Pattern tyre with fixed rotation direction

A pattern and tire technology, applied in the field of bionic directional pattern tires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical measures adopted to implement the above-mentioned purpose of the present invention are as follows:

[0023] The directional pattern tire of the present invention is suitable for high-performance sports cars, and the installation has a fixed direction.

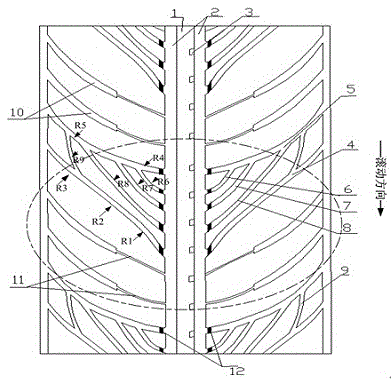

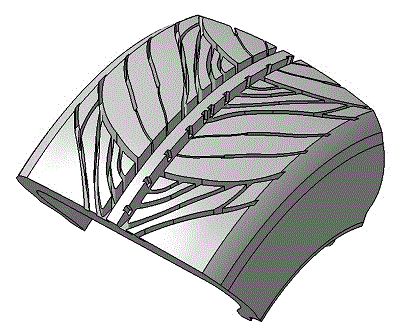

[0024] Such as figure 1 As shown, the tire tread is divided into two parts: the pattern center area and the shoulder area. Among them, in the center area of the pattern, along the axial width direction of the tire, there is a central pattern rib 1 along the circumferential direction in the center of the tire tread, and the width of the central pattern rib 1 accounts for 5%-6% of the axial width of the tread Between them, the height of the central pattern rib 1 is 8-10mm; the left and right sides of the central pattern rib 1 are provided with a rectangular pattern groove 2 with a strong drainage function along the tire circumferential direction, and the depth of the rectangular pattern groove 2 is equal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com