Silk material extrusion device for 3D printer nozzle

A technology of 3D printers and extrusion devices, which is applied to coating devices, 3D object support structures, additive manufacturing, etc. It can solve problems such as wire sticking, influence of feeding accuracy, and abnormal wire feeding, etc., to meet the requirements of feeding Accuracy requirements, easy loading and unloading of wire materials, and the effect of avoiding sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

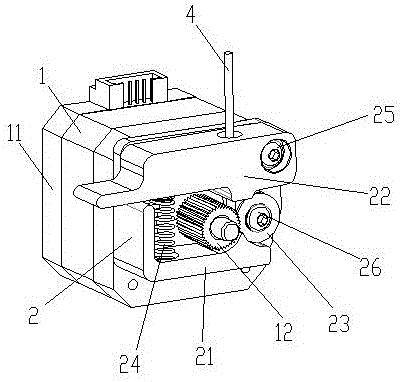

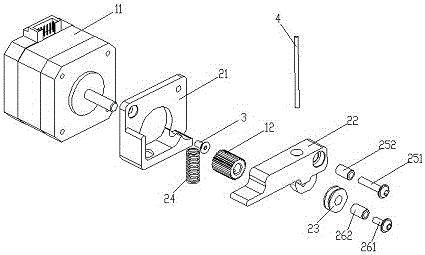

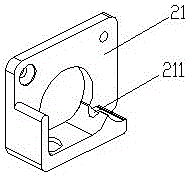

[0022] As shown in the figure, a wire extruding device for a nozzle of a 3D printer includes a driving device 1 and an elastic base 2; the driving device 1 includes a motor 11 and a gear 12, and the gear 12 is sleeved on the motor 11 On the output shaft; the elastic base 2 includes a base 21, a handle 22, a guide wheel 23 and a spring 24 between the base 21 and the handle 22, and the two ends of the spring 24 are respectively against the base 21 and the handle 22 The output shaft of the motor 11 passes through the base 21, and the base 21 is fixed to the motor 11; the base 21 is provided with a first rotating shaft 25, and the handle 22 is sleeved on the first rotating shaft 25; the handle 22 A second rotating shaft 26 is arranged on the top, and the guide wheel 23 is sheathed on the second rotating shaft 26 .

[0023] The base 21 and the handle 22 are resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com