Method and installation for assembling palletizable products

A technology for products and equipment, applied in the field of equipment for implementing the method, can solve problems such as pallet rejection, and achieve the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

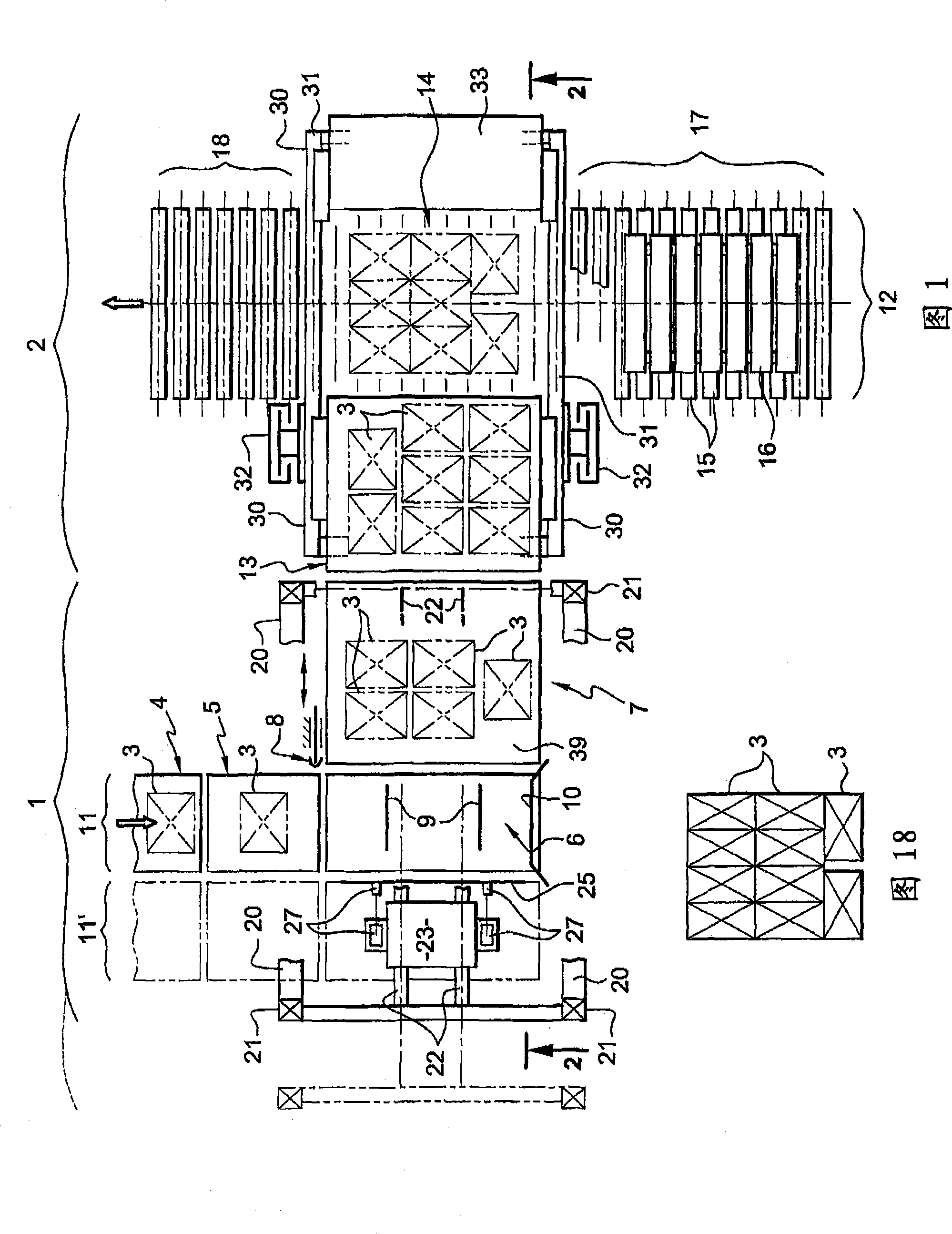

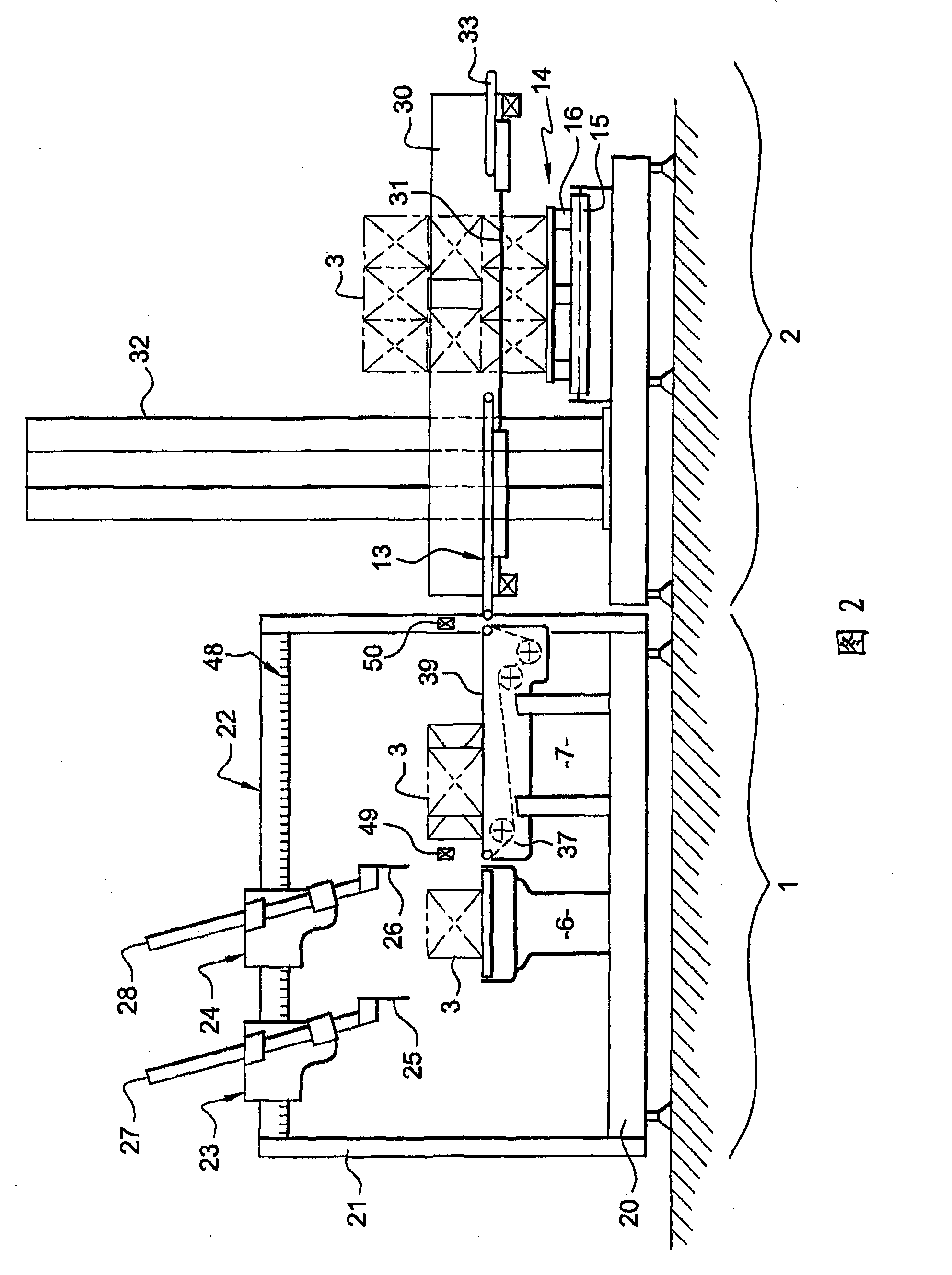

[0042] As shown in Figure 1, the facility consists of two main separate partitions: Partition 1 handles pre-processing and pre-assembly of products, and Partition 2 handles palletization of product layers.

[0043] Section 1 comprises a processing line 11 for supplying products 3, said processing line 11 comprising: conveyor means 4 for supplying and collecting said products 3; sorting conveyor means 5; pre-processing stations 6; Workstation 7 of said product 3 .

[0044] Like the sorting conveyor 5, the collection conveyor 4 is a conventional conveyor of the motor-driven endless belt type. The pretreatment station 6 comprises a table with motor driven rollers of small diameter. This pretreatment station is equipped with a pivot or pivots for orienting the product, a travel stop 9 for separating the product and an end stop 10 which delimits the processing line for conveying the product 3 11 endpoints.

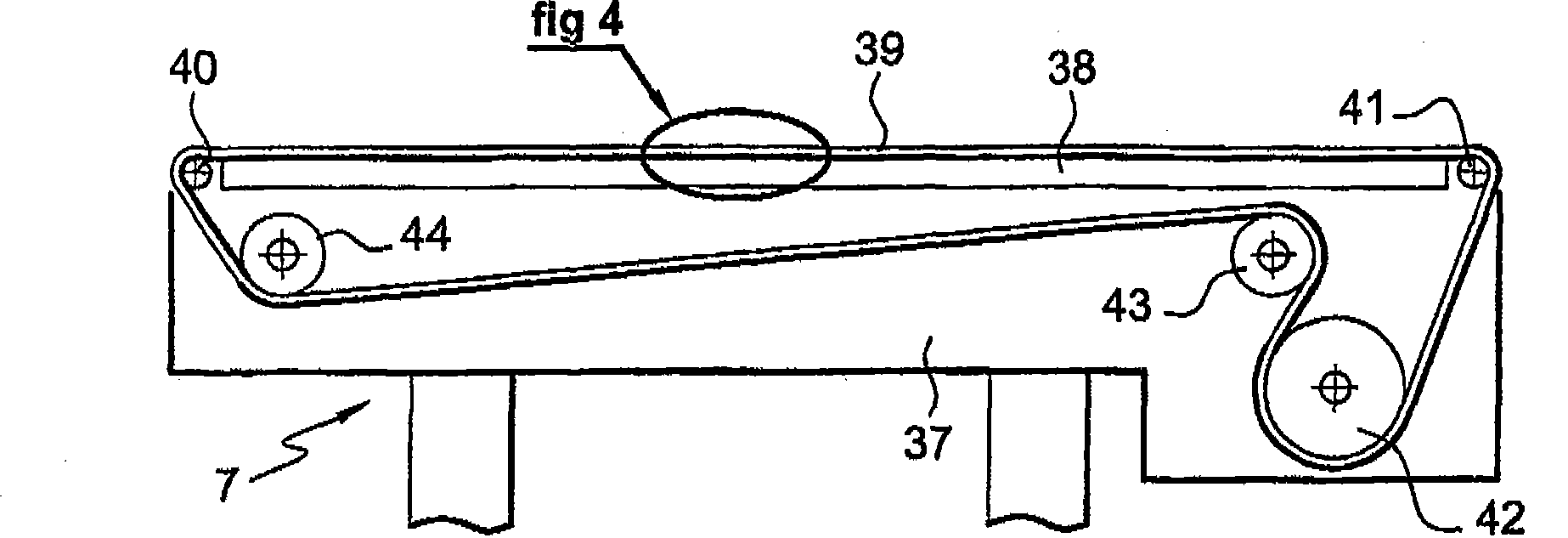

[0045]The pre-assembly station 7 comprises a work table arranged transv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com