Pretreated carbonaceous gold concentrate, preparation method thereof and gold extraction method

A gold concentrate and pretreatment technology, applied in the field of pretreatment of carbonaceous gold concentrate and its preparation, can solve the problems of high process energy consumption and high cost, and achieve the effects of improving reaction efficiency, eliminating influence and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The gold extraction method of the present embodiment, the steps are as follows:

[0049] 1. Prepare multiple cylindrical ore samples. During preparation, 6g of carbonaceous gold concentrate powder is pressed into a Ф2cm×1cm cylindrical ore sample by using a FYD-40-A desktop powder tablet press at 6MPa, and the cylindrical ore The samples were dried in a blast drying oven at 105°C for 12 hours;

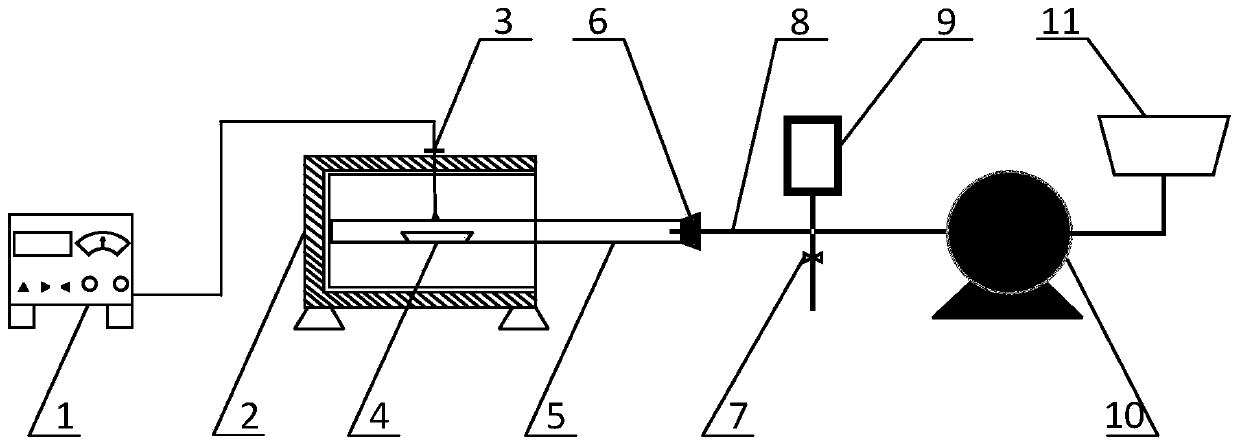

[0050] 2. Put the dried ore sample in the corundum porcelain boat 4 and put it into the quartz tube 5 of the vacuum tube furnace 2. The vacuum degree in the quartz tube 5 is kept at no more than 20Pa, and the vacuum pump is turned on to raise the temperature to 1000°C for the roasting experiment. After the calcination temperature was maintained for 50 minutes, the sample was cooled to room temperature with the furnace, and the rotary vane vacuum pump 10 was turned off. When firing, put every 2 samples in a corundum porcelain boat 4, and fire 4 samples each time, firing 3 times....

Embodiment 2

[0054] The gold extraction method of the present embodiment, the steps are as follows:

[0055] 1. Prepare multiple cylindrical ore samples. During preparation, 6g of carbonaceous gold concentrate powder is pressed into a Ф2cm×1cm cylindrical ore sample by using a FYD-40-A desktop powder tablet press at 6MPa, and the cylindrical ore The samples were dried in a blast drying oven at 105°C for 12 hours;

[0056] 2. Put the dried ore sample in the corundum porcelain boat 4 and put it into the quartz tube 5 of the vacuum tube furnace 2. The vacuum degree in the quartz tube 5 is kept at no more than 20Pa, and the vacuum pump is turned on to raise the temperature to 1100°C for the roasting experiment. After the calcination temperature was maintained for 60 minutes, the sample was cooled to room temperature with the furnace, and the rotary vane vacuum pump 10 was turned off. When firing, put every 2 samples in a corundum porcelain boat 4, and fire 4 samples each time, firing 3 times....

Embodiment 3

[0060] The gold extraction method of the present embodiment, the steps are as follows:

[0061] 1. Prepare multiple cylindrical ore samples. During preparation, 6g of carbonaceous gold concentrate powder is pressed into a Ф2cm×1cm cylindrical ore sample by using a FYD-40-A desktop powder tablet press at 6MPa, and the cylindrical ore The samples were dried in a blast drying oven at 105°C for 12 hours;

[0062] 2. Put the dried ore sample in the corundum porcelain boat 4 and put it into the quartz tube 5 of the vacuum tube furnace 2. The vacuum degree in the quartz tube 5 is kept at no more than 20Pa, and the vacuum pump is turned on to raise the temperature to 1100°C for the roasting experiment. After the calcination temperature was maintained for 70 minutes, the sample was cooled to room temperature with the furnace, and the rotary vane vacuum pump 10 was turned off. When firing, put every 2 samples in a corundum porcelain boat 4, and fire 4 samples each time, firing 3 times....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com