Shell structure for 3C (Computer, Communication and Consumer electronic) products

A shell and product technology, applied in the direction of electrical equipment shells/cabinets/drawers, electrical components, etc., can solve the problems of volume reduction, high material cost, overall shell volume and weight increase, etc., to reduce thickness, reduce material costs, reduce The effect of overall volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

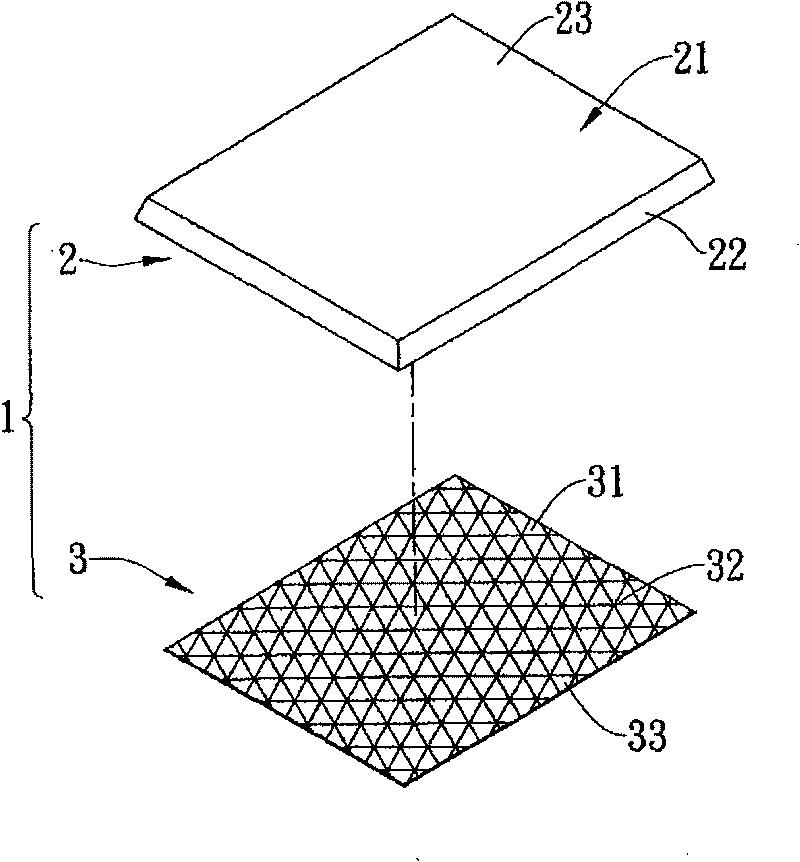

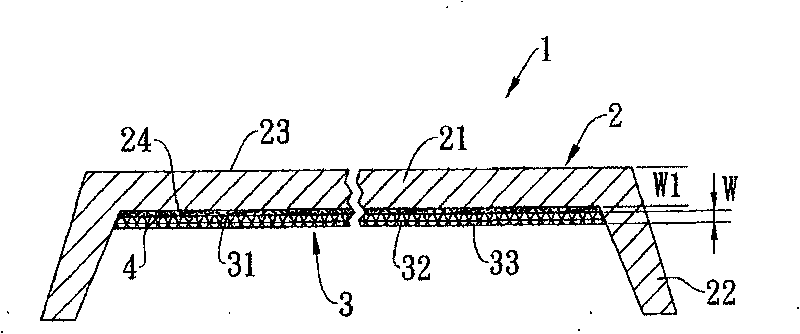

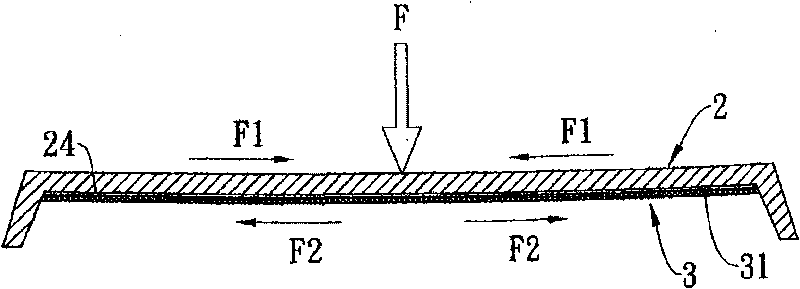

[0016] see figure 1 , 2 As shown, it is a preferred embodiment of the shell structure 1 of the 3C product of the present invention, including a plastic molded part 2 and a support plate 3 .

[0017] The plastic molded part 2 is molded by plastic injection, and includes a rectangular panel 21 and sides 22 extending downwards from the sides of the panel 21 to serve as a top cover for a notebook computer and form an outer surface 23 and an inner surface 24 opposite to the outer surface 23 . In practice, the plastic molded part 2 can also be in other shapes, and can be used as a structural material for various 3C products such as computers, electronics and communications, so as to protect the electronic components inside the 3C products.

[0018] The support plate 3 is in the shape of a thin plate, and the support plate 3 can also be a flat thin plate with holes or unevenness, the thickness of the plate is between 0.08 ~ 0.5mm, the thickness W of the support plate 3 Thinner tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com