Design and construction method of whole bundle type straw gasification device

A technology of a gasification device and a construction method, which is applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of complex manufacturing optimization and design of the whole bundle type straw gasification system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

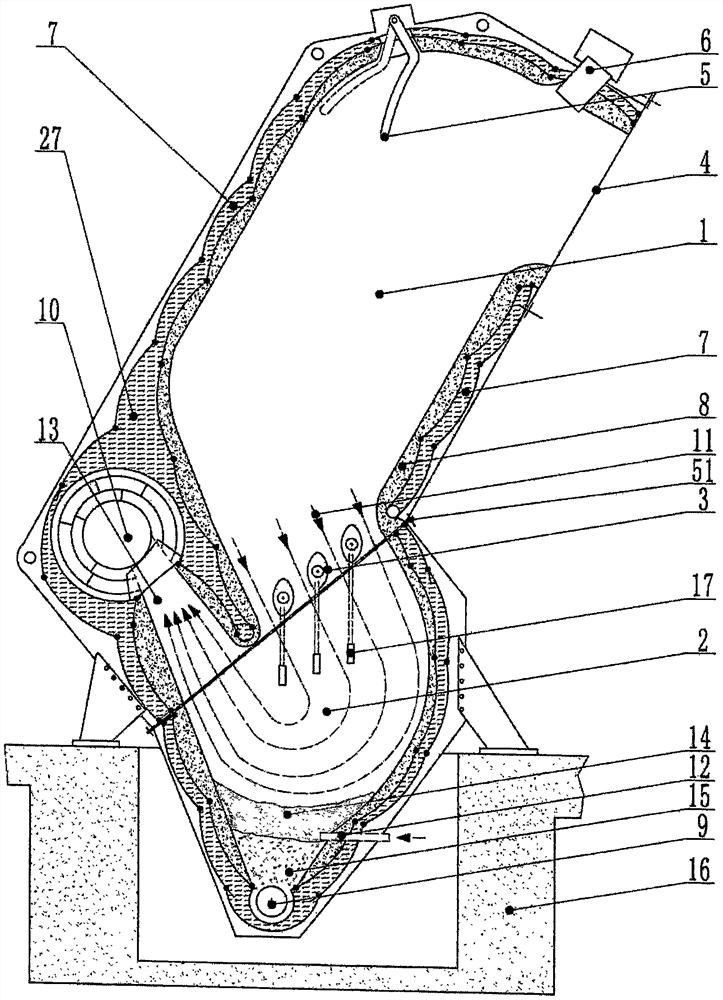

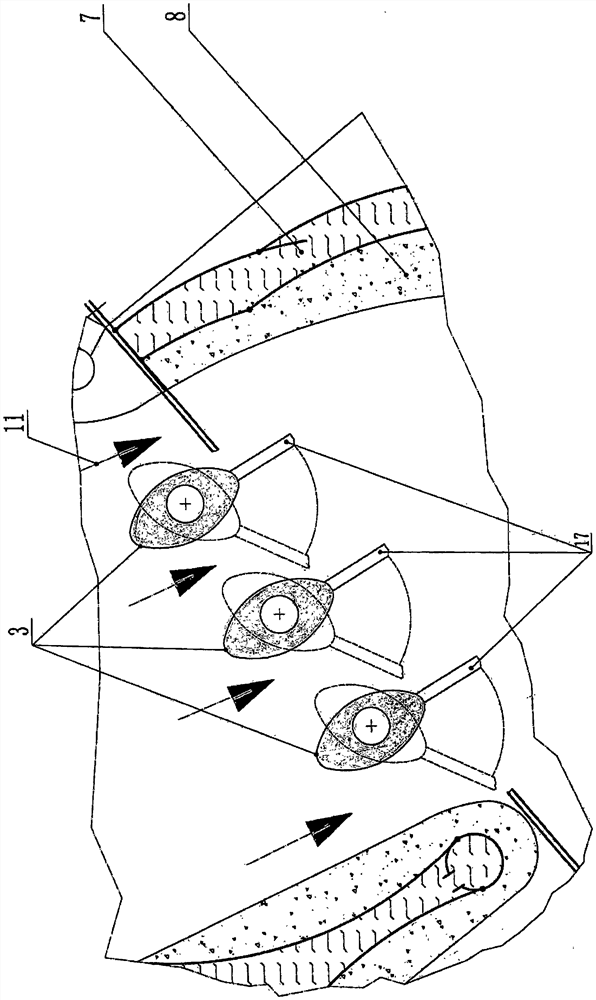

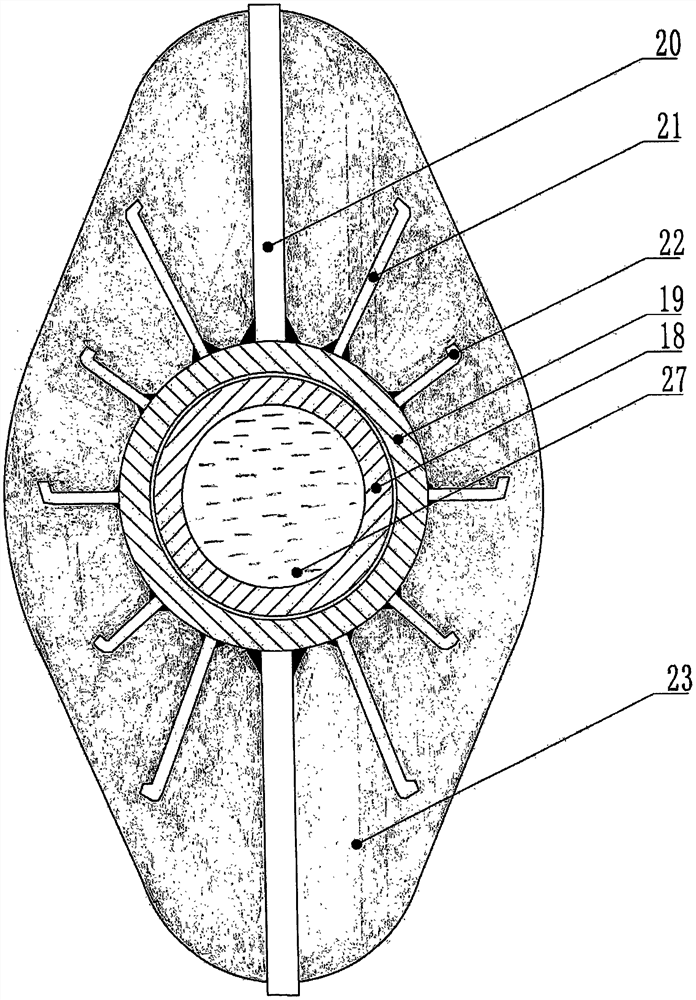

[0032] Application examples of the present invention will be explained in more detail below with reference to the drawings.

[0033] according to figure 1 The bundled straw gasification device has a rated thermal output of 4.7MW and a maximum thermal output of 5.3MW. The whole bale straw gasification chamber (1) can enter two straw round bales with a length of about 1.2 meters and a diameter of about 1.4 meters side by side at one time, and can accommodate up to 16 straws with a length of about 1.2 meters and a diameter of about 1.4 meters at a time. bale( figure 1 not shown).

[0034] The gasification of straw with a large capacity of more than 3000kg at one time can make the intensity of straw gasification very small, and only need a relatively low gasification temperature to generate a sufficient amount of combustible flue gas (11), which can avoid gasification to the greatest extent Coke is formed in the process and the ash remains essentially powdery and of high fertil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com