Gantry type circular stockyard material piling and taking machine

A circular stockyard and gantry-type technology, applied in the field of gantry-type circular stockyard stackers and reclaimers, can solve the problems of easy jamming and insufficient pressure bearing capacity, so as to increase the connection strength and prolong the service life , the effect of reducing the overall mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

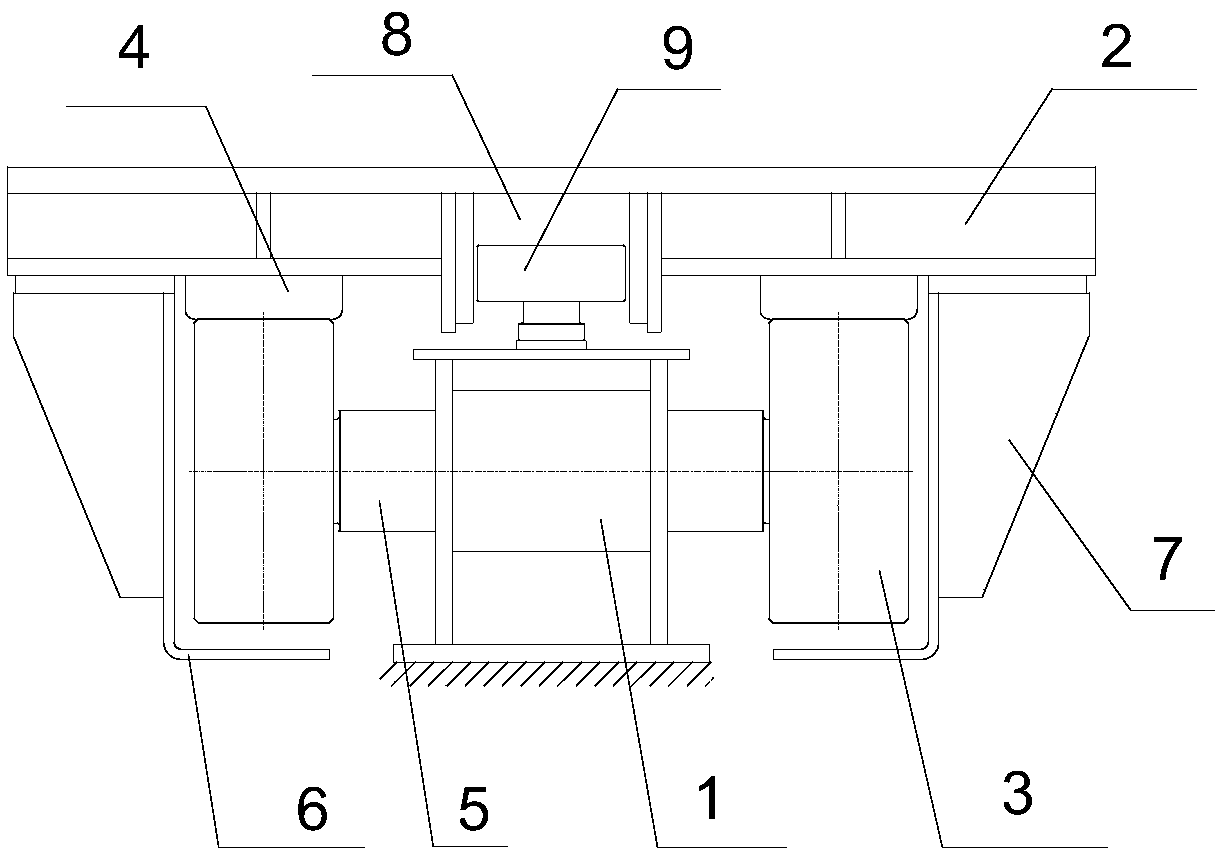

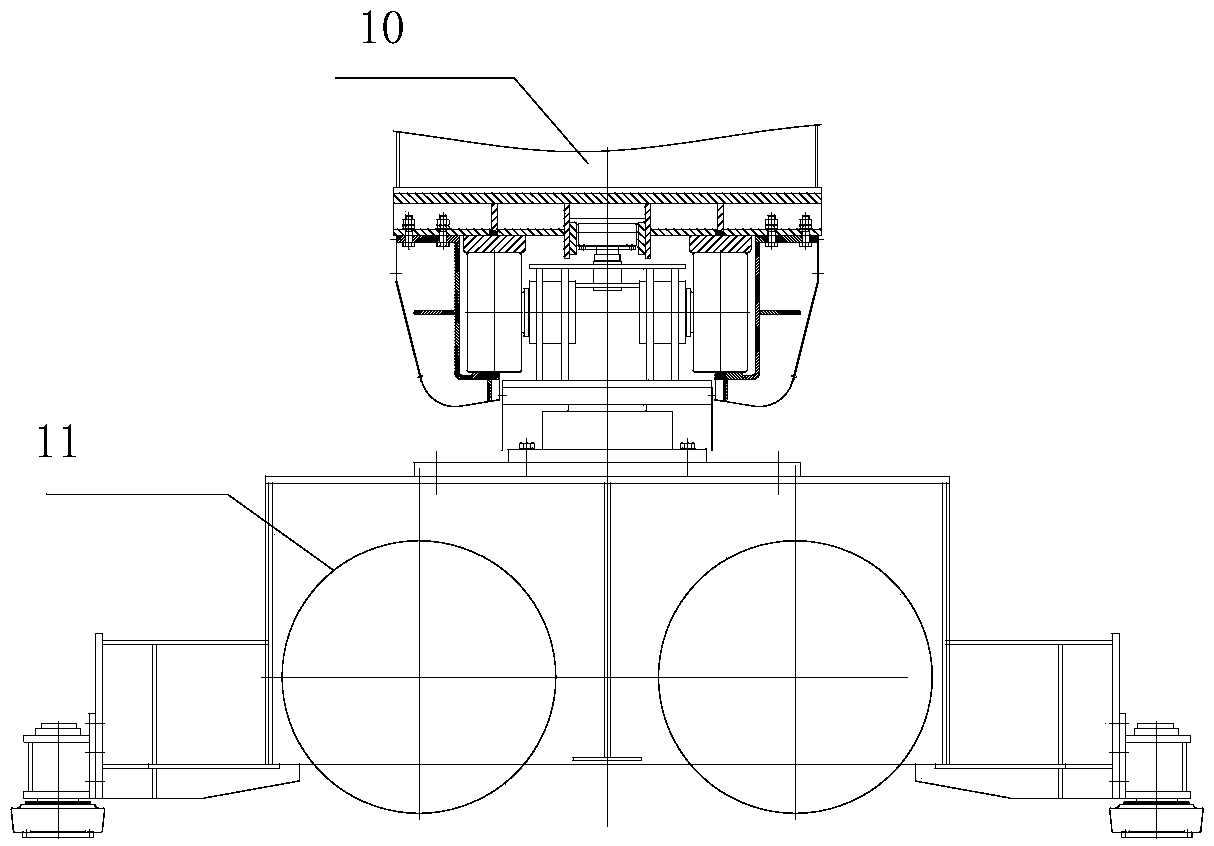

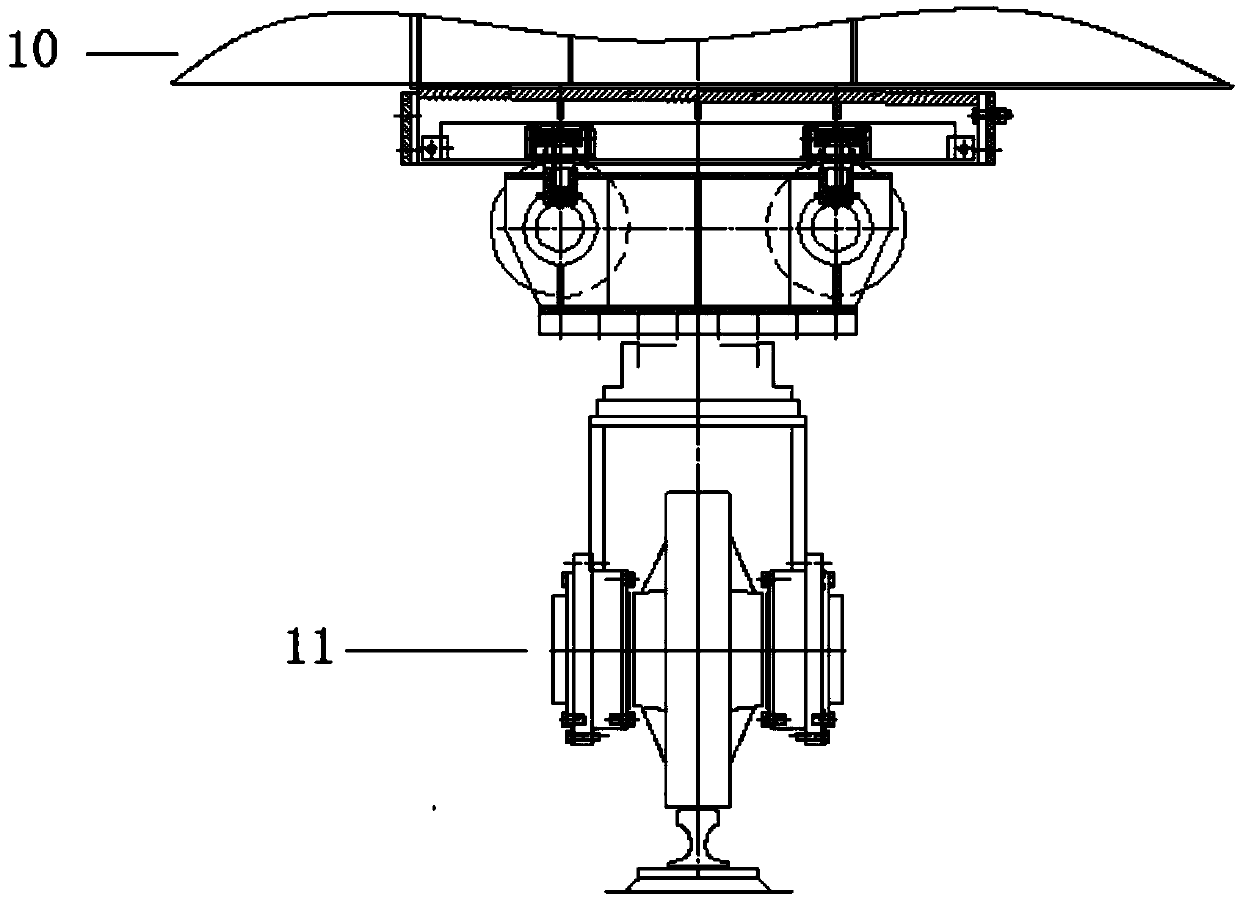

[0044] This embodiment provides a gantry-type circular stockyard stacker and reclaimer, including a circular track; a walking trolley 11, traveling along the circular track; a gantry 10, one end of which is rotatably connected to the The other end of the center of the circular track is movably connected with the walking trolley 11, and is driven by the walking trolley 11 to rotate around the center of the circular track; the follower device is arranged on the walking platform Between the vehicle 11 and the door frame 10, the door frame 10 and the walking trolley 11 are flexibly connected through the follow-up device, and the connection point of the door frame 10 can be connected relative to the walking trolley. 11 is displaced along the radial direction of the circular track; the follow-up device includes a bracket 1, the lower end of which is connected to the walking trolley 11; a top frame 2 is arranged above the bracket 1 and connected to On the door frame 10 : the rolling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com