder is used as adhesive in making diamond tool.

Owner:GRIPM ADVANCED MATERIALS CO LTD

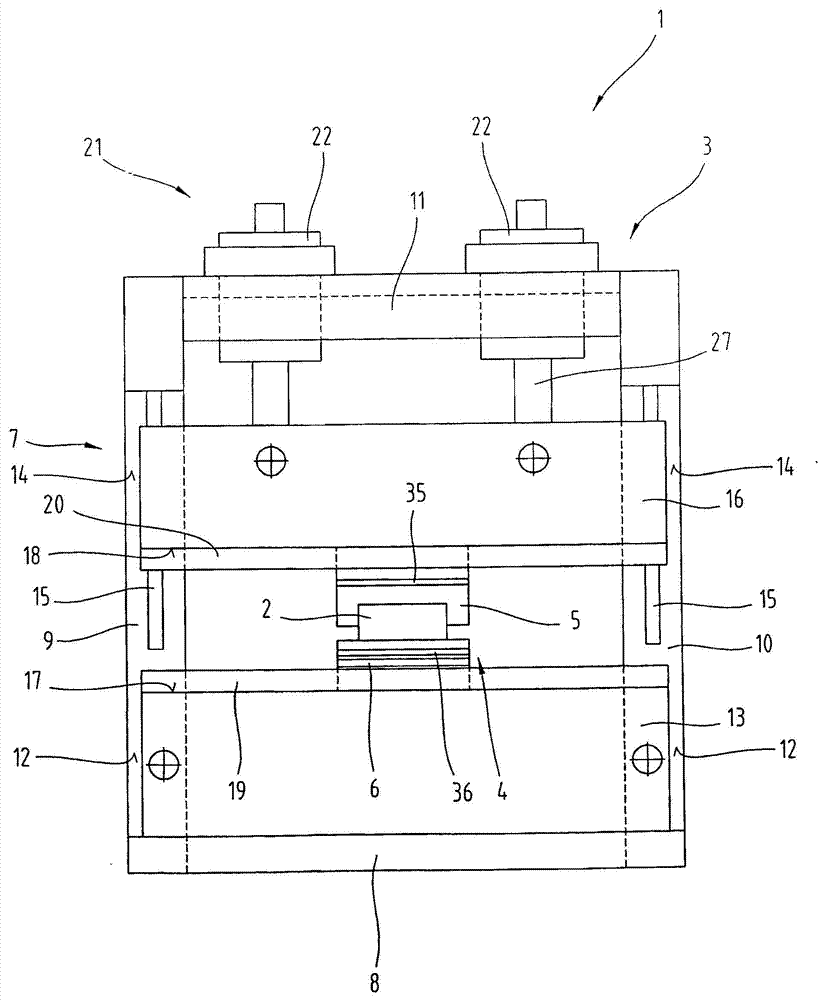

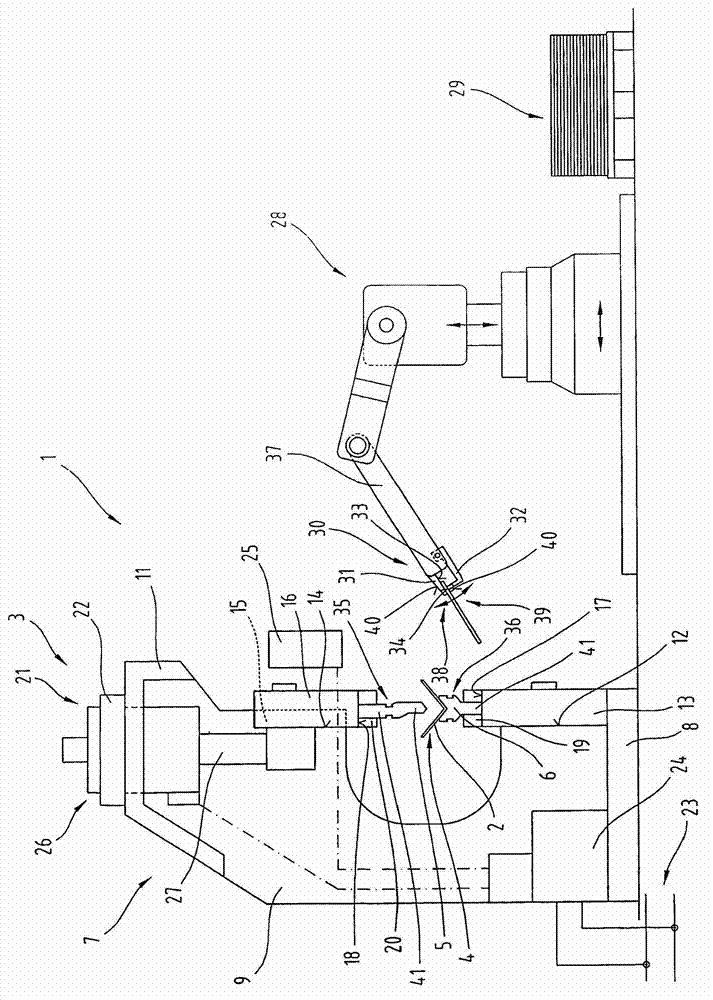

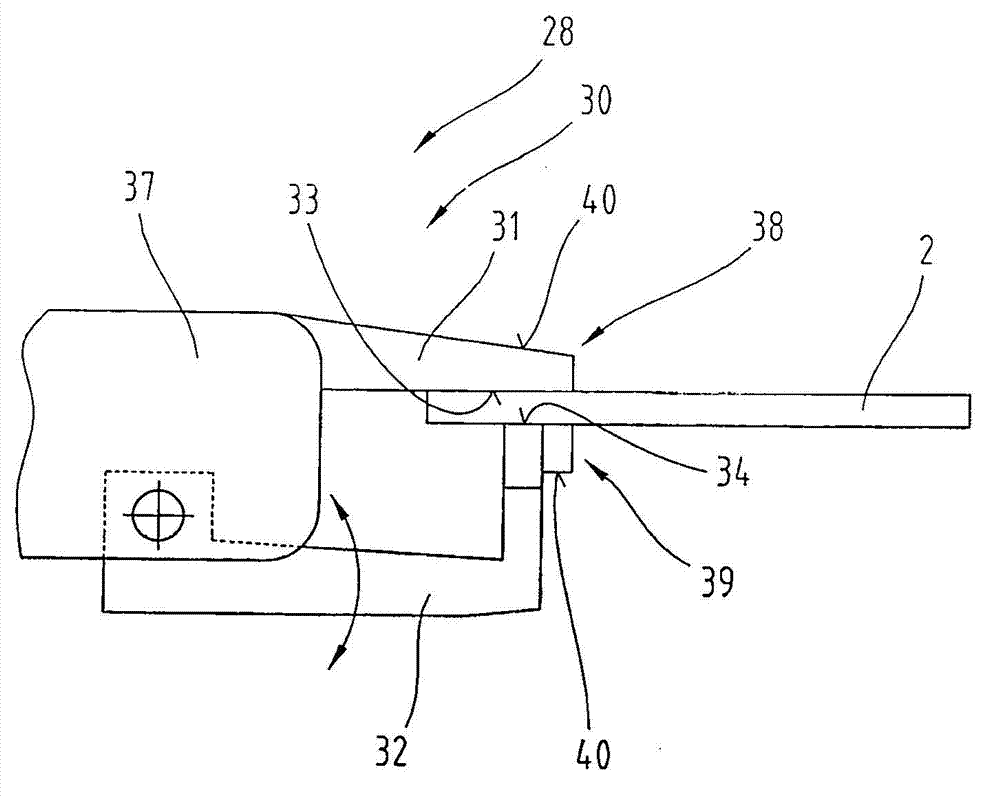

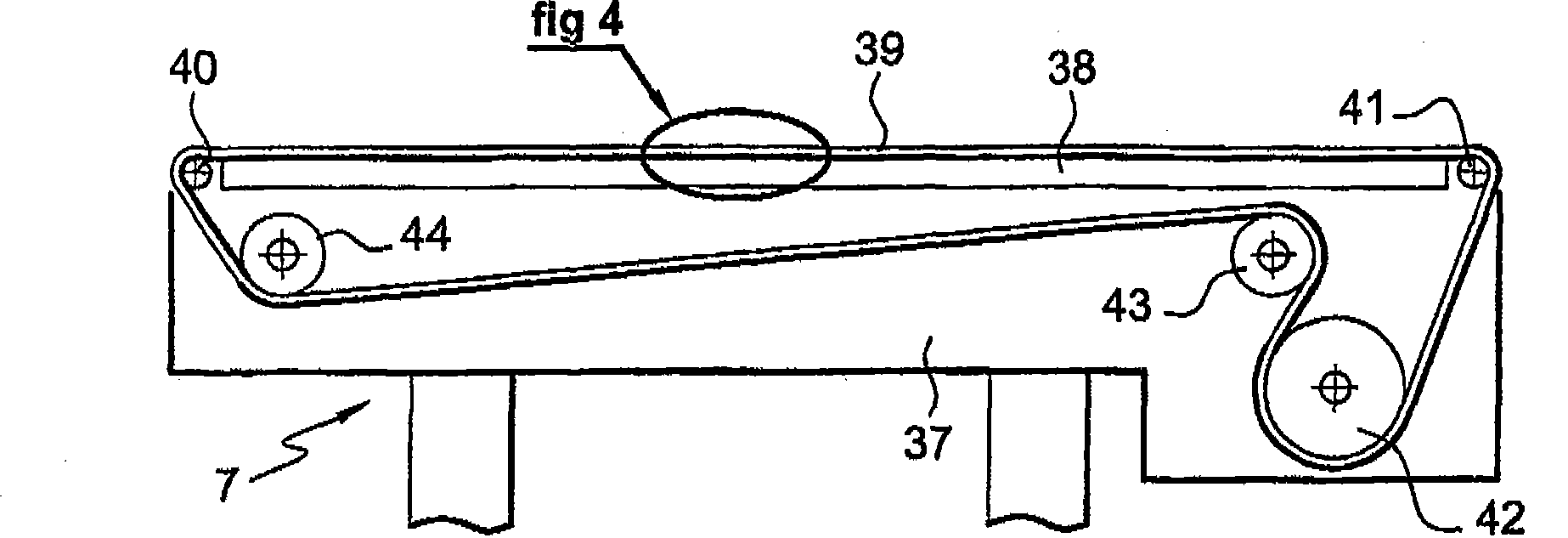

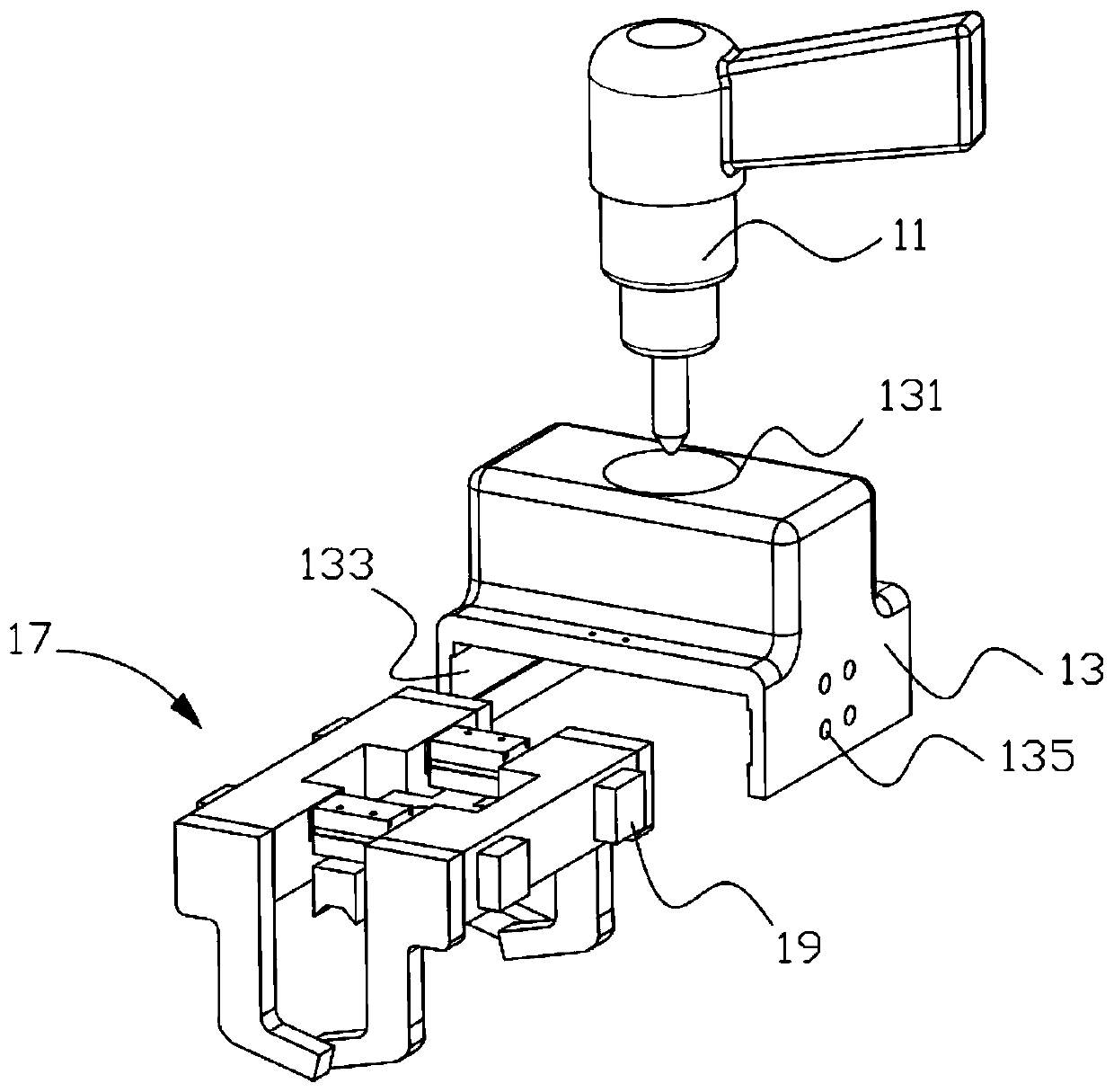

Production system, in particular for free-form bending, having integrated workpiece and tool manipulator

ActiveCN102712022AAchieve holdEnough gripShaping toolsMetal-working feeding devicesFree formEngineering

The invention relates to a production system (1) for free-form bending. The production system comprises a bending press (3) having bending tools (4), which are interchangeably retained in tool holders (19, 20), a manipulator (28) having gripping tongs (30), which have gripping fingers (31, 32) and a recess (35, 36) that is arranged in the bending tool (4) and that has stop areas (49, 50) spaced apart from each other for manipulating the bending tool (4). At the ends (38, 39) of the gripping fingers (31, 32), additional contact surfaces (40) are formed on sides of the gripping fingers (31, 32) facing away from each other. The ends (38, 39) of the gripping fingers (31, 32) are inserted into the recess (35, 36) in order to retain the bending tool (4). The contact surfaces (40) are pressed against the stop areas (49, 50) in the direction opposite from the clamping force for retaining the workpiece (2) to be produced.

Owner:TRUMPF MASCHEN AUSTRIA

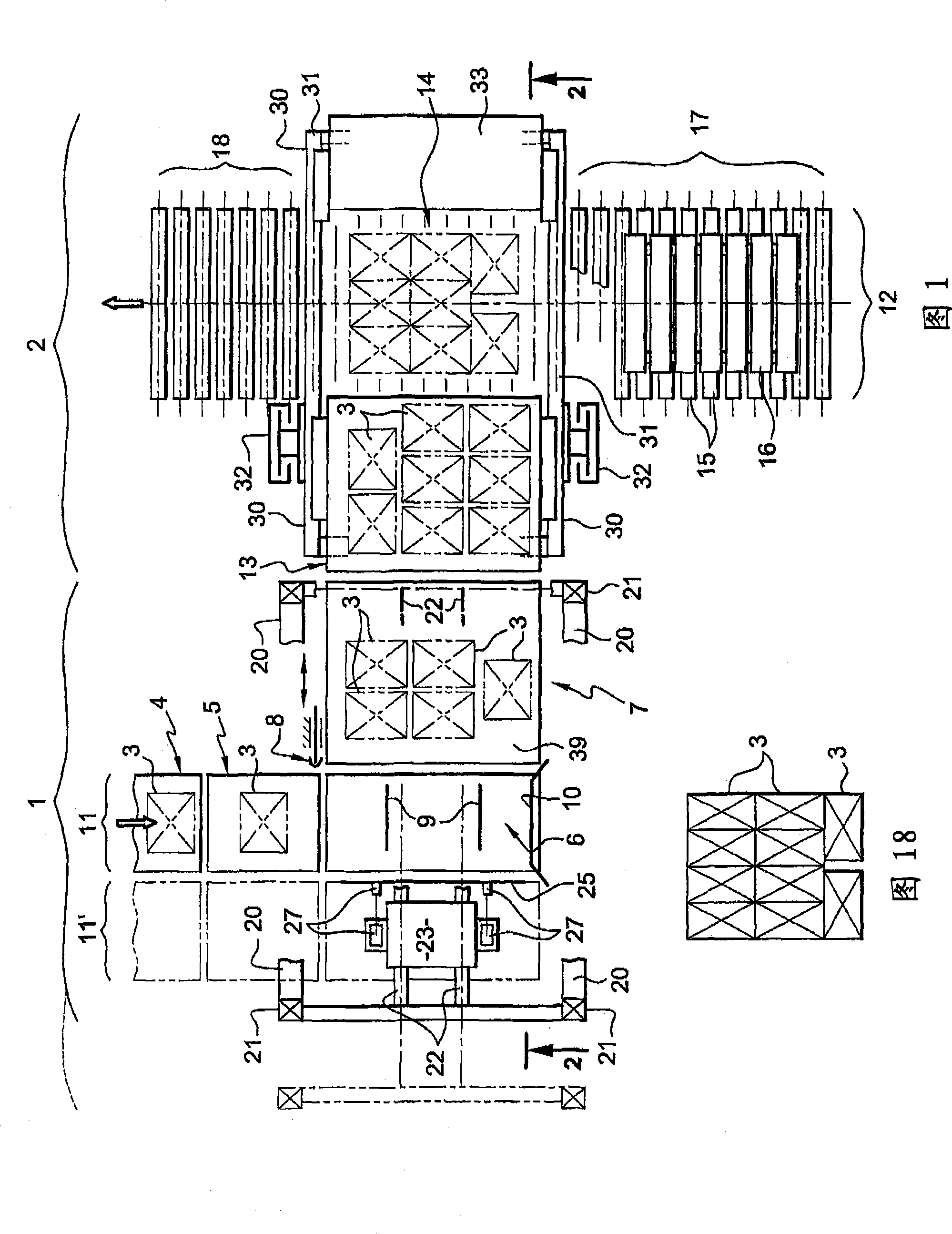

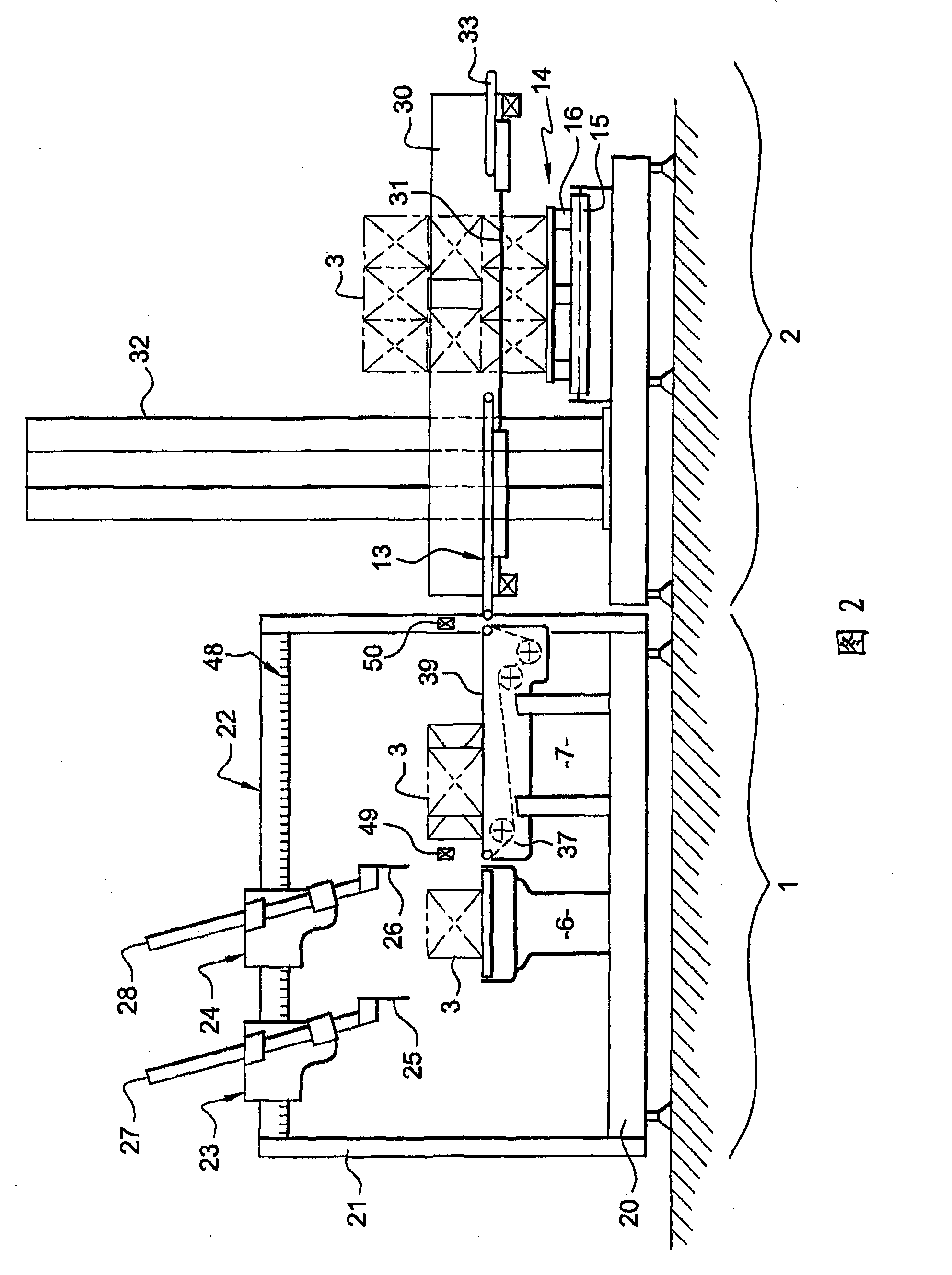

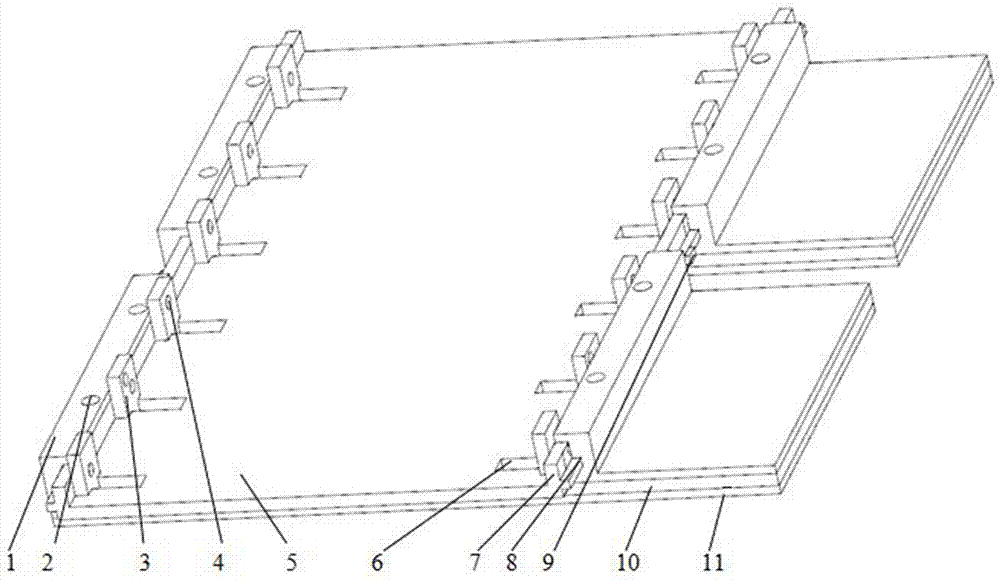

Method and installation for assembling palletizable products

InactiveCN101384488AIncreased palletization speedImprove stabilityPackagingStacking articlesModularityWaste management

The invention concerns a method which consists in cyclically: transferring a first row of products (3) between the station for preparing said products (6) and the pre-assembly station (7), at a speed V; transferring similarly a second row of products (3) onto said pre-assembly table (7), and in order to manage the docking of said second row with the row of products already set on said pre-assembly table (7), moving said set row at a speed v selected between zero and V, depending on the type or products (3); transferring, as the case may be, another row of products (3) onto the table (7), and, when the number of rows is reached to obtain said layer, transferring said layer onto the setting table (13) of the palletizing station (14). The installation comprises transfer means consisting of pushers (25) and (26) mobile between different stations, driven at suitable speeds. The invention also concerns, at the pre-assembly station (7), a modular endless belt which is supported and moves on a slider bed, said belt being mobile, driven at a speed which is related to that of the pushers (25) and (26).

Owner:SIDEL PARTICIPATIONS SAS

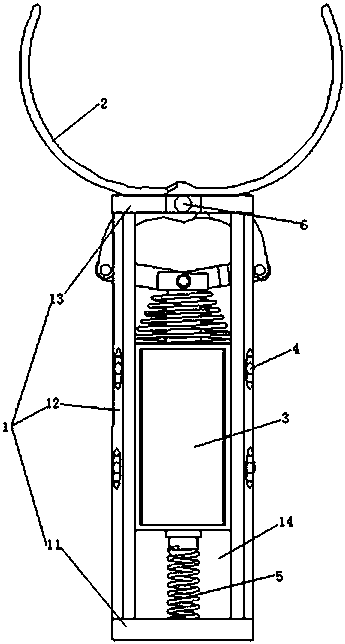

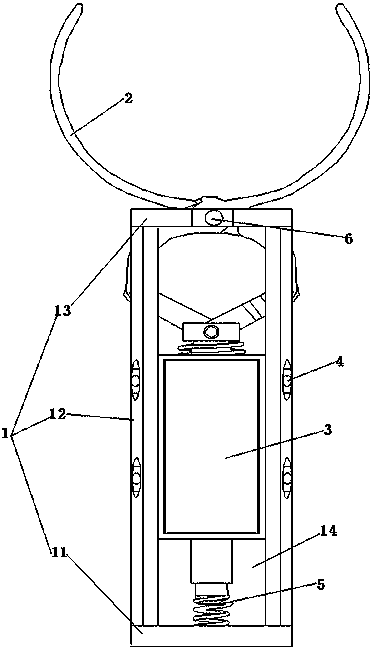

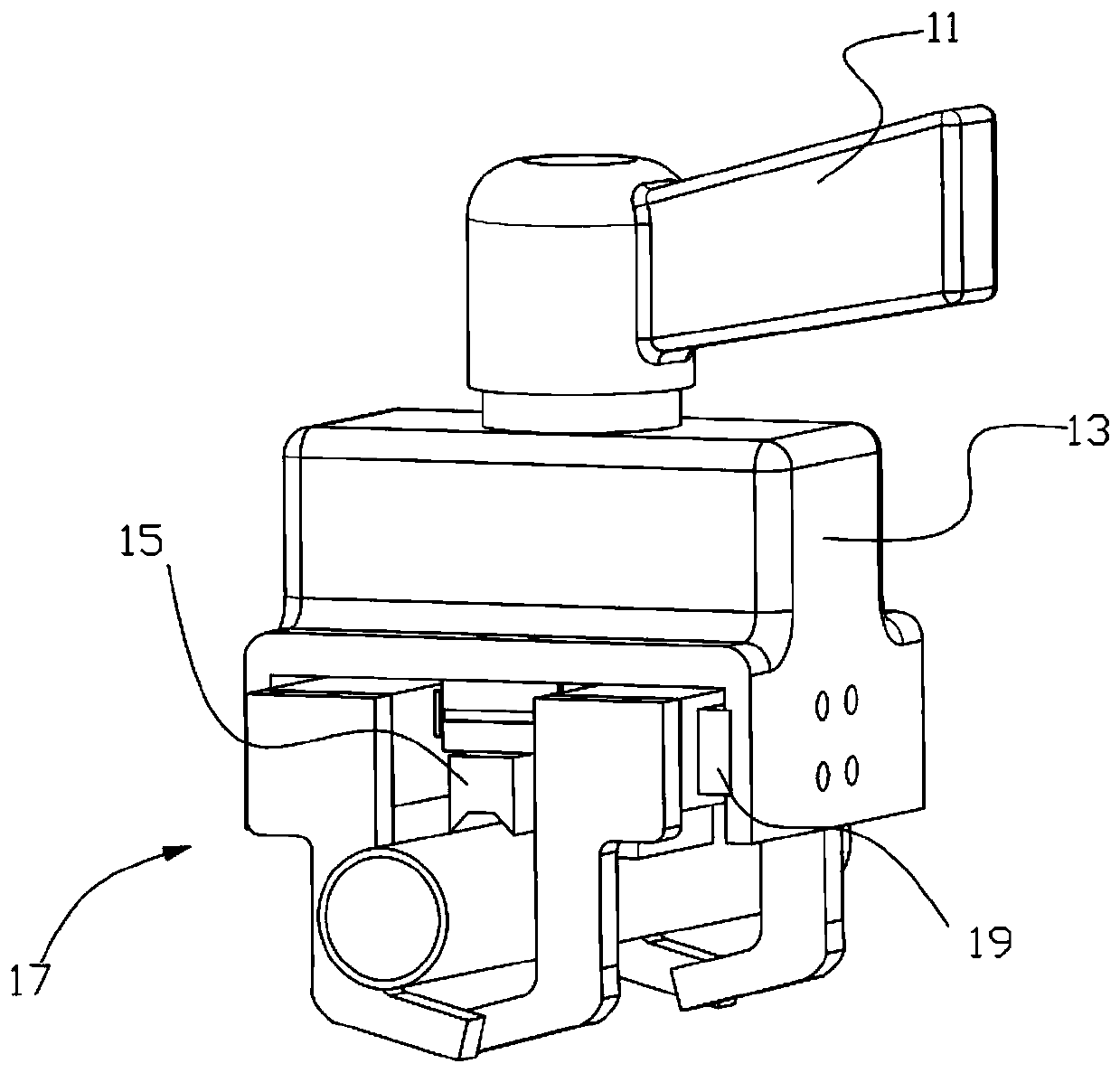

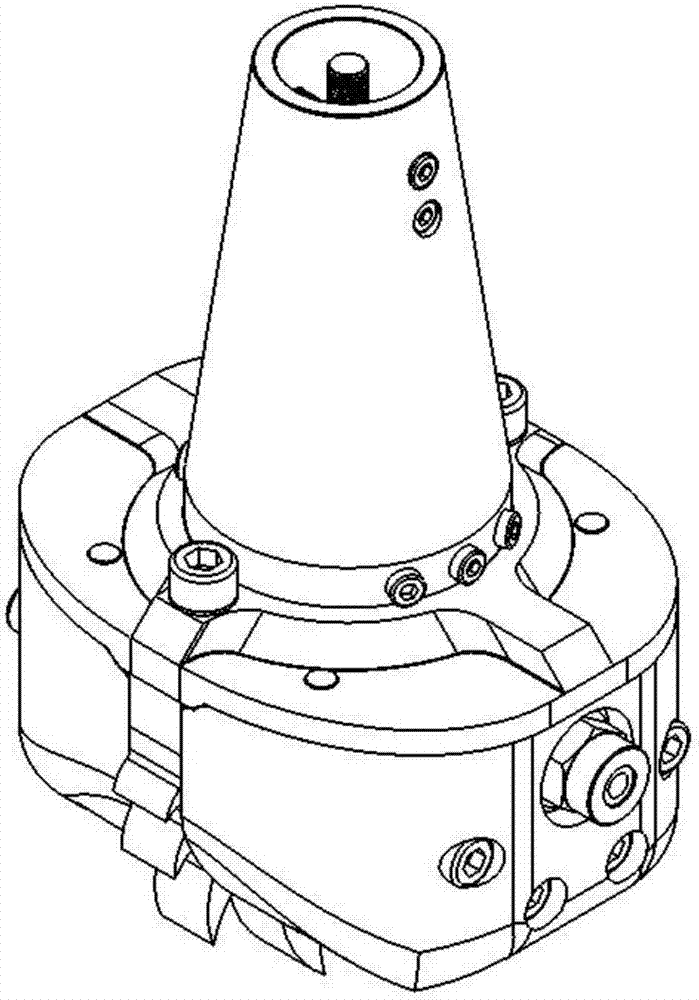

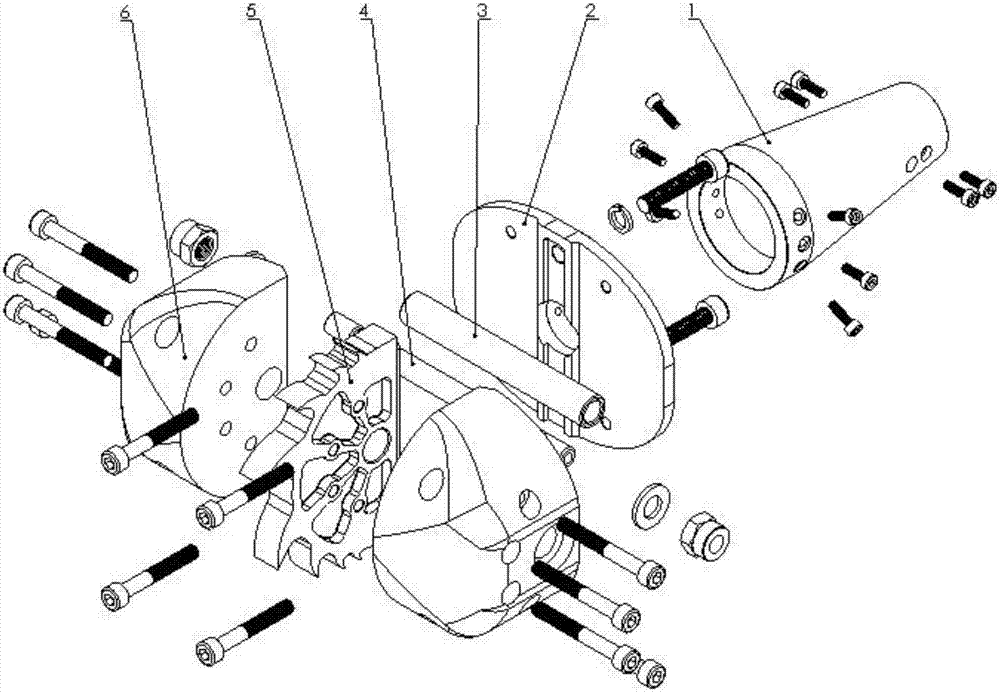

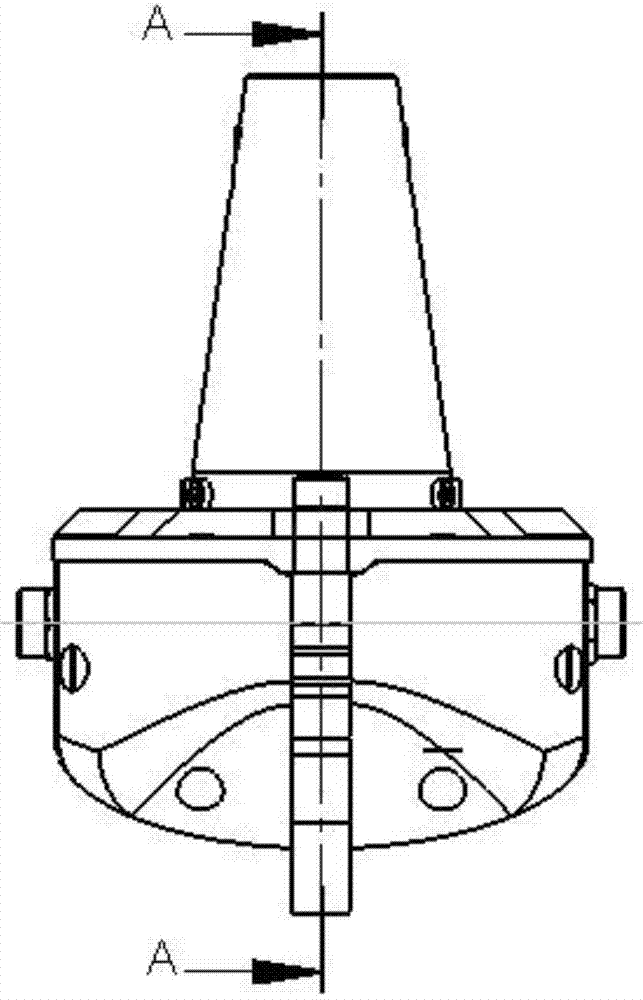

Automatic mechanical clamping jaw and robot

The invention discloses an automatic mechanical clamping jaw. The automatic mechanical clamping jaw comprises a support assembly, a driving assembly and a displacement adjusting assembly, wherein thesupport assembly is provided with a positioning cavity; the clamping jaw assembly is hinged to the upper end of the support assembly; the driving assembly is disposed in the positioning cavity, connected with the clamping jaw assembly and used for driving the clamping jaw assembly to close or open so as to tightly clamp or release objects; the driving assembly can move up and down relative to thesupport assembly so as to adjust the opening range of the clamping jaw assembly; and the displacement adjusting assembly is disposed on the support assembly and used for locking and fixing the drivingassembly so as to limit up-and-down movement of the driving assembly. The automatic mechanical clamping jaw provided by the invention is wide in application occasion, simple in structure, high in controllability and automatic degree. A robot with the automatic mechanical clamping jaw is further provided.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

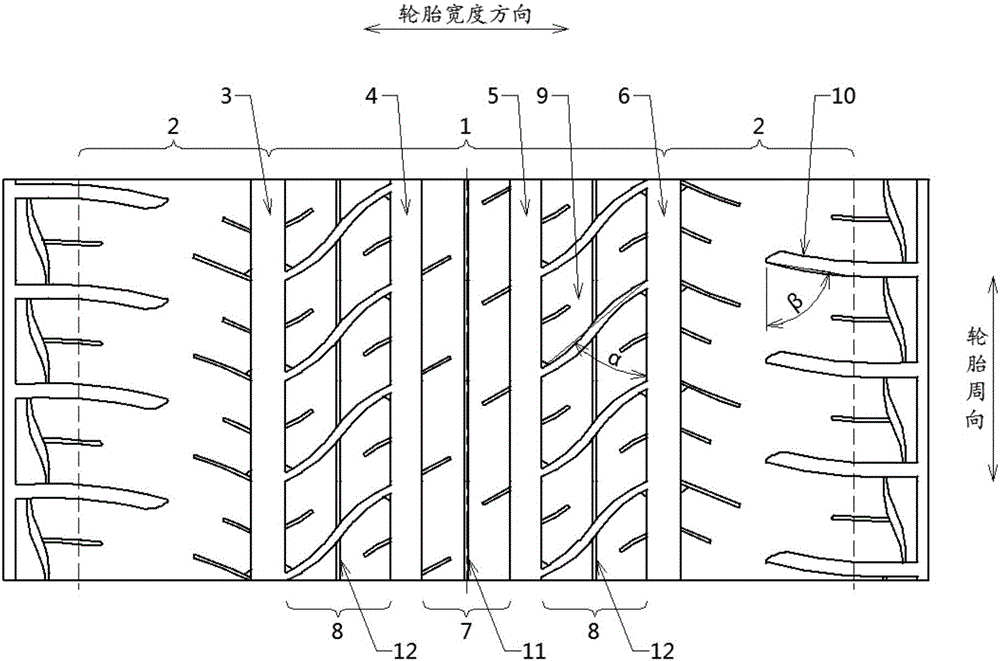

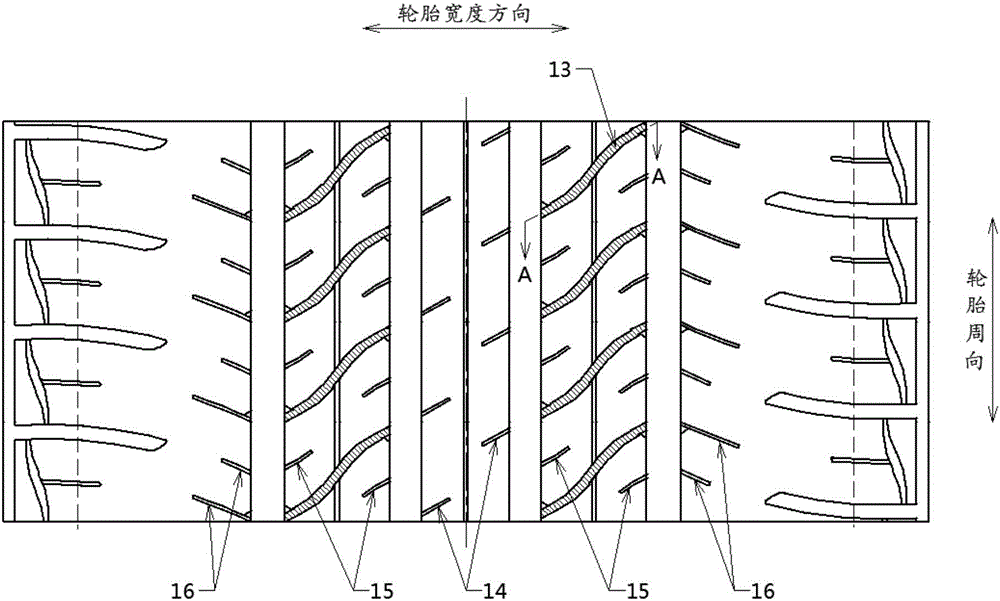

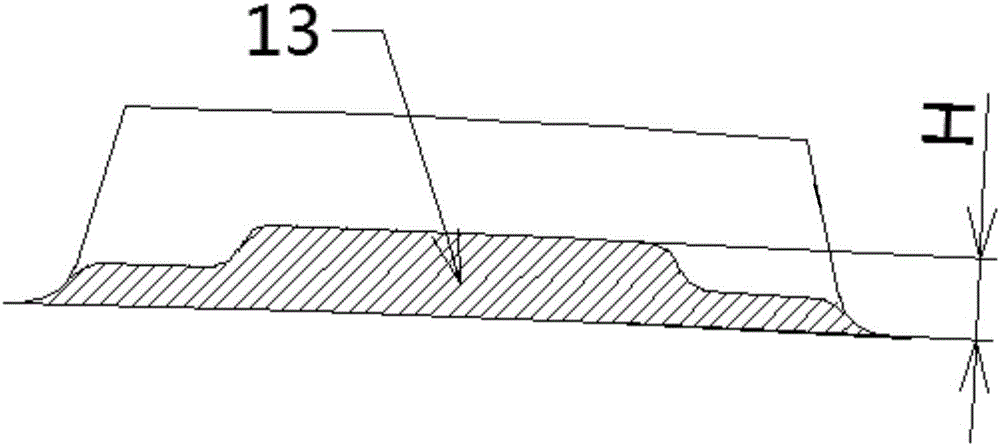

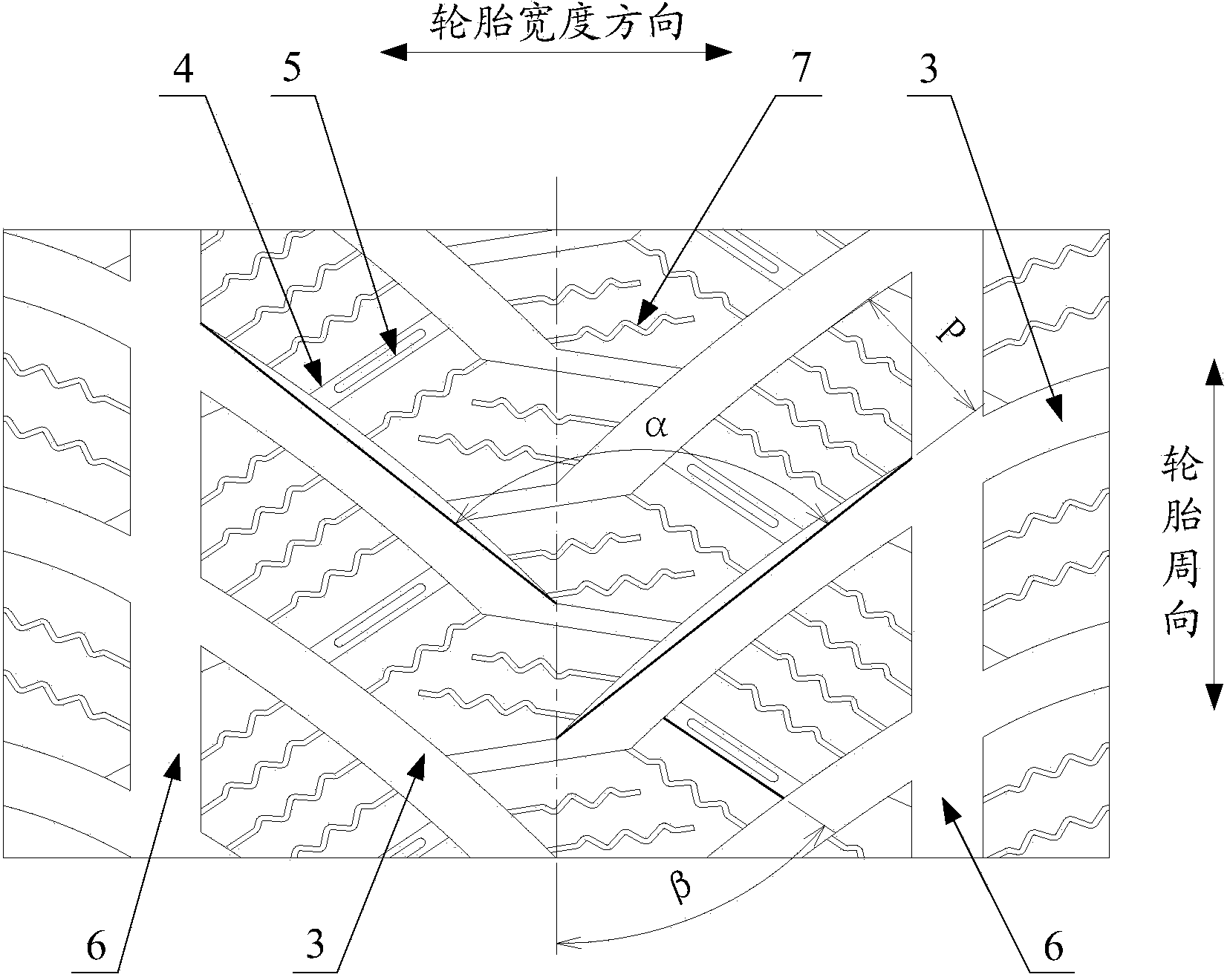

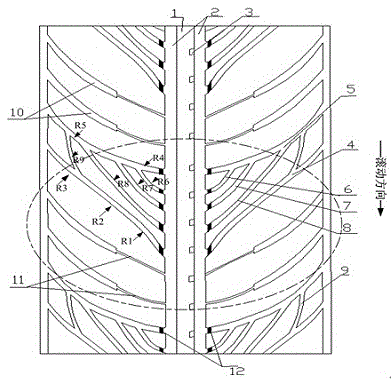

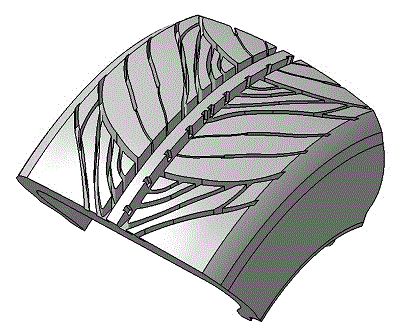

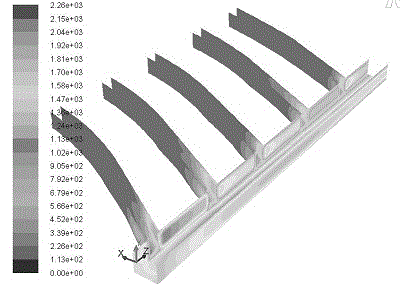

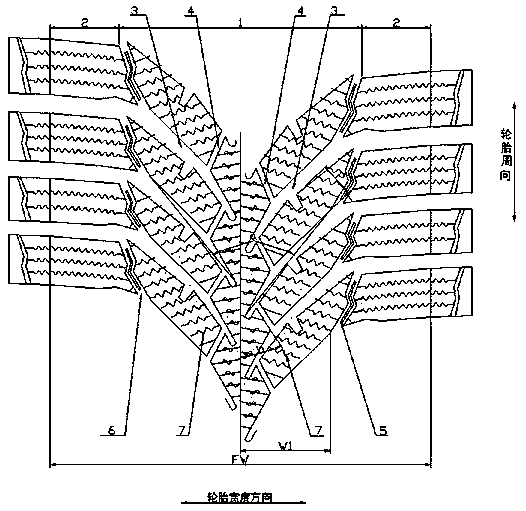

Pneumatic tire

ActiveCN106314039AEnough gripEnsure handling stabilityRoad vehicle tyresTyre tread bands/patternsMechanical engineeringRoad surface

The invention discloses a pneumatic tire. Main grooves in head and tail communication continuously extend in the circumferential direction of the pneumatic tire, so that rainwater can be discharged out in time; the water floating effect is lowered, so that the pneumatic tire maintains enough road holding force in real time; the operation stability is ensured. In addition, a plurality of transverse pattern blocks are bent to form an S shape; the S shape extends along the width direction of the tread of the pneumatic tire; a rubber connecting block is arranged in a gap between every two transverse pattern blocks, so that the deformation quantity of the pattern blocks is stable when the pneumatic tire rolls; the pneumatic tire can maintain good comfort and can effectively lower the noise, so that the deformation quantity of the pattern blocks is stable when the pneumatic tire rolls. Therefore the inflating tire achieves the effects that under the condition of maintaining the self operation and control stability on the dry pavement and the wet pavement, the comfort performance can be improved in a balanced way, and the noise is lowered.

Owner:CHENG SHIN RUBBER CHINA

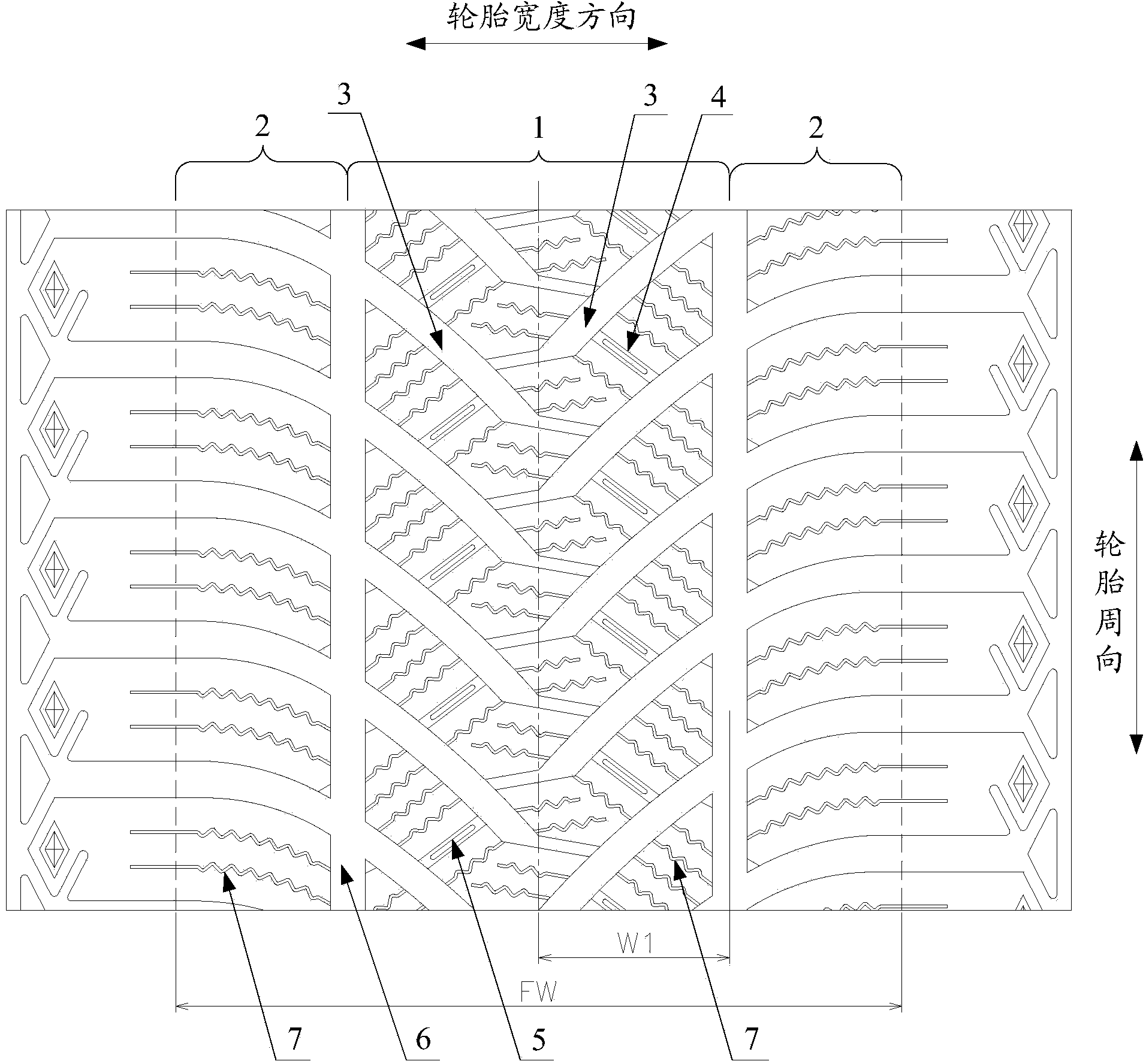

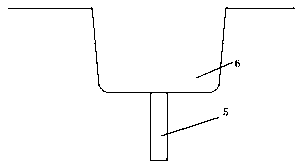

Pneumatic tyre

The invention provides a pneumatic tyre. The pneumatic tyre comprises a tread part and tyre shoulder parts positioned on the two sides of the tread part, wherein a V-shaped groove is formed in the tread part; two troughs of the V-shaped groove extend to different tyre shoulder parts and extend out of the tyre shoulder parts in the width direction of the pneumatic tyre. The pneumatic tyre has the advantages that as traditional sipes or cut grooves are replaced with the V-shaped groove formed in the pneumatic tyre, the pneumatic tyre has better brake performance on ice snow covered pavements, and the control stability of the pneumatic tyre can not be affected.

Owner:CHENG SHIN RUBBER CHINA

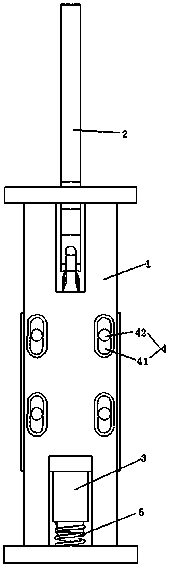

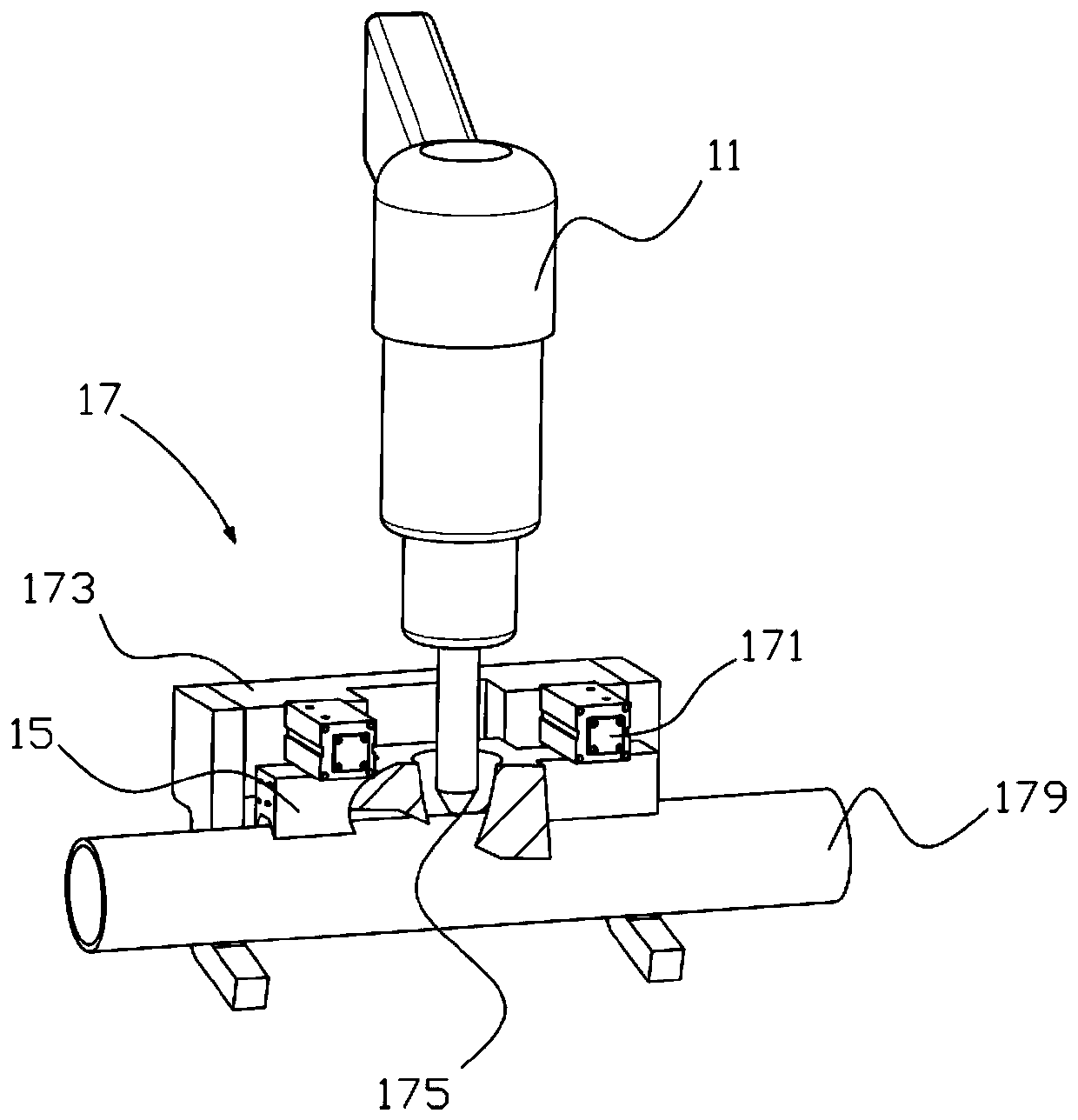

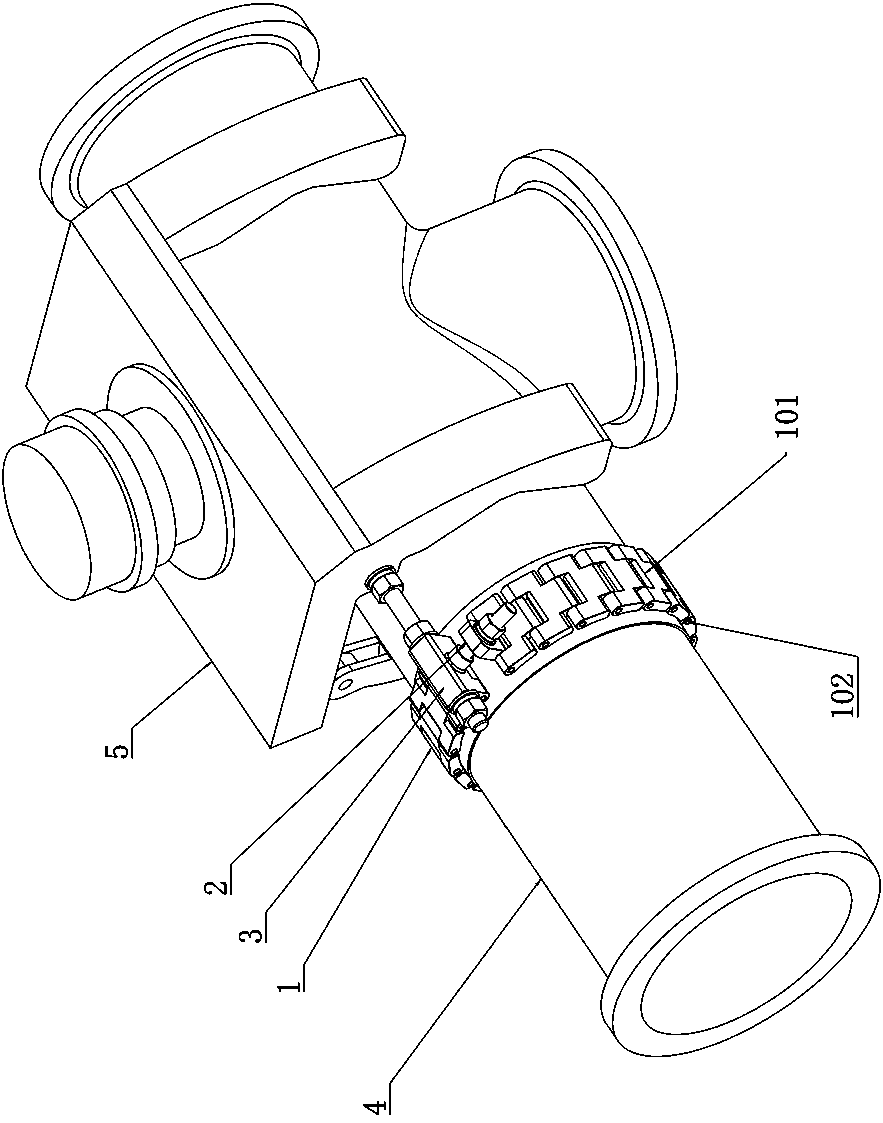

Mechanical arm end effector for leak stopping with pressure

ActiveCN109798415AHigh precisionMeet leak plugging requirementsGripping headsPipe elementsEngineeringActuator

The embodiment of the invention discloses a mechanical arm end effector for leak stopping with pressure. The mechanical arm end effector comprises an air impact hammer, a raised block, connecting blocks, a V-shaped self-centering module, and a clamping module. The clamping module is composed of air cylinders and two clamping jaws, the air cylinders are installed between the two clamping jaws, eachof the clamping jaws consists of a depressed block and two L-shaped plates, the connecting blocks are fixedly arranged on the outer sides of the two clamping jaws, the clamping module is installed atthe two ends of the raised block through the connecting blocks, the V-shaped self-centering module is fixedly arranged under the air cylinders, the air impact hammer is fixedly arranged on the raisedpart of the upper end of the raised block and penetrates through the V-shaped self-centering module, and leak points on leaked equipment are subjected to beating and striking and leak stopping. The mechanical arm end effector is novel in structural design and convenient to operate and can be applied to the beating and striking and leak stopping of various-sized leaked pipelines, self-centering can be realized by the V-shaped self-centering module, and leak stopping accuracy is high.

Owner:HUANENG SHANTOU HAIMEN POWER GENERATION CO LTD +1

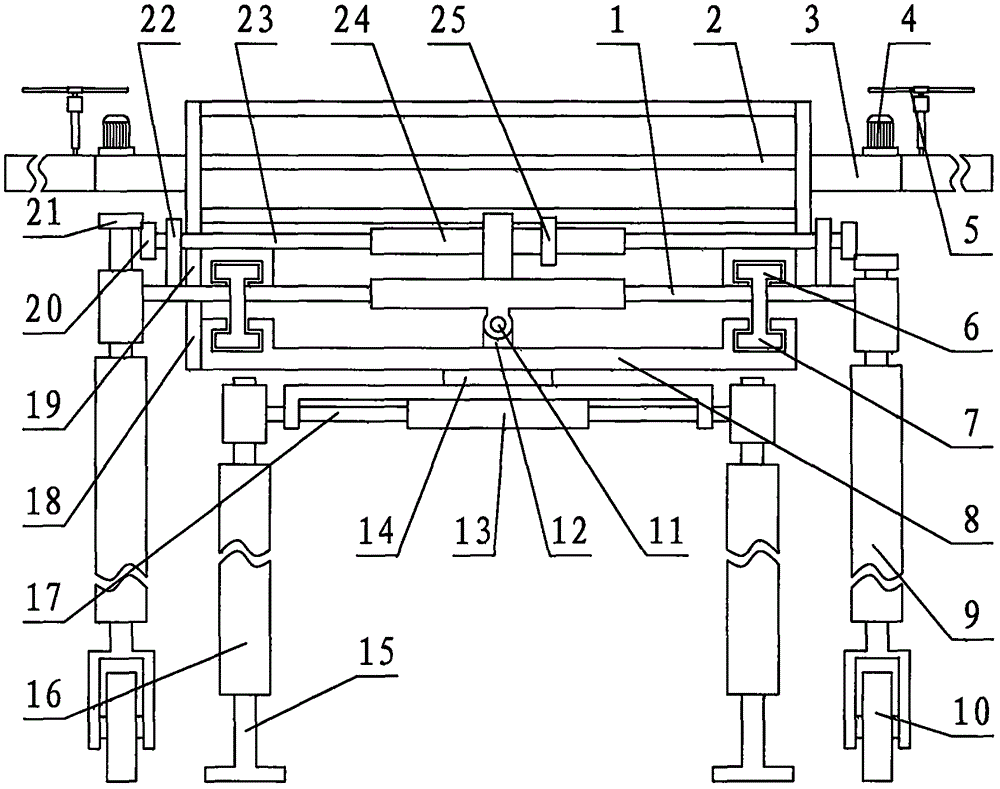

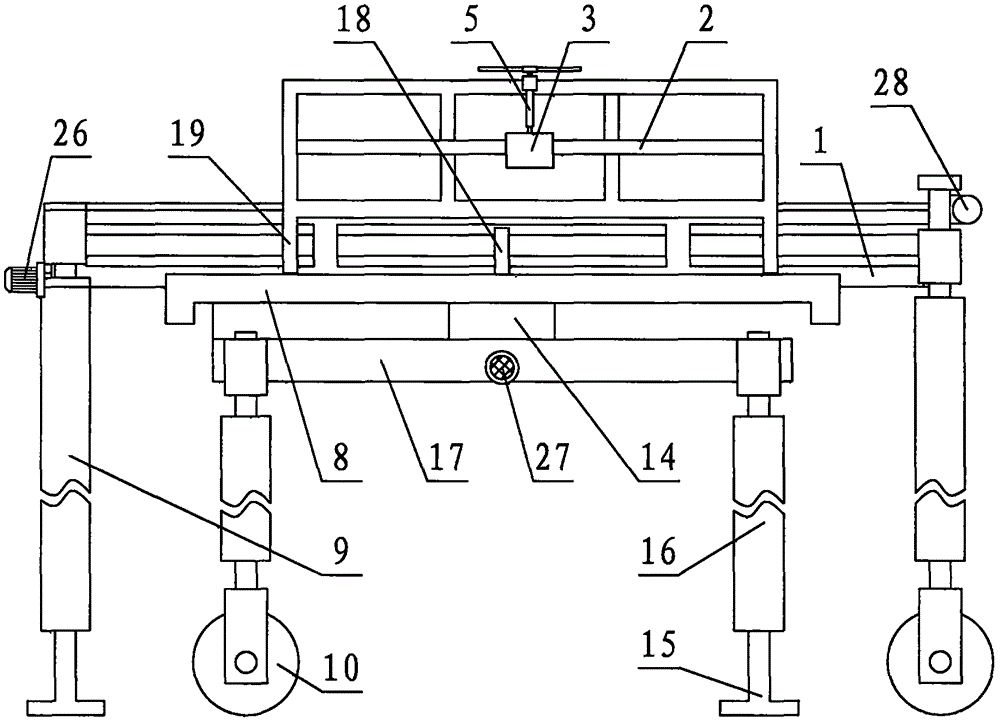

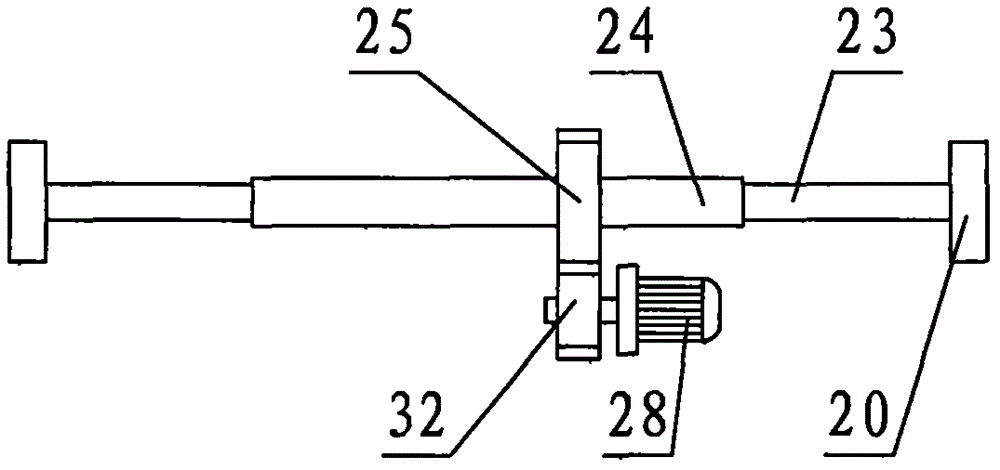

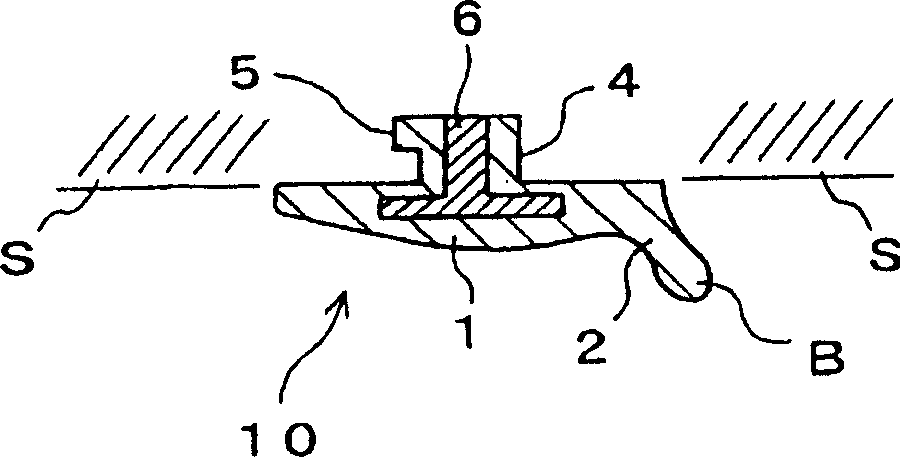

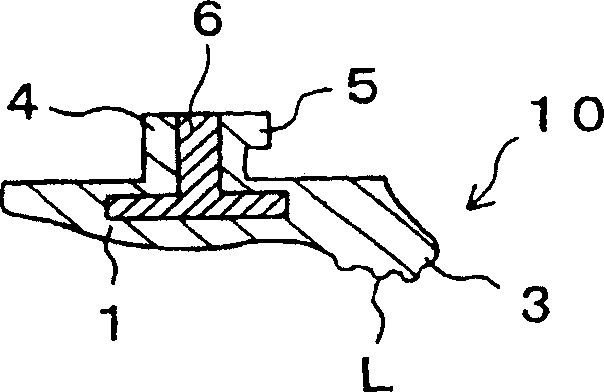

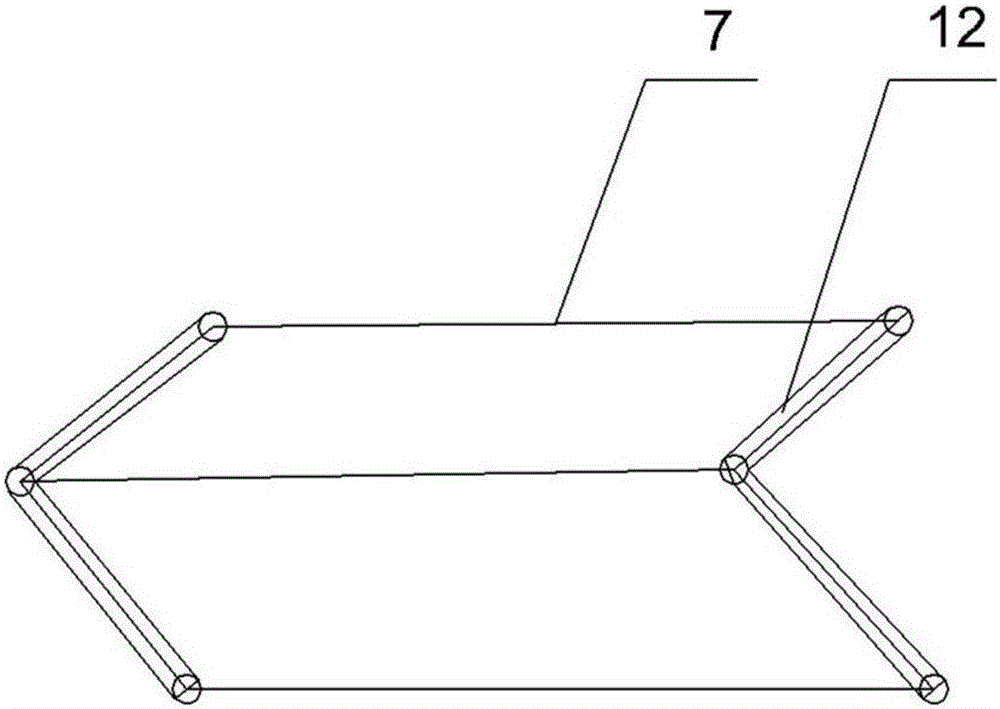

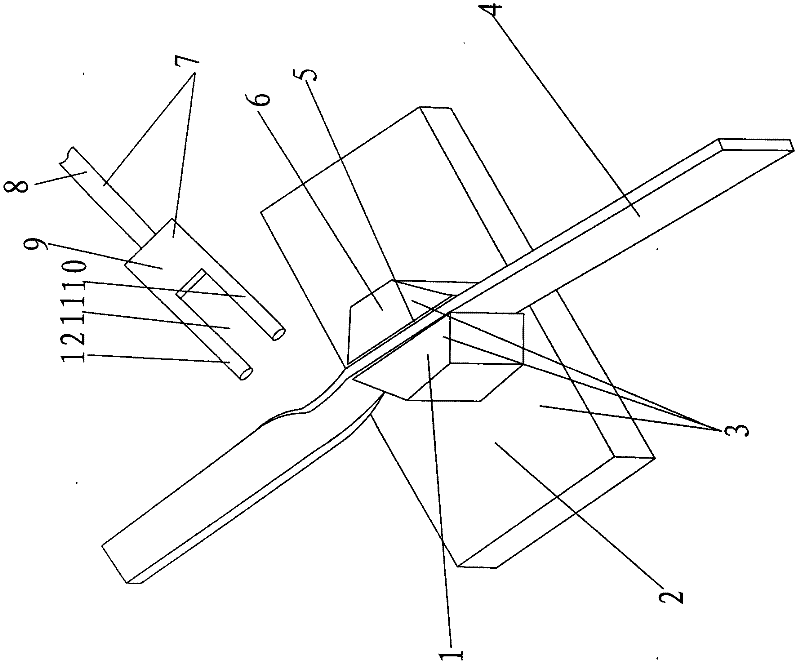

Spraying device of partially flight

InactiveCN106494524AAvoid damageEnough gripMechanical steering gearsElectrical steeringTerrainAerospace engineering

The invention relates to a spraying device of partially flight, comprising an external expansion bracket, wherein slider A slidably connecting with the lower surface of a luggage rack and slider B slidably connecting with the upper surface of a link platform are respectively arranged at the upper and lower surface. And a fixed base is provided with the center of the upper surface of the link platform which is connected with a unidirectional screw through threads. The both sides of the unidirectional screw ratably relate to the lower surface of the external expansion bracket, and the lower surface of the link platform is connected with the upper surface of an internal expansion bracket through a rotary table. Four capes of the external expansion bracket are ratably connected with retractable external putters, wherein the bottom of two forward external puttershave walking wheels connected with and the bottom of two backward external putters have support units connected with. And four capes of the internal expansion bracketare ratably connected withretractable external putters, wherein the bottom of two forward internal putters have support units connected with and the bottom of two backward internal putters have walking wheels connected with. The spraying device of partially flight has the advantages of increasing the carrying weight of the drug and powerful terrain adaptability.

Owner:JIYUAN VOCATIONAL & TECHN COLLEGE

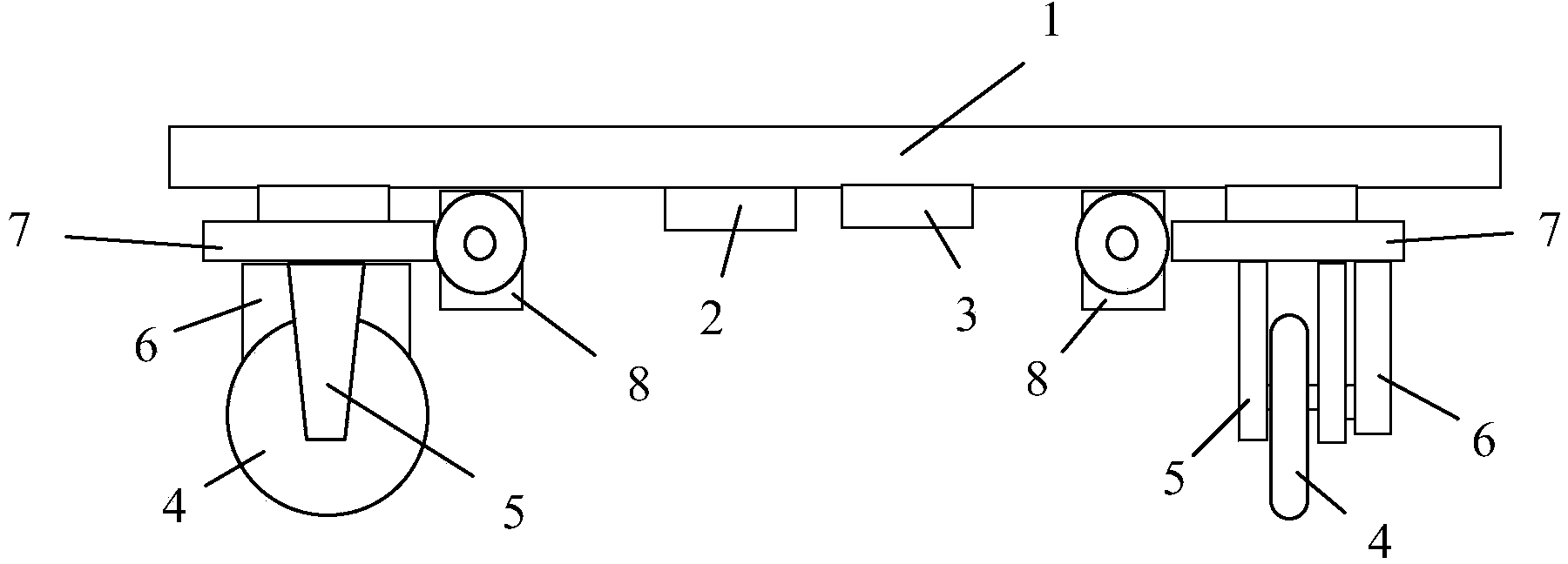

Four-wheel independent drive transfer trolley

A four-wheel independent drive transfer trolley comprises an objective table, a battery and a master controller. Four wheel type supporting devices are arranged in the bottom face of the objective table. Any one of the wheel type supporting devices comprises a wheel, a wheel suspension gear, a wheel driving mechanism, a wheel mounting base and a wheel steering driving mechanism. Each wheel suspension gear and each wheel driving mechanism are fixedly connected to the corresponding wheel mounting base, each wheel driving mechanism is connected with the corresponding wheel, and each wheel mounting base is connected with the bottom face of the objective table through a rotating shaft and a thrust bearing. Each wheel steering driving mechanism is fixed in the bottom face of the objective table, and each wheel steering driving mechanism is connected with the corresponding wheel mounting base. According to the four-wheel independent drive transfer trolley, needed turning radius limitation in the moving process is greatly reduced, the trolley is suitable for narrow areas with extremely compact space, the four wheels are respectively connected with one independent driving mechanism, when a work environment swings, enough road holding force can be generated, and stable operation can be kept.

Owner:SHANGHAI DESHENG MIGAO ELEVATOR

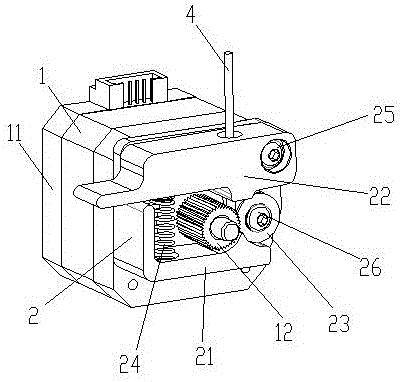

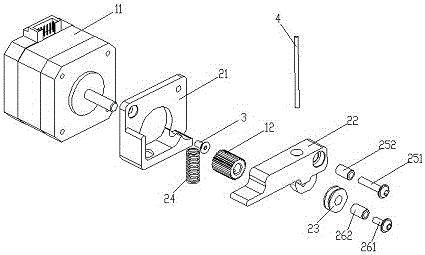

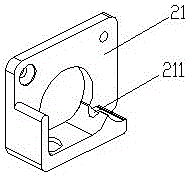

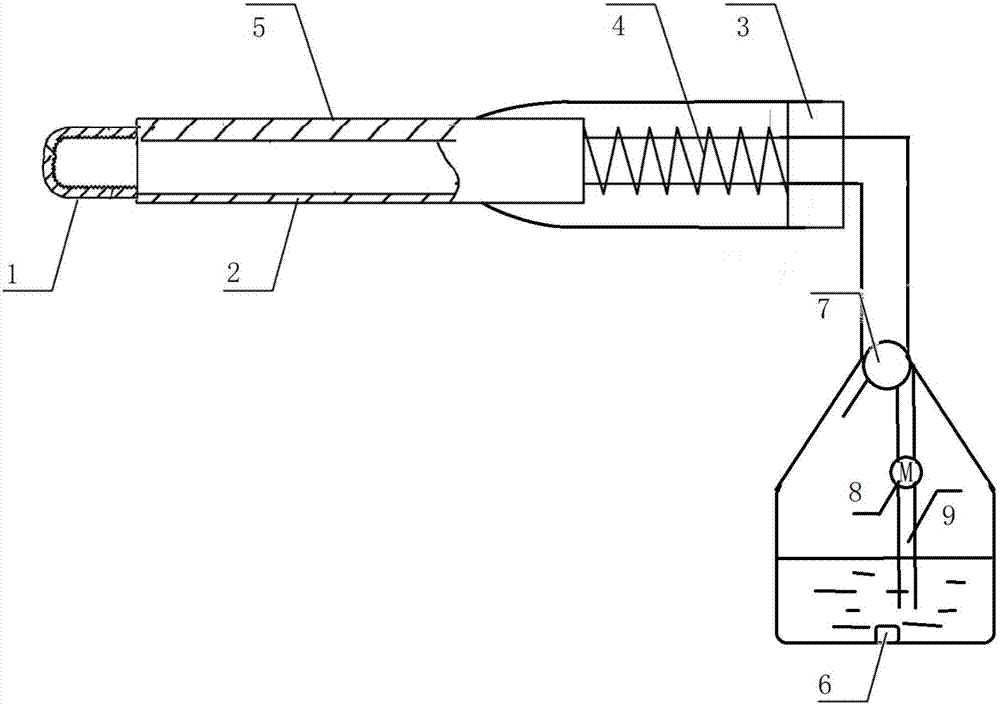

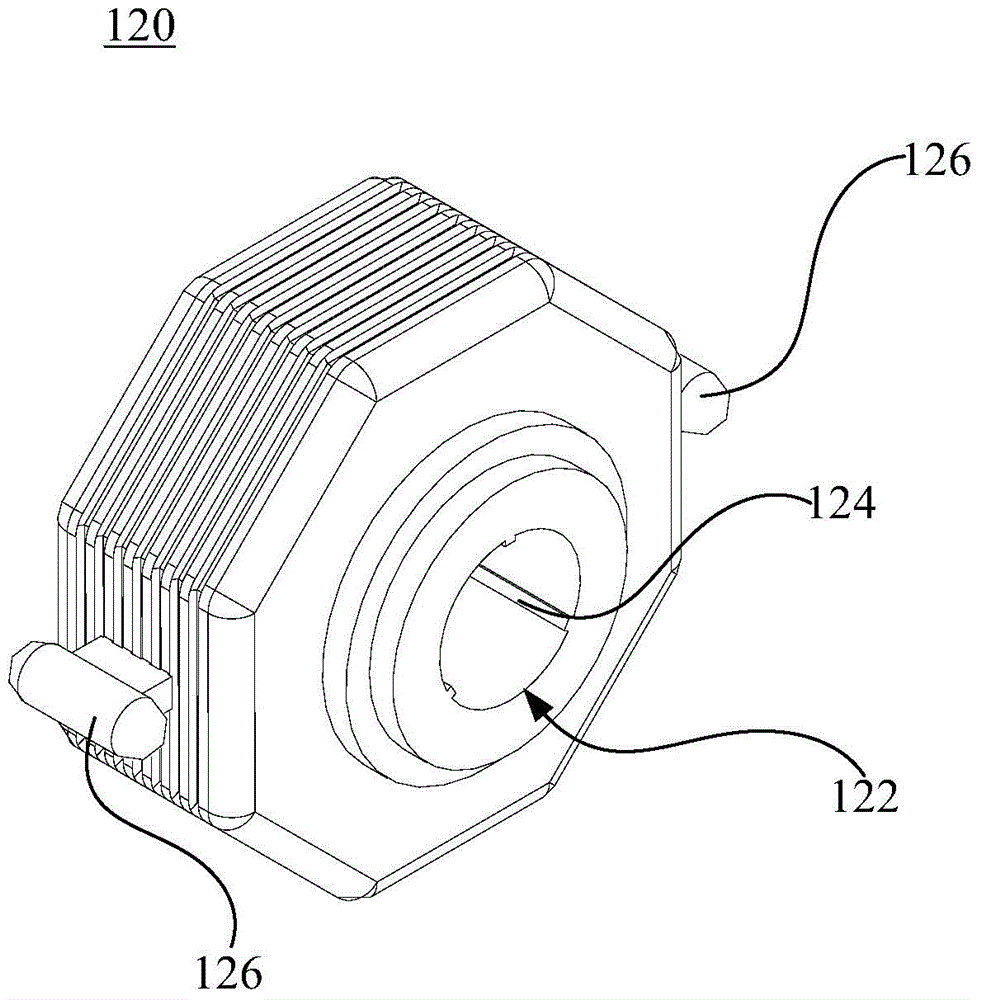

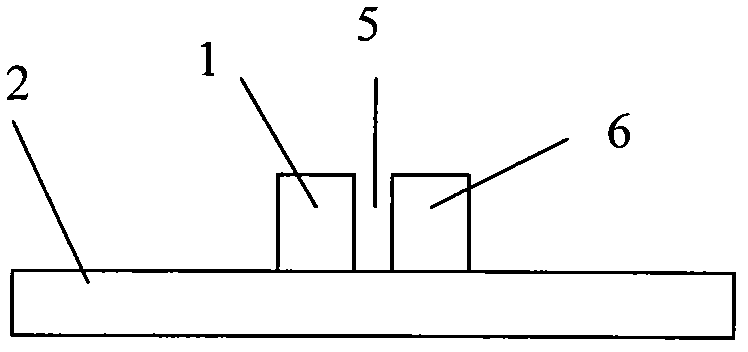

Silk material extrusion device for 3D printer nozzle

InactiveCN106738881AEnough gripAvoid sticking3D object support structuresApplying layer meansEngineering3d printer

The invention discloses a silk material extrusion device for a 3D printer nozzle. The silk material extrusion device comprises a driving device and an elastic base. The driving device comprises a motor and a gear. An output shaft of the motor is sleeved with the gear. The elastic base comprises a base body, a handle, a guide wheel and a spring located between the base body and the handle, and the two ends of the spring abut against the base body and the handle correspondingly. The output shaft of the motor penetrates through the base body, and the base body is fixed to the motor. The base body is provided with a first rotary shaft sleeved with the handle. The handle is provided with a second rotary shaft sleeved with the guide wheel. The silk material extrusion device has high feed precision and reliability and is simple in structure and low in cost.

Owner:ZHEJIANG SHENGTAI DEFENSE TECH CO LTD

Spike for golf shoes

Owner:JAPANA CO LTD

Connection element for hydraulic pipe

The invention discloses a hydraulic pipe connector, which includes a joint body, a hydraulic oil pipe and a nut. There is a movable groove at one end of the joint body, the ferrule is installed in the movable groove and its inner wall is attached to the outer peripheral wall of the hydraulic oil pipe, the ferrule is composed of a buffer part and a sealing part, and the sealing part is along the axial direction of the ferrule toward The inner conical surface extends inside the interface, and there is an annulus between the first sealing surface, the second sealing surface and the hydraulic oil pipe. The first sealing surface is in close contact with the outer peripheral wall of the hydraulic oil pipe, the annular space is maintained between the second sealing surface and the outer peripheral wall of the hydraulic oil pipe, the inner wall of the sealing part body is in close contact with the outer peripheral wall of the hydraulic oil pipe, and the side of the buffer The wall and the arc-shaped expansion part on the outer wall are respectively closely attached to the side walls of the movable groove, so as to ensure the airtightness of the ferrule assembly under high temperature and high pressure conditions.

Owner:黄磊

High-abrasion-resisting diamond saw blade

InactiveCN108145793ANo shedding problemLow melting pointMetallic material coating processesCircular sawsBond interfaceHigh entropy alloys

The invention provides a high-abrasion-resisting diamond saw blade. Diamond single crystals are directly welded to a steel base, and main teeth and auxiliary teeth are formed. The situation of tool bit falling is avoided in the cutting process, and materials with iron nails can be cut. Due to the fact that no tool bit is additionally arranged, the problem of tool bit falling is completely avoidedin the cutting process, and the high-abrasion-resisting diamond saw blade is safe and reliable. Silver-copper-based welding powder is low in melting temperature and good in mobility. The alloy belongsto high-plasticity alloy, and due to the slow cooling process after welding, stress is fully released, and fracturing is avoided. Due to the fact that titanium and chromium are added, a film of TiC and CrC can be formed on the surface of the diamond at high temperature, and the diamond is protected from burning loss at high temperature. A thin layer of (FexCry)C can be formed on the bonding interface of chromium and the steel base, enough holding force is formed on diamond particles through the alloy bonding strength of the diamond tool bit and the steel base, and therefore the diamond cannotfall off in the cutting work. The outer surface of the diamond tool bit is coated with a layer of high-entropy alloy coating through a laser cladding method, and the abrasion resisting performance ofthe saw blade is effectively improved.

Owner:JIANGSU YOUHE TOOLS CO LTD

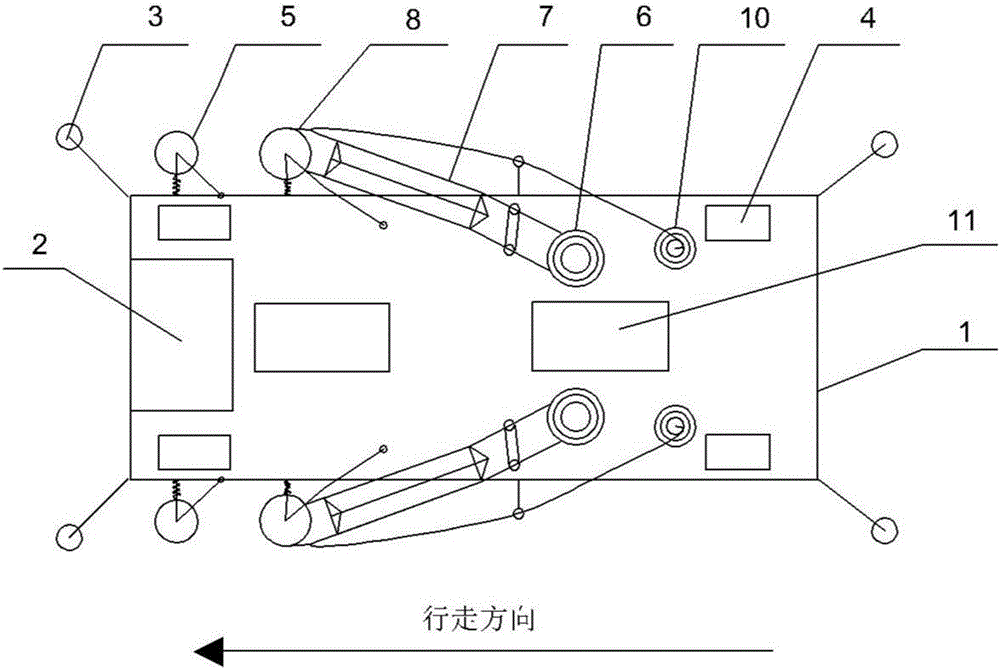

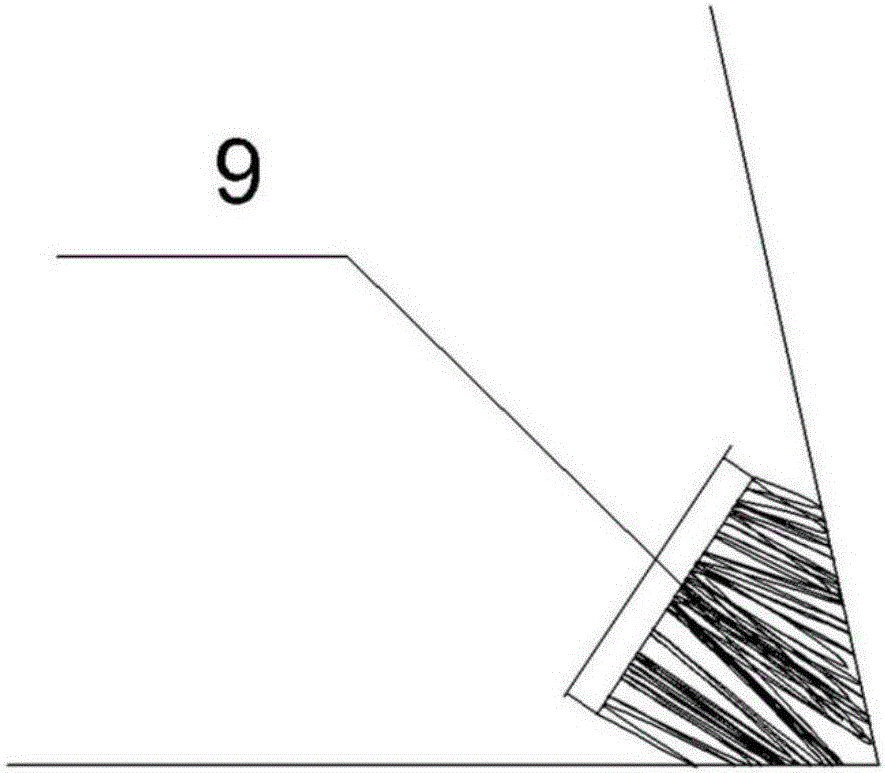

Mounting trolley of welding backings for steel structure U-shaped ribbed plate

The invention discloses a mounting trolley of welding backings for a steel structure U-shaped ribbed plate. A pair of welding backings is symmetrically paved on an inner groove in a narrow and small space formed by a steel top plate and the U-shaped ribbed plate; the mounting trolley comprises a trolley body, a traveling mechanism, a reforming mechanism and an aluminum foil adhesive tape pre-deformation mechanism, wherein the traveling mechanism comprises at least two pair of guide wheels, at least two pairs of traveling wheels and a traveling motor; the reforming mechanism comprises at least one pair of first pressing wheels and at least one pair of first elastic members which are separately and symmetrically arranged; and the aluminum foil adhesive tape pre-deformation mechanism comprises a pair of pay-off wheels, a pay-off motor, a pair of V-shaped guide plates, a pair of second pressing wheels, a pair of second elastic members, a pair of hair brushes and a pair of third elastic members. According to the mounting trolley disclosed by the invention, the welding backings can be mounted in the narrow and small space on the back of a fillet weld of the steel structure U-shaped ribbed plate, the requirements on a welding process and an assembling process of a production field are loosened, the weld penetration of the fillet weld of the steel structure U-shaped ribbed plate is prevented, good positive and negative forming of the fillet weld is realized, the consumption of manpower and material resources is reduced, and the production efficiency and the quality are improved. The mounting trolley has relatively-high application value.

Owner:HUBEI TIANGAO BRIDGE ENG CO LTD

Urethra cleaning and fumigating device for urology department

InactiveCN107951540AReduce frictionAvoid damageEnemata/irrigatorsSurgeryUrethraUpper urinary tract infection

A urethra cleaning and fumigating device for the urology department comprises a sleeve, a handle, a grabbing ring and a fumigating device body. An elastic structure is connected between the handle andthe sleeve. A grabbing ring guide groove is formed in the sleeve. One end of the grabbing ring is fixed to the sleeve, and the other end of the grabbing ring is fixed to the handle through the grabbing ring guide groove. The handle is connected with the fumigating device body. By means of the urethra cleaning and fumigating device, the size of the grabbing ring and the grabbing force on a brokencalculus structure are controlled by the handle. Meanwhile, sawteeth are arranged on the inner side of the grabbing ring, the grabbing force of the grabbing ring can be increased, and broken calculusis prevented from falling down. After calculus in the urethra is grabbed, vapor medicine can be directly guided into the urethra for fumigating through the fumigating device body, and urinary tract infection is prevented or other related treatment is conducted. The urethra cleaning and fumigating device is simple in structure and convenient to operate and can effectively eliminate broken calculusin the urethra on the premise of avoiding friction injuries to the urethra.

Owner:江苏翊博雷明医疗科技有限公司

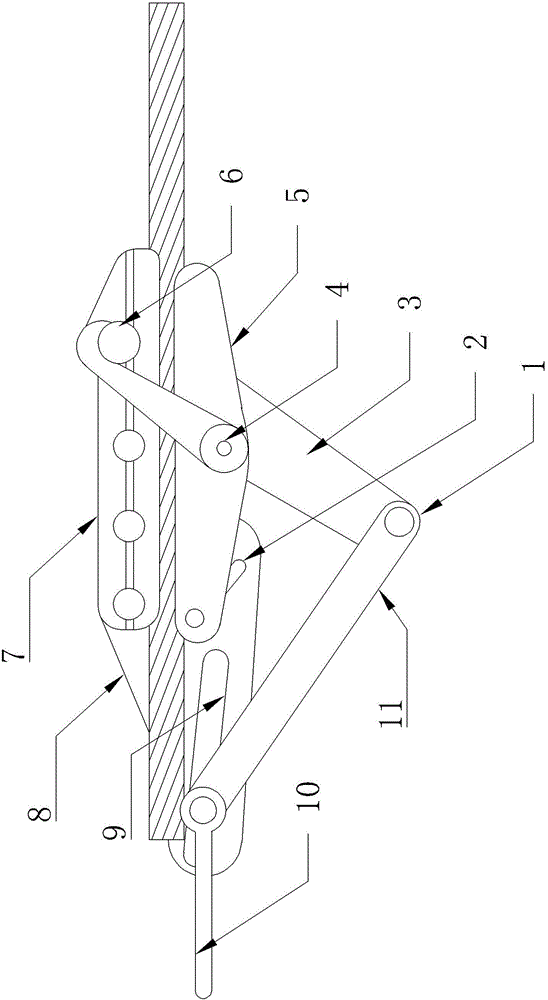

Wire clamping device specially for carbon-fiber composite core wire

InactiveCN106711895APrevent core shrinkageEnough gripAdjusting/maintaining mechanical tensionEngineeringMechanical engineering

The invention, which belongs to the technical field of power line construction equipment, provides a wire clamping device specially for a carbon-fiber composite core wire. The wire clamping device having advantages of convenience in usage and good stringing effect comprises a clamp base. A horizontal upper clamp mouth is fixed at the upper rear end of the clamp base; a first bar-shaped chute that is inclined downwardly and backwardly from the front end is formed in the front end of the clamp base; a first horizontal shaft is arranged in the first bar-shaped chute in a sliding manner and is connected with a rear end of a towing ring and an upper front end of a first connecting rod respectively; the lower rear end of the first connecting rod is connected with a lower front end of a second connecting rod by a horizontal second shaft; the upper rear end of the second connecting rod is connected with the rear of the upper clamp mouth by a horizontal third shaft; the middle of the second connecting rod is connected with the middle of a lower clamp mouth arranged horizontally by a horizontal fourth shaft; and the front end of the lower clamp mouth is connected with a horizontal fifth shaft.

Owner:STATE GRID LIAONING ELECTRIC POWER CO LTD SHENYANG POWER +2

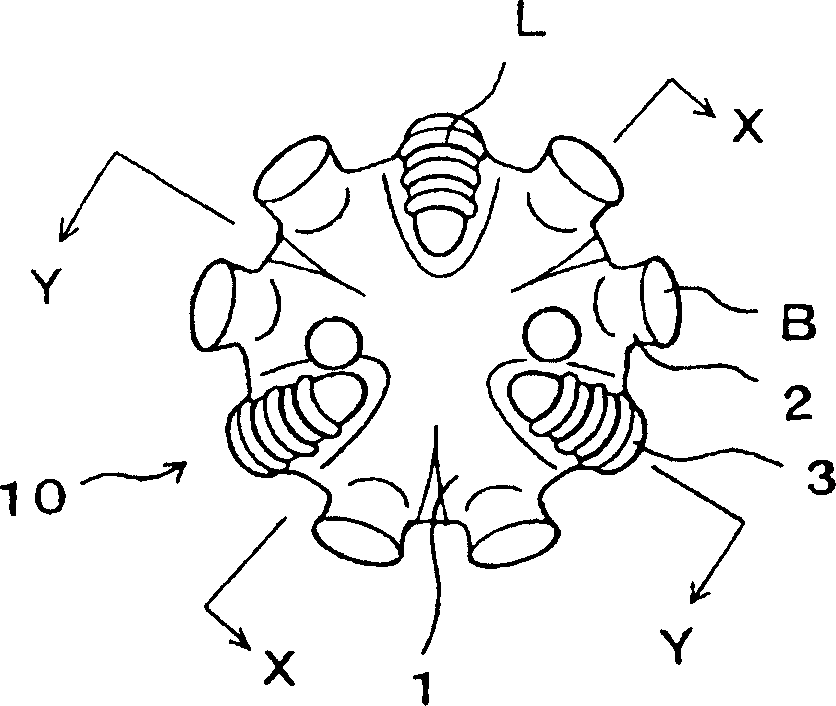

Ratchet foot device for quadruped robots

The invention discloses a ratchet foot device for quadruped robots. The ratchet foot device is mounted to a foot of a quadruped robot. The ratchet foot device comprises a foot tray, a connecting flat plate, a large hollow pin, a small hollow pin, a ratchet and a ratchet cushion block. The foot tray is connected with the shank part of the quadruped robot, the connecting flat plate is fixedly connected with the foot tray through bolts, the ratchet and the ratchet cushion block are fixed on the connecting flat plate through bolts, and then the ratchet and the ratchet cushion block are fixed through the large hollow pin and the small hollow pin to prevent relative slippage between the ratchet and the ratchet cushion block. Based on the unique ratchet design, the quadruped robot generates desired friction and grip forces when contacted with the ground. The ratchet foot device for quadruped robots, disclosed by the invention, has the characteristics of simple structure, light weight, convenience for assembly and disassembly, strong grip force and excellent motor capability.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

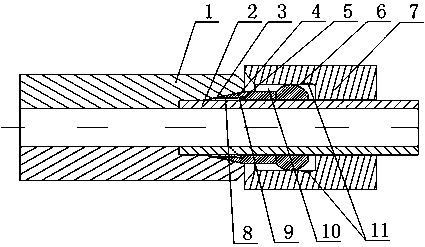

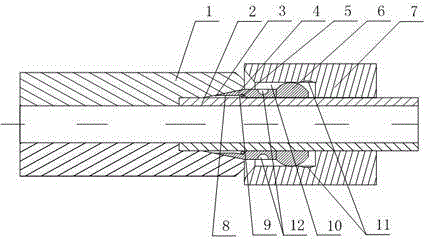

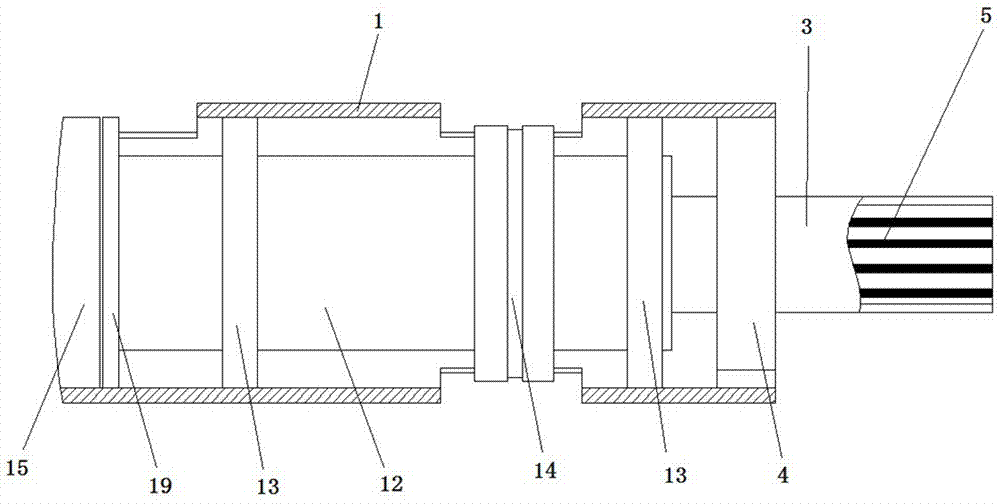

Multi-level seal hydraulic pipe ferrule

InactiveCN105351643AEnough gripImprove air tightnessJoints with sealing surfacesEngineeringHigh pressure

The invention discloses a multi-level seal hydraulic pipe ferrule. The multi-level seal hydraulic pipe ferrule comprises a connector body, a hydraulic oil pipe and a nut, wherein the hydraulic oil pipe is sleeved with the connector body; an inner conical face connector is arranged at the connection end of the connector body and the hydraulic oil pipe; a movable groove is formed in the end, right facing the connector body, of the nut; a ferrule body is installed in the movable groove, the inner wall of the ferrule body is attached to the peripheral wall of the hydraulic oil pipe, the ferrule body is composed of a buffer portion and a sealing portion, the sealing portion extends into the inner conical face connector in the axis direction of the ferrule, and a first sealing face and a second sealing face form an annular space along with the hydraulic oil pipe. The first sealing face is tightly attached to the peripheral wall of the hydraulic oil pipe, the second sealing face and the peripheral wall of the hydraulic oil pipe keep an annular space, the inner wall of the body of the sealing portion is tightly attached to the peripheral wall of the hydraulic oil pipe, and the lateral wall of the buffer portion and the arc expansion portion on the outer wall of the buffer portion are tightly attached to the lateral wall of the movable groove respectively, so that air tightness of a ferrule assembly under high temperature and high pressure is ensured.

Owner:四川海搏液压机械有限公司

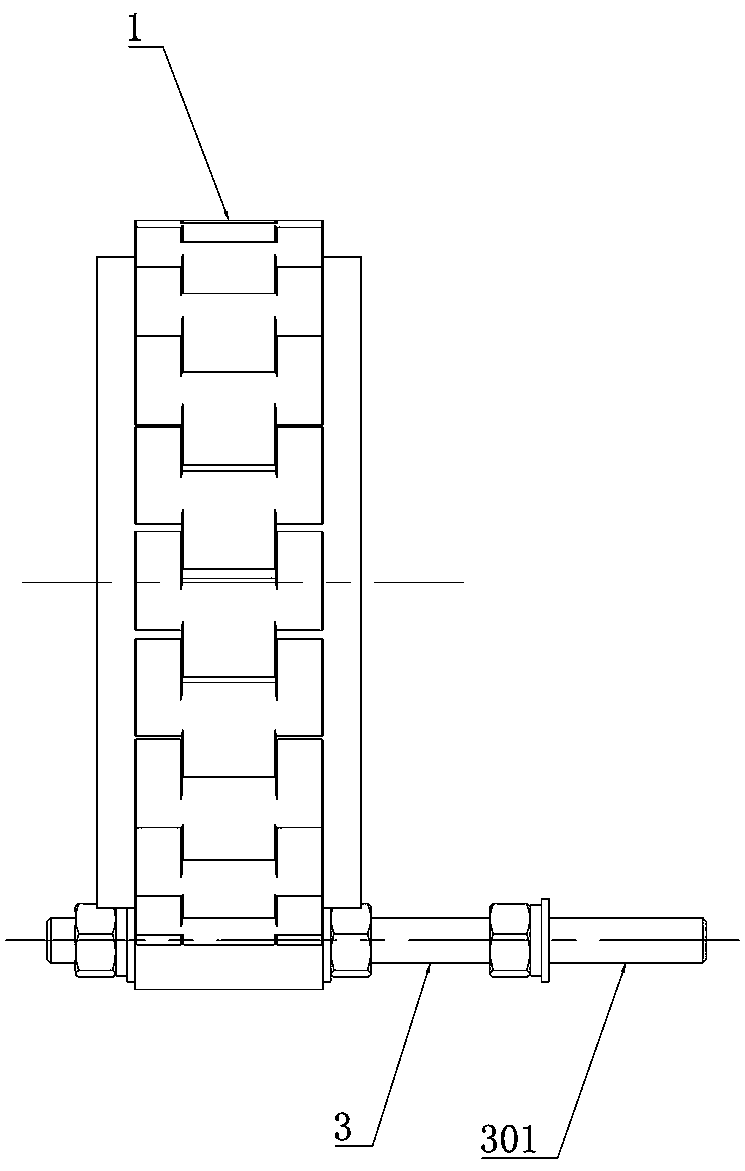

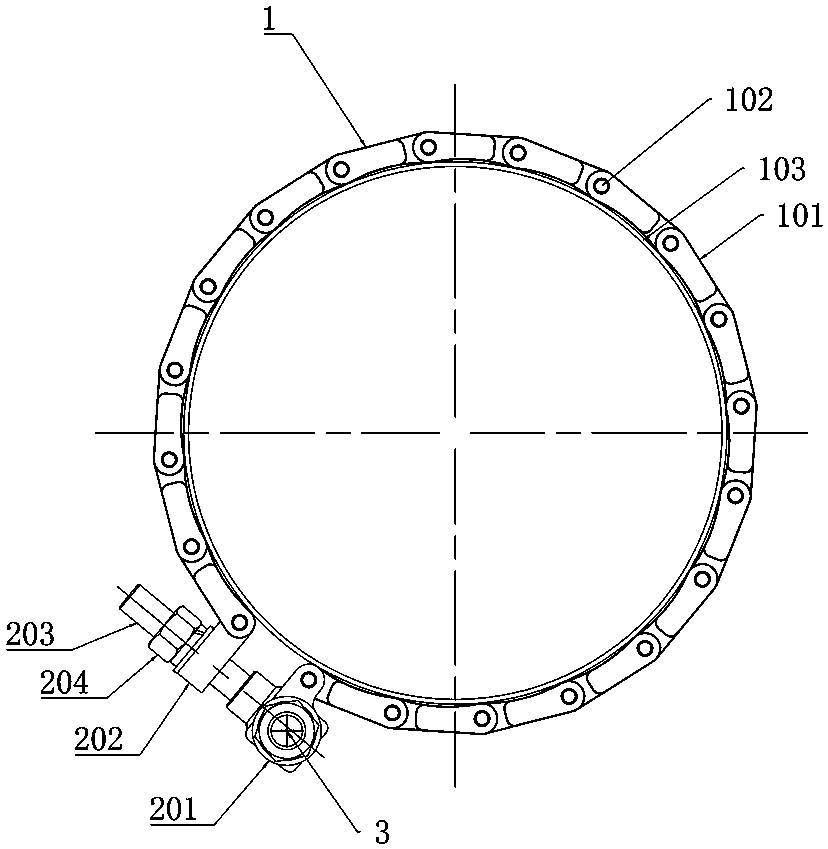

Anti-skid device for GIS tube busbar fixture

InactiveCN108365583AGuaranteed reliabilityAvoid deformationSwitchgear arrangementsBus-bar installationBusbarClosed loop

The invention discloses an anti-skid device for a GIS tube busbar fixture. The device comprises multiple pressing blocks, the pressing blocks are rotatably connected in sequence to form a chain, and the chain is used for fixing a GIS tube busbar tightly; a closed loop is formed by connecting the two ends of the chain through a connecting assembly, and adjustment is conducted on the fixing force onthe chain through the connecting assembly. The anti-skid device for the GIS tube busbar fixture has the advantages of being simple in structure, good in anti-skid effect and the like.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

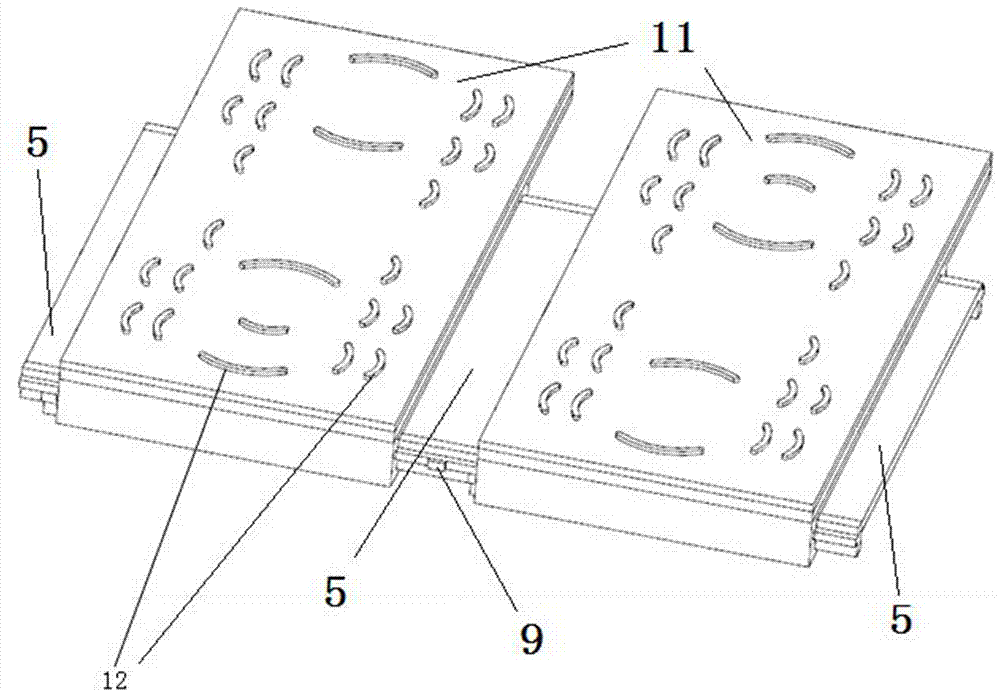

Pattern tyre with fixed rotation direction

ActiveCN104149553AReduce stress concentrationPlay the role of silencerTyre tread bands/patternsWater dischargeWater flow

The invention discloses a pattern tyre with the fixed rotation direction. The tyre is mounted in the fixed direction. A tread central region is composed of a tyre central peripheral rib and two vertical pattern grooves; S-shaped and C-shaped pattern grooves which extend from the tread central region to a tyre shoulder part are divided into tyre shoulder regions. Three arch-shaped pattern grooves are formed between the S-shaped and C-shaped pattern grooves and are used for communicating the vertical pattern grooves and the C-shaped pattern groove; one arch-shaped pattern groove which is only communicated with the S-shaped and C-shaped pattern grooves is formed in the part close to a tyre side edge. Tyre patterns are combined by the S-shaped pattern groove and the C-shaped pattern groove to form a single pitch; two arc-shaped sharp-knife-shaped pattern grooves and an anti-slipping fine groove are formed in each of blank regions of pattern gaps with different pitches. The directional pattern tyre can rotate in the fixed direction; the grounding performance of a tyre is not influenced and the water flow resistance can be alleviated; a water discharging speed is increased and an excellent anti-slipping performance on a wetland and a water accumulated road surface is provided.

Owner:JIANGSU PUNAILI RUBBER CO LTD

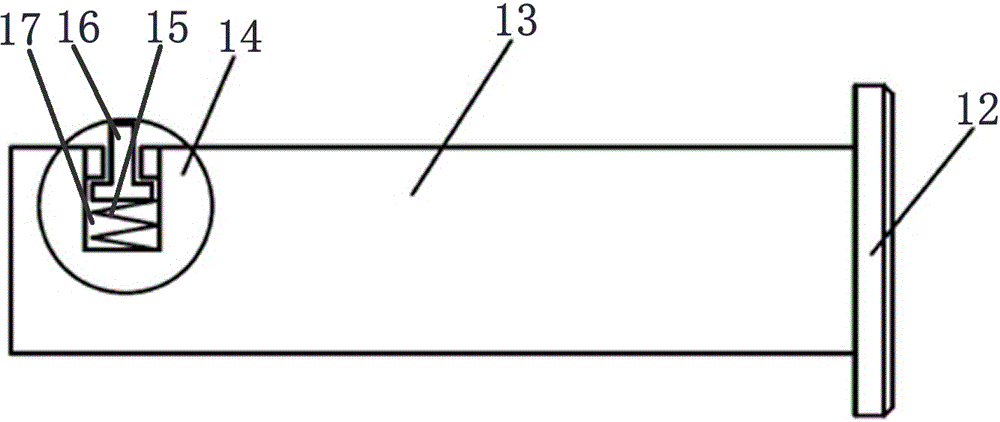

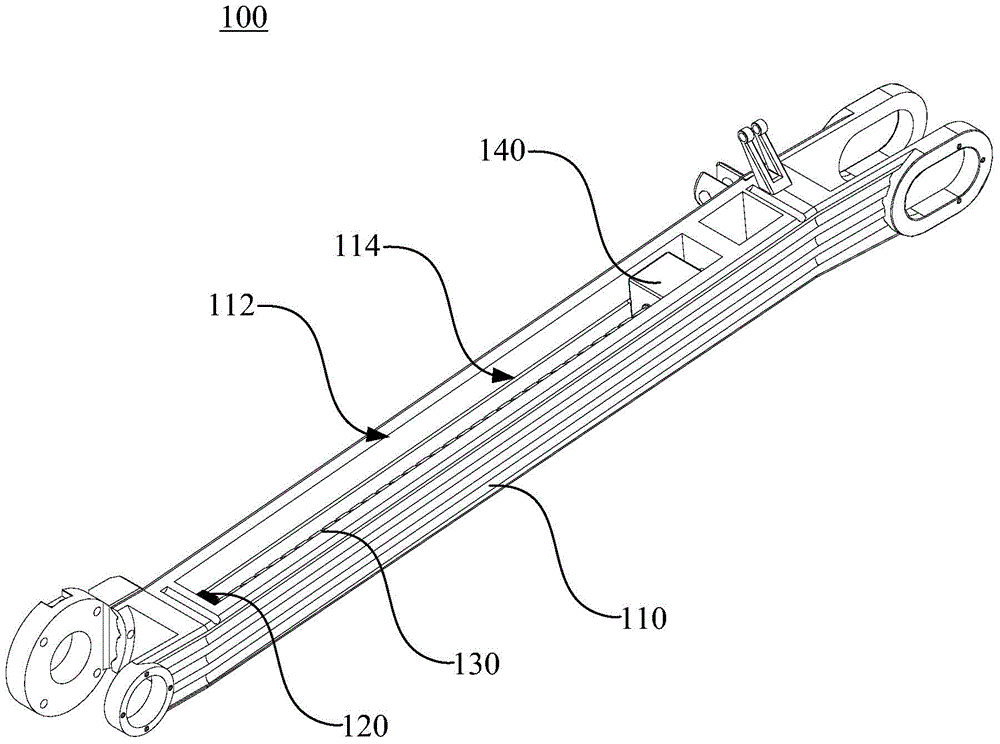

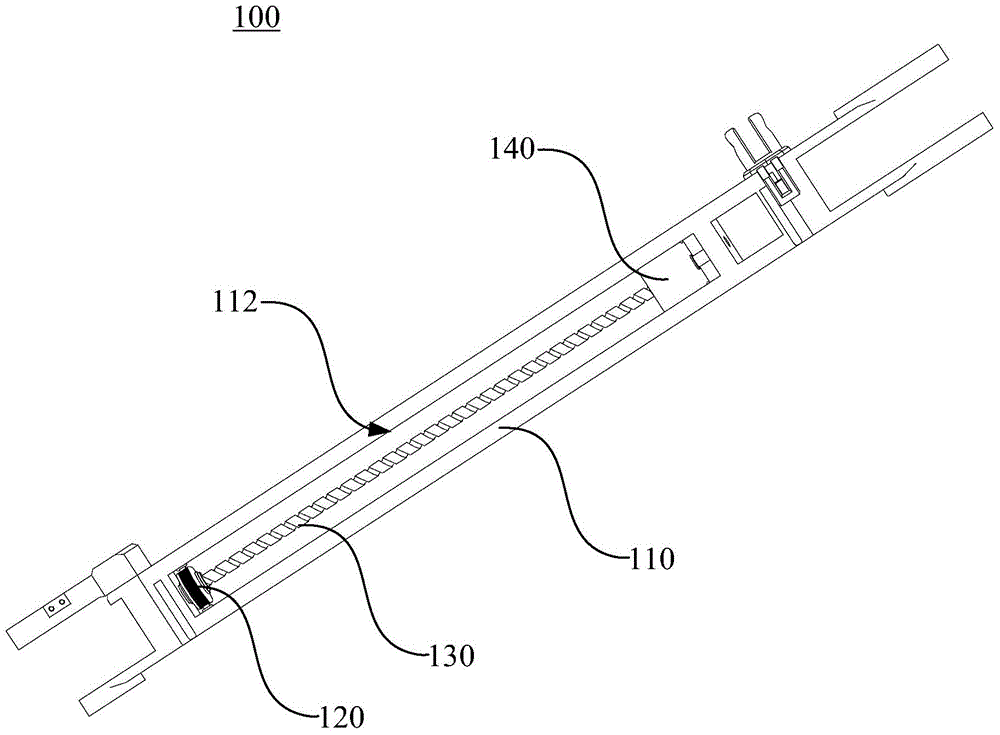

Motor vehicle and starting balance system thereof

The invention relates to a motor vehicle and a starting balance system thereof. The starting balance system of the motor vehicle comprises a motor vehicle gravity balance device, a sensor and a central controller, wherein the motor vehicle gravity balance device comprises a positioning beam, a motor, a screw rod and a gravity center regulating block; a slide long hole is formed in the positioning beam; the motor is arranged at one side of the slide long hole; the screw rod is arranged on the motor; the gravity center regulating block is slidly arranged in the slide long hole; the screw rod rotates for driving the gravity center regulating block to slide in the slide long hole; the motor drives the screw rod to rotate, so that the gravity center regulating block slides in the slide long hole; the sensor is used for measuring pressure / inertia data of the motor vehicle; the central controller is used for receiving and analyzing the data measured by the sensor and controlling the motor. The starting balance system of the motor vehicle can be used for balancing the gravity center of the vehicle when the motor vehicle starts, so that the front wheel of the motor vehicle is guaranteed to have enough ground gripping force, and the motor vehicle is stably started.

Owner:东莞光洋信息科技有限公司

Anti-skid shoe supporting device for mountaineering and use method thereof

ActiveCN107095387AAdequate adjustment marginImprove compatibilityFasteningsEngineeringMechanical engineering

The invention provides an anti-skid shoe supporting device for mountaineering and a use method thereof. The anti-skid shoe supporting device comprises a shoe supporting platform and an anti-skid shoe sole under the shoe supporting platform; the shoe supporting platform comprises a shoe supporting plate, convex guide rails, wire buckle sliding grooves, stopping blocks, a wire buckling device and foot side supporting plates, and the convex guide rails, the wire buckle sliding grooves, the stopping blocks, the wire buckling device and the foot side supporting plates are installed on the shoe supporting plate; the convex guide rails are arranged on the left side and the right side of the shoe supporting plate; the foot side supporting plates are arranged on the convex guide rails in a sliding mode, and locking screw holes are formed in the foot side supporting plates; the wire buckle sliding grooves are transversely formed in the shoe supporting plate, and the wire buckle sliding grooves are formed between the two convex guide rails and are closely adjacent to the two convex guide rails respectively; the wire buckling device is composed of a plurality of wire buckling blocks which are arranged in the wire buckling sliding grooves in a sliding mode, and cable holes capable of making shoe body fixing cables to penetrate are formed in the wire buckling blocks. The device can be compatible with shoes with various sizes, and can bear large loads and large impact force.

Owner:FUZHOU UNIV

Novel differential

The invention belongs to the field of automobile parts, and particularly relates to a novel differential. The novel differential comprises a machine case; a left output half shaft and a right output half shaft are arranged in the machine case; the outer circle face of the left output half shaft is sequentially sleeved with a first left half shaft gear, a first transmission gear and a second left half shaft gear from left to right; the first left half shaft gear and the second left half shaft gear are fixed to the outer circle face of the left output half shaft; teeth on the first left half shaft gear and the second left half shaft gear are opposite in rotating direction; the left side and the right side of the first transmission gear are provided with teeth engaged with the first left half shaft gear and the second left half shaft gear; the structure of the right output half shaft is the same as that of the left output half shaft; the exteriors of the left output half shaft and the right output half shaft are wrapped by transmission sleeves which can slide in the axis direction of the left output half shaft; the inner walls of the transmission sleeves are connected with the first transmission gear and a second transmission gear correspondingly; and shifting fork rings and driven gear rings are arranged on the outer walls of the transmission sleeves. The device is simplified in structure and low in cost.

Owner:孙超

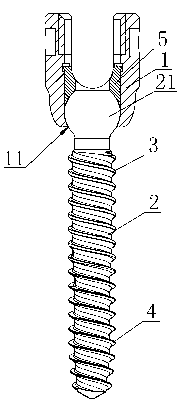

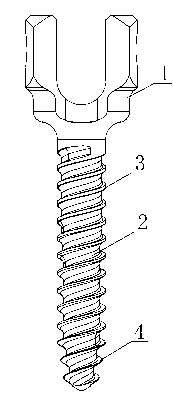

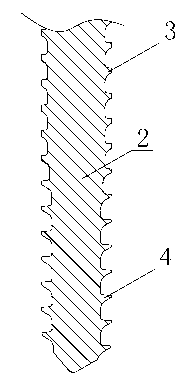

Spine bolt

InactiveCN103006308AHigh strengthIncrease the leadInternal osteosythesisFastenersEngineeringBone Cortex

The invention discloses a spine bolt which comprises a U-shaped bolt base on which a bolt main body is connected; an upper section of threads and a lower section of threads, which are connected with each other, are arranged on the bolt main body; the upper section of threads are cortical bone threads located at a cortical bone section; the lower section of threads are cancellous bone threads located at a cancellous bone section; the outer diameter of the cortical bone threads is the same with the outer diameter of the cancellous bone threads, and the inner diameter of the cortical bone threads is bigger than the inner diameter of the cancellous bone threads, so the diameter of the part of the bolt main body, which is located at the cortical bone part is bigger than the diameter of the part of the bolt main body, which is located at the cancellous bone part; and the cortical bone threads and the cancellous bone threads are both double threads. The spine bolt has the beneficial effects that flexural deformation of the spine bolt is effectively avoided, the bonding strength between the bolt main body and the bone of a human body is guaranteed, the nailing speed of the spine bolt is greatly improved, and the probabilities of surgical bleeding infection and the emergence of other complications are effectively reduced.

Owner:SUZHOU XINRONG BEST MEDICAL INSTR

Special equipment for bending power wire

InactiveCN102545090AImprove cable qualitySimple structureCable installation apparatusCopper wireEngineering

The invention discloses special equipment for bending a power wire, relating to special equipment for power industry and being capable of conveniently and simply bending an aluminium wire or copper wire in different directions, ensuring high finished product ratio and keeping the appearances of the bent wires basically unified. The special equipment comprises a fixed seat and a spanner, wherein the fixed seat comprises a base, a left clamping block and a right clamping block, the left clamping block, the right clamping block and the base are fixedly connected, and a gap is remained between the left clamping block and the right clamping block so as to form a wire locating slot; the spanner is formed by connecting a spanner head and a holding rod, the spanner head is provided with an inwards-bent spanner opening, and metal rods of which the cross sections are round are arranged at the upper side and the lower side of the spanner opening; the left clamping block and the right clamping block are of trapezoids or tetrahedrons; the width of the wire locating slot is 10-12mm; the spanner opening is rectangular, and the distance between the upper side and the lower side of the spanner opening is smaller than the width of a wire; and the length of the holding rod is 1-1.5m. The special equipment has the active effects that convenience in use and high bending quality are realized, the rejection rate is reduced, and the waste is reduced, therefore, the special equipment is very suitable for being applied to the power supply bureau and various electric power installation industries.

Owner:商丘市天宇电力工程有限公司

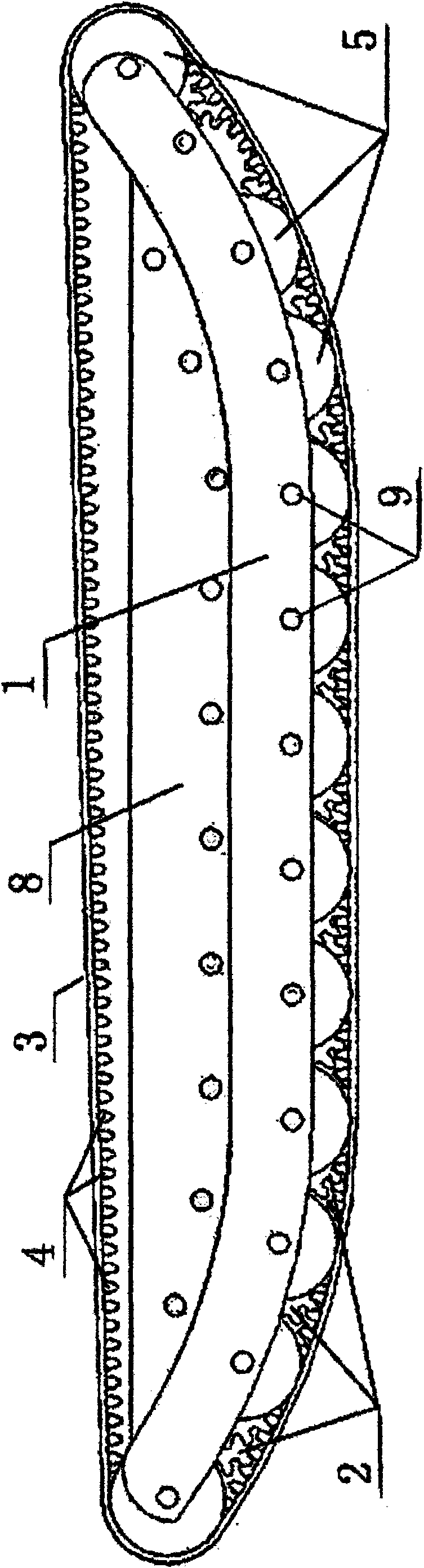

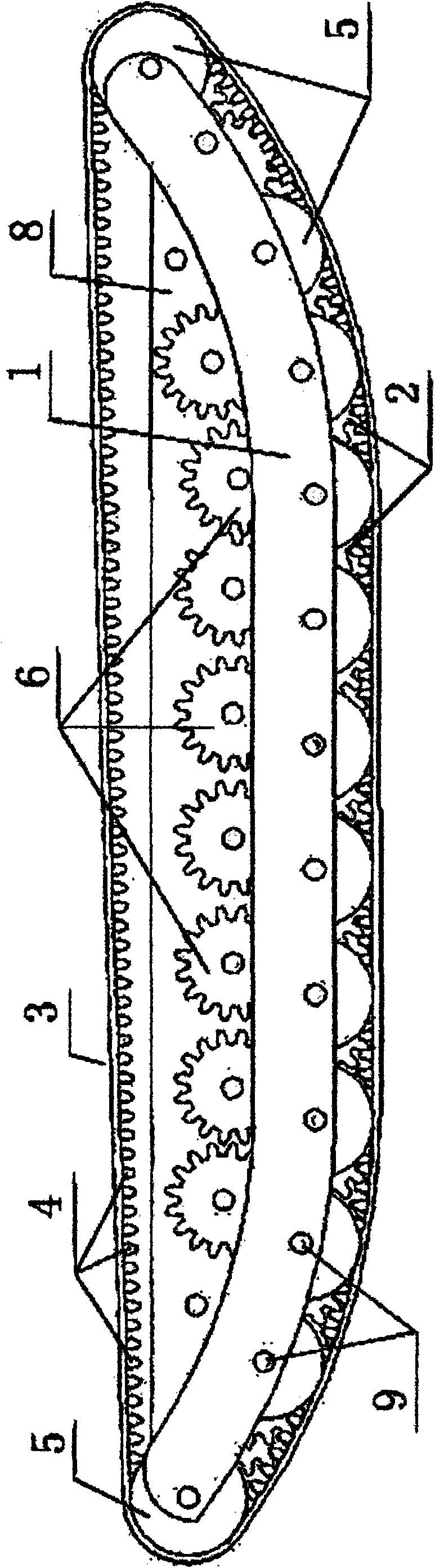

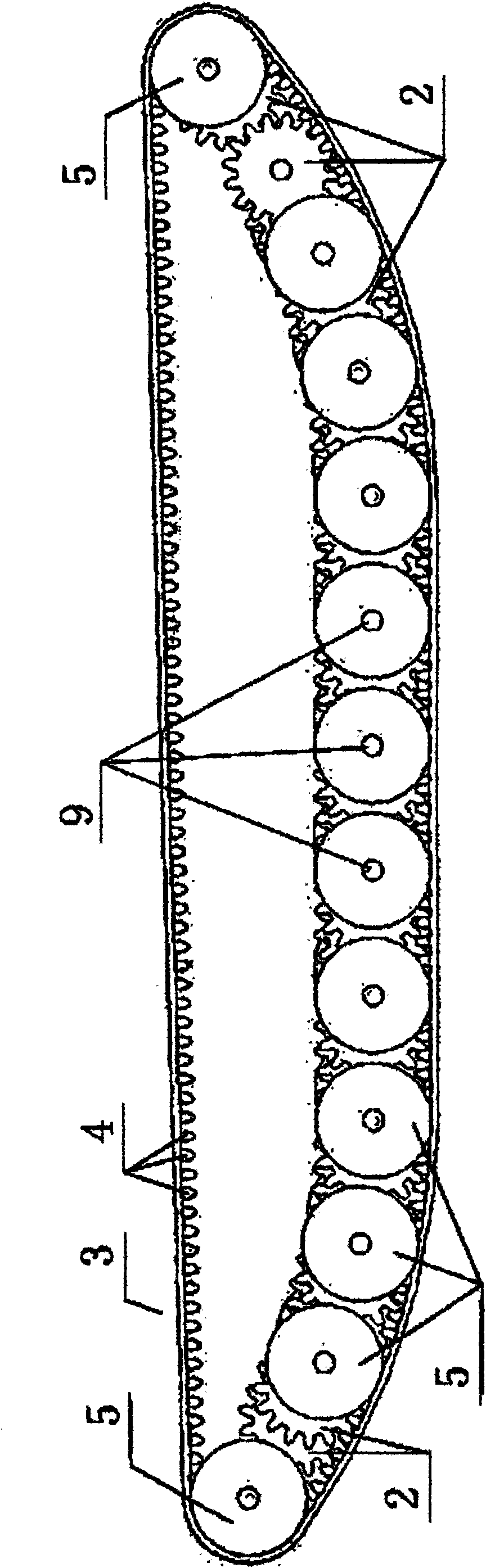

Staggered supporting wheel type crawler device

InactiveCN102050161AReduce secondary impactLarge secondary impactEndless track vehiclesEngineeringPulley

Owner:孙继华

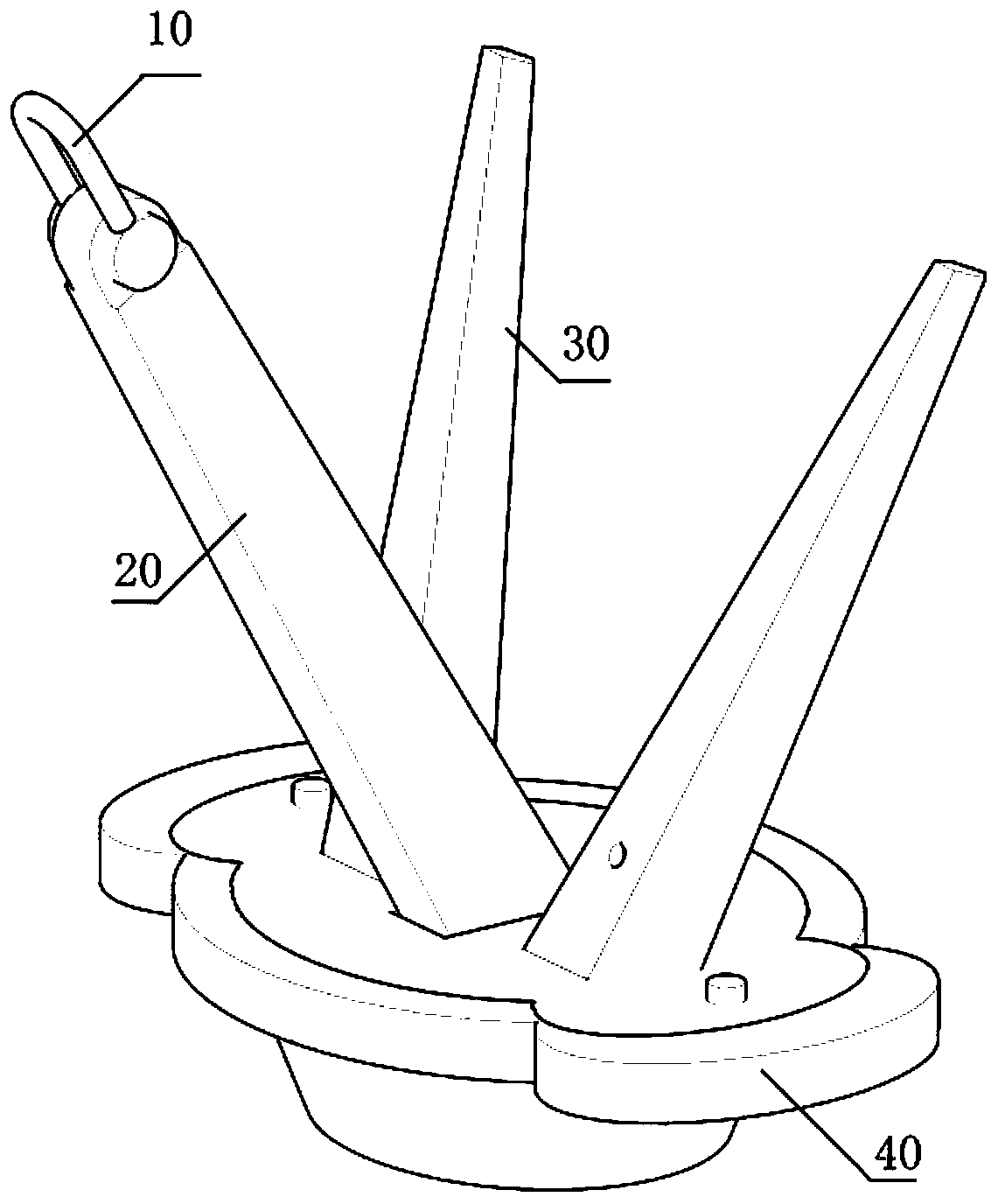

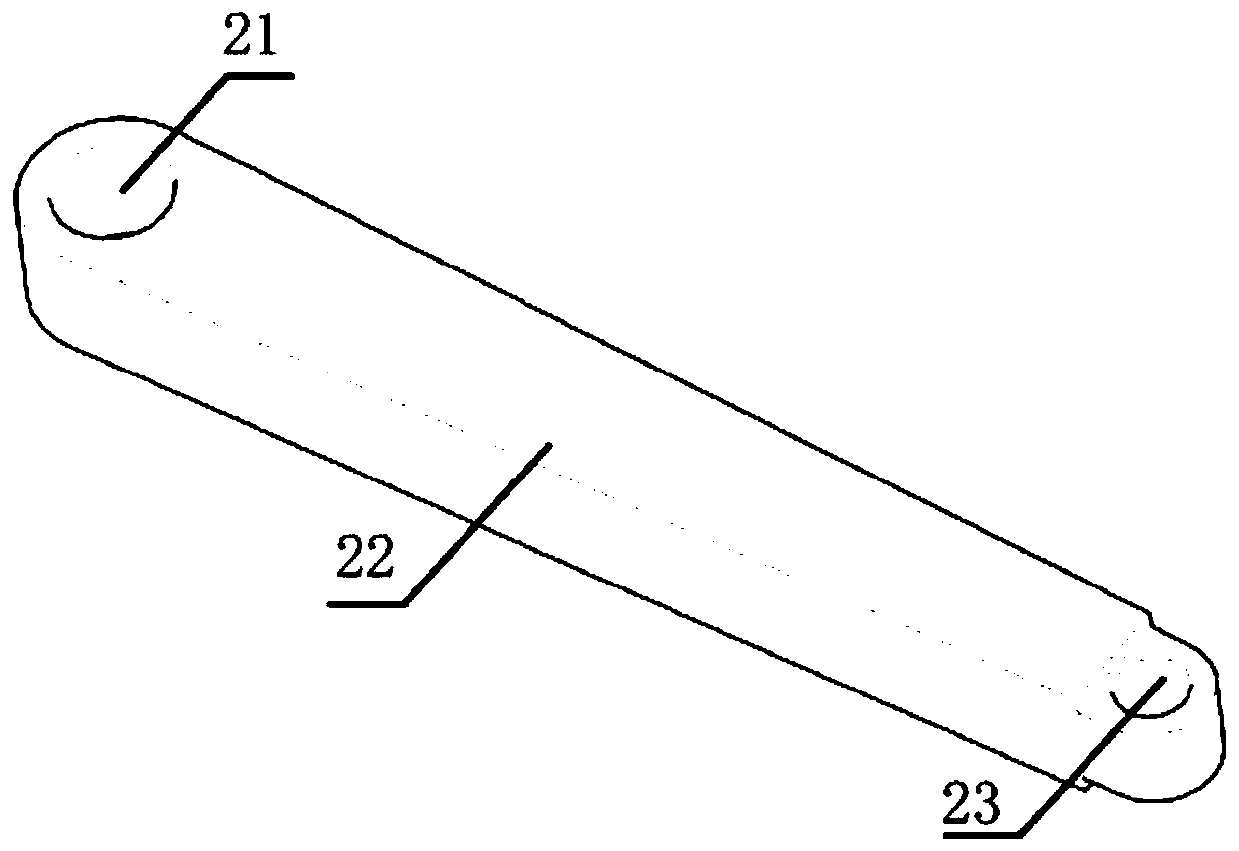

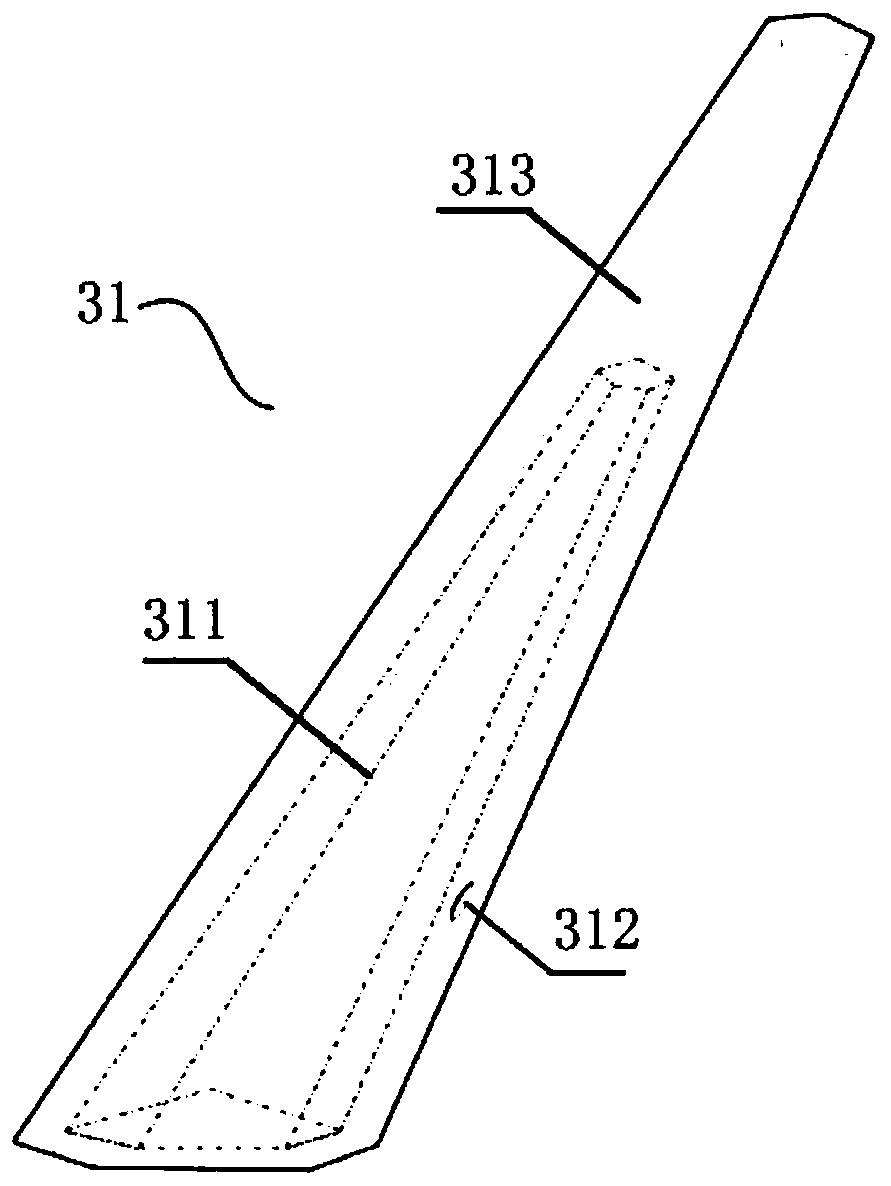

Size adjustable boat anchor used for water surface positioning of stone dumper

ActiveCN110304201AMeet stability requirementsEnough gripAnchorsMarine engineeringStructural composition

The invention discloses a size adjustable boat anchor used for water surface positioning of a stone dumper. The size adjustable boat anchor used for water surface positioning of the stone dumper comprises a shackle, an anchor shank, anchor jaws and an anchor crown; the shackle is mounted at the top end of the anchor shank; the bottom of the anchor shank is hinged to the anchor crown; the anchor crown comprises an internal anchor crown and a plurality of layers of external anchor crowns embedded and fixed outside the internal anchor crown; and the anchor jaws comprise internal anchor jaws and aplurality of layers of external anchor jaws, wherein the internal anchor jaws are fixed on the internal anchor crown, and the plurality of layers of external anchor jaws are embedded and fixed outside the internal anchor jaws. According to the size adjustable boat anchor used for water surface positioning of the stone dumper, according to a site actual situation and sailor experience, the numberof the assembled anchor jaws and the assembled anchor crowns are selected to change the model of a boat anchor so as to satisfy a requirement that a located boat is stable in water surface operation;other boat anchors with different types do not need to be carried; and therefore, the application range is wide; and meanwhile, the size adjustable boat anchor used for water surface positioning of the stone dumper has the advantages of simple structural composition, convenient mounting and detaching, high construction efficiency and lower cost.

Owner:CHINA FIRST METALLURGICAL GROUP

Stone excavation fragmentation device for fractured rock layer and method for installing and using same

ActiveCN109519120AEfficient, safe and reliable excavationSimple structureVibration drillingControl lineEnergy supply

The invention discloses a stone excavation fragmentation device for a fractured rock layer and a method for installing and using the same. The fragmentation device comprises a fragmentation drilling device, a hydraulic energy supply device and a walking system. The fragmentation drilling device comprises a vertical drilling head, an expander, a positioning oil cylinder, a fragmentation vibrator, avertical adjustment oil cylinder and a fragmentator oil pump. The hydraulic energy supply device includes a fragmentator positioning telescopic arm, a fragmentator telescopic arm supporting frame, afragmentator oil supply system and an oil supply pipe. The walking system includes a generator set, an operation room, a walking track, a walking system supporting frame, a power line and a control line. The stone excavation fragmentation device intends to replace a traditional construction process with an automatic large-scale mechanical device to achieve the purpose of reducing safety risks andimproving production efficiency. By technical comparison analysis and defect analysis of current stone excavation construction links of the fractured rock layer, we find that a conventional drilling and blasting excavation process has the problem that a large amount of fire work materials must be used and the safety guarantee coefficient is low.

Owner:CHINA MCC17 GRP

Snow tire

The invention provides a snow tire. The braking performance of the snow tire is improved without affecting the operation stability. The snow tire comprises a tire tread and tire shoulders positioned on the two sides of the tire tread; multiple pattern grooves extend in the transverse direction of the tire tread and are uniformly arranged in the circumferential direction of the tire tread; the leftand right shapes, structures and dimensions of the pattern grooves relative to the central line of a tire tread pattern are consistent and the pattern grooves are alternately arranged relative to thecentral line of the tire tread pattern; the pattern grooves comprise V-shaped grooves formed in the tire tread; two grooves forming each V-shaped groove extend to the tire shoulders on the two sides;and the tire shoulders extend out in the width direction of the snow tire.

Owner:SHOUGUANG FIREMAX TYRE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com