Wire clamping device specially for carbon-fiber composite core wire

A composite core and carbon fiber technology, which is applied in the direction of adjusting/maintaining mechanical tension, can solve the problems of increasing the construction cost and difficulty of the conductor, breaking the composite core, and increasing the construction time of the erection, so as to reduce the construction time of the erection and avoid being broken. The effect of high security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

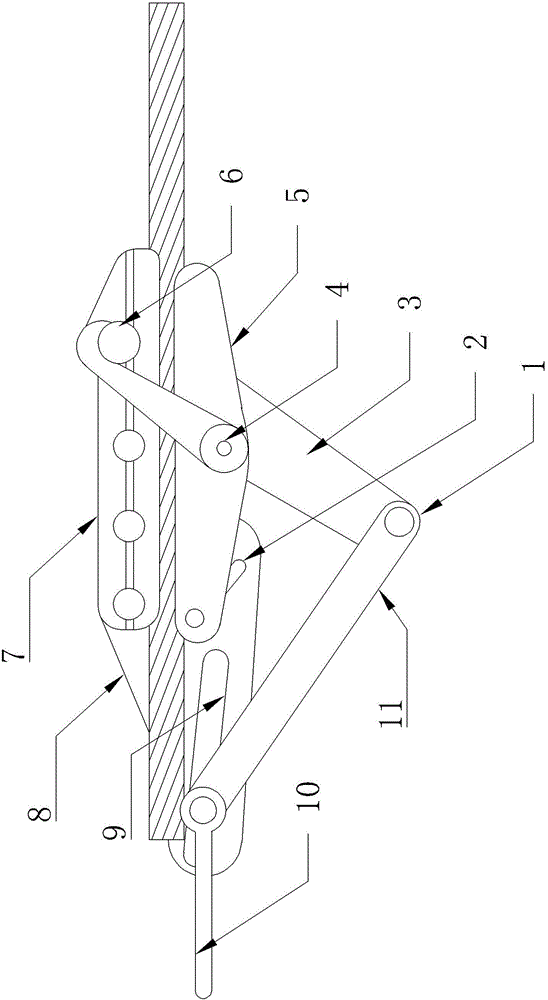

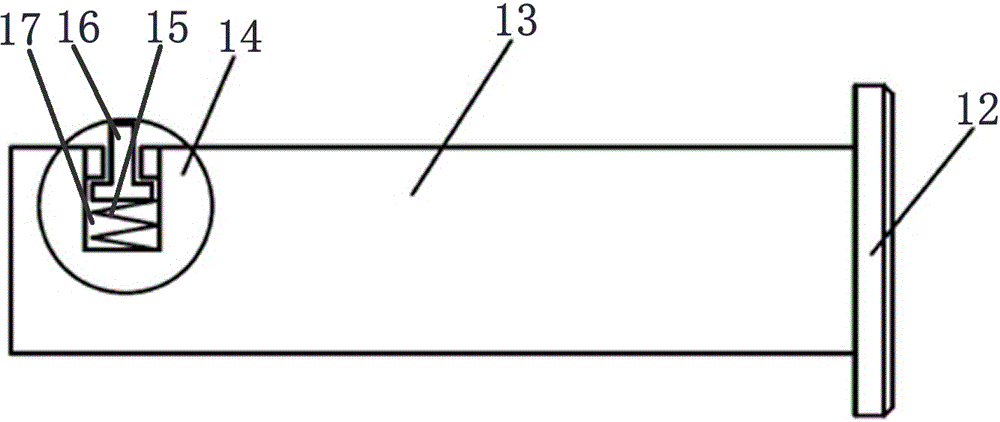

[0025] As shown in the figure, the present invention includes a clamp base 8, the rear upper end of the clamp base 8 is fixed with a horizontal upper jaw 7, and the front end of the clamp base 8 is provided with a first bar-shaped chute 9 inclined backward from the front end. A horizontal first shaft is slidingly arranged in the chute 9, and the first shaft is respectively connected with the rear end of the traction ring 10 and the front upper end of the first connecting rod 11, and the rear lower end of the first connecting rod 11 is connected to the second connecting rod through the horizontal second shaft 1. 3. The front and lower ends are connected, the rear upper end of the second connecting rod 3 is connected to the rear of the upper jaw 7 through the third horizontal axis 6, and the middle part of the second connecting rod 3 is connected to the middle part of the lower jaw 5 arranged horizontally through the fourth horizontal axis 4 , the front end of the lower jaw 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com