High-strength and low-rigidity porous titanium implant

A technology of porous titanium and implants, applied in the fields of dental implants, medical science, dentistry, etc., can solve problems such as failure of dental implants, failure to guarantee the mechanical strength of implants, etc., and achieve the effect of improving the success rate and good stress environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A high-strength and low-rigidity porous titanium implant provided by the present invention will be further described in detail through examples below.

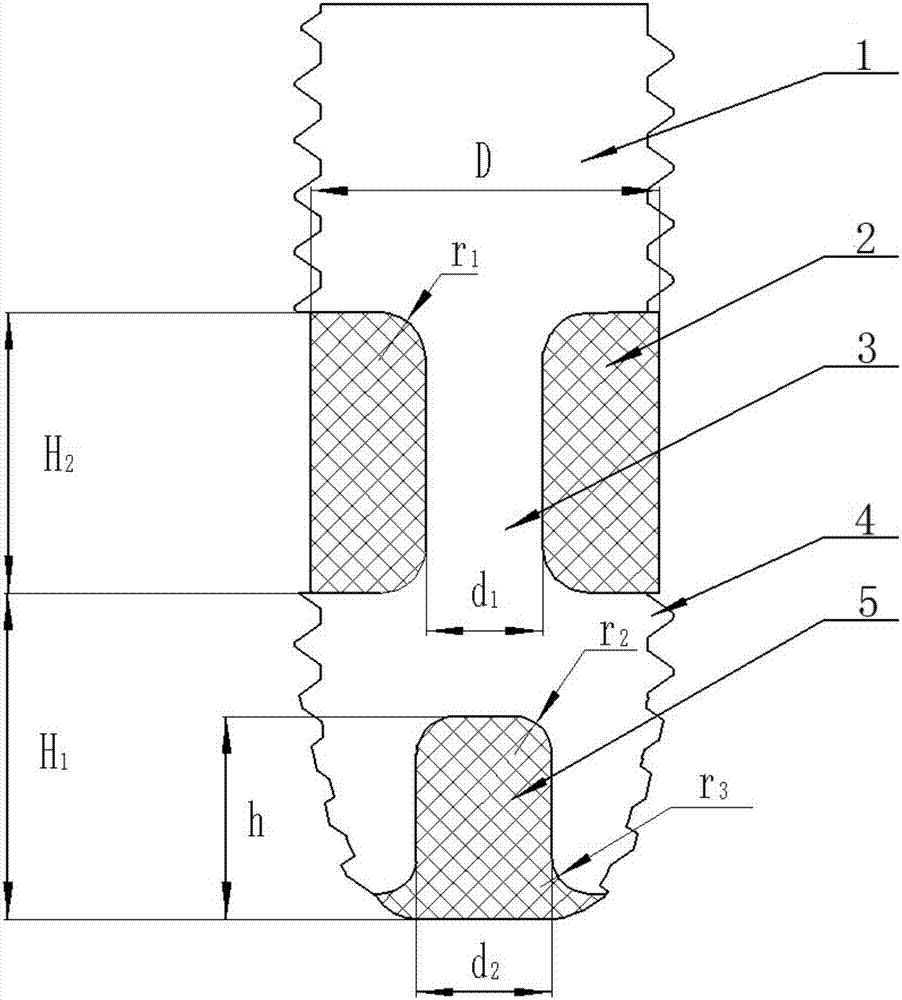

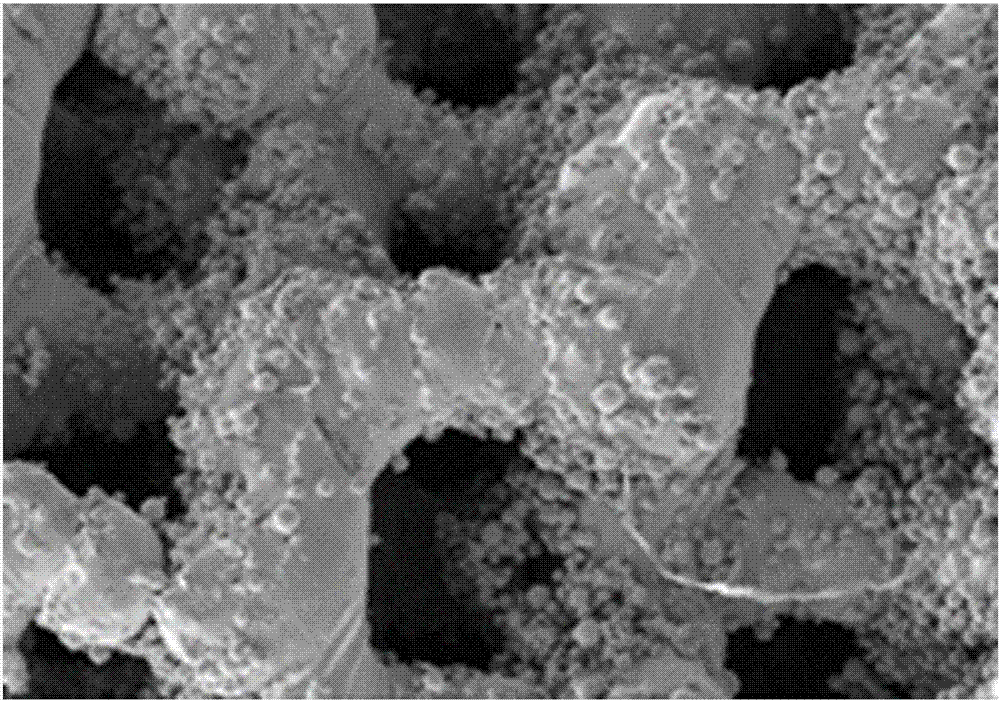

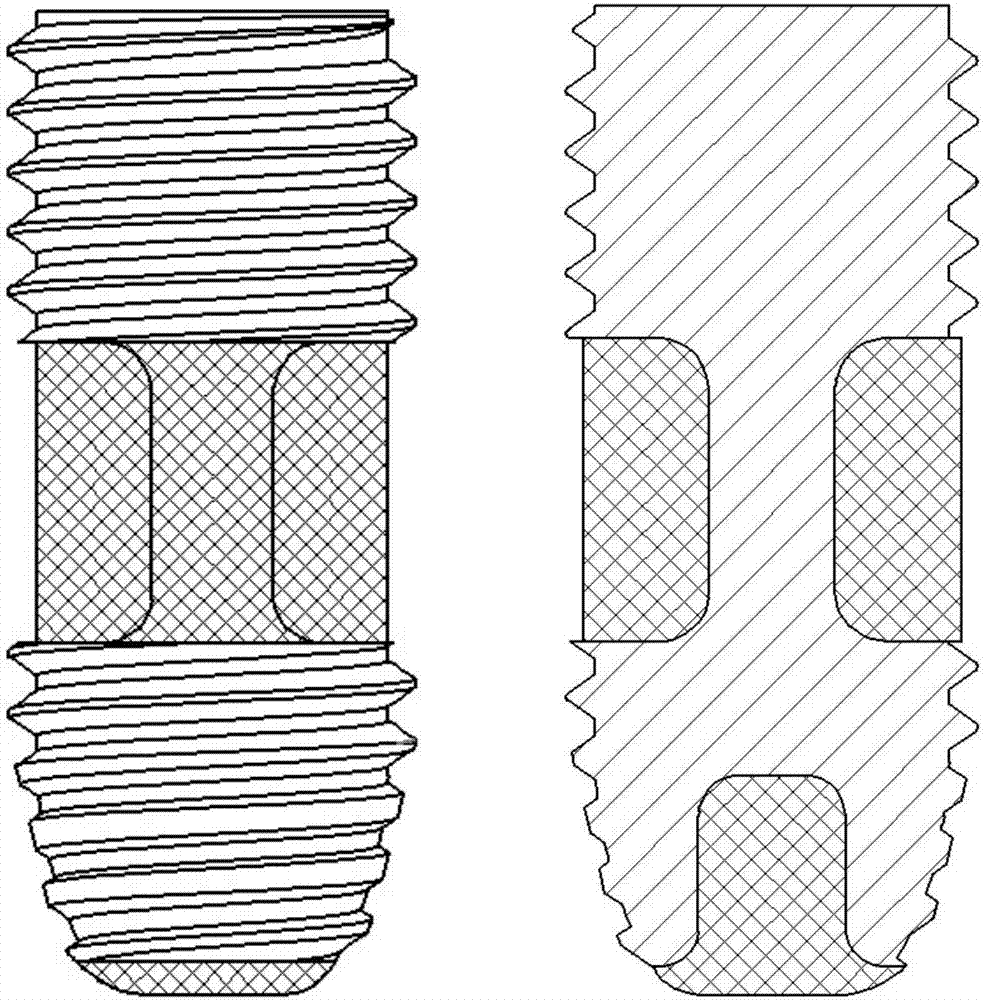

[0025] The material of the porous titanium implant is Ti-6Al-4V, which is obtained by 3D printing by laser selective melting technology. The titanium substrate is a screw with a diameter of 4.5 mm and a height of 12.5 mm. The threaded part is modified. The middle porous structure 2 is a porous cylinder with a height of 4 mm and a diameter equal to the diameter of the threaded part 1. The diameter of the tip porous structure 5 is 1.5 mm. The depth is 3mm. The pore diameters of the porous structure parts were all 500 μm. The supporting structure part is a solid cylinder with a diameter of 2 mm. After measurement, the structural stiffness of the porous titanium implant is about 26GPa, and the compressive strength is about 715MPa.

[0026] If the implant is a pure titanium solid structure, the material is Ti-6Al-4V, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com