Ultra-high molding door

A super high, door core board technology, applied in the direction of door leaf, window/door, fire door, etc., can solve problems such as bending deformation, and achieve the effect of prolonging service life, ensuring safety, and improving fire performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below with reference to the accompanying drawings.

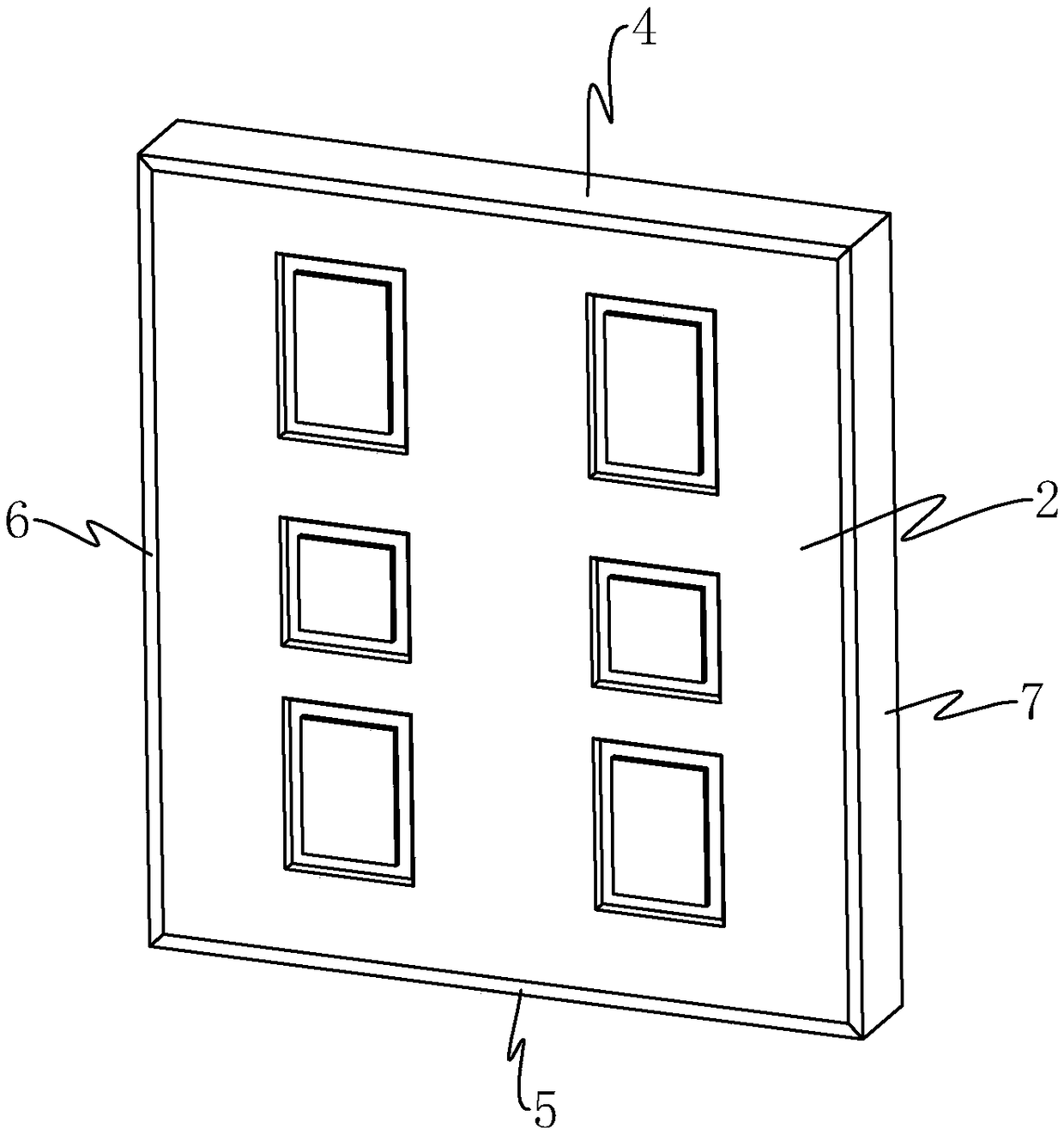

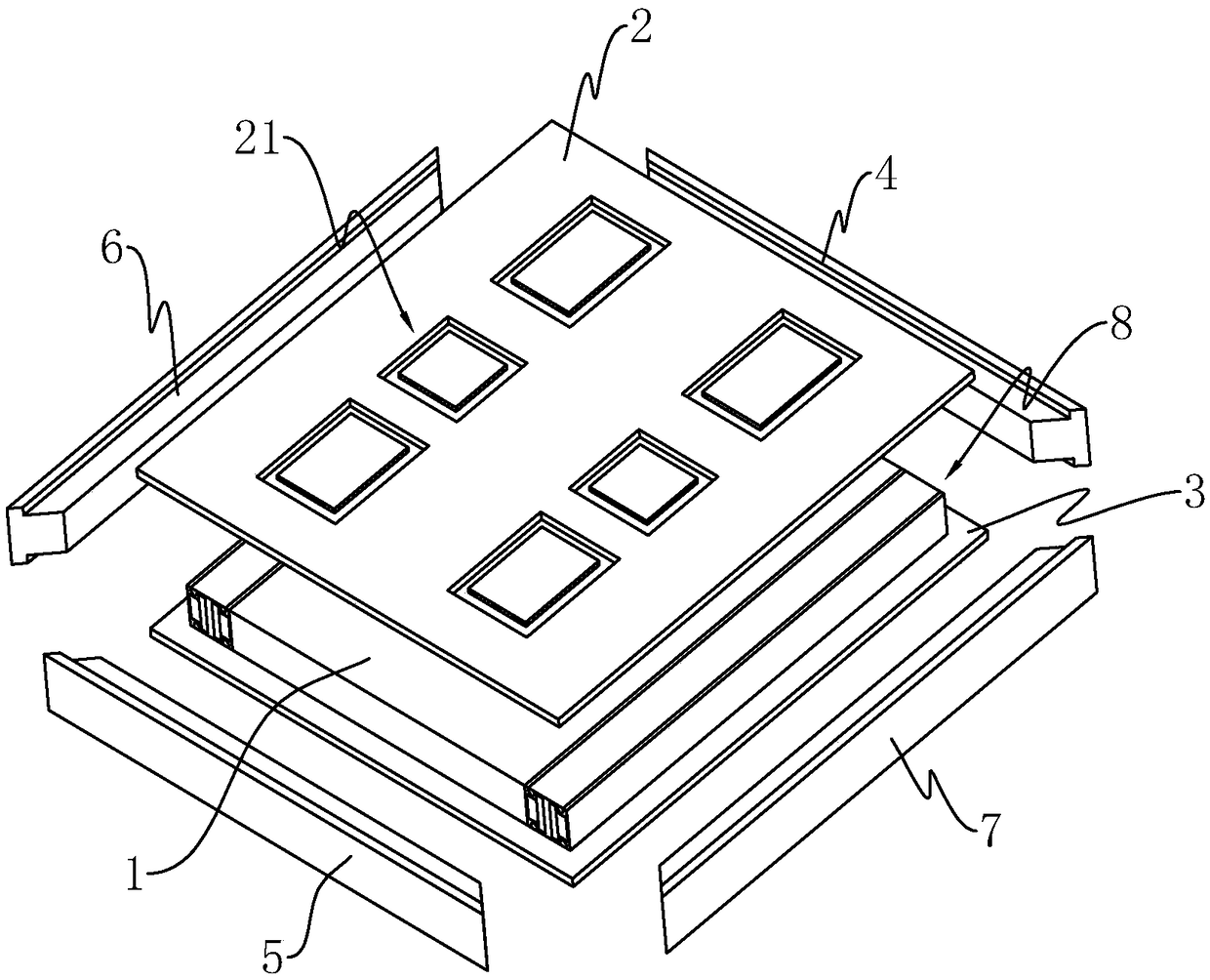

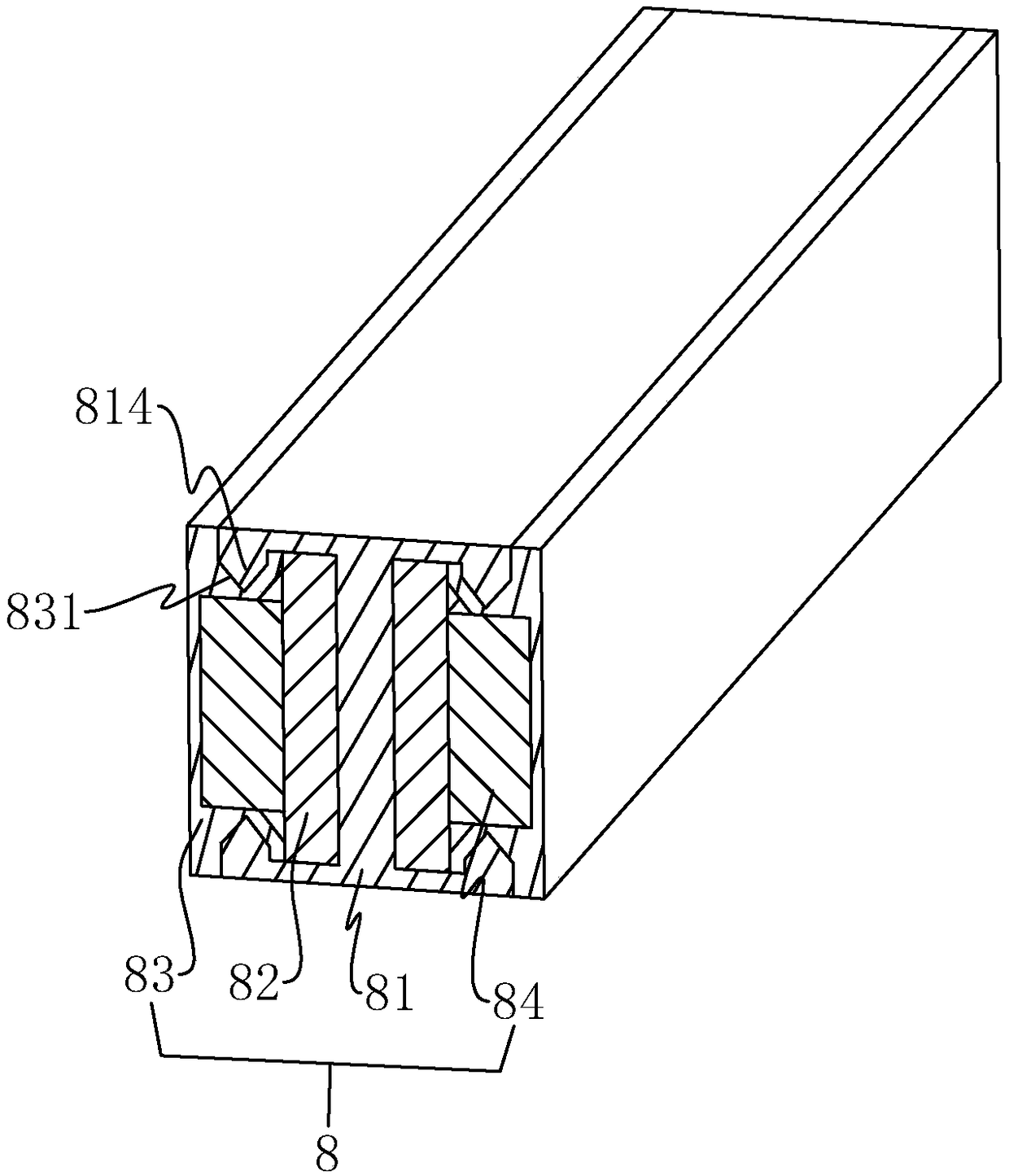

[0037] See attached Figure 1-2 , a super-high profile door, comprising a core board 1, the two sides in the thickness direction of the core board 1 are respectively bonded and fixed with a first panel 2 and a second panel 3 by fireproof sealant; wherein, the first panel 2 faces away from the door The surface of the core board 1 is formed with textures 21 for decoration. The part of the first panel 2 and the second panel 3 located on the outer side of the door core board 1 is surrounded by a reserved gap, and the periphery of the door core board 1 is respectively provided with an upper sealing board 4, a lower sealing board 5, a left sealing board 6 and a The right cover plate 7; the upper cover plate 4, the lower cover plate 5, the left cover plate 6 and the right cover plate 7 are all embedded in the reserved gap, and bonded with the first panel 2 and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com