Patents

Literature

42results about How to "Sufficient impact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sheet for card, and card

InactiveUS20130075480A1Excellent in of of embossabilityImprove heat resistanceSynthetic resin layered productsBooksCard stockPolymer science

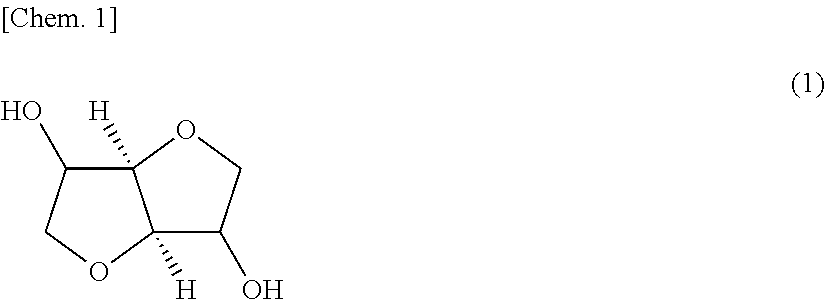

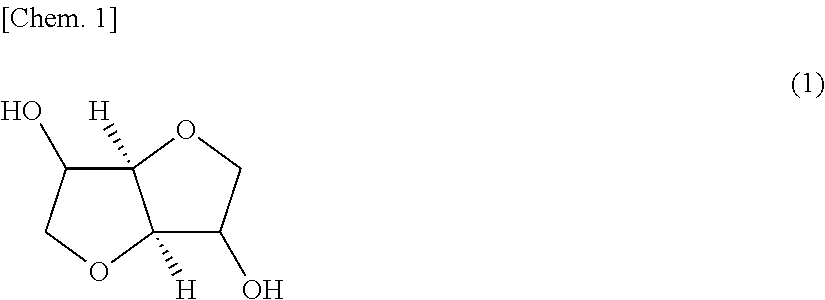

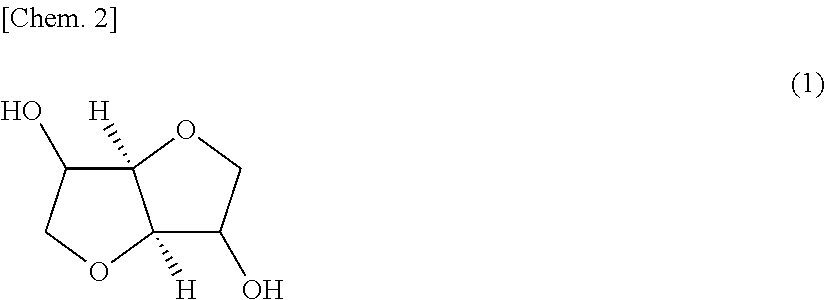

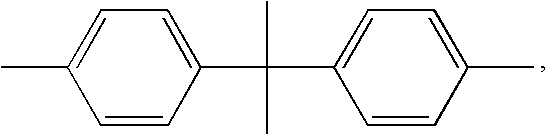

The invention is to provide a sheet for cards which is excellent in terms of all of heat resistance, weatherability, rigidity, punchability, and embossability and which employs a plant-derived resin, and to provide a card. The invention relates to a sheet for cards which has a layer constituted of a resin composition (X) containing, as a main component, a polycarbonate resin (A) that contains structural units (a) derived from a dihydroxy compound represented by the following formula (1) and that has a glass transition temperature lower than 130° C.

Owner:MITSUBISHI CHEM CORP +1

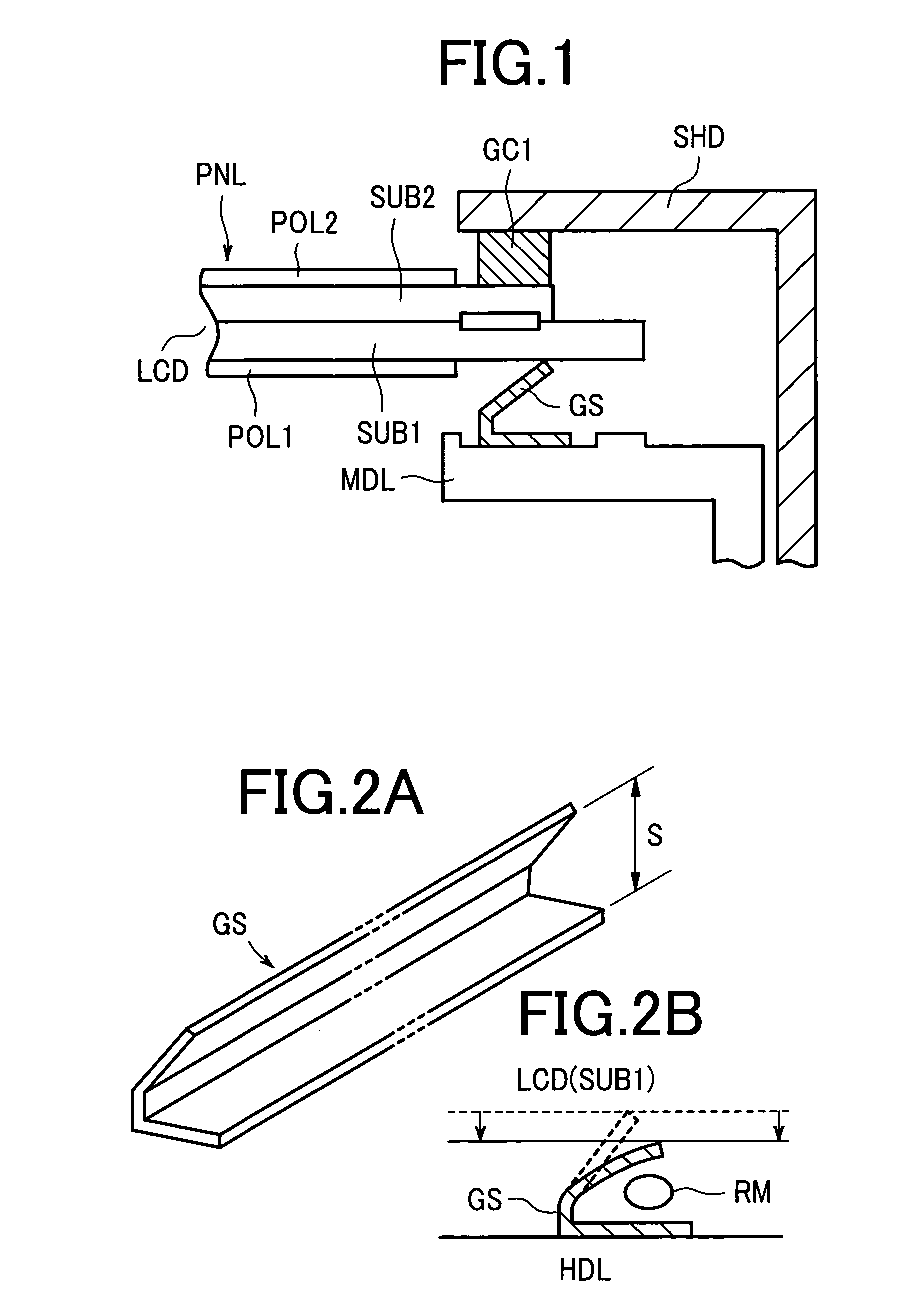

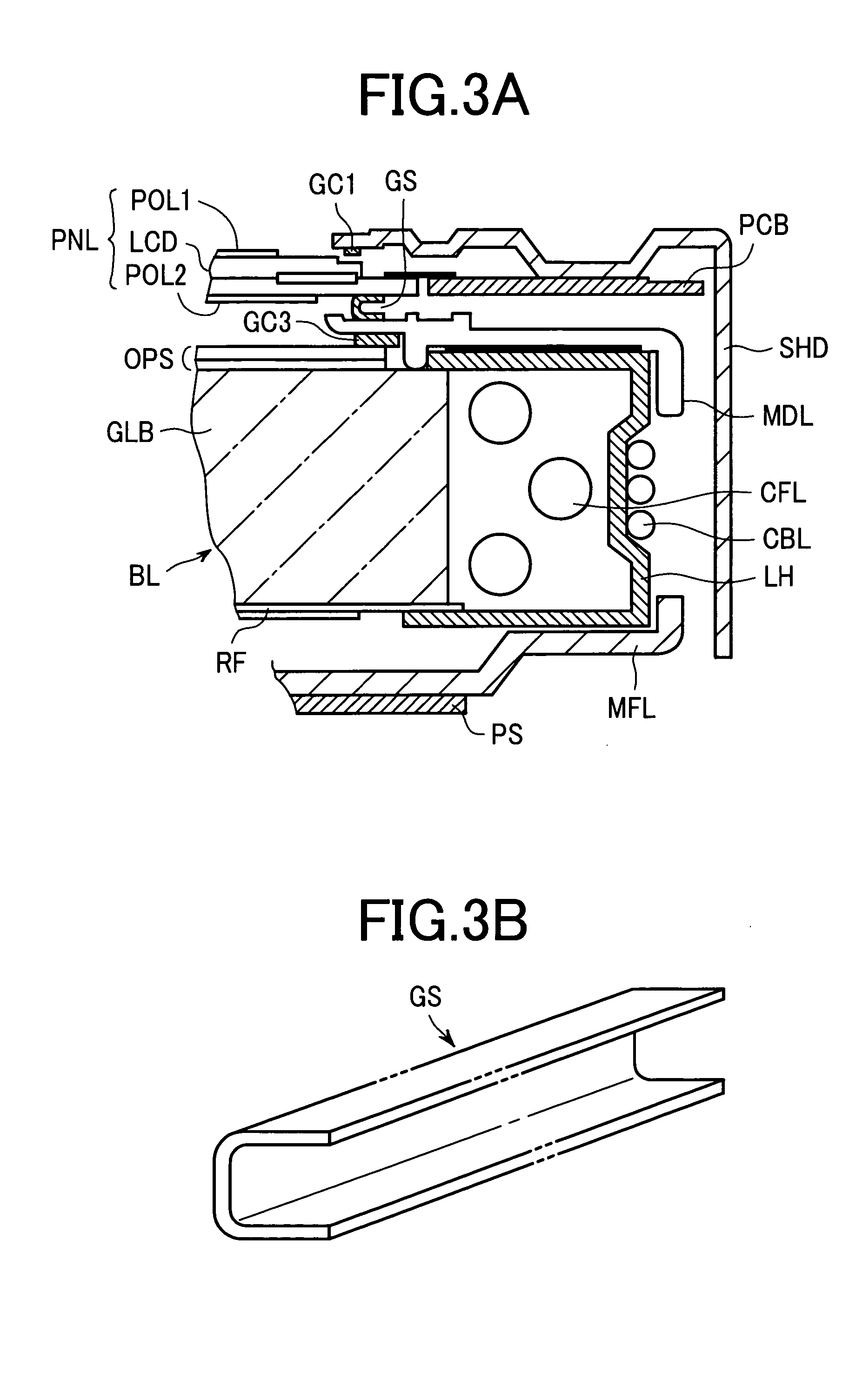

Display device

InactiveUS20050062899A1Sufficient impact resistanceAvoid pressureNon-linear opticsIdentification meansLiquid-crystal displayDisplay device

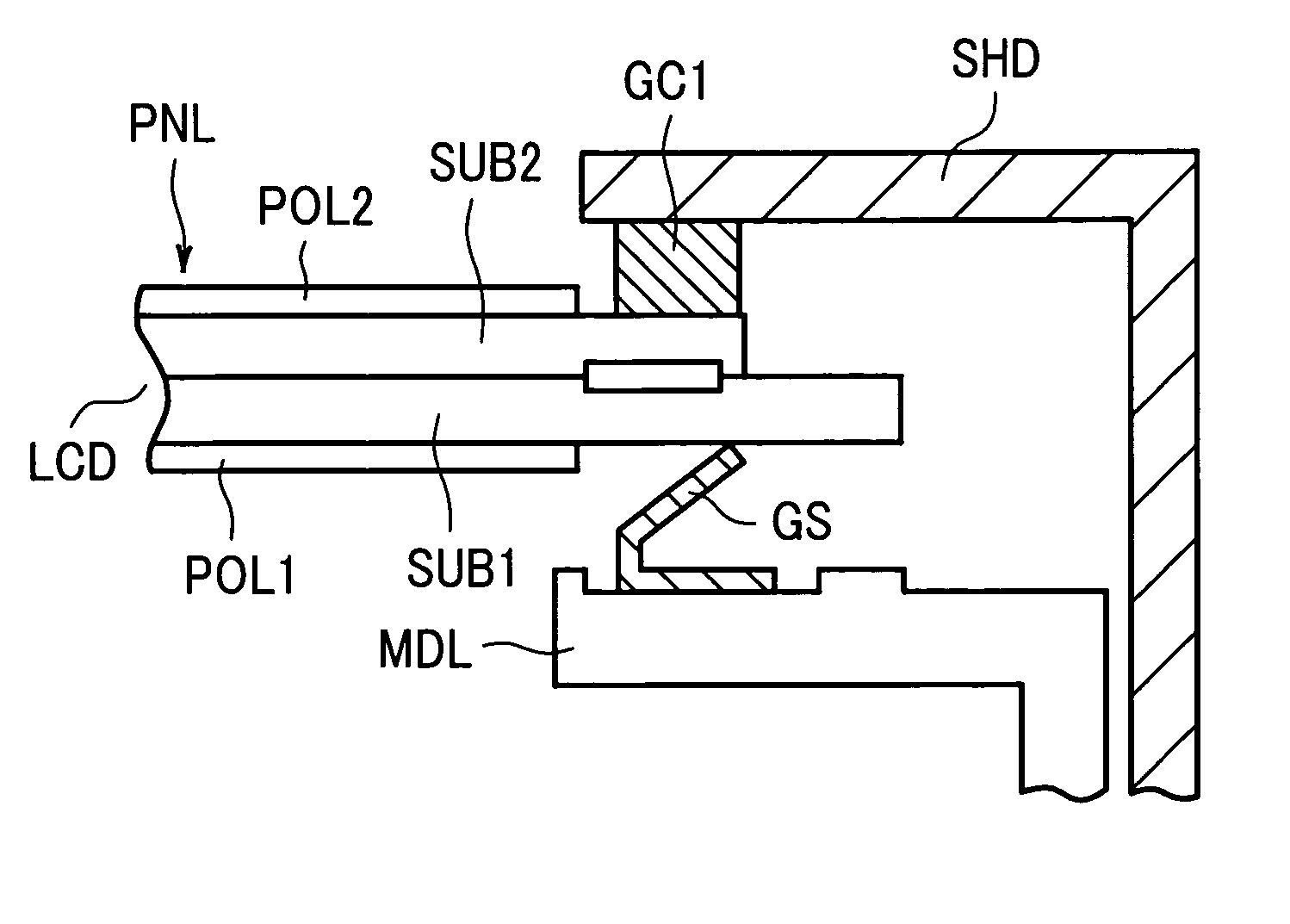

A defective display is obviated by preventing the intrusion of a foreign substance in a gap defined between a constitutional member, such as an upper frame, an intermediate frame, a backlight device or the like, and a display panel and by suppressing the application of a stress to the display panel. A shaped elastic member is interposed between a liquid crystal display panel and a mold of a backlight device. One longitudinal side surface of the shaped elastic member is fixedly mounted on the backlight device and the other longitudinal side surface of the shaped elastic member is non-fixedly mounted on the liquid crystal display panel, such that the other longitudinal side surface is always brought into contact with the liquid crystal display panel to prevent the generation of a gap therebetween.

Owner:HITACHI DISPLAYS

Sealing Material for Solar Battery, Sheet for Sealing Solar Battery, and Solar Battery Module Using the Same

ActiveUS20090165847A1Reducing neck-inImprove productivityOther chemical processesPV power plantsPhysical chemistryEngineering

[Task] To provide a solar battery sealing material obtained by using an olefin-based (co)polymer, which is excellent in flexibility, stress-absorbing property, transparency, and impact-resistant strength at low temperature, and with which the productivity is improved by omitting a cross-linking treatment if necessary.[Solving Means] A solar battery sealing material containing 1 to 40 parts by weight of polypropylene (i) which has a propylene unit of more than 90 mol %; and 60 to 99 parts by weight of a propylene.ethylene-based copolymer (ii) which has a propylene unit of 45 to 90 mol %, an ethylene unit of 10 to 25 mol %, and an α-olefin unit (a) having 4 to 20 carbon atoms of 0 to 30 mol % ((i)+(ii)=100 parts by weight). The solar battery sealing material further contains 5 to 95 parts by weight of an ethylene.α-olefin copolymer (B), based on 95 to 5 parts by weight of the total amount of (i) and (ii) ((i)+(ii)+(B)=100 parts by weight).

Owner:MITSUI CHEM INC

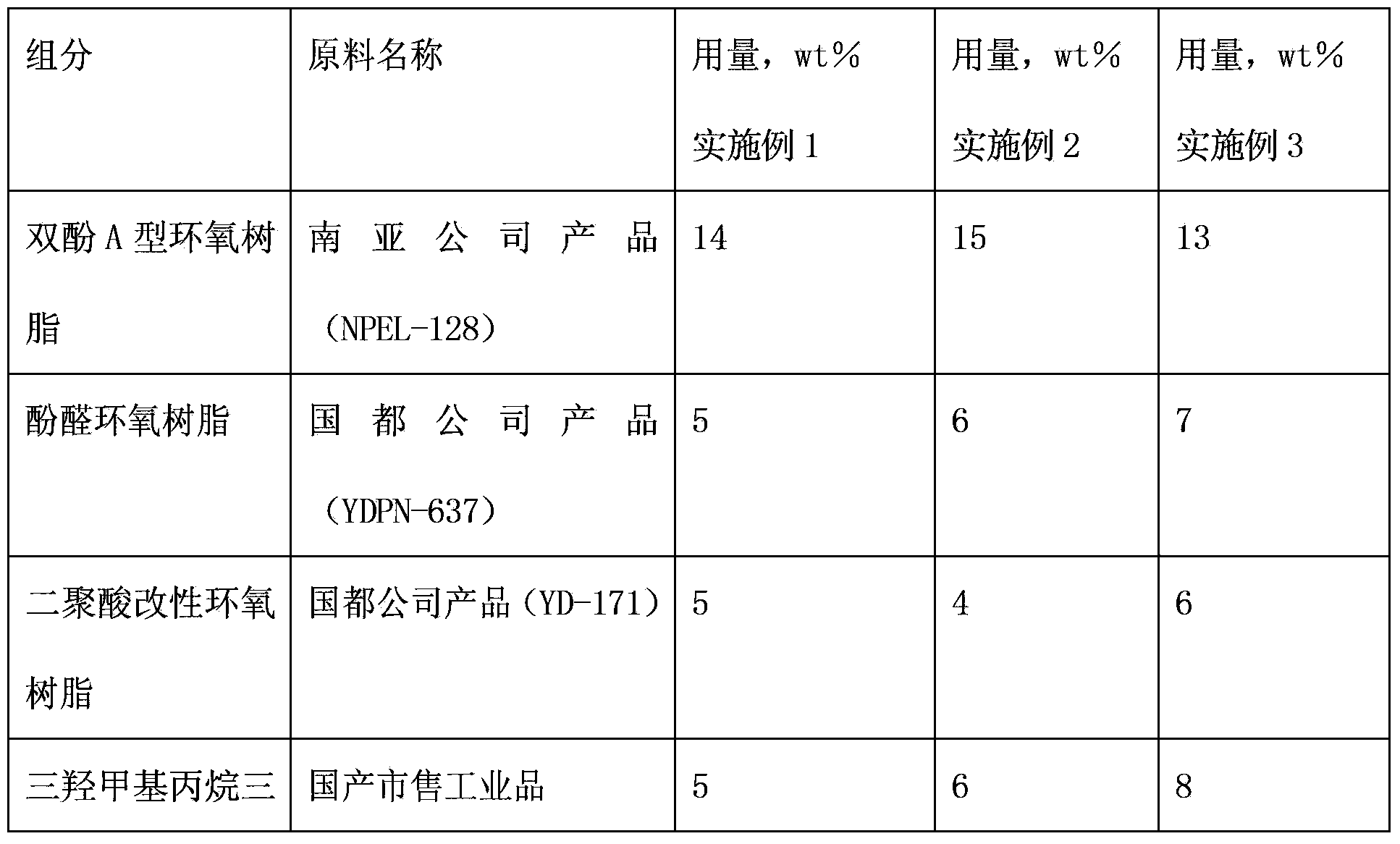

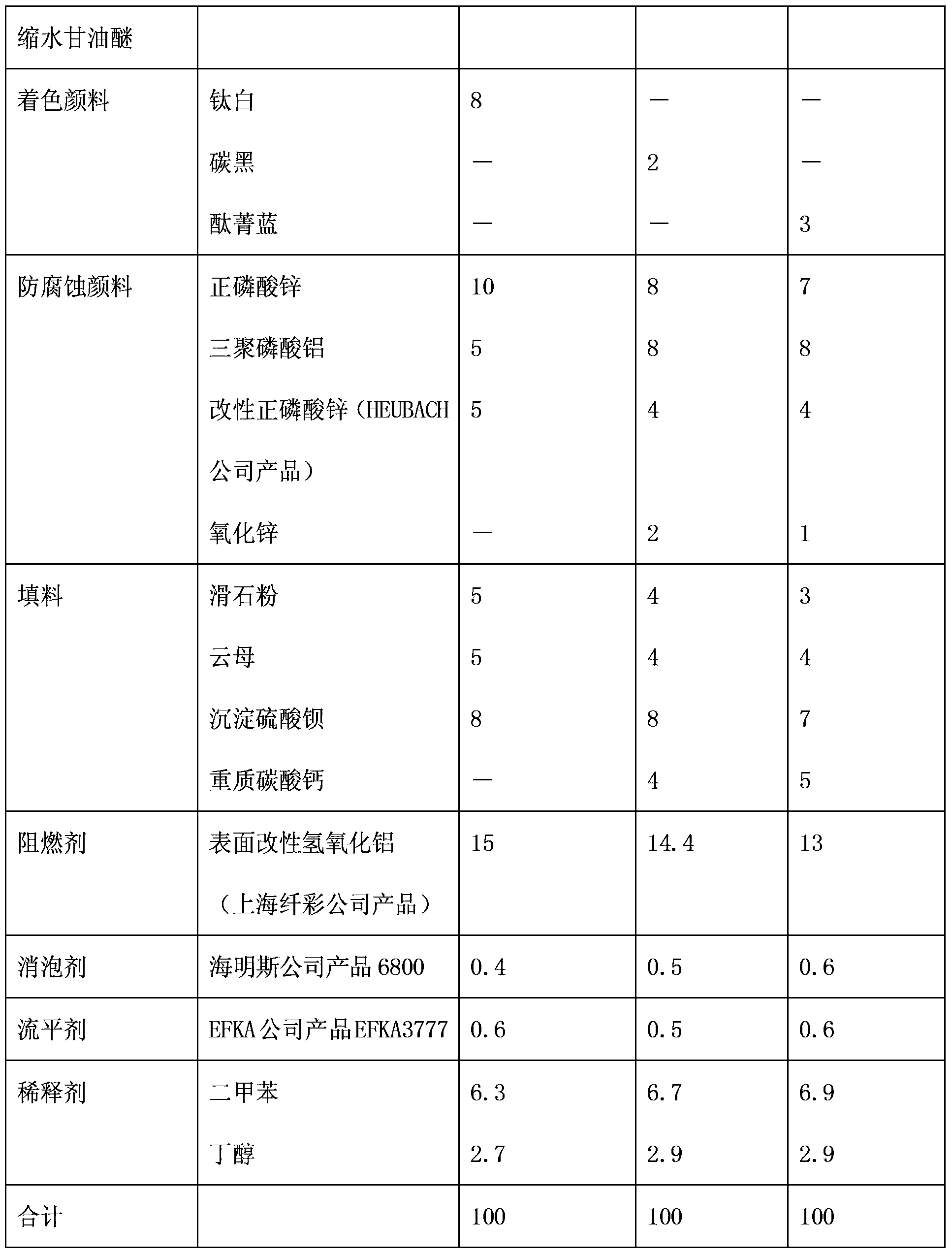

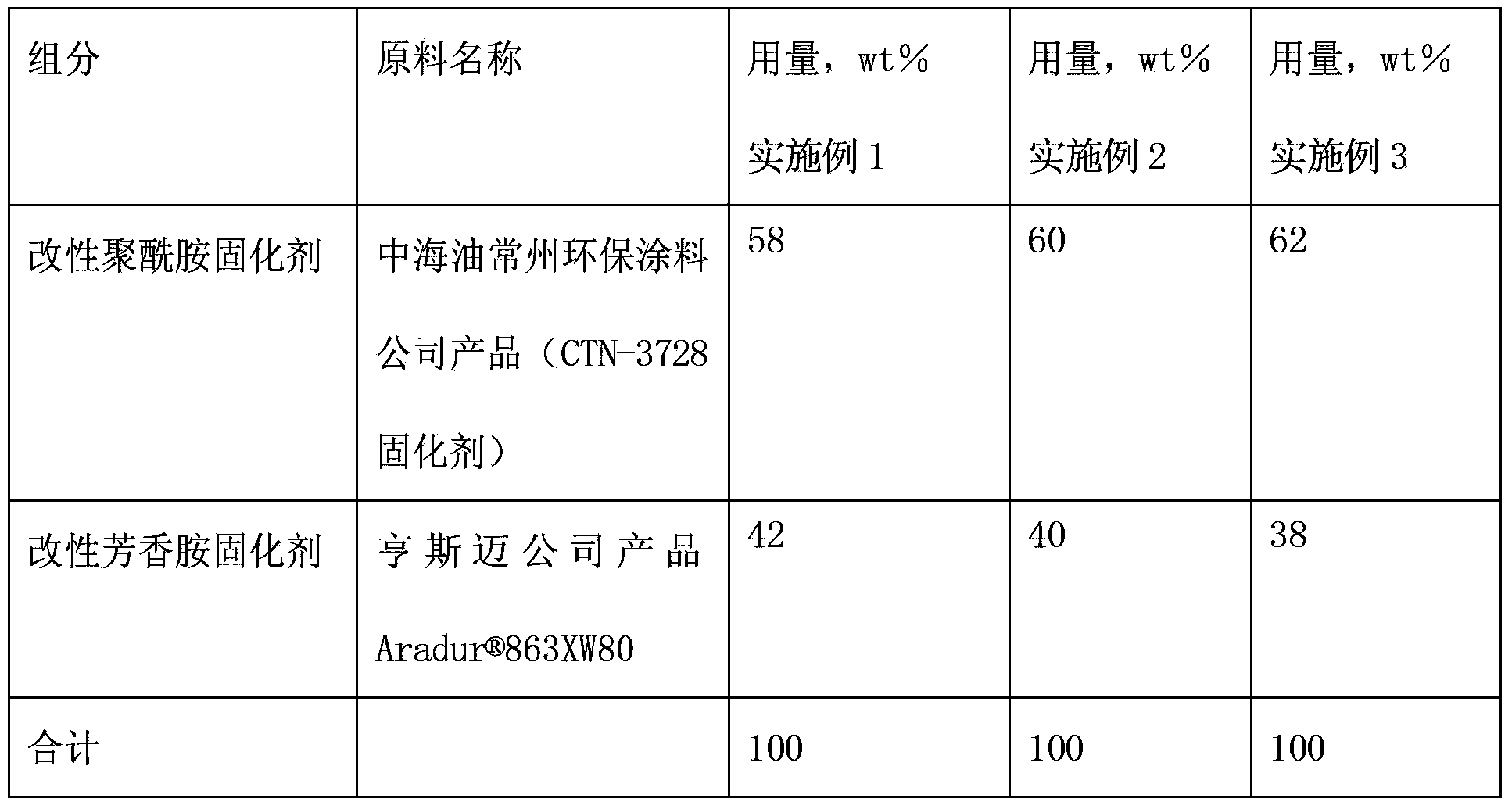

Radioresistant and anticorrosive primer-topcoat high-solid coating and preparation method thereof

ActiveCN103351788ALow viscosityMake up for the shortcomings of lack of flexibilityAnti-corrosive paintsEpoxy resin coatingsPolyamideFire retardant

The invention relates to a radioresistant and anticorrosive primer-topcoat high-solid coating and a preparation method thereof. The radioresistant and anticorrosive primer-topcoat high-solid coating comprises a component A and a component B, wherein the component A consists of the following components in percentage by mass: 12-18% of bisphenol A epoxy resin, 4-8% of novolac epoxy resin, 4-8% of dimeric dibasic acid modified epoxy resin, 5-10% of trimethylolpropane triglycidyl ether, 2-10% of a coloring pigment, 15-25% of an anticorrosive pigment, 15-25% of a filler, 10-20% of a flame retardant, 0.3-0.8% of a defoaming agent, 0.3-0.8% of a leveling agent and 5-10% of a diluting agent; the component B consists of the following components in percentage by mass: 55-65% of a modified polyamide curing agent and 35-45% of a modified aromatic amine curing agent; before construction, the component A and the component B are uniformly mixed together according to a mass ratio of 3-4:1. The radioresistant and anticorrosive primer-topcoat high-solid coating has excellent radiation protection performance and strong decontaminating capability, passes through an analog DBA (design basis accident) test, has excellent corrosion resistance and is low in VOC (volatile organic compound) content.

Owner:CHINA NAT OFFSHORE OIL CORP +4

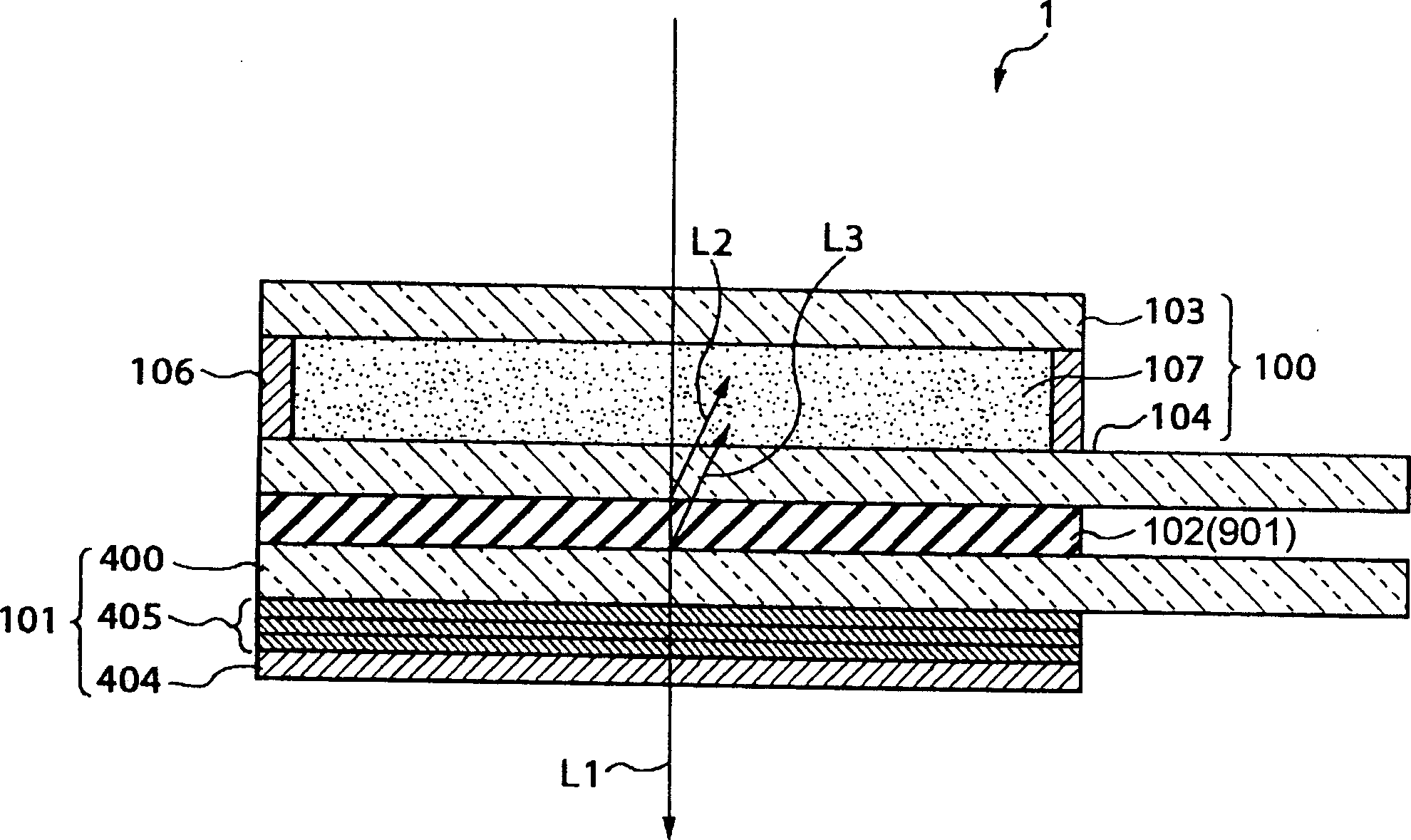

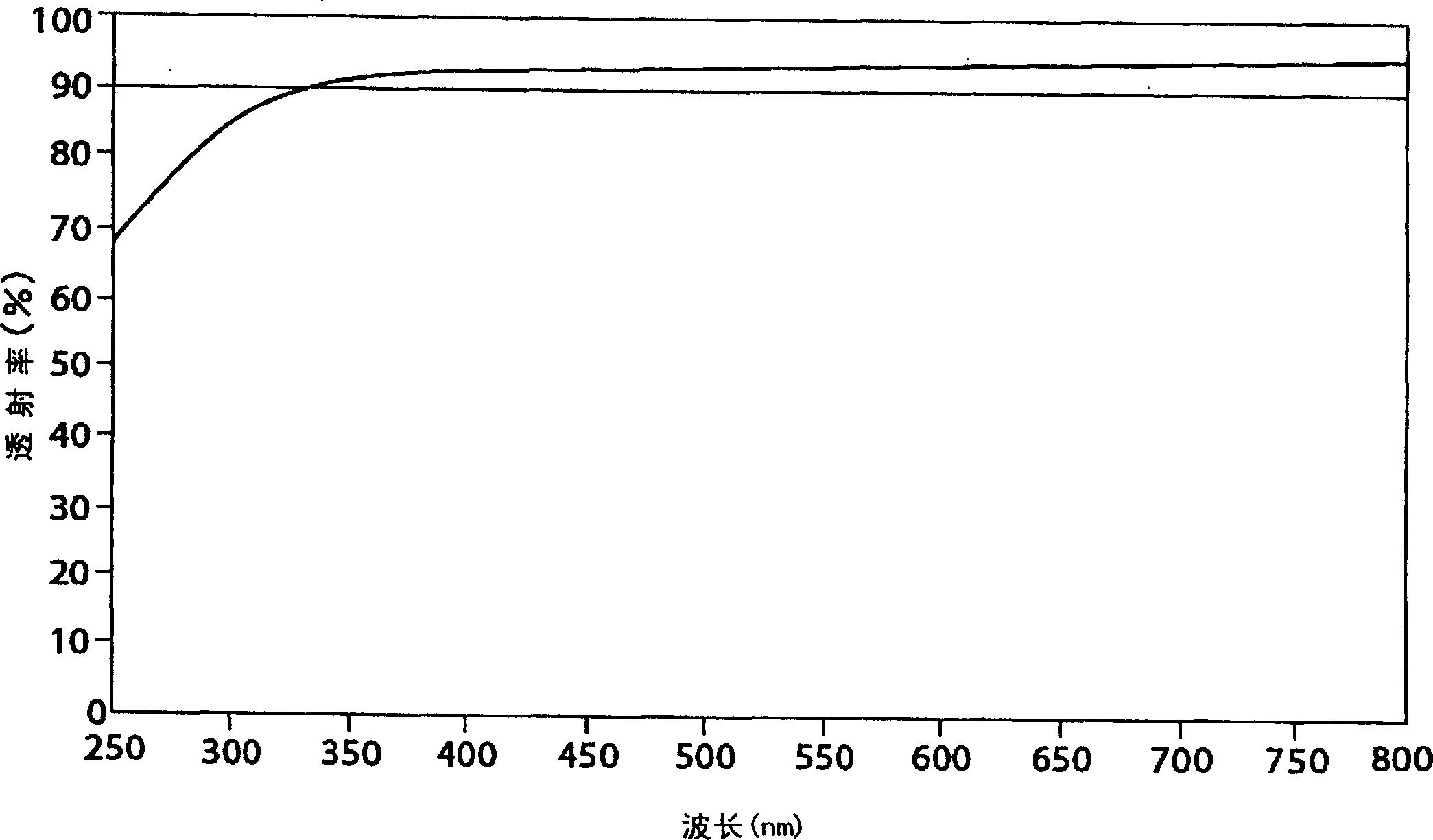

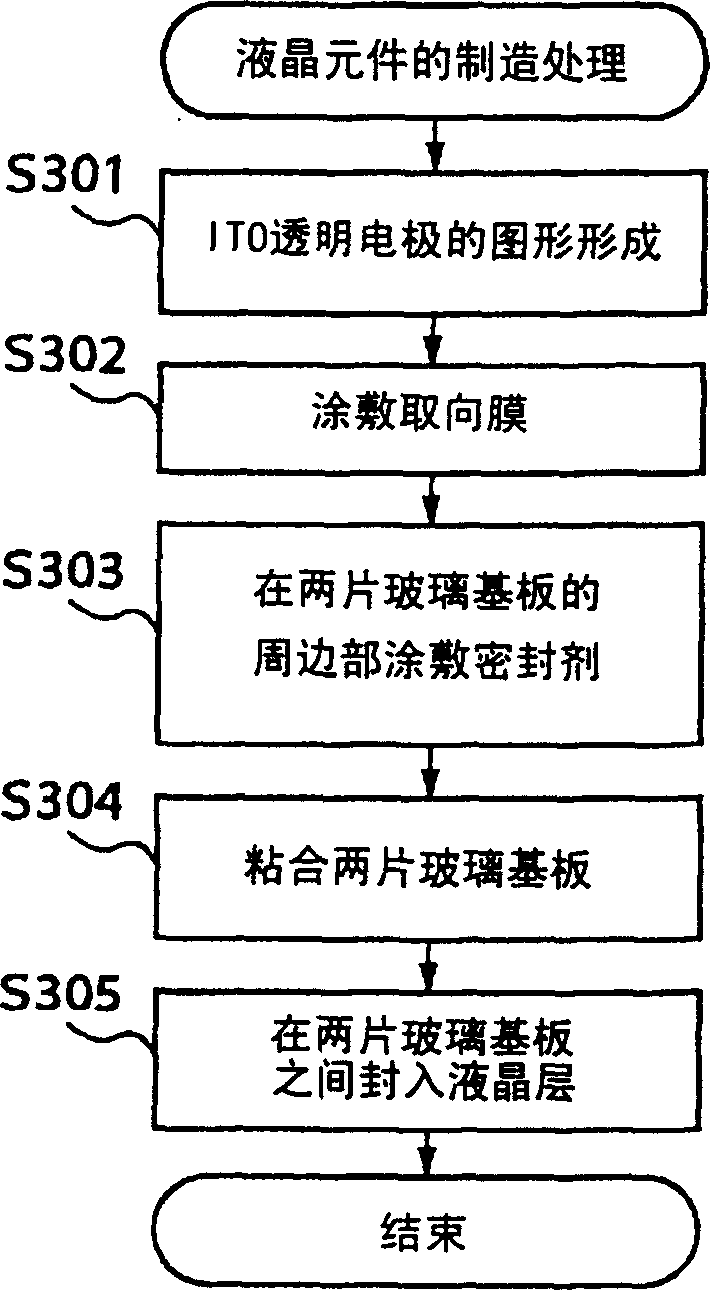

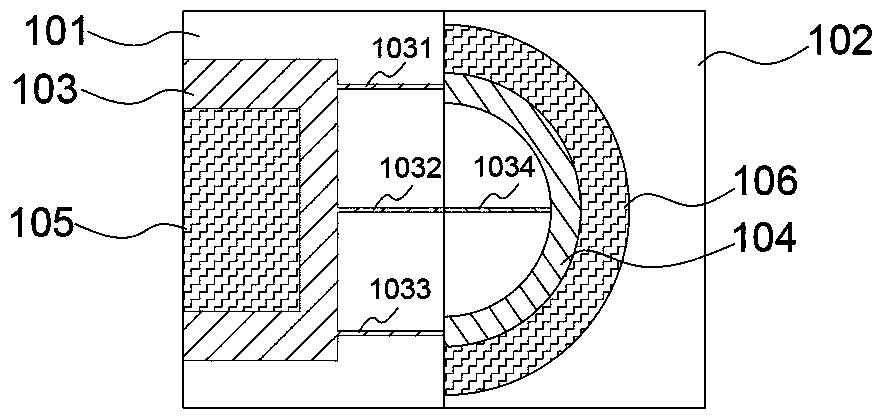

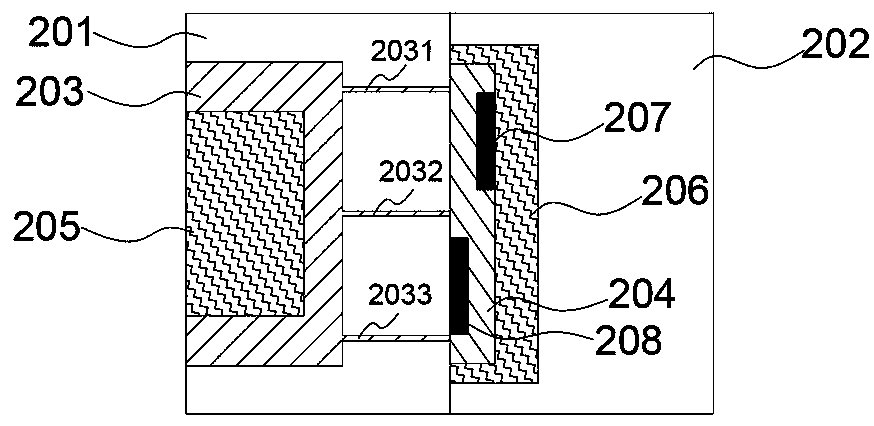

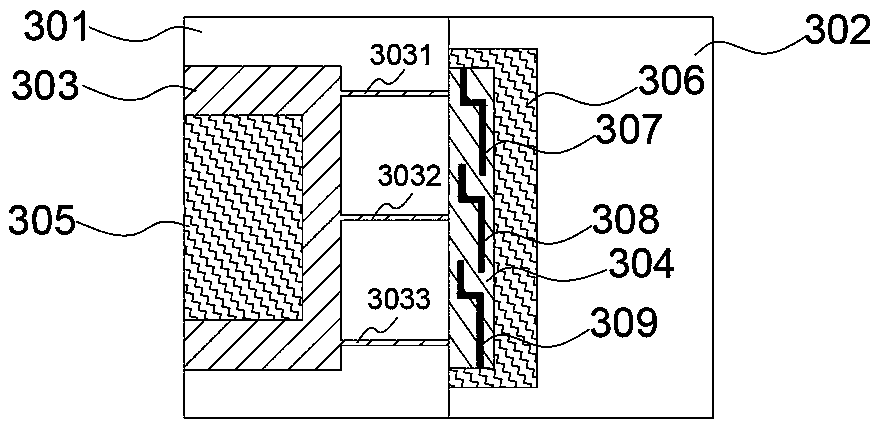

Reflective liquid crystal display device

InactiveCN1550848ALight transmittance does not decreaseSufficient impact resistanceStatic indicating devicesLife-savingLiquid-crystal displayTransmittance

Provided is a reflection type liquid crystal display capable of enhancing transmissivity of light transmitted from a liquid crystal element. The reflection type liquid crystal display 1 is provided with the liquid crystal element 100 having glass substrates 103 and 104 and a liquid crystal layer 107, a solar battery 101 provided with a glass substrate 400, a photovoltaic force generating part 405, and a light absorbing layer 404, a rubber sheet layer 102 intervening between the glass substrate 104 of the liquid crystal element 100 and the glass substrate 400 of the solar battery 101, and a non-figured driving circuit.

Owner:NANOX

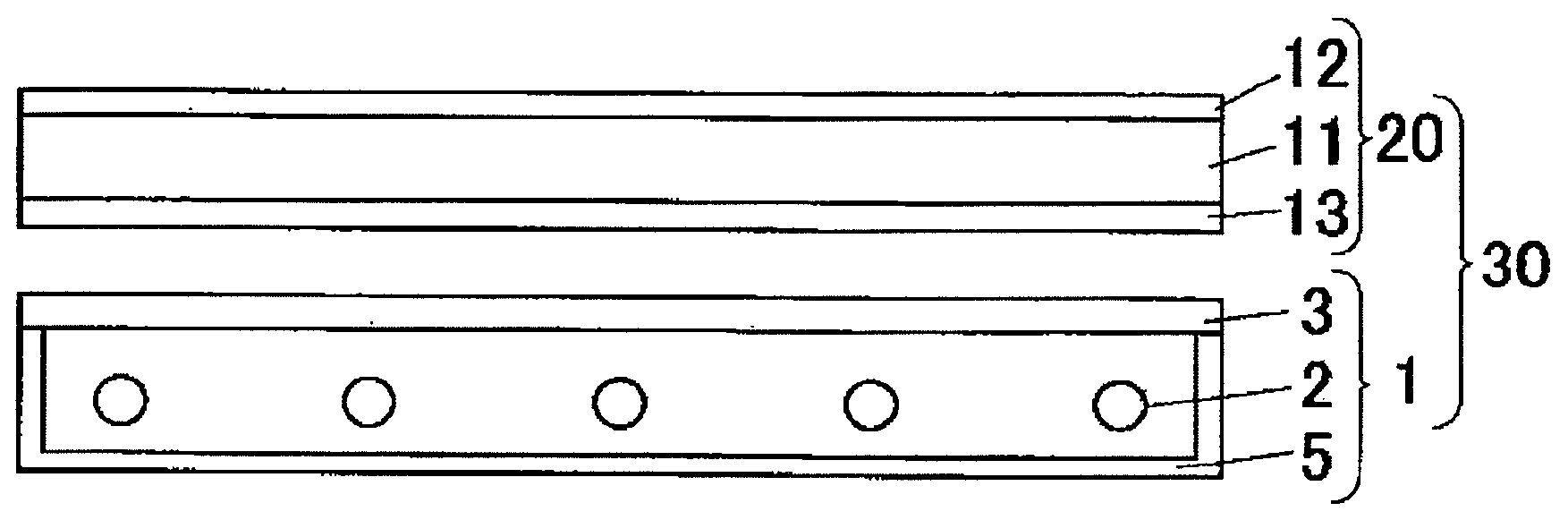

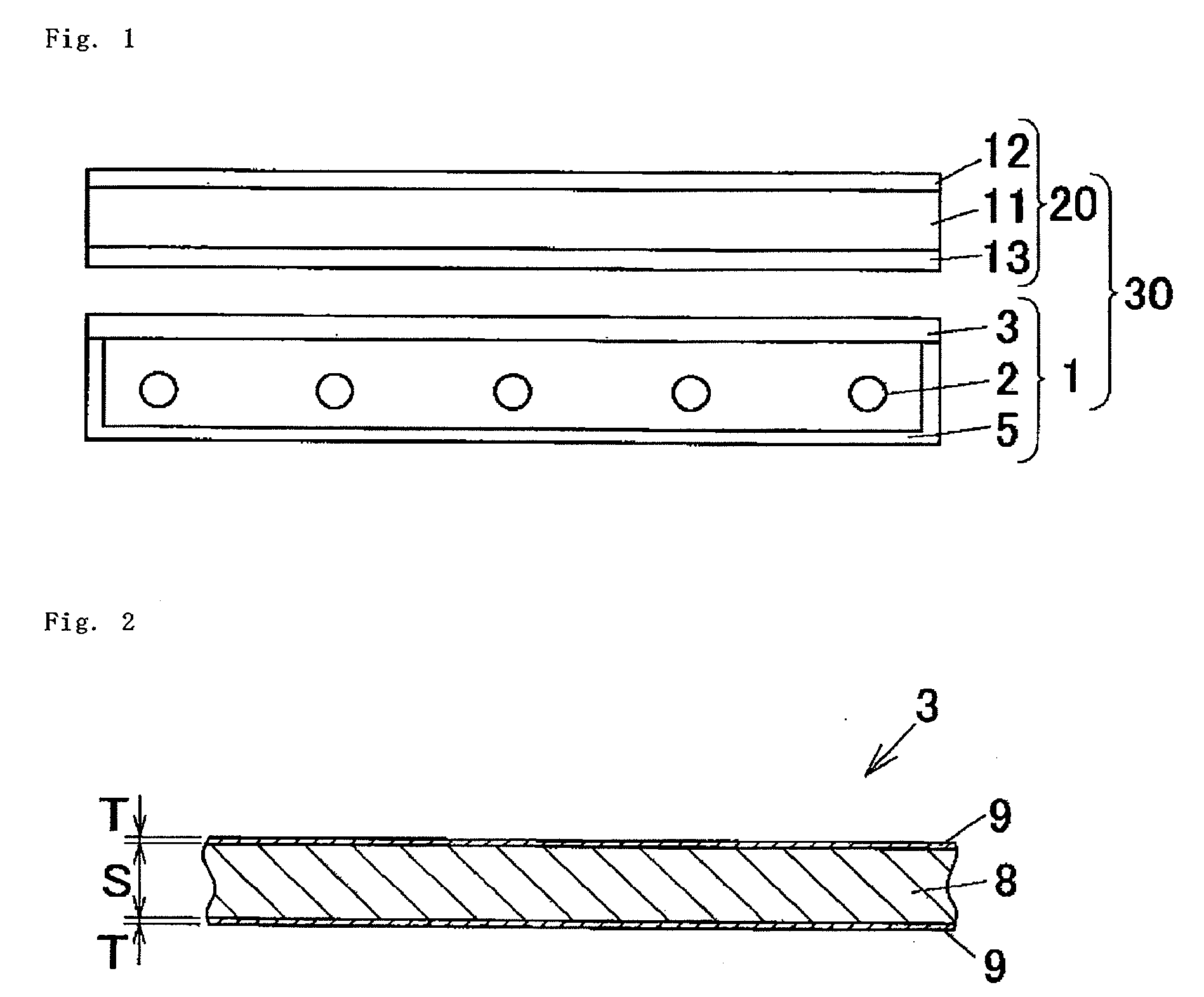

Light diffuser plate, surface light source, and liquid crystal display

InactiveUS20090190067A1Sufficient impact resistanceLow costDiffusing elementsGlobesSurface layerLiquid-crystal display

An object of the present invention is to provide a light diffuser plate sufficiently suppressed in its yellowish coloring or the like and excellent in impact resistance.The present invention relates to a light diffuser plate comprises a base layer which contains a styrenic resin and light diffuser particles, and a surface layer which contains a polycarbonate resin and which is laminated on at least one surface of the base layer. As the styrenic resin, a styrenic monomer-methacrylic acid copolymer resin is preferably used.

Owner:SUMITOMO CHEM CO LTD

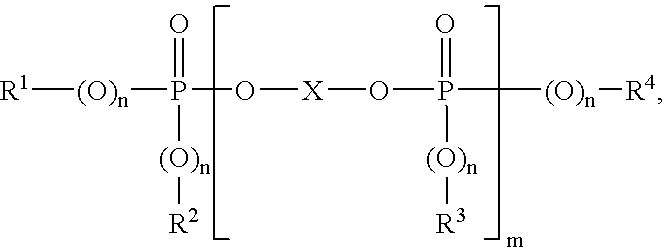

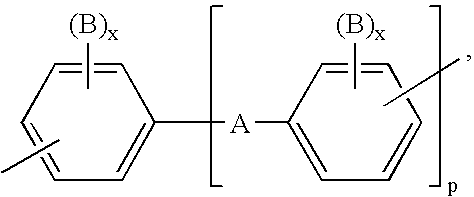

Flame-retardant polyamide molding composition

InactiveUS20070021535A1Sufficient impact resistanceGood resistance to chemicalPolyolOrganophosphorous compounds

A flame retardant molding composition contains a) from 43 to 93.5 parts by weight of polyamide, b) from 2 to 12 parts by weight of melamine cyanurate, c) from 1.5 to 15 parts by weight of polyol having at least 3 OH groups per molecule, and d) from 3 to 30 parts by weight of an organophosphorus compound, with the proviso that the parts by weight of components a) to d) give a total of 100. The molding composition has excellent fire properties and, despite the use of the particulate material melamine cyanurate, is flexible.

Owner:EVONIK DEGUSSA GMBH

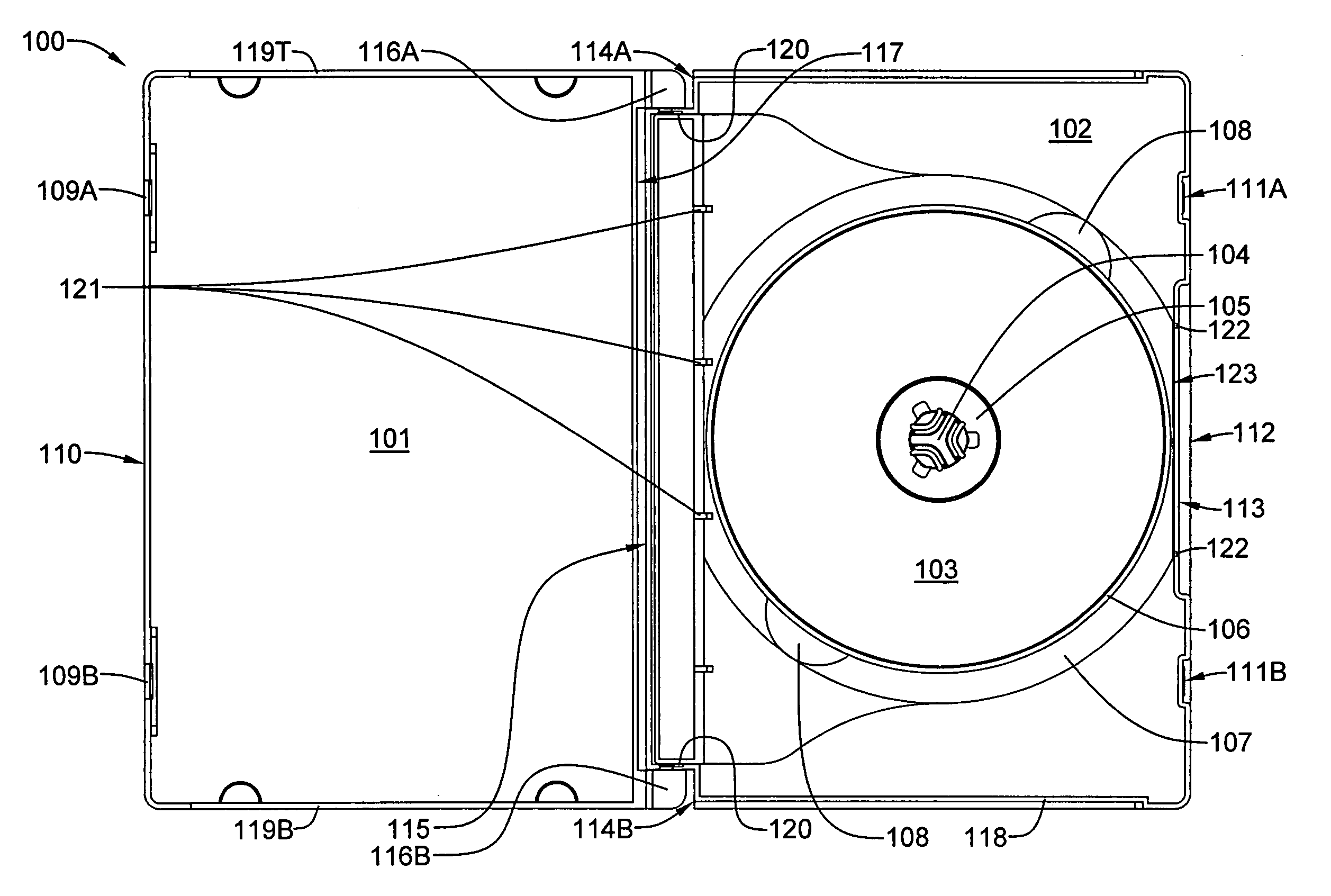

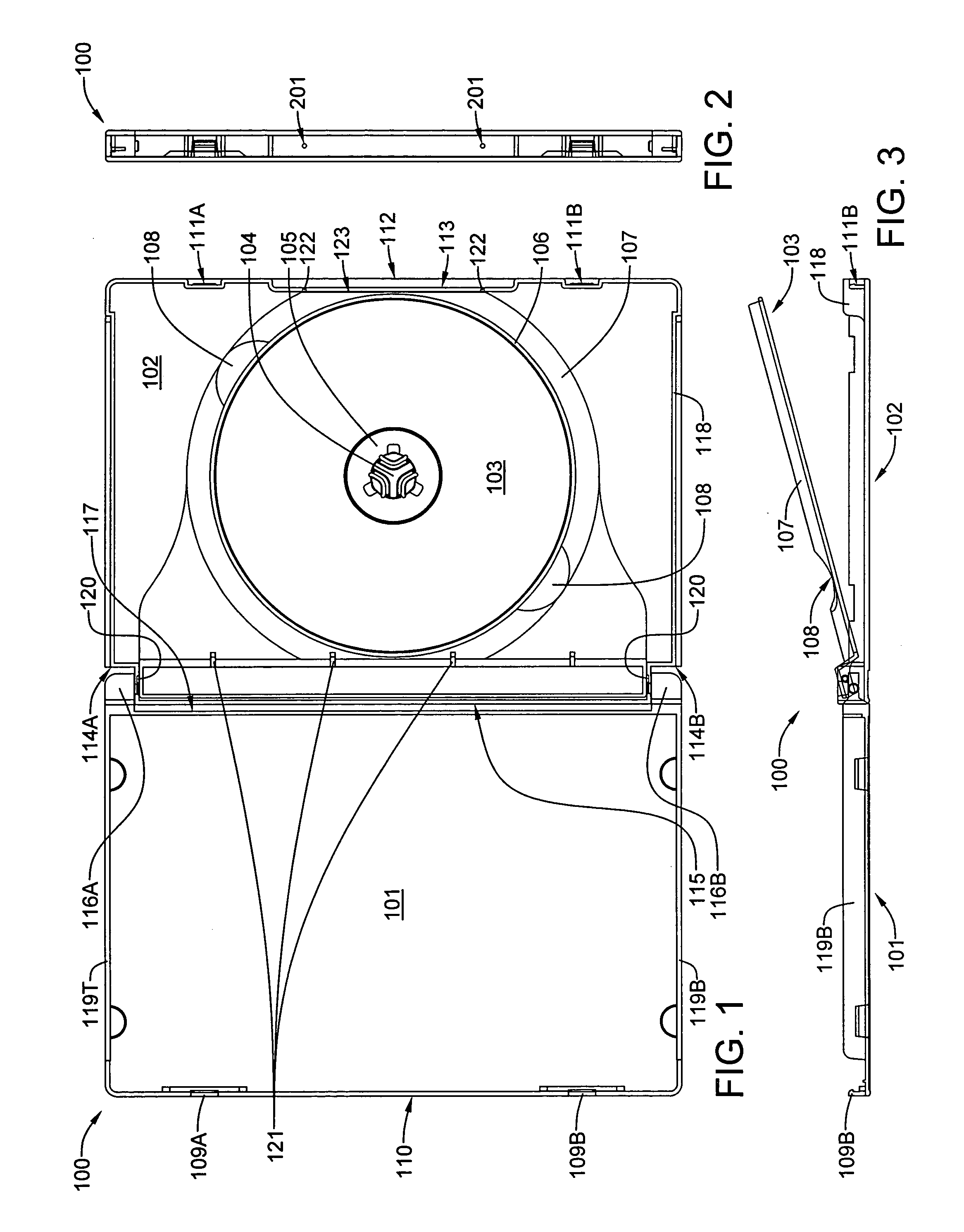

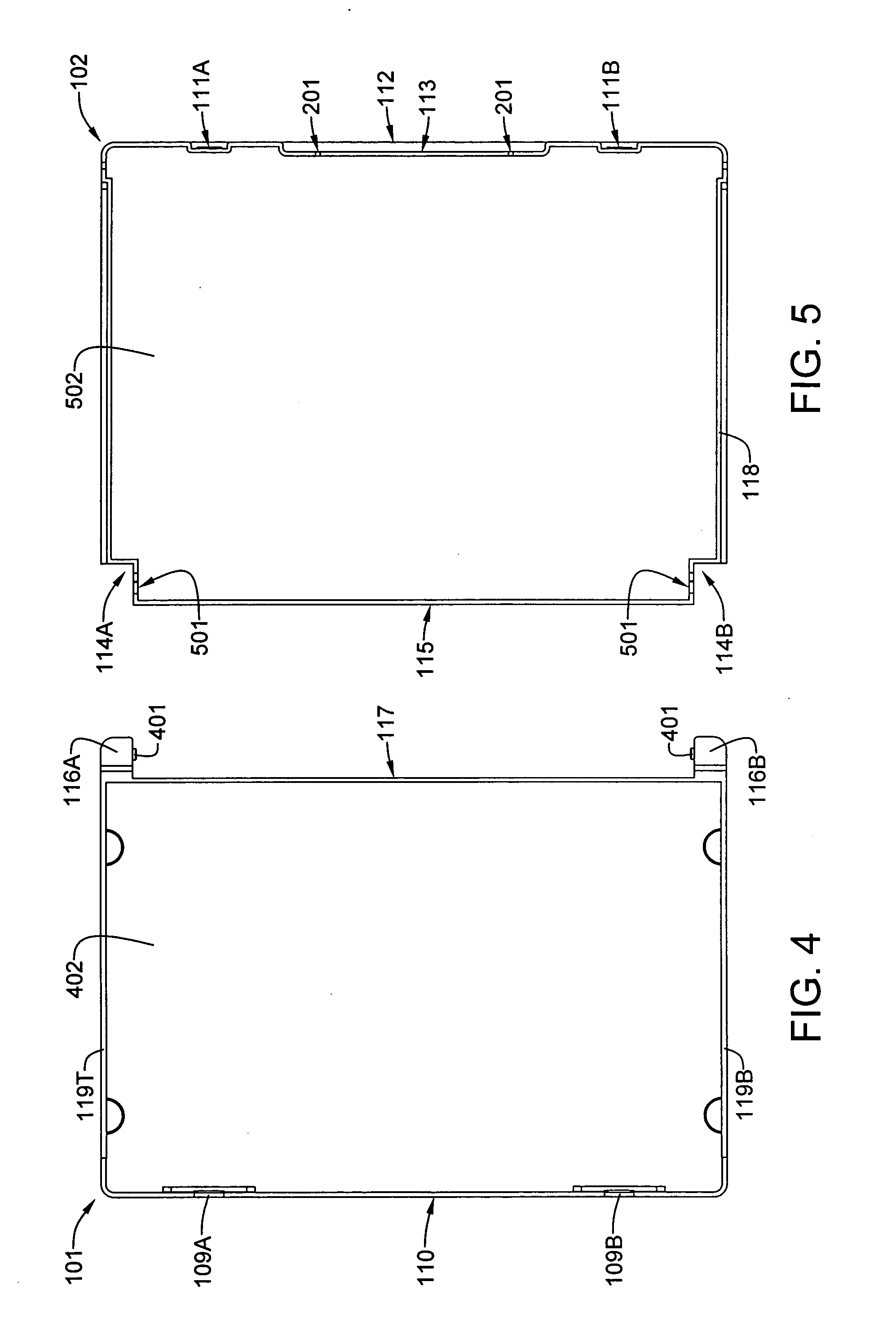

Protective case for information storage disc

InactiveUS20050150791A1More to mechanical damageImprove structural strengthRecord information storageOther accessoriesSolid componentFront edge

A three-piece jewel case for information storage discs, such as CDs and DVDs, is of the clam-shell type, and includes a base portion having a pair of generally rectangular hinge recesses positioned at adjacent corners along a rear side edge thereof, a lid portion having a pair of generally rectangular hinge arms positioned at adjacent corners along a rear side edge thereof, and a media tray having a lid portion supporting hub, which snaps into the base portion. For a preferred embodiment of the case, the media tray is hingeably connected to the base portion along the rear side edge. Each hinge arm has a rectangular solid component that extends from the outer edge to the inner edge and from the front edge to the back edge thereof. This feature rigidifies the rectangular hinge so that it is much more resistant to mechanical damage from crushing or dropping loads.

Owner:OSBORN WARREN R +1

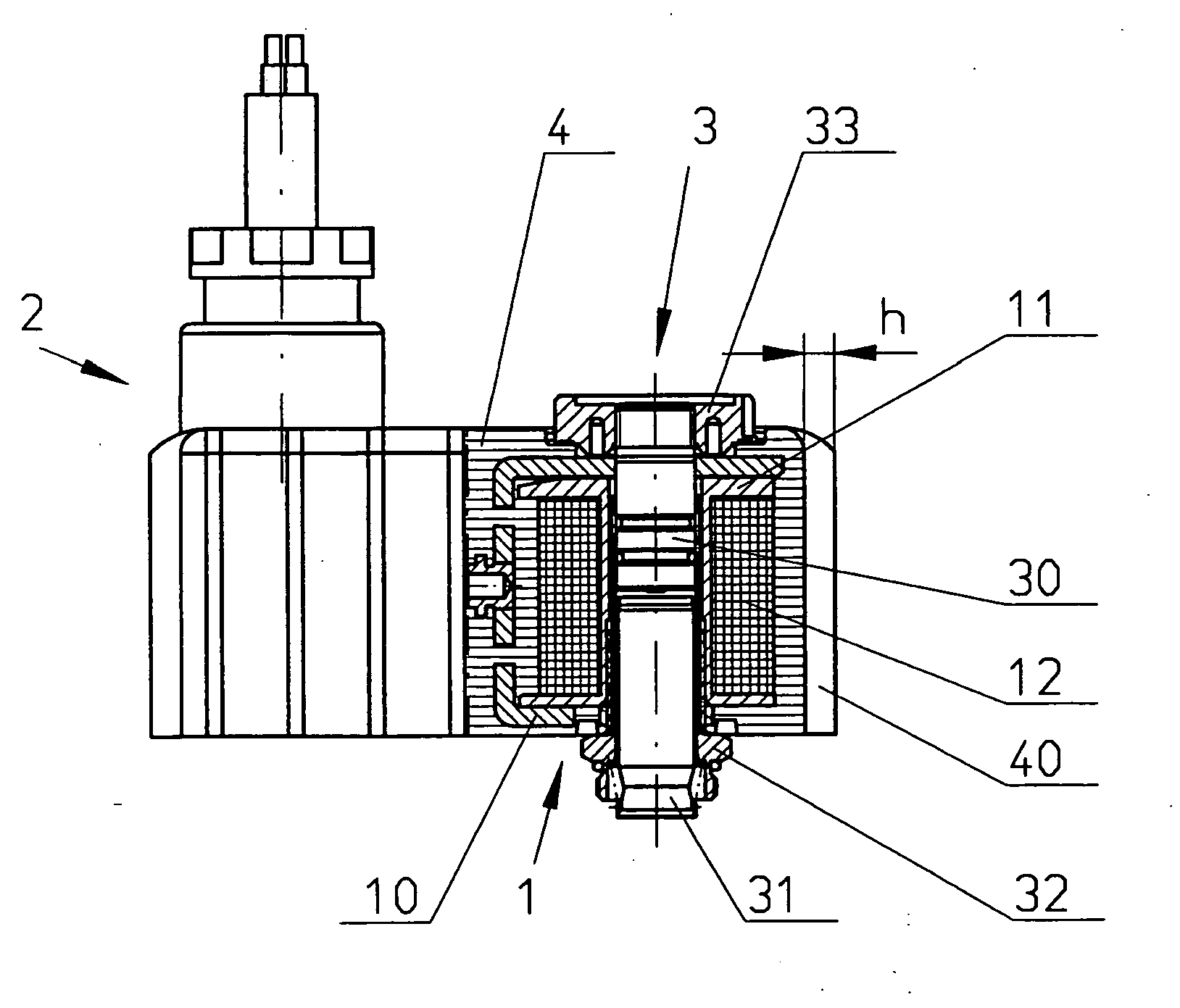

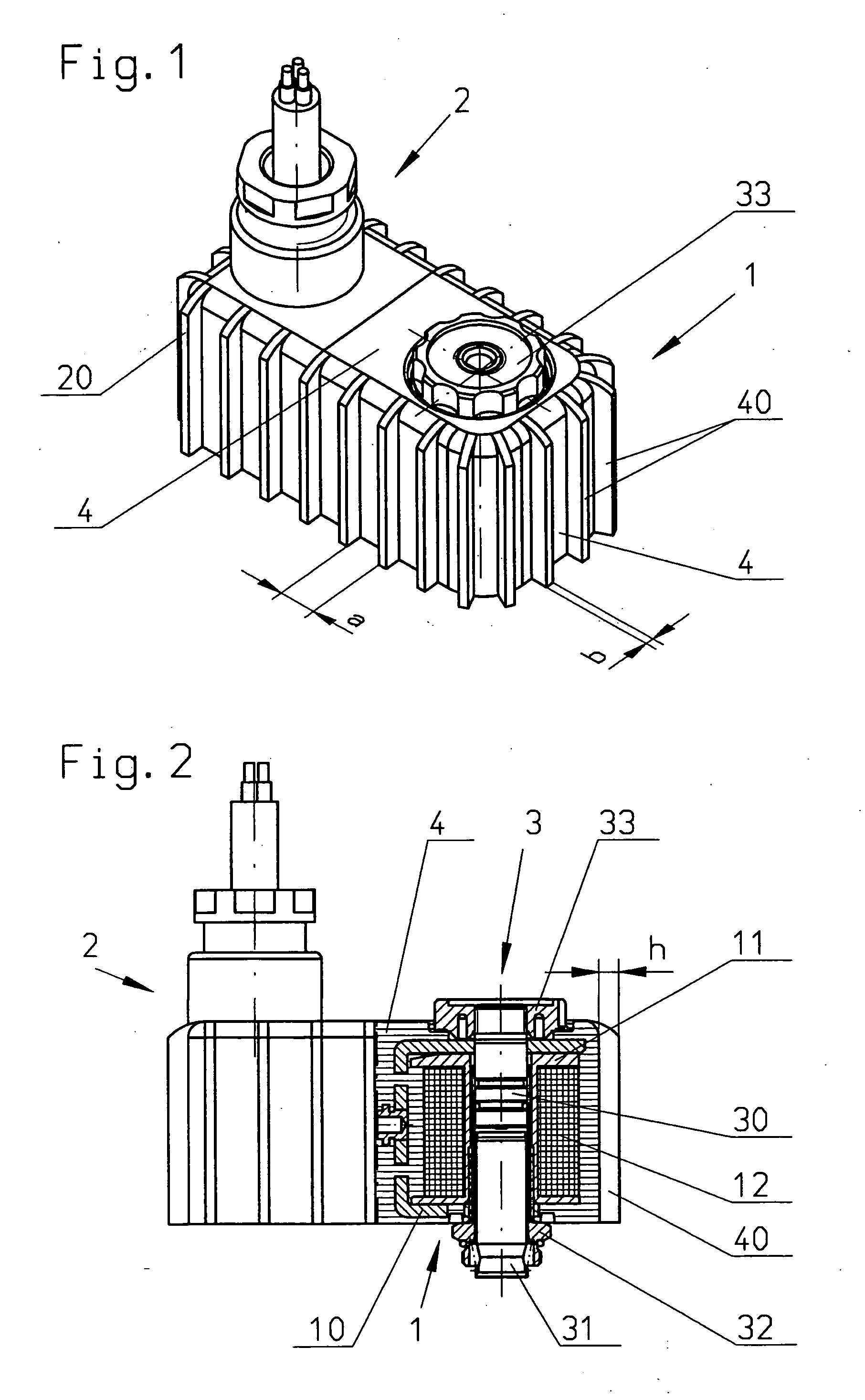

Brushless motor

InactiveCN101557155AReduce in quantityReduce noiseSupports/enclosures/casingsBrushless motorsEngineering

A brushless motor includes a rotor; a motor shaft supporting the rotor; a bearing section radially supporting the motor shaft; a thrust receiving section receiving an end of the motor shaft in the thrust direction; and an elastic damper ring being fitted on the motor shaft, the elastic damper ring being located between a circular groove, which is formed in the vicinity of the end of the motor shaft received by the thrust receiving section, and an end face of the bearing section.

Owner:SHINANO KENSHI

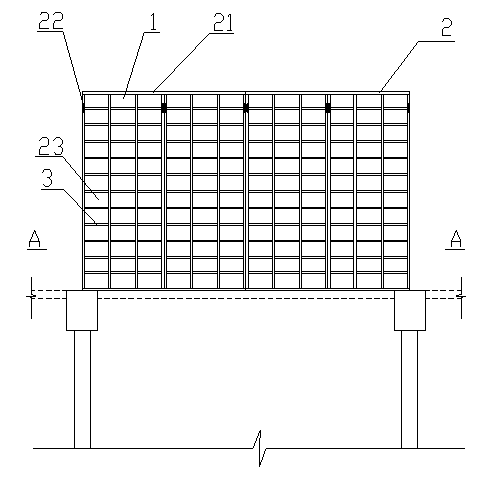

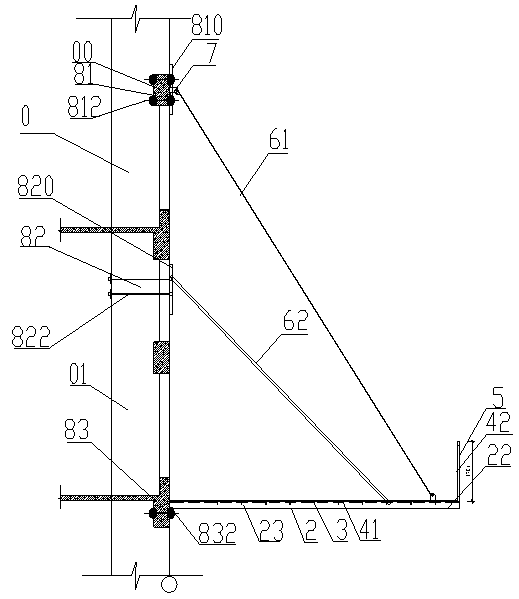

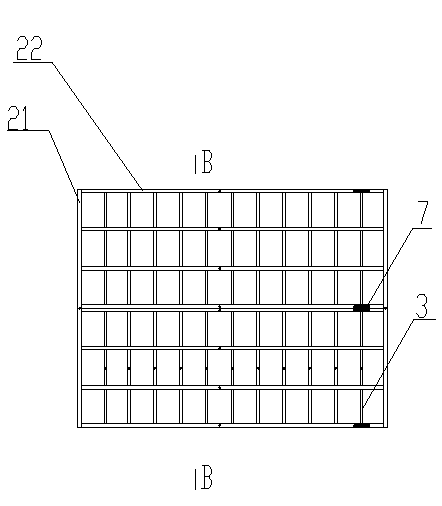

Large cantilever unit type protective canopy suitable for high-rise building construction

ActiveCN103321438AImprove impact resistanceImprove securityBuilding material handlingEngineeringTongue and groove

The invention provides a large cantilever unit type protective canopy suitable for high-rise building construction, which comprises a plurality of protective canopy units, wherein each protective canopy unit comprises two vertical main beams, a plurality of horizontal main beams, secondary beams, handrails, a first panel, a second panel, a traction device and a connection device; the horizontal main beams are perpendicularly connected between the two vertical main beams, so as to form a framework plane; the secondary beams are arranged in the framework plane, and are perpendicular to the horizontal main beams; handrails are perpendicular to the framework plane; the first panel is paved on the framework plane; the second panel is paved and fixed between the handrails; one end of the traction device is fixedly connected to the main structure of a building; the other end of the traction device is fixedly mounted with the main structure of the building; one end of the connection device is fixed on the horizontal main beams; the other end of the connection device is fixedly mounted to the main structure of the building; certain included angles are formed between the connection device and the horizontal main beams; the protective canopy units are connected into a whole through tongue-and-groove connection.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

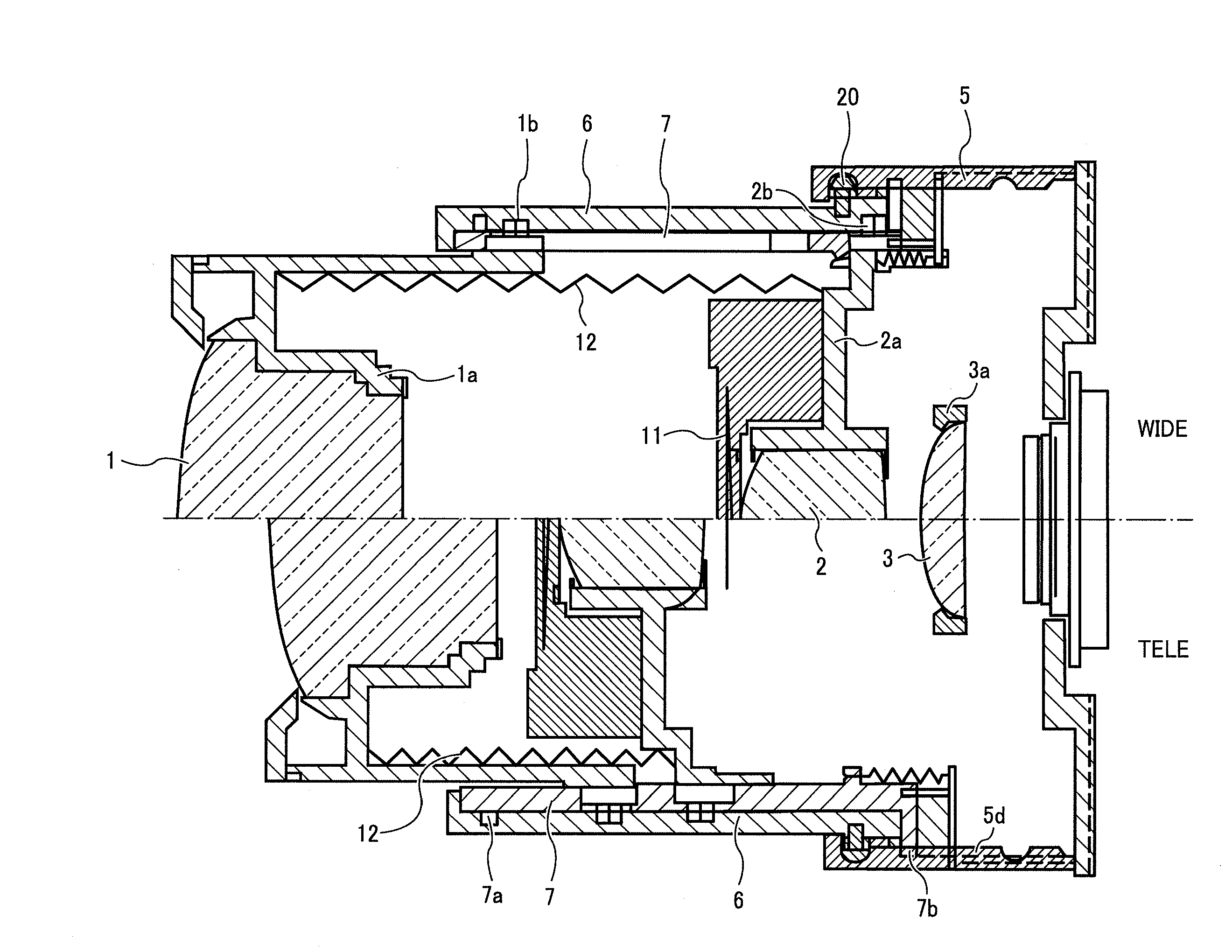

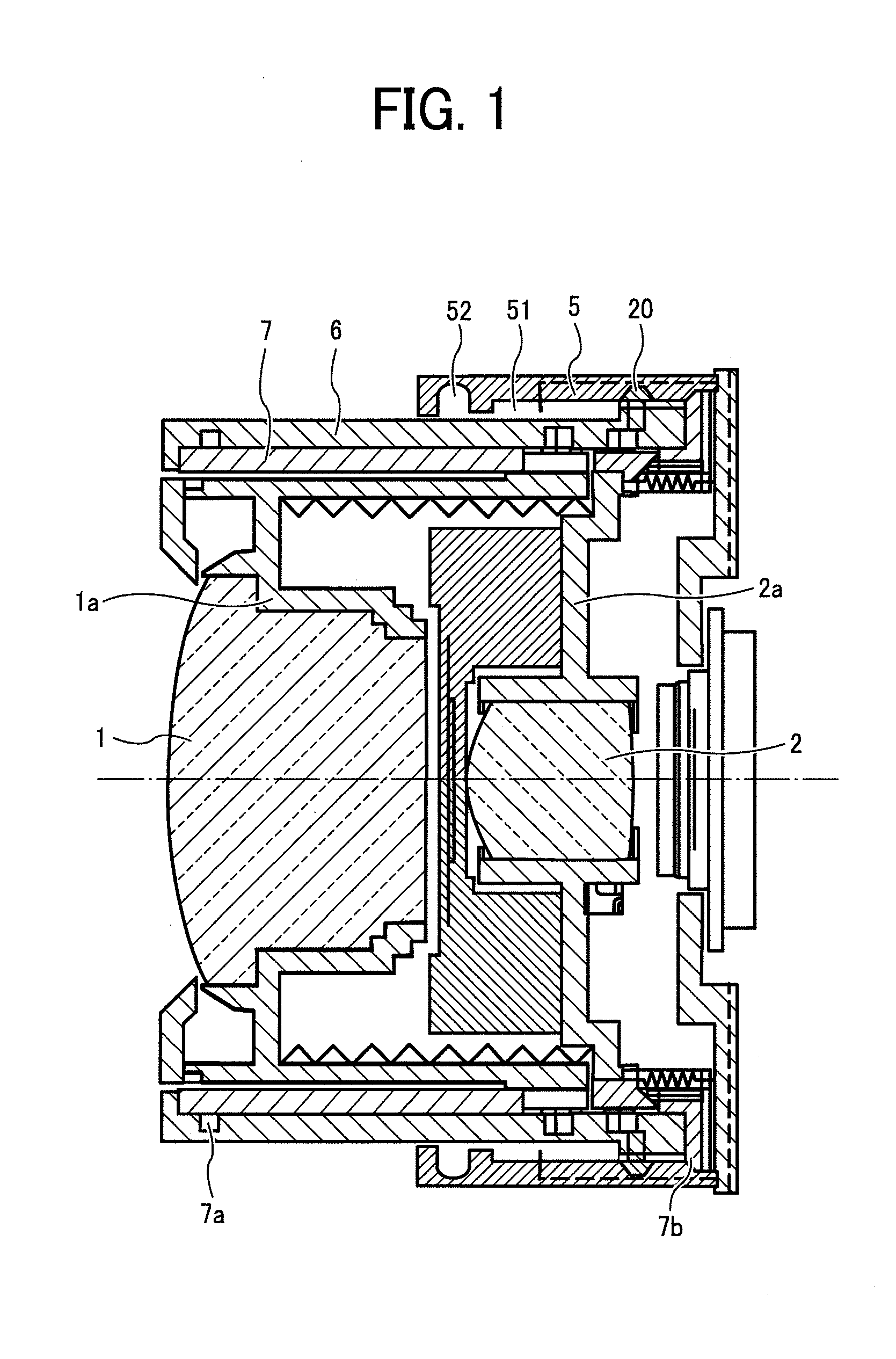

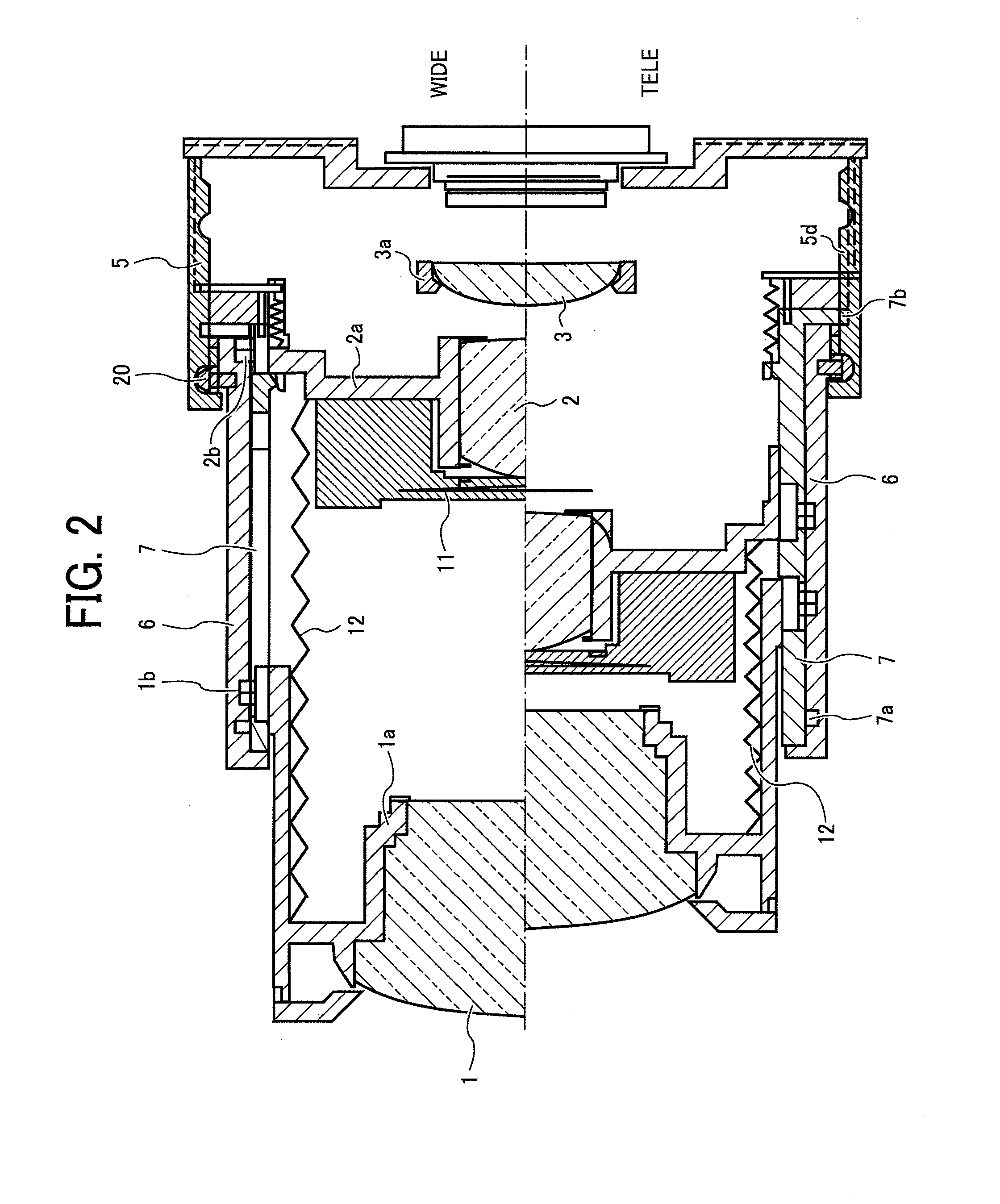

Lens driving device and image forming apparatus

A lens driving device includes a lens, a lens frame configured to support the lens, a drive mechanism configured to cause the lens frame to move upon an optical axis, and a fixed member configured to support the drive mechanism. The drive mechanism includes a rotational cylinder capable of moving upon the optical axis, a cam part on the fixed member and a cam follower which is formed on the rotational cylinder fitting with the cam part and has a conical portion and a cylindrical portion. The cam part includes a tapered cam groove formed such that the rotational cylinder extends in the optical axis upon a range whereupon the rotational cylinder moves from the collapsed state to a photography state and a planar surface formed such that the rotational cylinder does not move upon the optical axis upon the photography range, even if the rotational cylinder rotates. The conical portion fits with the cam groove of the cam part upon the range whereupon the rotational cylinder moves upon the optical axis, and the cylindrical portion fits with the planar surface of the cam part upon the range whereupon the rotational cylinder does not move upon the optical axis.

Owner:RICOH KK

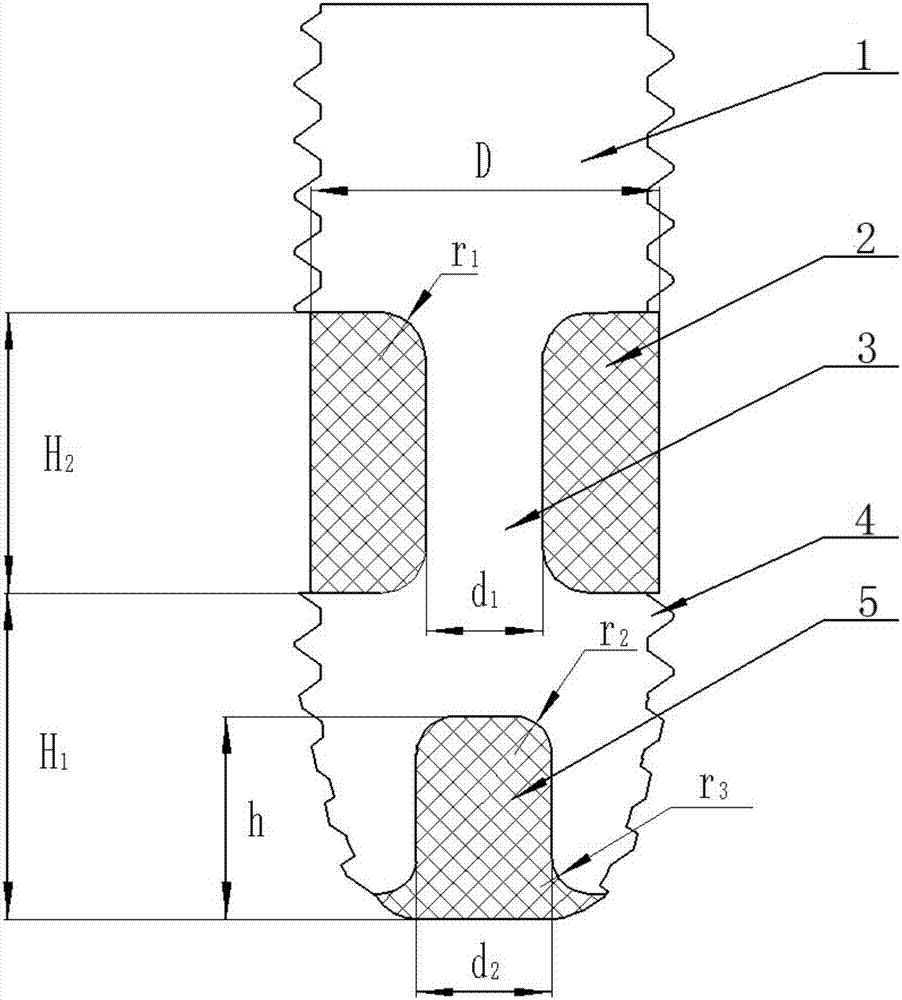

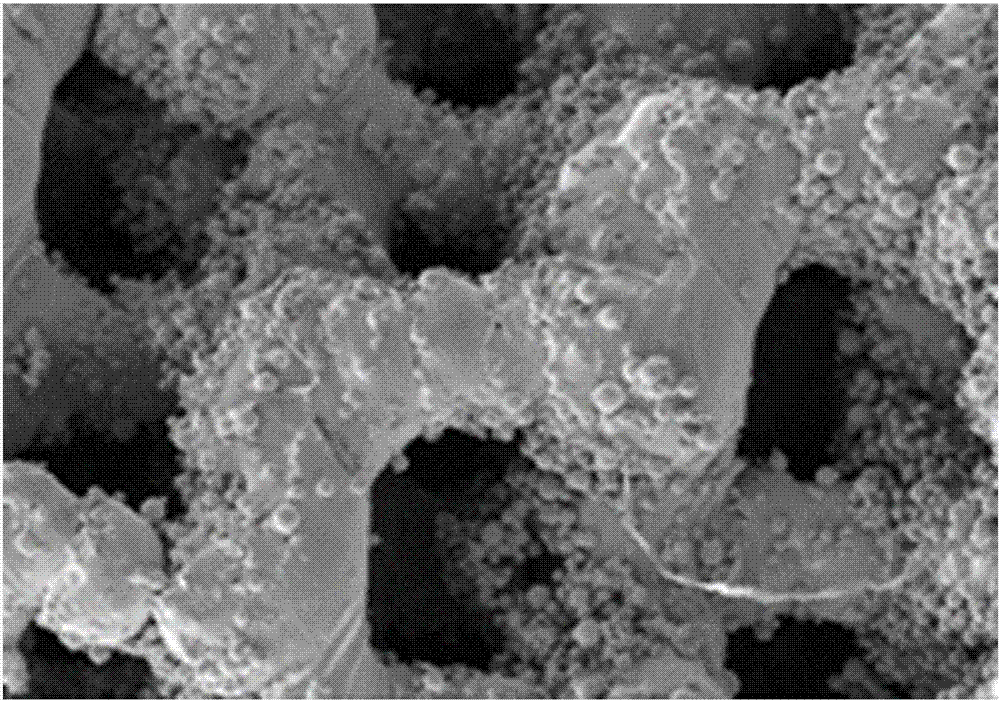

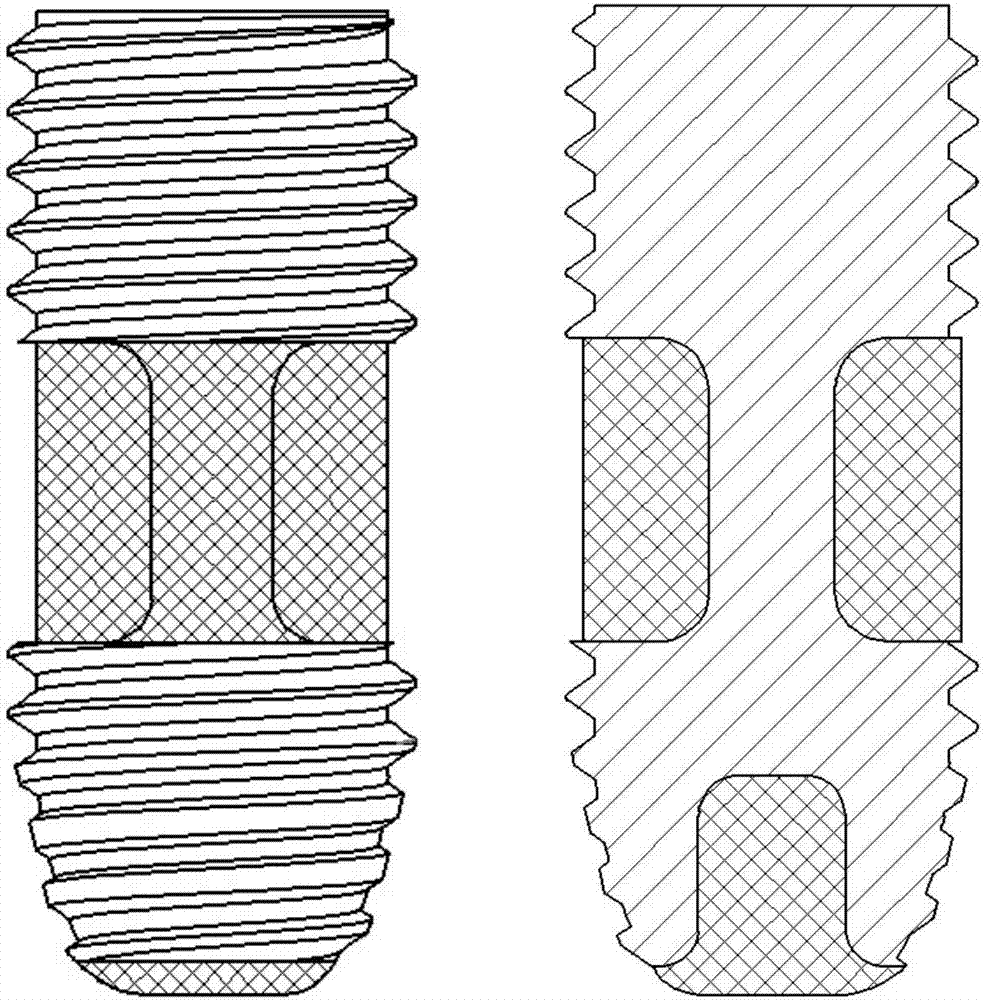

High-strength and low-rigidity porous titanium implant

InactiveCN107126281AIncrease success rateSufficient compressive strengthDental implantsBone tissueHigh intensity

The invention provides a high-strength low-rigidity porous titanium implant. The porous titanium implant comprises threaded parts, a porous structural part, and a support structure part. The upper segment and the lower segment of the porous titanium implant are the threaded parts, porous structures are embedded in the middle segment and the tip end, and the support structure part is embedded in the middle segment porous structure to connect the upper threaded part with the lower threaded part. The porous titanium implant has sufficient compressive strength, and has a controllable elastic modulus similar to that of human skeletons, the contact position of the implant and bone tissues has a good stress environment, and the porous structures capable of promoting bone integration can improve the success rate of the dental implant.

Owner:SHANGHAI JIAO TONG UNIV

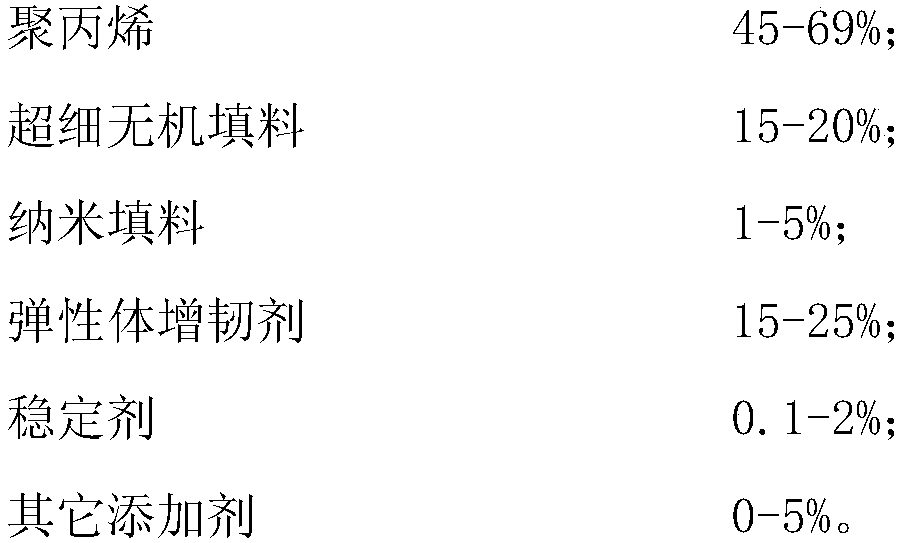

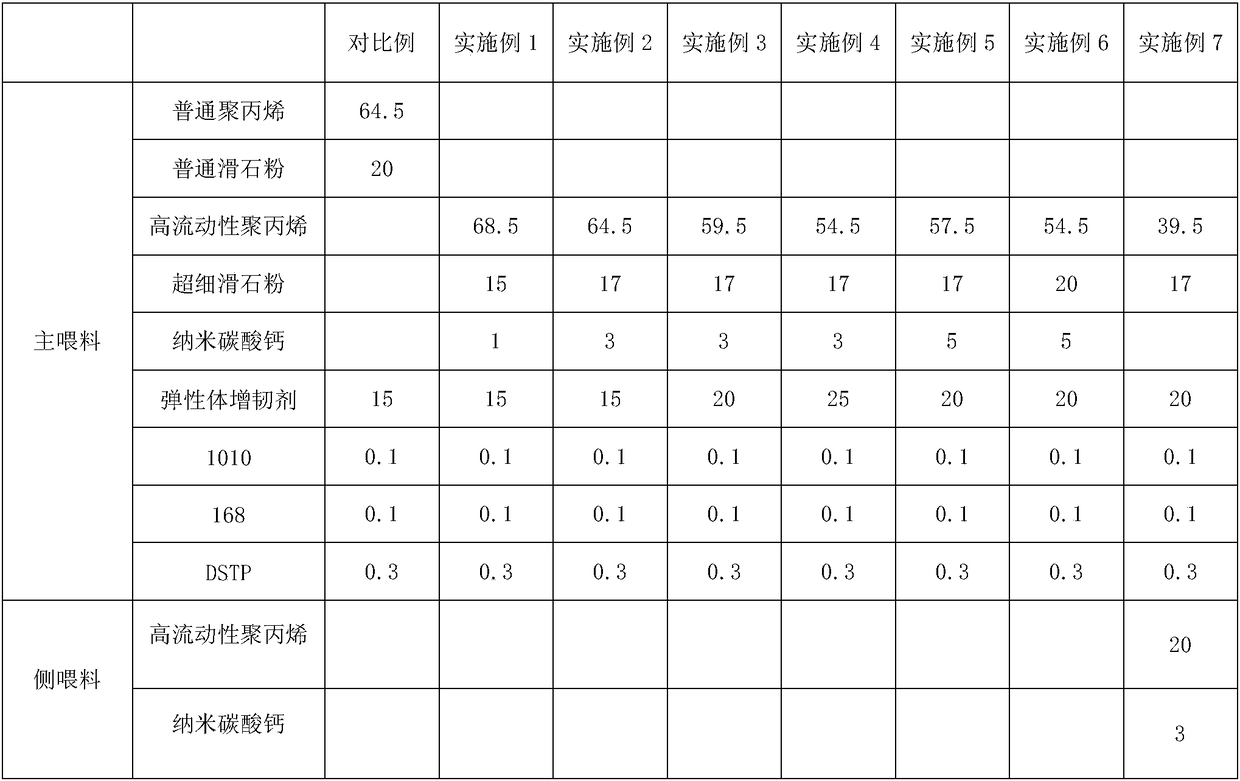

Polypropylene nanocomposite with ultrahigh flowability as well as high rigidity and shock resistance and preparation method of polypropylene nanocomposite

The invention discloses a polypropylene nanocomposite with ultrahigh flowability as well as high rigidity and shock resistance and a preparation method of the polypropylene nanocomposite. The polypropylene nanocomposite with ultrahigh flowability as well as high rigidity and shock resistance is prepared from the following raw materials in percentage by weight: 45-69% of polypropylene, 15-20% of ultrafine inorganic filler, 1-5% of nanofiller, 15-25% of elastomer toughening agent, 0.1-2% of stabilizer and 0-5% of other additives. The polypropylene nanocomposite with ultrahigh flowability as wellas high rigidity and shock resistance has the advantages that 1, the spherical nanofiller generates a synergistic effect with a high-flowability polypropylene resin matrix due to the size effect andshape characteristic, so that the flowability of the polypropylene composite can be greatly improved, excellent processing property is obtained, and the polypropylene nanocomposite is suitable for injection molded parts with extremely thin walls; 2, due to the synergistic effect among the spherical nanofiller, micro-scale flaky inorganic powder and a traditional elastomer toughening agent, the shock resistance of the material can be effectively improved on the premise that the rigidity is kept not reduced; and 3, the polypropylene nanocomposite can be used for large thin-wall injection moldedparts of which the wall thicknesses are smaller than 2.2mm, the weights of the parts are greatly reduced, and meanwhile, the parts can be kept to have enough strength and shock resistance.

Owner:CHONGQNG PRET NEW MATERIAL +4

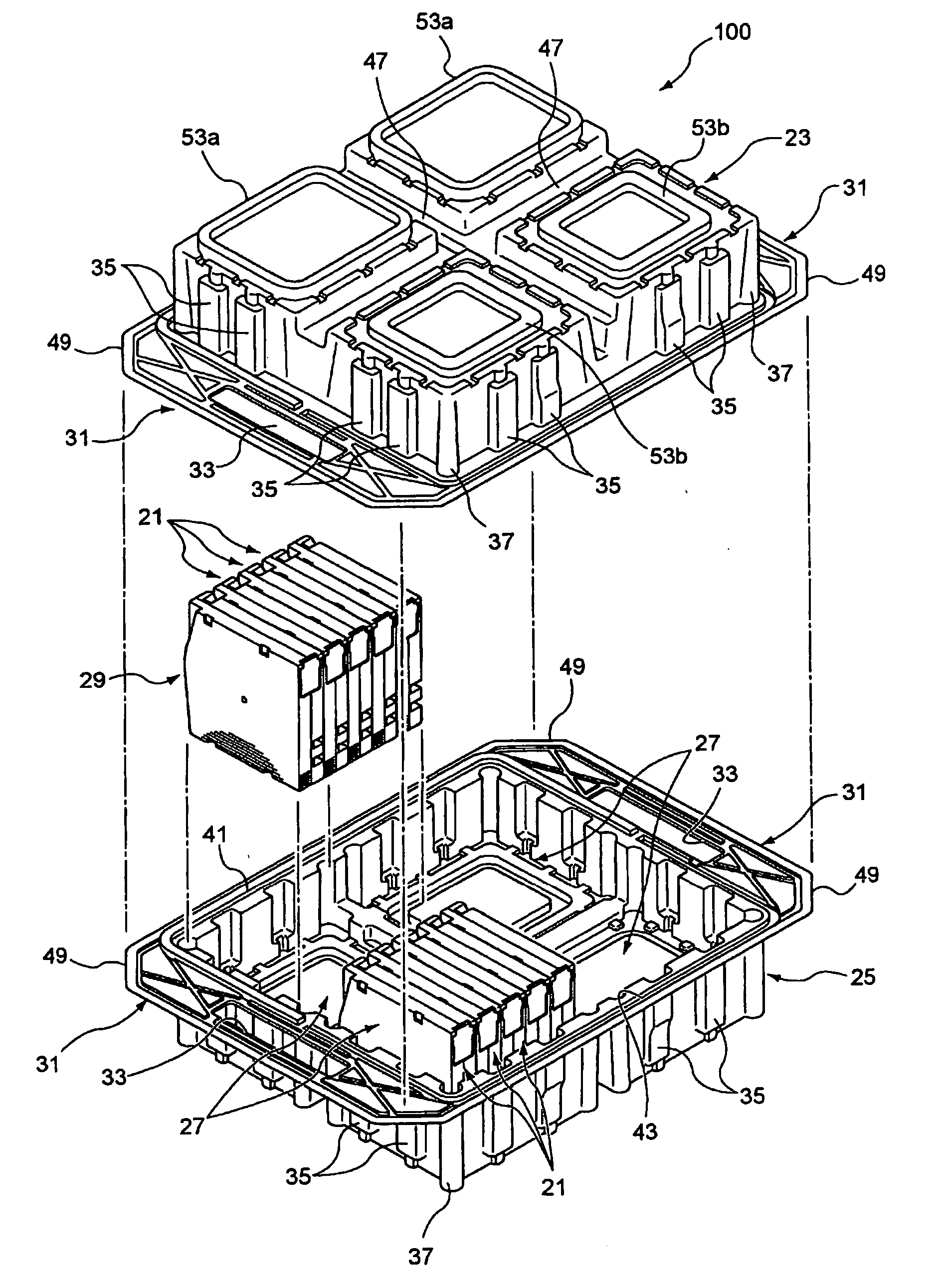

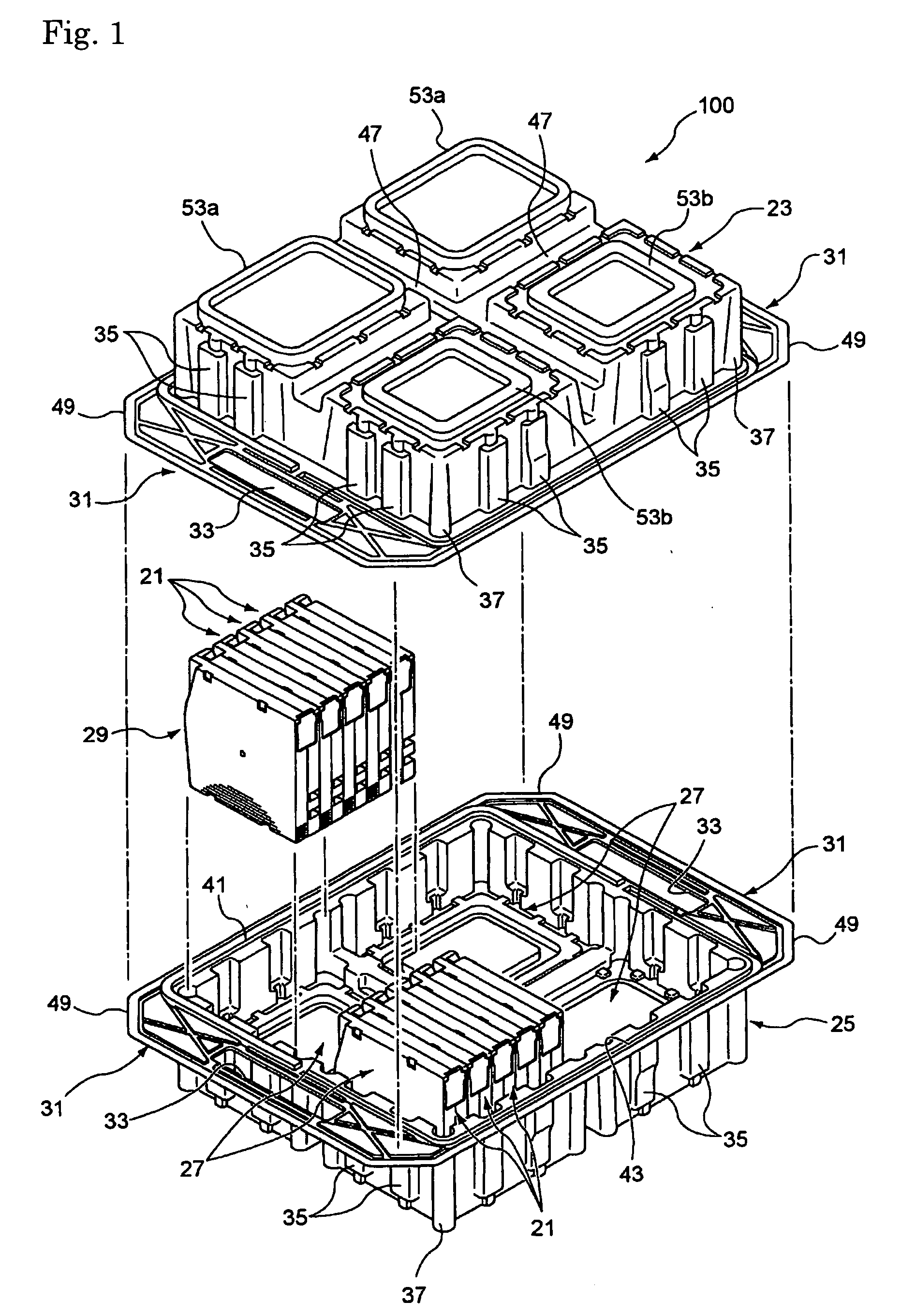

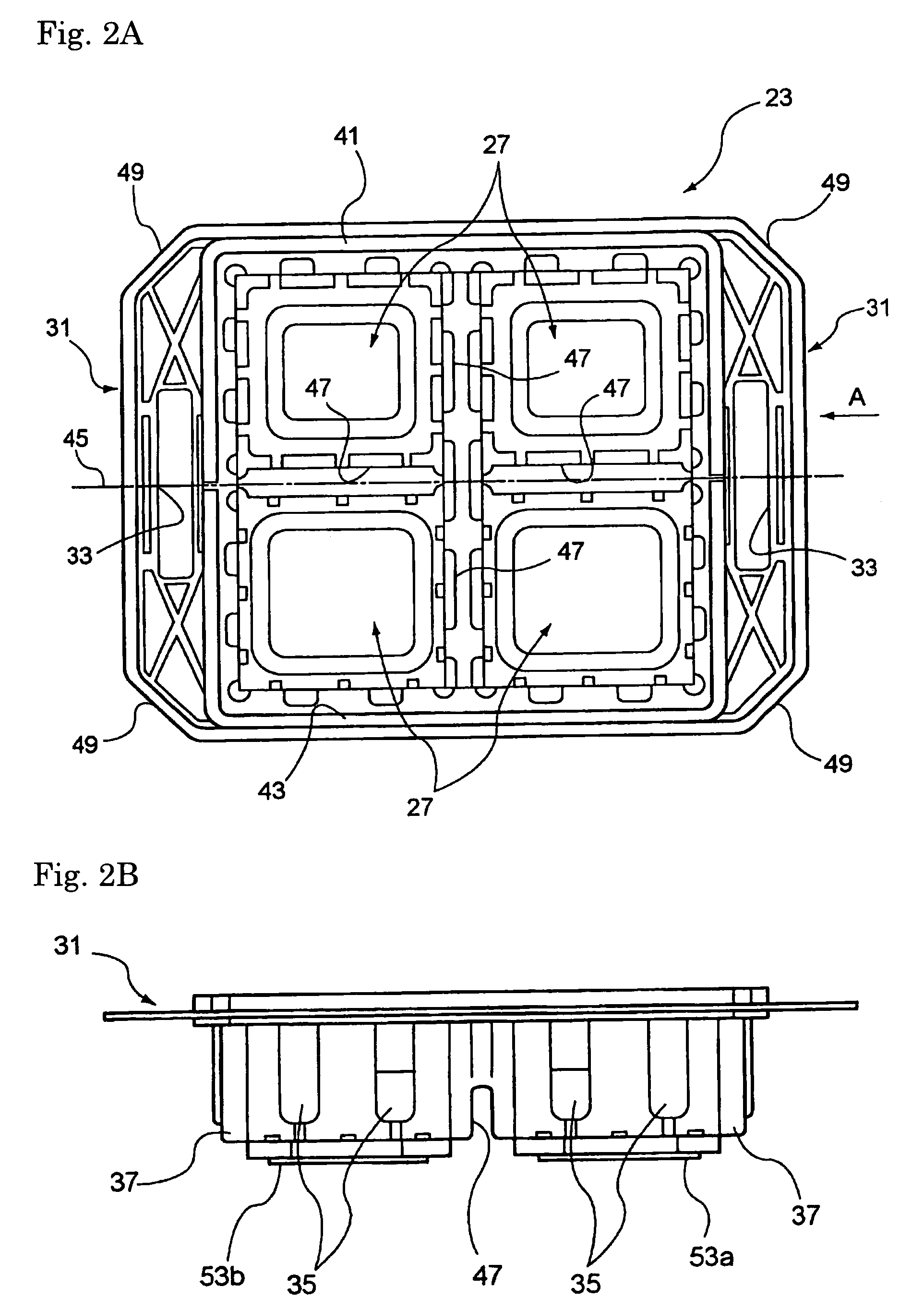

Cartridge accommodation case

InactiveUS20070209952A1Guaranteed to workSufficient impact resistanceRecord information storageOther accessoriesEngineeringMechanical engineering

A cartridge accommodation case includes a generally rectangular cartridge accommodation top case formed with partitioned rooms for holding plural cartridges and a generally rectangular cartridge accommodation bottom case having partitioned rooms which have substantially the same shape as and opposed to the partitioned rooms of the top case. The top case and the bottom case have the same structure and are provided with projections and recesses which can engage each other. The cartridge accommodation case is given, inside, partitioned rooms which are two times larger in space than the partitioned rooms of the top case and the bottom case when the top case and the bottom case are placed one on the other and the projections and the recesses are engaged with each other. The top case and the bottom case are provided with ribs which are fitted into / with each other when cartridge accommodation cases are stacked.

Owner:FUJIFILM CORP

Preparing method of engineering machine final drive gear

ActiveCN111690794ATough enoughSufficient impact resistanceVacuum evaporation coatingSputtering coatingCarbide coatingGear wheel

The invention belongs to the technical field of engineering machine final drive gear manufacturing, and particularly relates to a preparing method of an engineering machine final drive gear. Through aphysical vapor deposition technology, surface carburizing and coating treatment are carried out, a carbide coating, a PVD method and a carburizing technology are combined, a carburizing diffusion layer is prepared between the carbide coating and a workpiece substrate through an ion sputtering method, that is, a workpiece surface is subjected to surface carburizing treatment through the ion sputtering method, an ion plating and magnetron sputtering composite method is adopted for depositing a NbHfMoC carbide coating with components changed in a gradient manner, the substrate material hardnesscan be improved, the attaching property of a substrate deposition coating and the substrate can be reinforced, the physical property difference between the deposition coating and the substrate material can be reduced, the anti-wear property of the engineering machine final drive gear part can be improved, the gear surface treatment efficiency is effectively improved, and the service life of the engineering machine final drive gear can be prolonged.

Owner:JINING UNIV

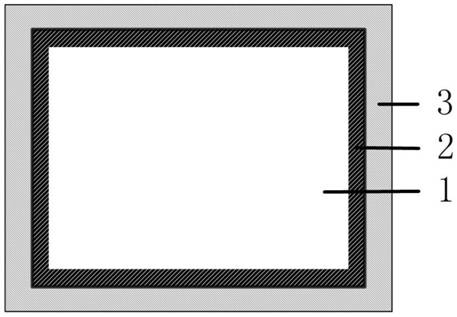

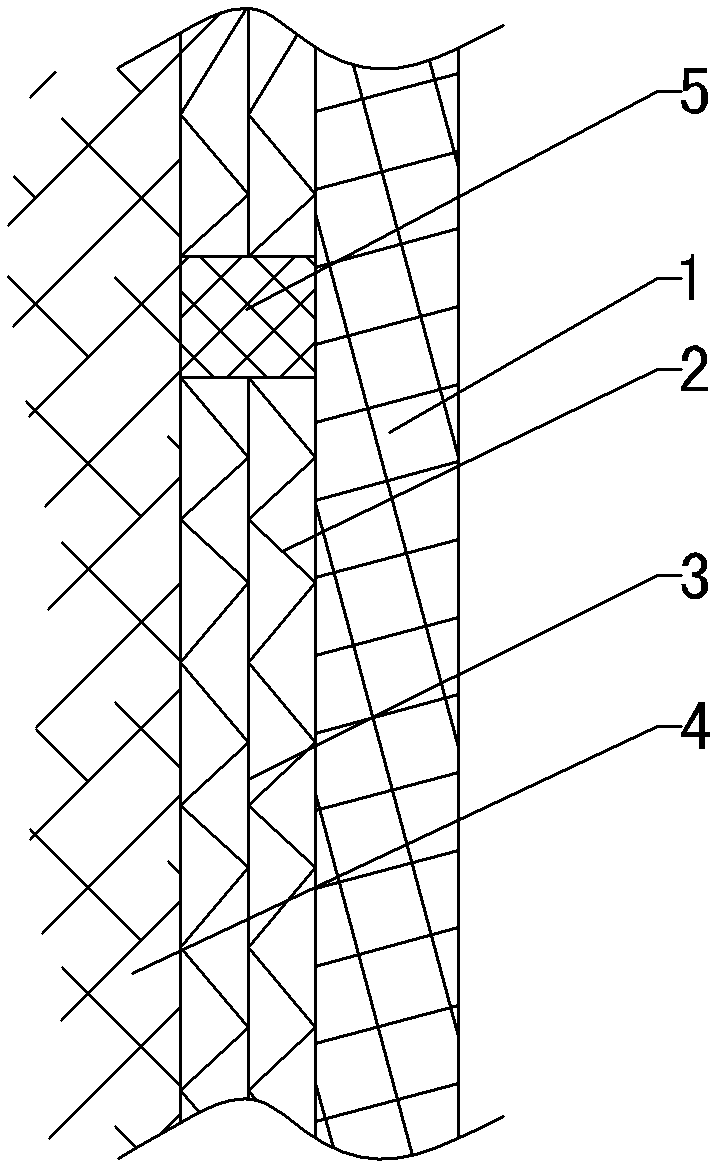

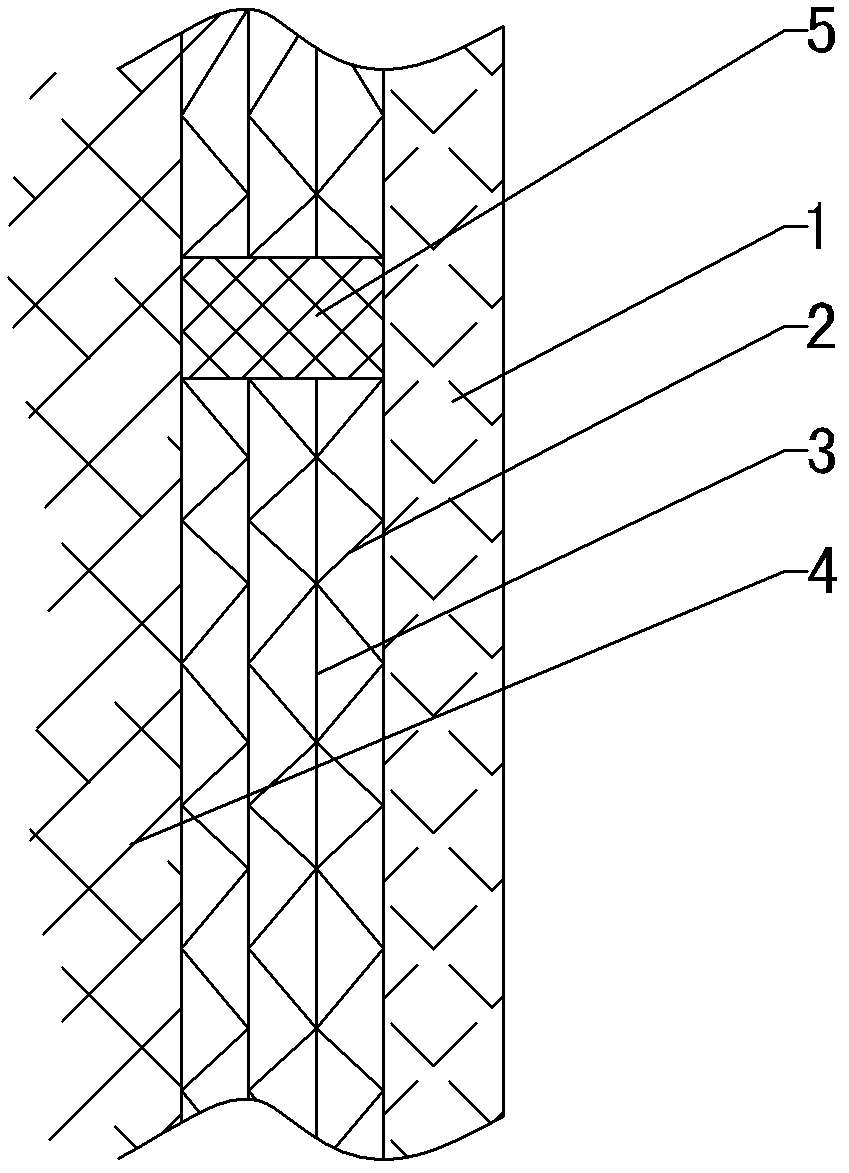

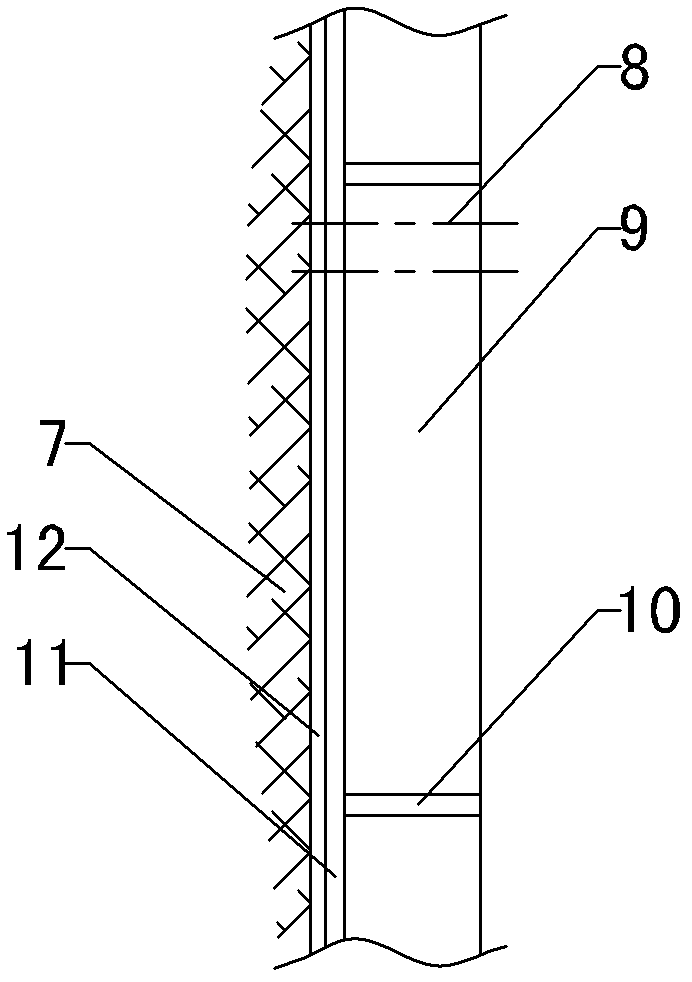

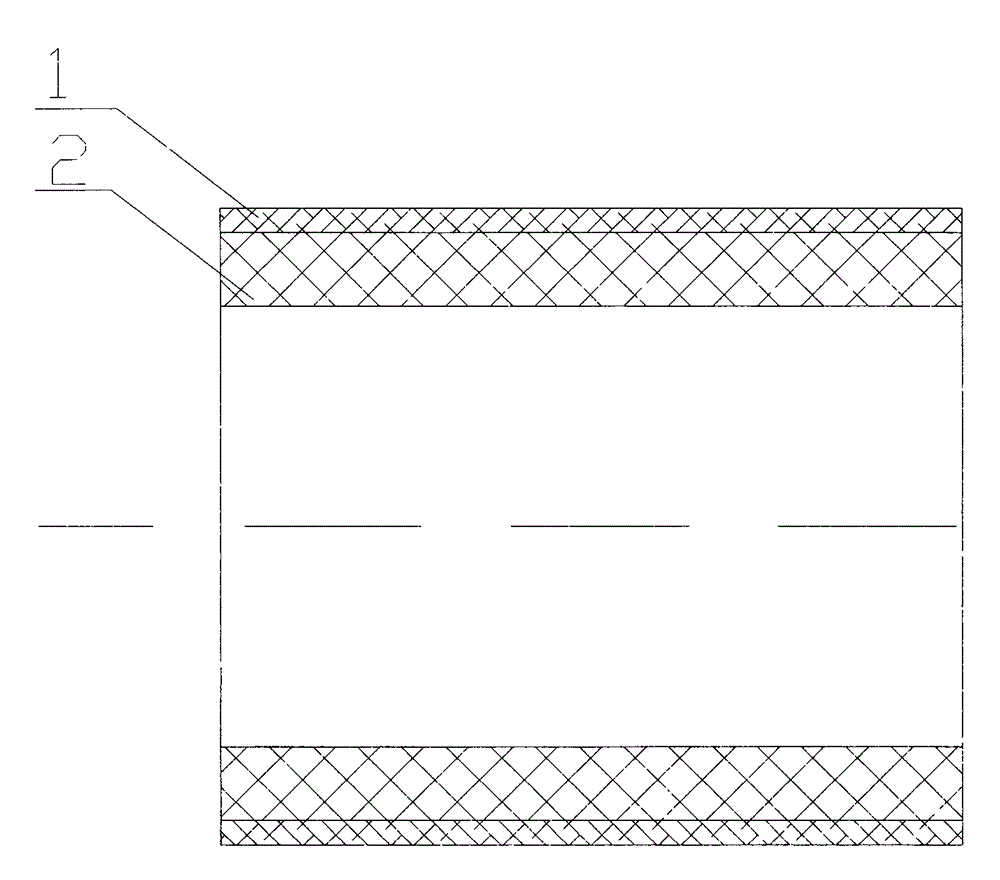

Method for constructing green and energy-saving building

ActiveCN102619311AStrong enoughSufficient impact resistanceCovering/liningsBuild-up roofsSurface layerEngineering

A method for constructing a green and energy-saving building belongs to the technical field of building construction and particularly relates to a method for constructing surface layers of walls. The method includes steps of 1.1, manufacturing supporting and protecting surface layers (1) with different shapes and structures; 1.2, mounting cushion blocks (5) or filler strips on the surface of a cleaned wall (4), and brush coating a cement-based adhesive layer on the surface of the wall (4); 1.3, adhering a reflecting layer (3) on another side surface of a mesh (2) via convex closures; 1.4, adhering another mesh (2) on the other surface of the reflecting layer (3) by the same method; and 1.5, mounting the supporting and protecting surface layers (1) manufactured in the step 1.1 by the aid of the cushion blocks (5) or filler strips. The method has the advantages of environmental protection, energy conservation, high utilization rate of renewable resources, low energy consumption for heating and refrigerating of the building, remarkable heat-insulation effect, wide application range and the like.

Owner:山东起凤建工股份有限公司 +2

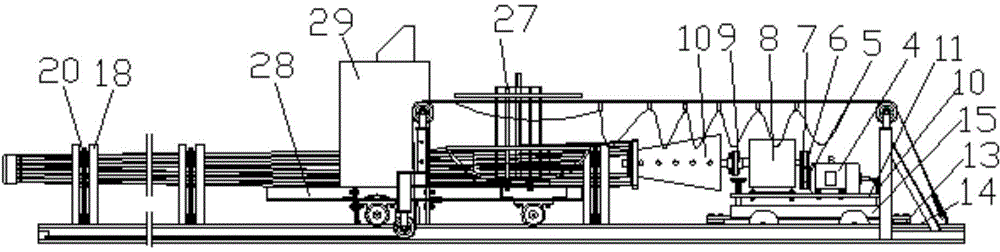

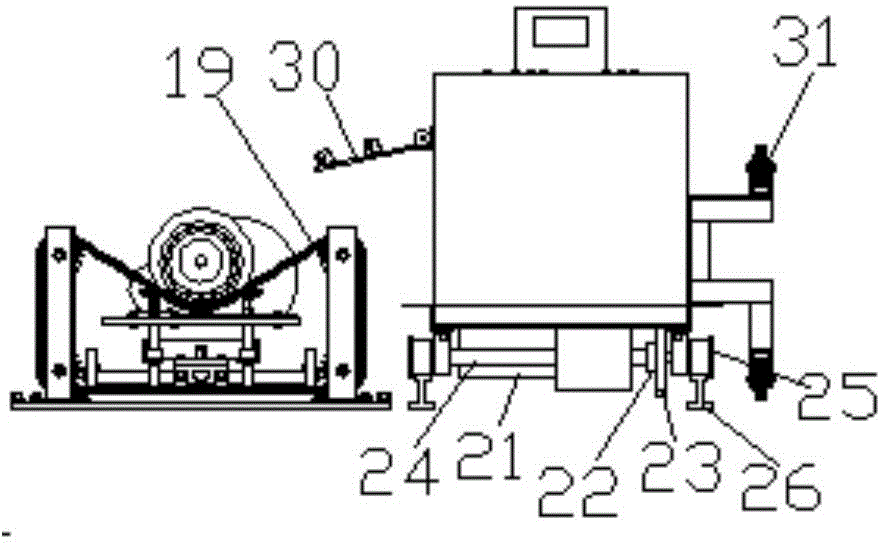

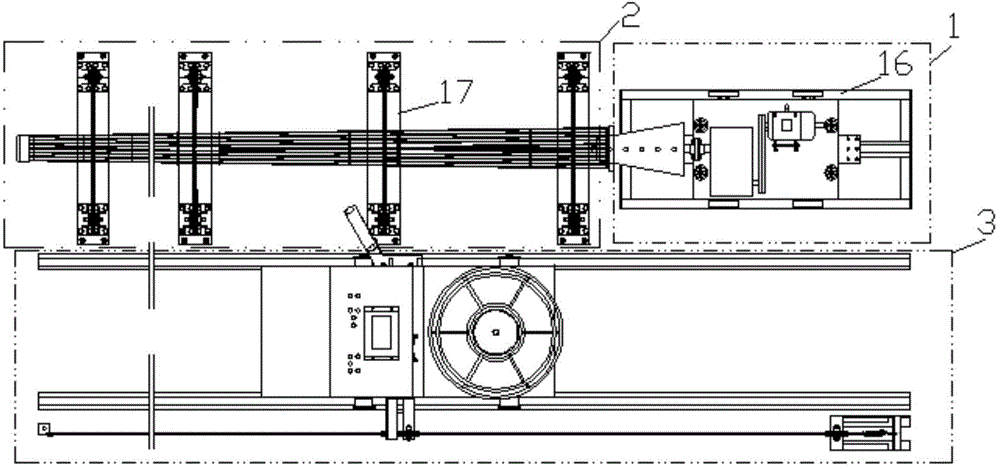

Automatic pole helical reinforcement winding system

InactiveCN104646574AOperational securityRealize automated productionMeshed-ring wire networkSprocketEngineering

The invention relates to an automatic pole helical reinforcement winding system, which comprises a carriage mechanism, a carrier mechanism and a trolley mechanism, the carriage mechanism is mounted at one end of the carrier mechanism, the center of the carriage mechanism is superposed with the center of the carrier mechanism, the carrier mechanism comprises a plurality of supports, sprocket wheels are mounted on the supports, chains are wound on the sprocket wheels, and the supports are respectively fixed on a ground foundation by using expansion bolts; the trolley mechanism is mounted in parallel beside the carrier mechanism, double rails are adopted as a traveling track, a four-wheeled trolley is placed on the track, and an operating platform, an electric control cabinet and a reel stand are arranged on the four-wheeled trolley. The automatic pole helical reinforcement winding system can be adopted to rapidly and automatically wind a pole helical reinforcement, operation is simple, labor intensity is low, and moreover, the automatic pole helical reinforcement winding system has enough strength and anti-toppling and anti-impact capability, thus ensuring that the equipment can stably operate and is durable.

Owner:GUANGXI POWER LINE EQUIP FACTORY

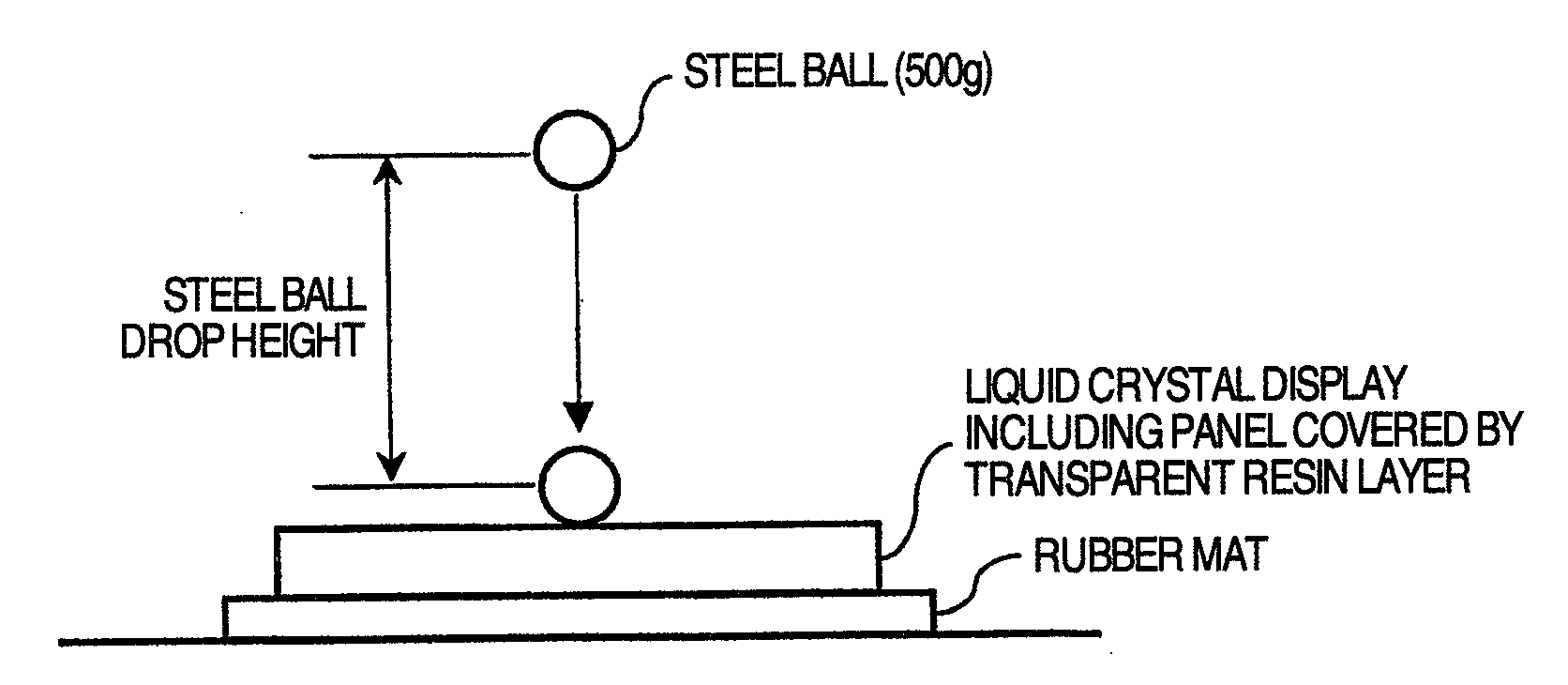

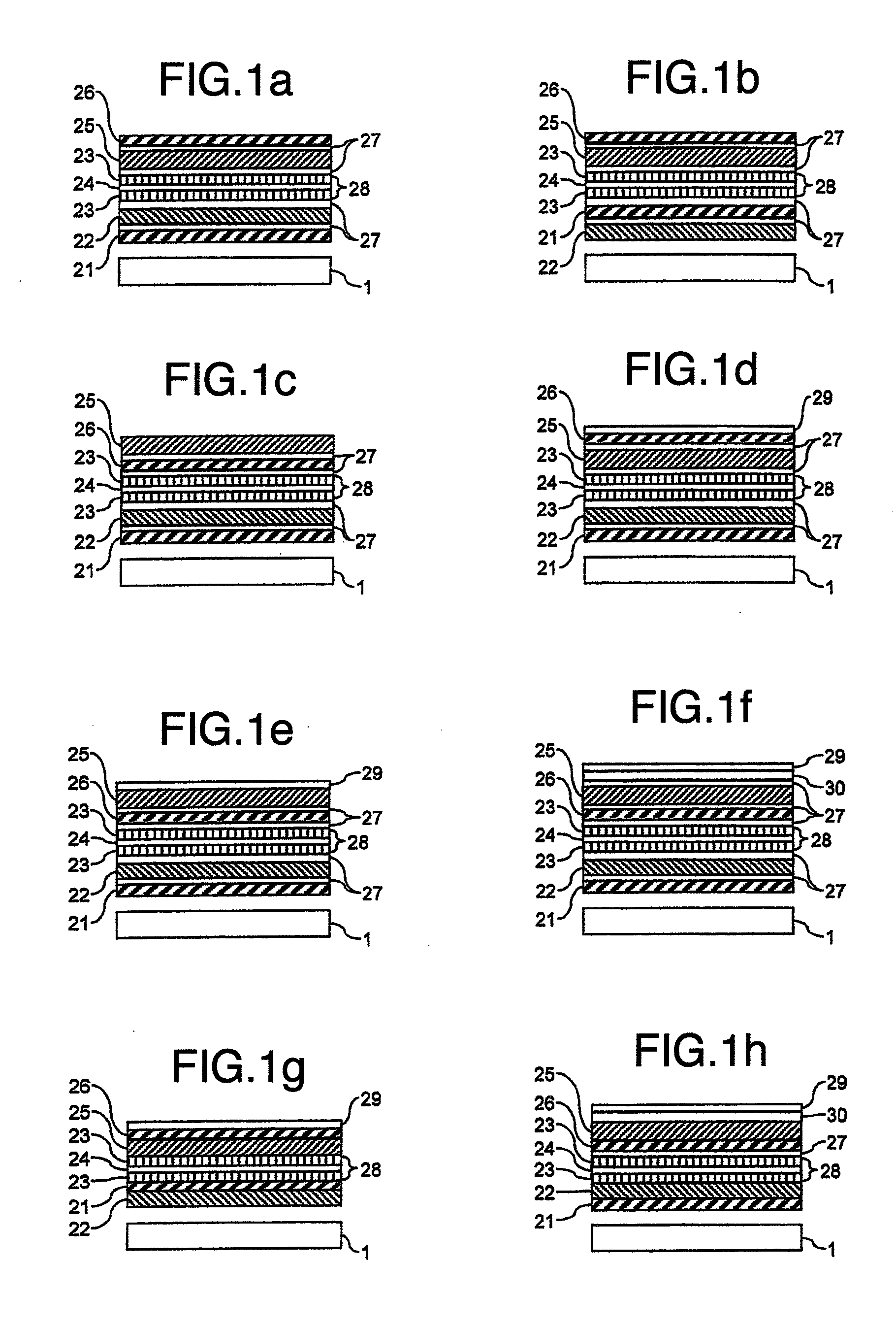

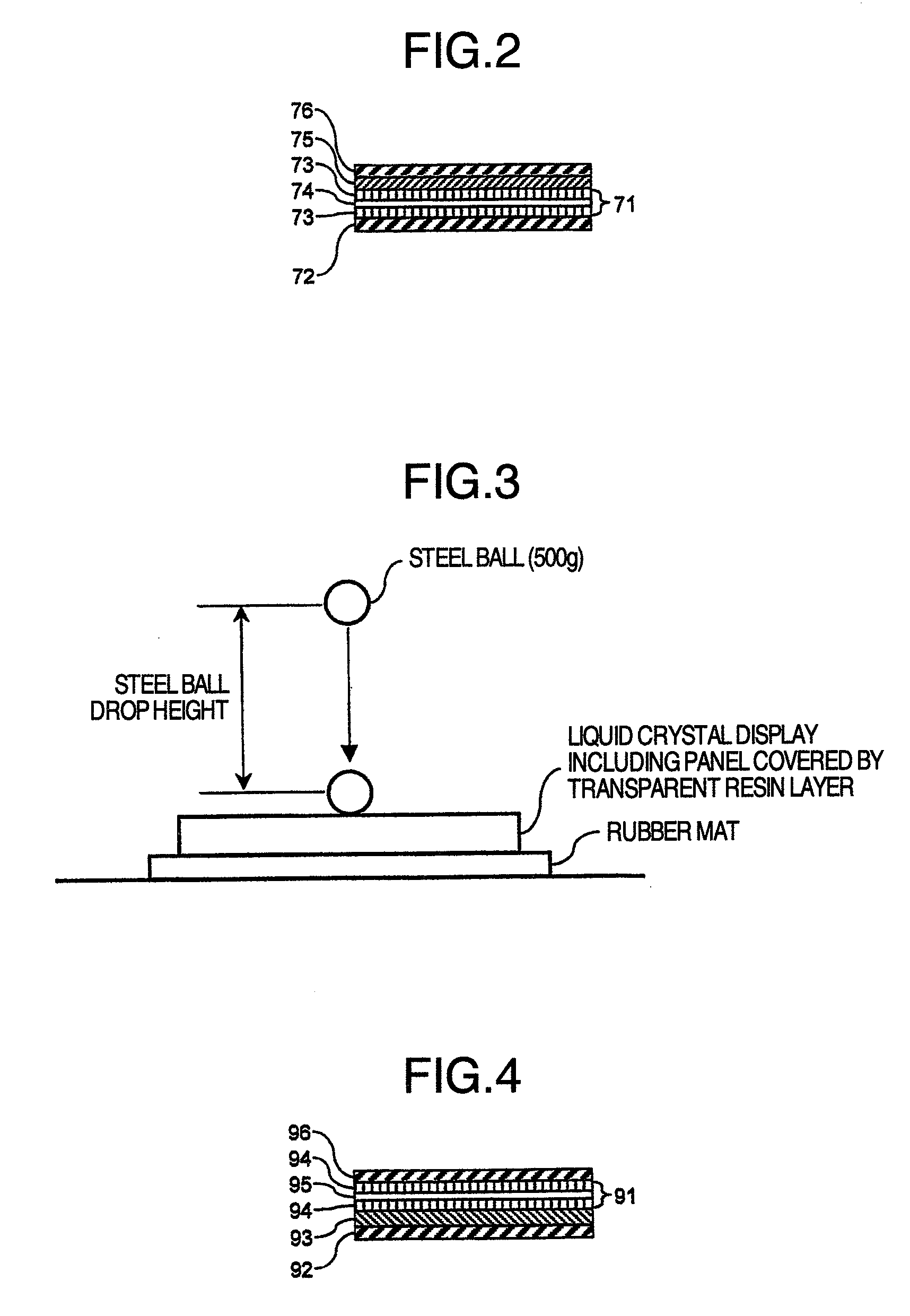

Liquid crystal display

ActiveUS20080192181A1Sufficient impact resistanceDisplayed image is restrainedNon-linear opticsLiquid-crystal displayThermal expansion

In a liquid crystal display comprising a liquid crystal layer, a pair of substrates between which the liquid crystal layer is arranged, a pair of polarizing plates arranged between which the substrates are arranged, and a light source arranged at an outside of the polarizing plates, the liquid crystal display further comprises a first transparent resin layer arranged between the liquid crystal layer and the light source and a second transparent resin layer to be arranged between the viewer and the liquid crystal layer, and a linear thermal expansion coefficient of the first transparent resin layer is smaller than that of the second transparent resin layer.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

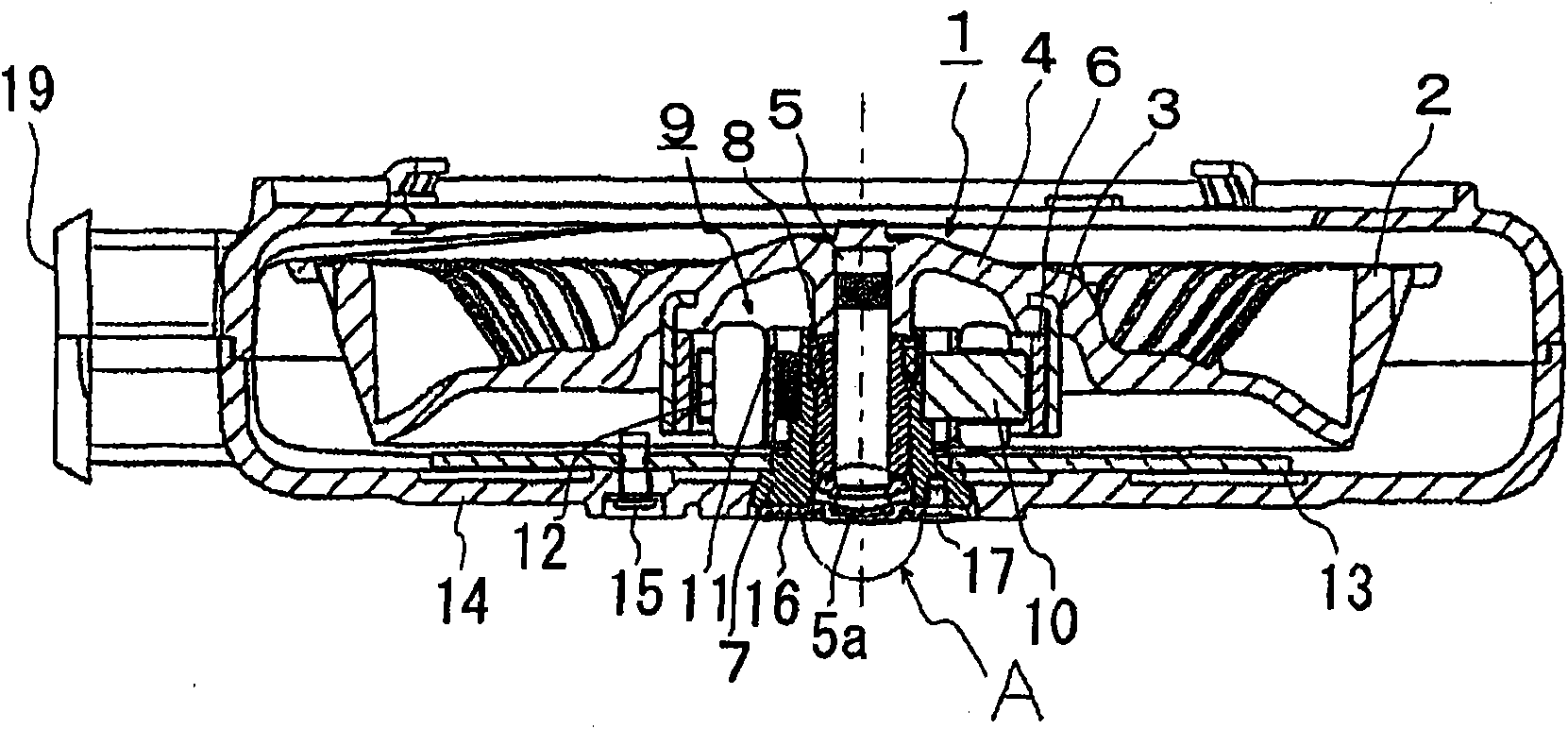

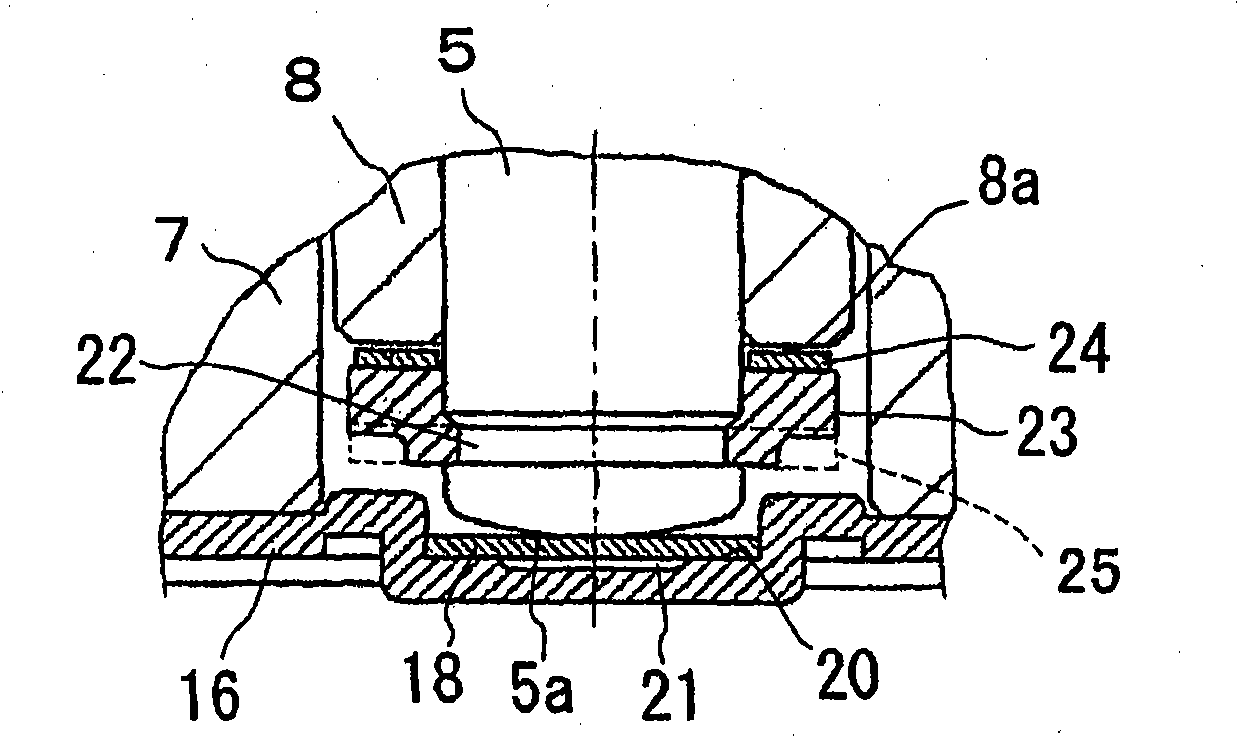

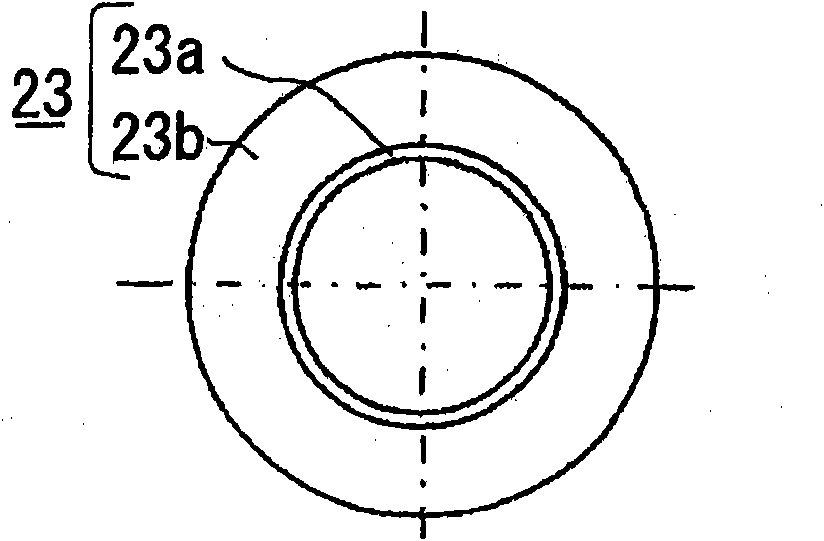

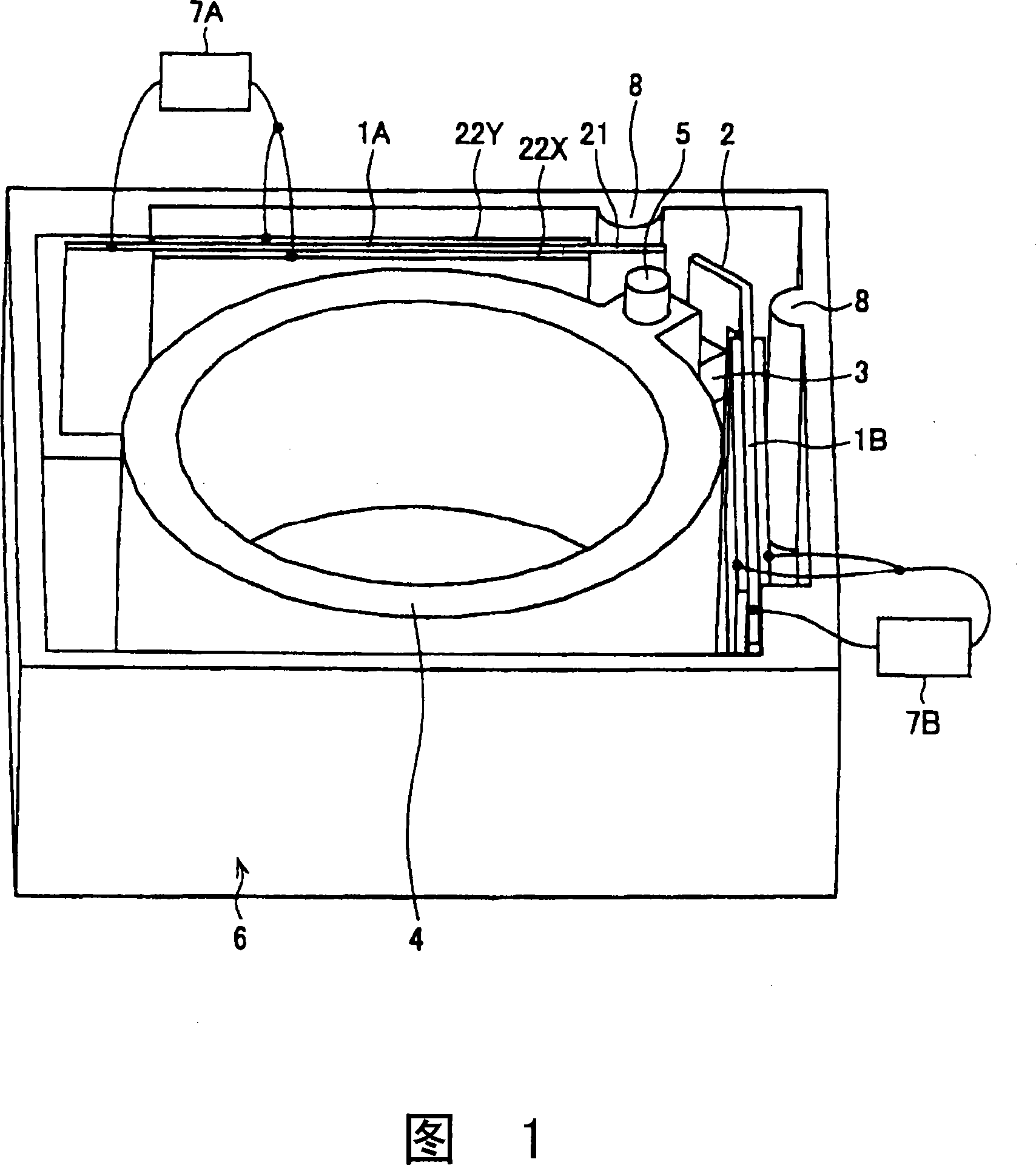

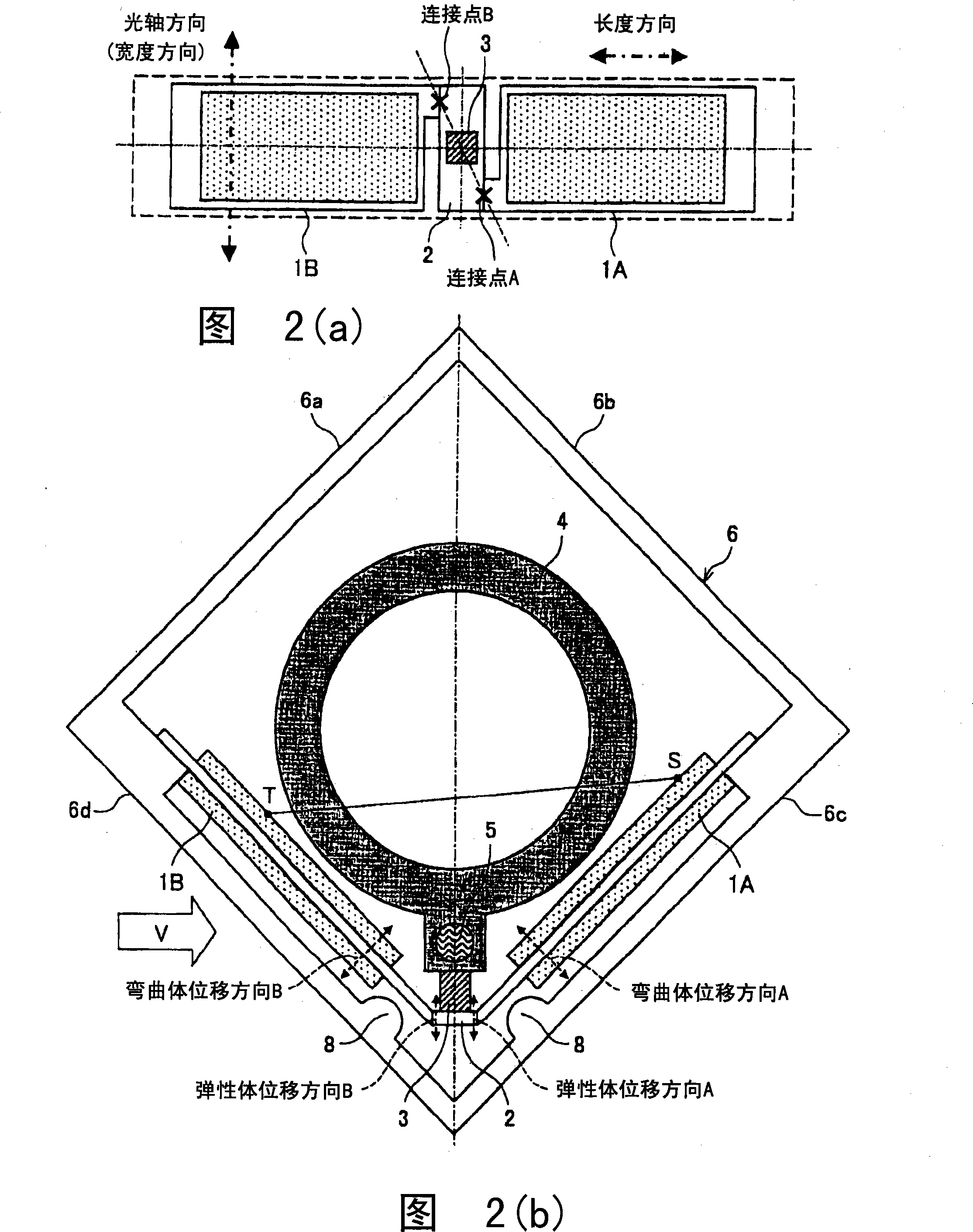

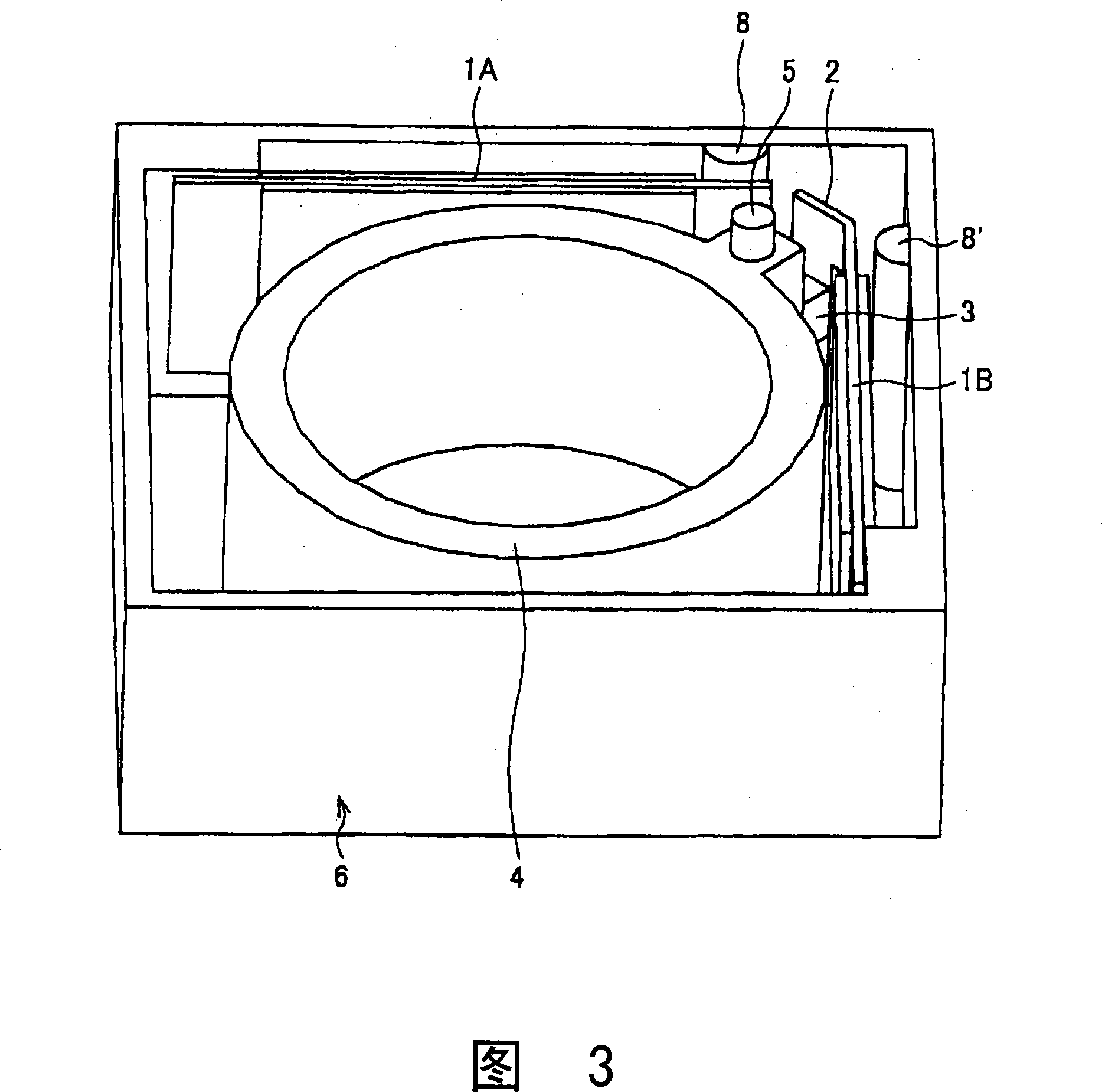

Driving apparatus

InactiveCN101247095ASufficient impact resistancePiezoelectric/electrostriction/magnetostriction machinesMountingsElectricityEngineering

To realize a driving apparatus where vibrational movement of a piezoelectric element is ensured; sufficient impact resistance is provided; and damages to the piezoelectric element is prevented, a driving apparatus of the present invention has: a flex movement member 1A or 1B for serving as a driving source to drive a lens barrel 4, the flex movement member including: a piezoelectric member 22X or 22Y which extends and contracts under electric control; and a shim 21 larger than the piezoelectric member 22X or 22Y, the piezoelectric member and the vibrational plate attached to each other; and protruding sections 8 for restricting an excessive flex movement of the shim 21 of the flex movement member 1A or 1B, the protruding sections 8 being at a position where the protruding sections 8 will not contact with the piezoelectric member 1A or 1B of the flex movement member 22X or 22Y when the flex movement member is making an excessive flex movement beyond a maximum flex movement amount, where the maximum flex movement amount is greatest among flex movement amounts necessary for the flex movement member 1A or 1B to drive the lens barrel 4. This provides the driving apparatus with enough impact resistance, and prevents damage to the piezoelectric element.

Owner:SHARP KK

Composite component containing amorphous alloy and preparation method of composite component

The invention discloses a composite component containing an amorphous alloy. The composite component comprises an amorphous alloy prefabricated assembly and a low melting point assembly. The amorphousalloy prefabricated assembly comprises one or more amorphous alloy prefabricated parts, and the low melting point assembly is a combination part comprising a plurality of low melting point materials;the low melting point materials are polymer materials or metal materials with the melting point being lower than 800 DEG C; and the thickness of each amorphous alloy prefabricated part is 0.1-6 mm. The prefabricated assembly with the specific shape is prefabricated through the characteristics that the amorphous alloy has high strength and can be used for forming a complex structure, then the lowmelting point assembly is injected into a mould to be combined with the prefabricated amorphous alloy to form and prepare the composite component, the composite component simultaneously has the characteristics of high strength of the amorphous alloy and high plasticity of the low melting point assembly, thus the prepared composite component can still have sufficient strength and impact resistanceperformance at the weak position of the significantly-thinned component or the component of a special-shaped structure, and meanwhile, the overall weight of the component can also be decreased.

Owner:DONGGUAN JIANYE MATERIAL TECH CO LTD

Self-protecting wearable flux-cored wire of hot-rolling blooming roll

InactiveCN103659040AExtended service lifeMeet working conditionsWelding/cutting media/materialsSoldering mediaCarbon steelAlloy

The invention relates to a self-protecting wearable flux-cored wire of a hot-rolling blooming roll. The flux-cored wire consists of a low-carbon steel outer skin and a flux core, and is characterized by comprising the following components in percentage by total mass of the flux-cored wire: 0.2 to 0.3 percent of C, 1.1 to 1.3 percent of Si, 1.5 to 1.8 percent of Mn, 6 to 7 percent of Cr, 1.4 to 1.6 percent of Mo, 0.5 to 1 percent of V, 1.2 to 2 percent of W, 5 to 6 percent of CaF, 2, 4 to 5 percent of TiO2, 0.45 to 0.6 percent of CaCO3, 0.4 to 0.6 percent of SiO2 and the balance of iron. The flux-cored wire has the advantage that the hardness of a surfacing alloy can be guaranteed to be more than HRC55.

Owner:天津雷公焊接材料有限公司

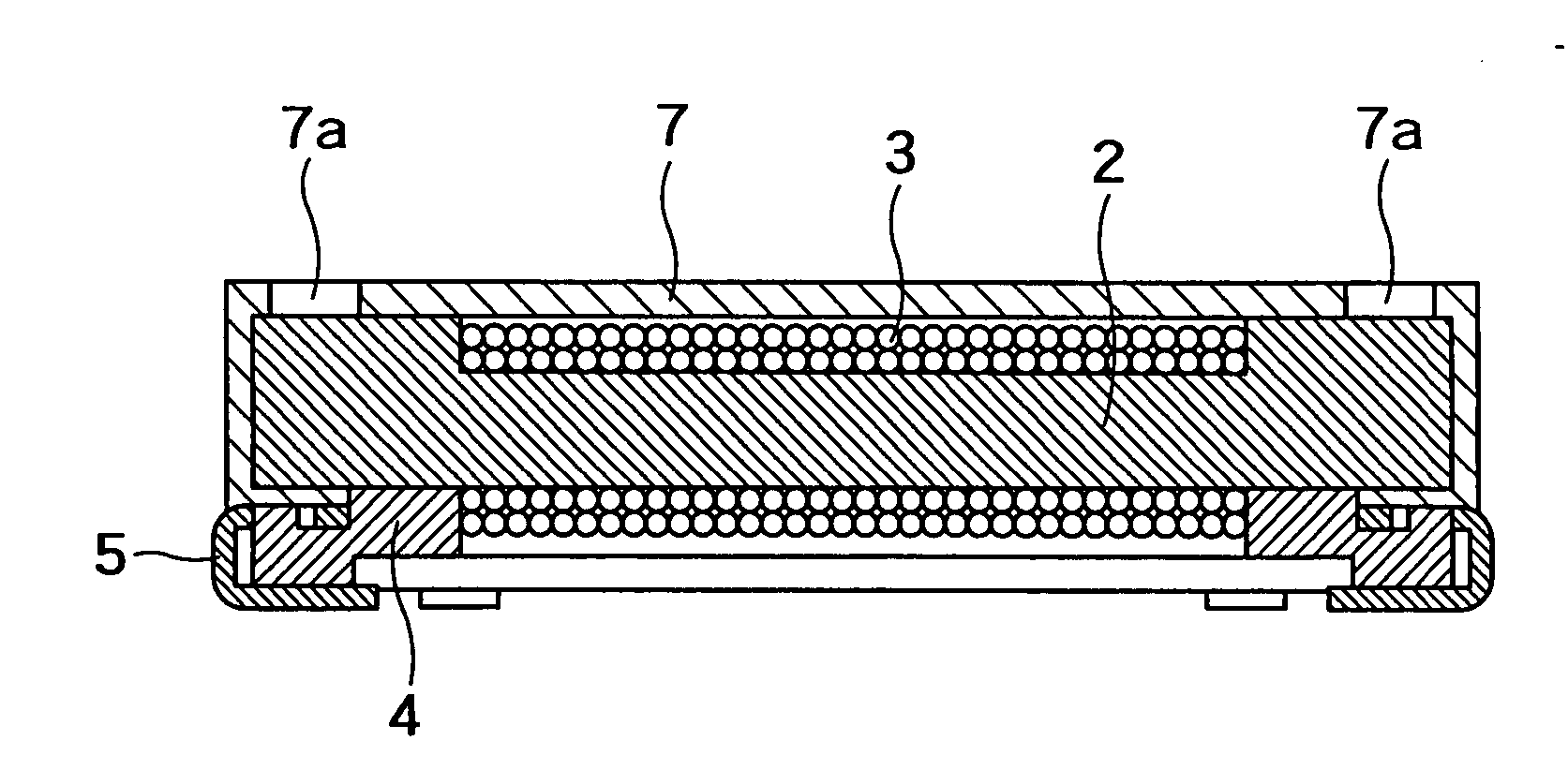

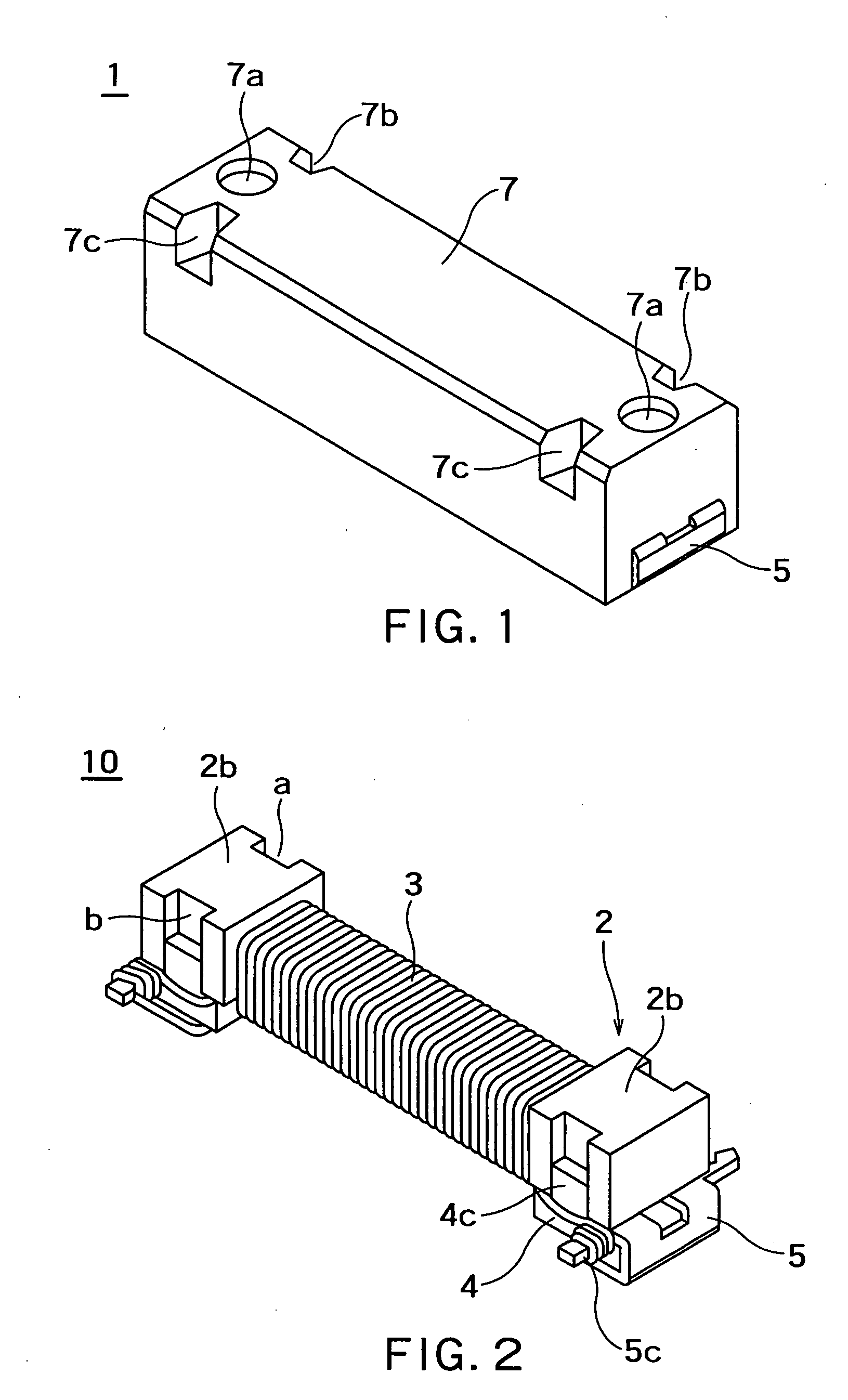

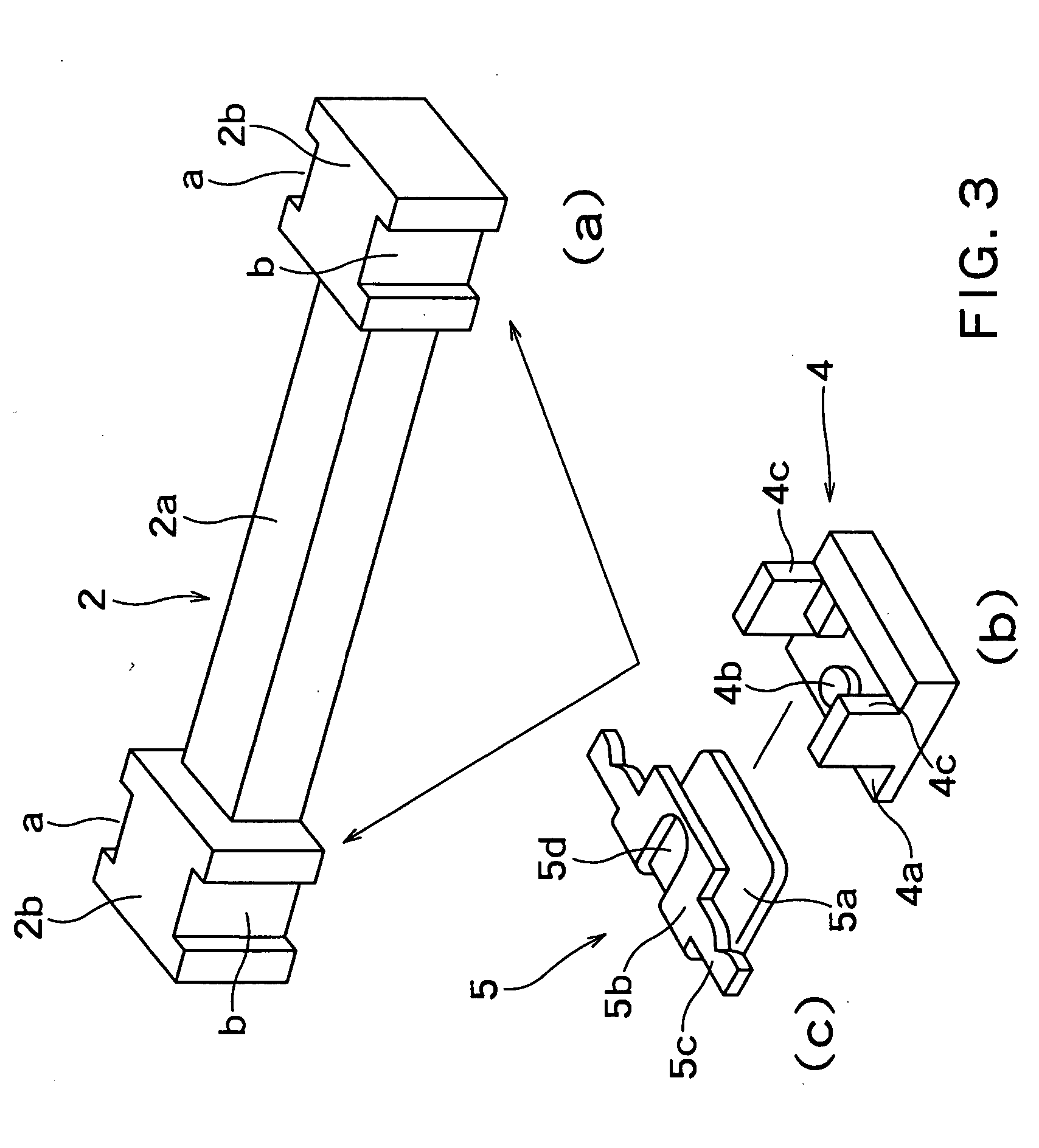

Miniature surface-mount electronic component and method for manufacturing the same

ActiveUS20070268102A1Sufficient impact resistanceSufficient vibrationTransformers/inductances casingsCoils manufactureEngineeringConductor Coil

A miniature surface-mount electronic component which can ensure sufficient impact resistance and vibration resistance especially in an application to a severe use environment such as a vehicle-mounted coil, by putting some contrivance into a method for fixing a coil in a molding process and a method for holding a core and terminals. A miniature surface-mount electronic component including a bar-shaped core 2 on which a winding wire 3 is wound, and metal plates 5, with an outer casing 7 made of an insulating resin molded, includes flanges 2b substantially quadrangular in section at both ends of the bar-shaped core 2, and vertical grooves a and b are provided on side surfaces of the flanges 2b of the bar-shaped core 2 as fixing portions for preventing positional displacement occurring when the outer casing 7 is molded.

Owner:MURATA MFG CO LTD

Thermoplastic Resin Composition For Hot Plate Welding, Molded Article Thereof, And Resin Conjugate

ActiveUS20200207971A1Excellent surface appearanceSufficient impact resistancePolymer sciencePolymer chemistry

A thermoplastic resin composition is provided from which a molded article that has excellent string resistance at the time of hot plate welding, a highly excellent surface appearance, generates a small amount of gas from the material, and has sufficient impact resistance as a material for a lamp housing can be obtained. The thermoplastic resin composition contains a thermoplastic resin component (A) and a saponified fatty acid ester (B), in which a content of the saponified fatty acid ester (B) is in a range of 0.1 parts by mass to 10 parts by mass with respect to 100 parts by mass of the thermoplastic resin component (A).

Owner:TECHNO UMG CO LTD

Carbon fiber-wound graphite bearing

InactiveCN105299049AHigh strengthOvercoming deterioration in corrosion resistanceBearing componentsFiberCarbon fibers

The invention proposes a carbon fiber-wound graphite bearing. The carbon fiber-wound graphite bearing comprises a machined graphite bearing sleeve, wherein a layer of woven carbon fibers is at least wound on the surface of a carbon material of the graphite bearing sleeve. As one layer of carbon fibers is wound on the surface of the carbon material, the strength of the graphite bearing is improved, the defects of the graphite bearing inlaid with a metal cover under bad working conditions are overcome, and the problem of bearing failure due to easy fall and release of the bearing under the conditioner of higher temperature caused by different thermal expansion coefficients of metal and the carbon material in a metal-inlaid graphite bearing in the prior art is solved. The carbon fiber material and the carbon graphite material are substantially identical in thermal expansion coefficient, so that no loose and fall phenomenon can be generated even if under the condition of high temperature. In addition, the carbon fiber-wound graphite bearing further solves the problems of weakening of corrosion resistance and still incapability of achieving the corrosion resisting effect of a pure carbon graphite material under the condition of having such strong-corrosion liquid as strong acid and strong alkali in the prior art; and the carbon fiber material just can overcome the difficulties.

Owner:CHENGDU ZHONGCHAO CARBON SCI & TECH

Molded article and process for producing the same

InactiveUS20090197079A1Promote degradationImprove the immunityGlass/slag layered productsThin material handlingLignin degradationInjection moulding

In a molded article containing a plant material and a thermoplastic resin, and formed by injection molding, the thermoplastic resin is contained in an amount of 5 to 50% by mass, and the plant material is contained in an amount of 50 to 95% by mass when the total amount of the thermoplastic resin and the plant material is taken as 100% by mass, and a material containing lignin in an amount of 10% by mass or more when the total amount of the plant material is taken as 100% by mass is used as the plant material. And, a process for producing a molded article includes the mixing step of mixing a plant material, water and a thermoplastic resin to obtain a molding material, and the injecting and molding step of injecting the molding material in a molding die and molding the molding material with the molding die to obtain the molded article. In the mixing step, a material containing lignin in an amount of 10% by mass or more when the total amount of the plant material is taken as 100% by mass is used as the plant material, the thermoplastic resin is mixed in an amount of 5 to 50% by mass and the plant material is mixed in an amount of 50 to 95% by mass when the total amount of the thermoplastic resin and the plant material is taken as 100% by mass, water is mixed in an amount of 5 to 200% by mass based on 100% by mass of the plant material, and the plant material, water and the thermoplastic resin are mixed while thermofusing the thermoplastic resin.

Owner:TOYOTA BOSHOKU KK

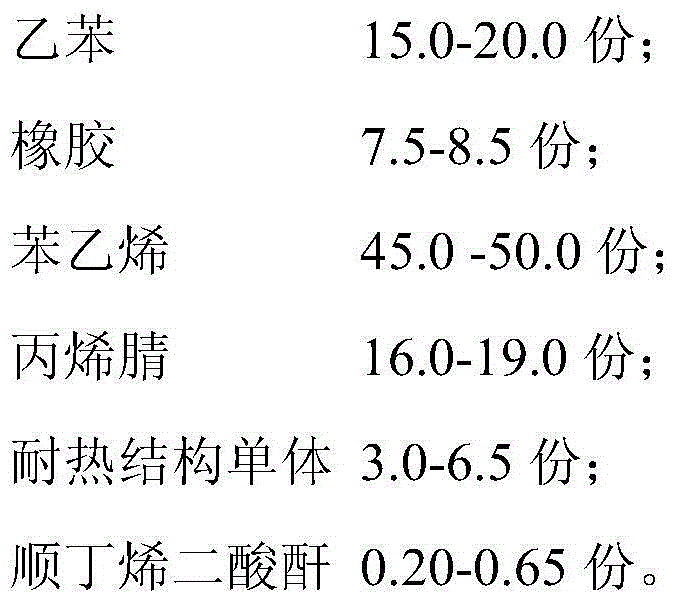

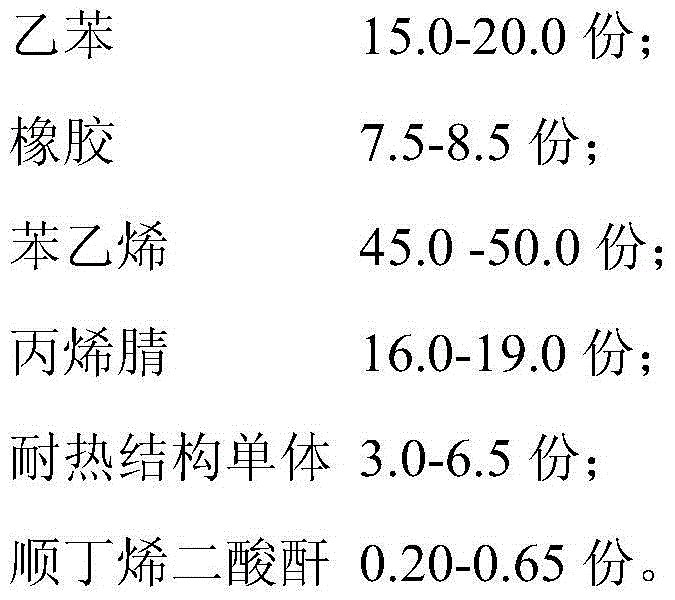

ABS with high heat resistance and preparing process thereof

InactiveCN105778003AImprove heat resistanceSufficient impact resistancePolymer scienceHeat resistance

The invention discloses an ABS composition with high heat resistance.The ABS composition is composed of a rubber dispersion phase existing in the particle form and a styrene and acrylonitrile copolymer continuous phase.The composition contains a heat-resisting monomer, and Vicat softening point is higher than 112 DEG C.The composition further contains a maleic anhydride copolymer.The ABS composition prepared with the method has high heat resistance, low monomer residue level, lower energy consumption and more stable performance, and sufficient impact resistance and other general performances are maintained.

Owner:SHANGHAI HUAYI POLYMER

Solenoid

InactiveUS20050190033A1Low costSave materialTransformers/inductances casingsTransformers/inductances coils/windings/connectionsPlastic materialsSolenoid valve

Owner:NASS MAGNET GMBH

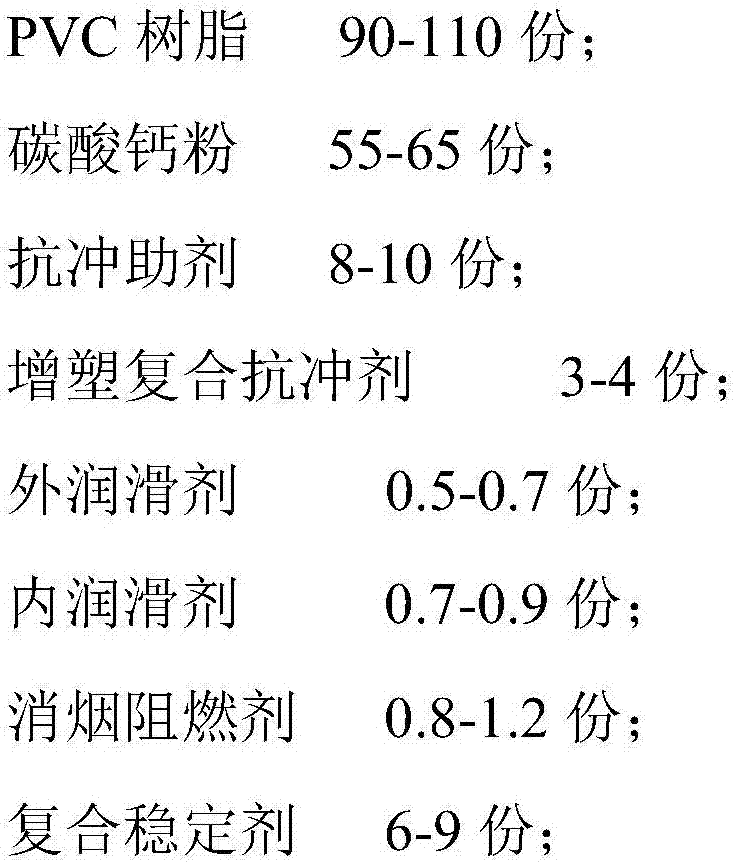

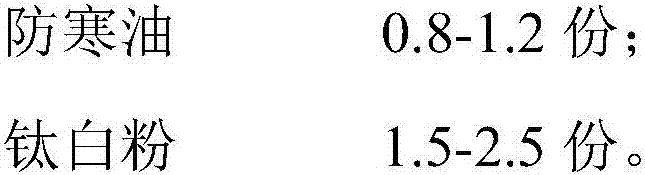

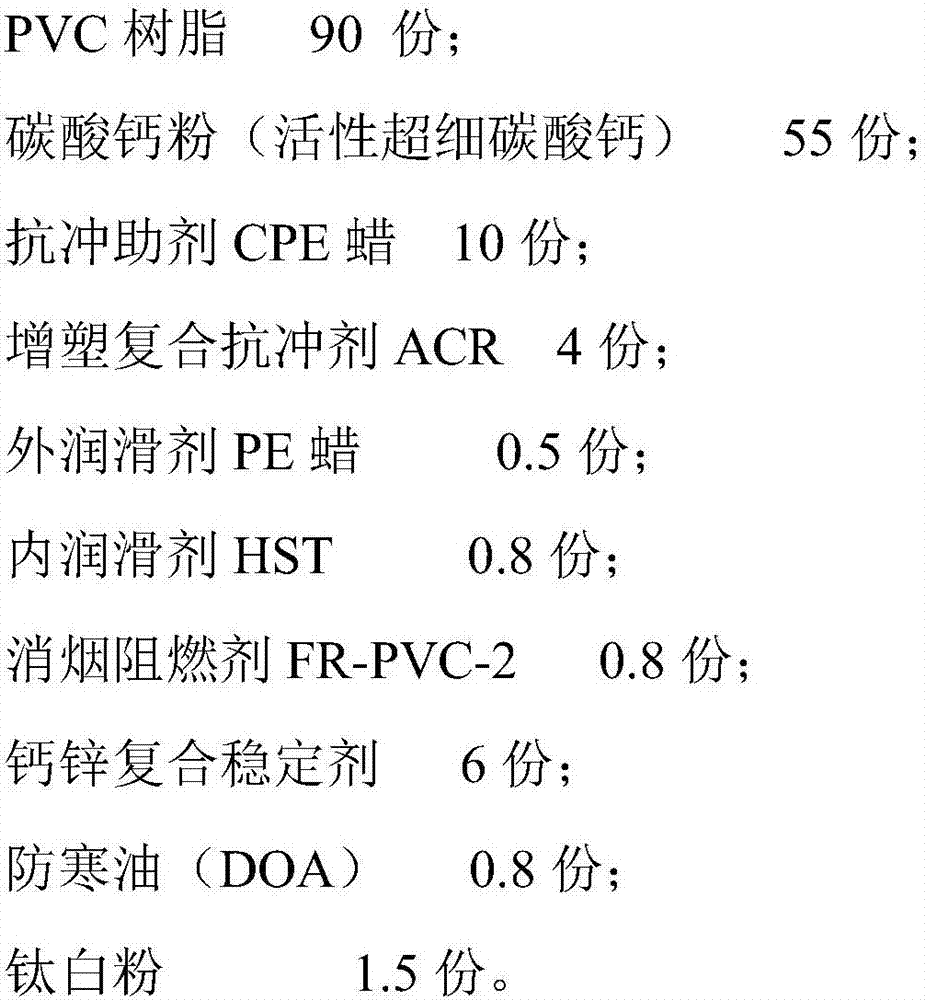

PVC passenger car air duct board

The invention discloses a PVC passenger car air duct board produced through extrusion molding. The PVC passenger car air duct board is prepared from the following raw materials in parts by weight: 90-110 parts of PVC resin, 55-65 parts of calcium carbonate powder, 8-10 parts of an anti-impact aid, 3-4 parts of a plasticizing compound anti-impact agent, 0.5-0.7 part of an outer lubricant, 0.7-0.9 part of an inner lubricant, 0.8-1.2 parts of a smoke-abatement flame retardant, 6-9 parts of a compound stabilizer, 0.8-1.2 parts of cold-proof oil and 1.5-2.5 parts of titanium dioxide.

Owner:苏州大友汽车配套件有限公司

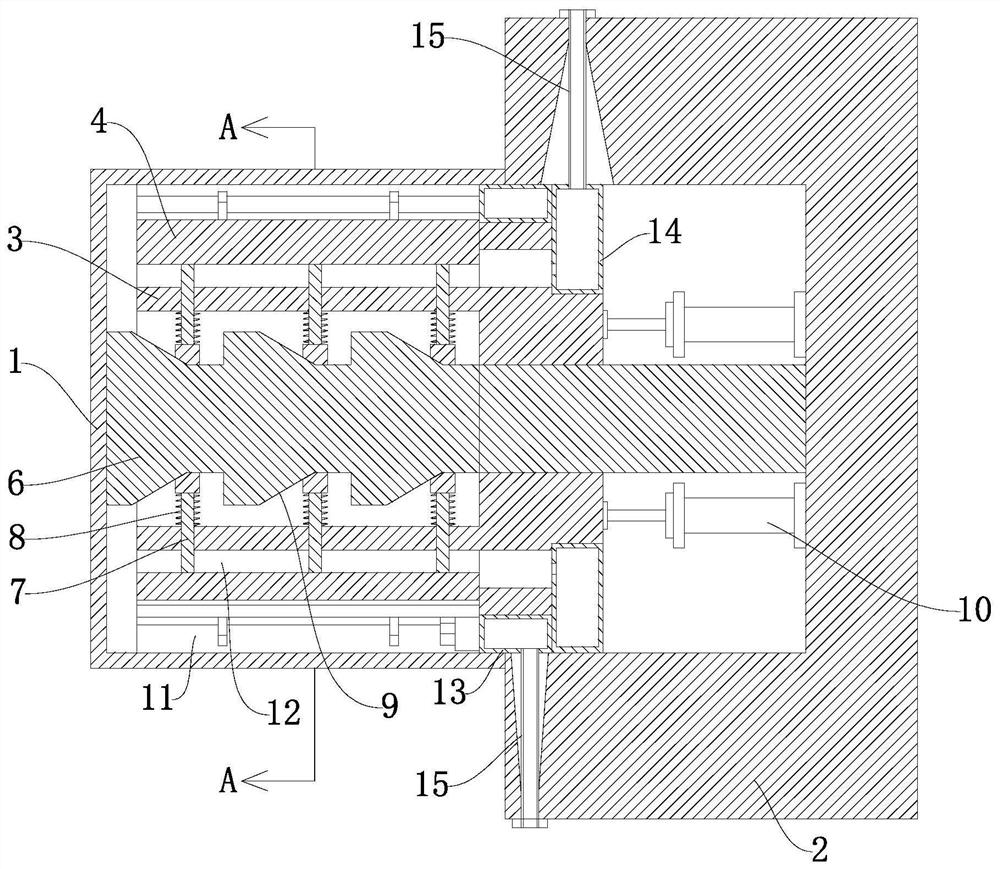

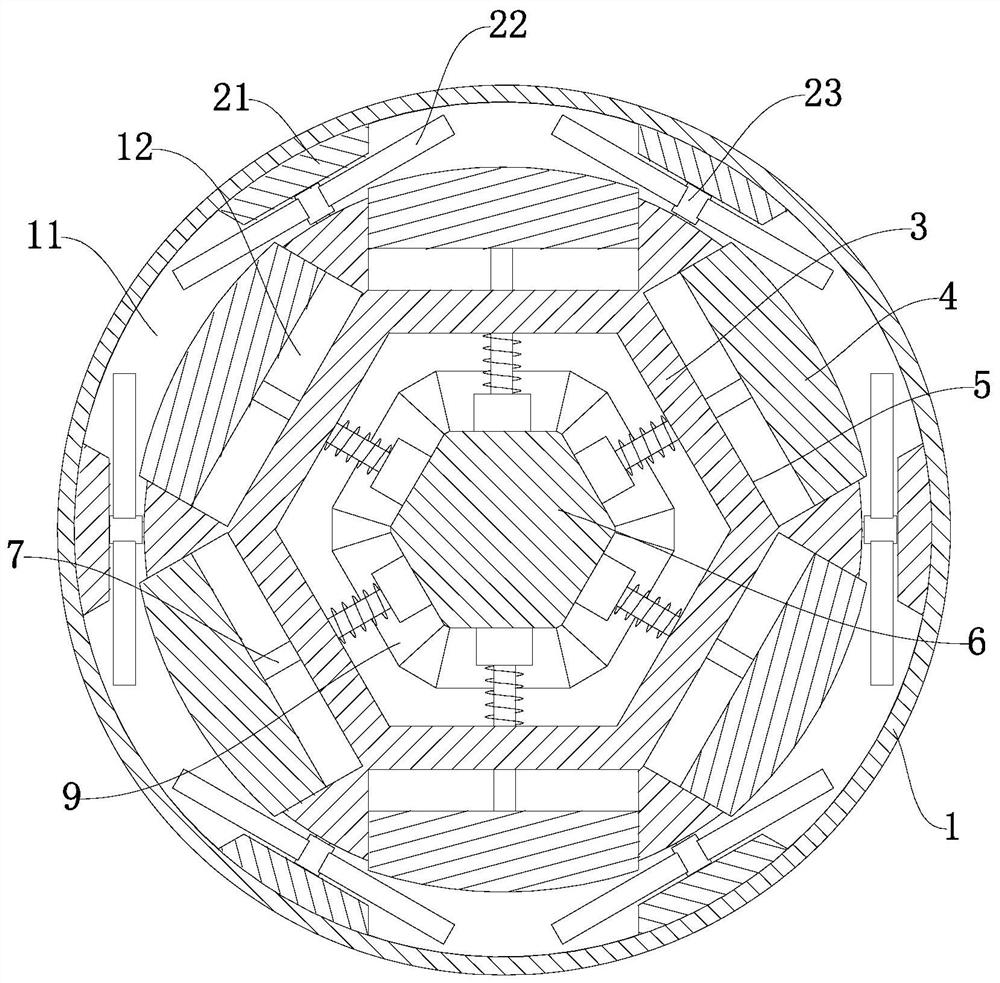

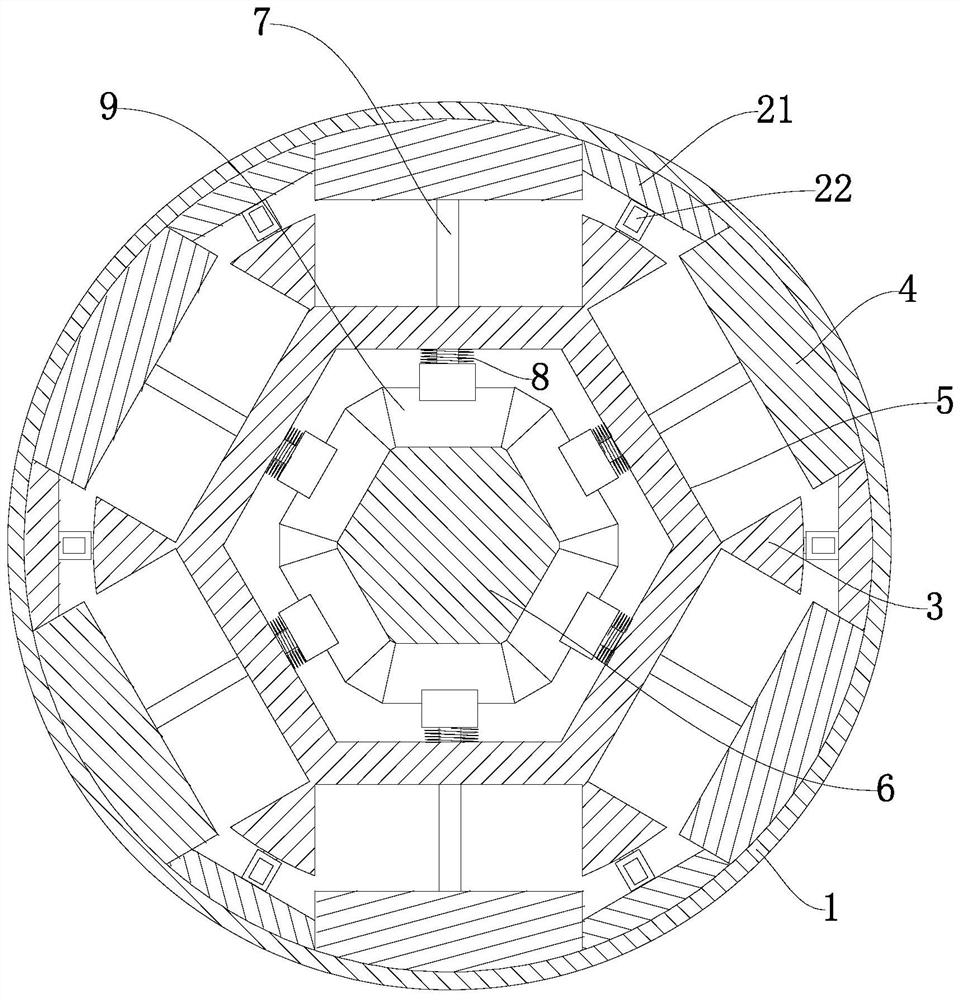

Automobile mold core cooling structure

The invention discloses an automobile mold core cooling structure, and belongs to the technical field of automobile molds. The automobile mold core cooling structure comprises a core, a core seat, a cooling structure and a supporting mechanism; the cooling structure comprises a cooling water inlet channel, a cooling water return channel, a cooling water inlet ring and a cooling water return ring, wherein the cooling water inlet ring and the cooling water return ring are arranged on a supporting cylinder; and the cooling water inlet ring and the cooling water return ring are connected with an external water pipe through cooling water pipes. The supporting mechanism is arranged in the core and can support the inner wall of the core, so that under the condition that the inner wall of the core is designed to be thin, it can be ensured that the core has enough impact resistance, the good service life is kept, and the cooling effect is improved; and a fan assembly is further arranged in the core, turbulent flow can be increased, the temperature difference between the cooling water flow close to the inner wall of the core and the outer wall of the supporting cylinder is reduced, and the cooling effect is improved.

Owner:江苏久祥汽车电器集团有限公司

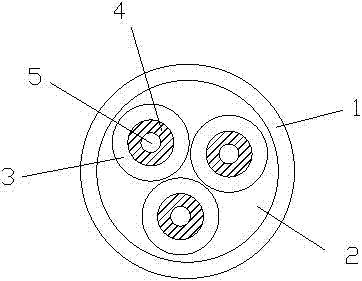

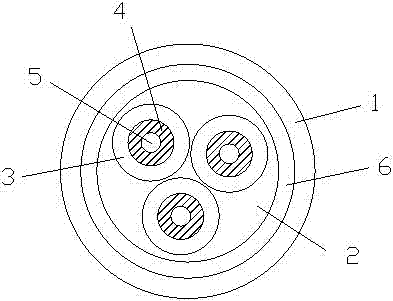

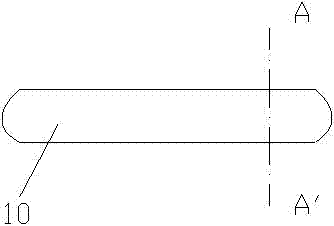

Impact-resistant cable

InactiveCN107331450ASufficient impact resistanceImprove insulation performanceInsulated cablesInsulated conductorsElectrical conductorEngineering

The invention provides an impact-resistant wire and cable, comprising a first outer sheath, an inner sheath, a shielding layer, at least one insulating layer and at least one conductor, the insulating layer surrounds the conductor, the shielding layer surrounds the insulating layer, The first outer sheath surrounds the shielding layer, the inner sheath is filled between the outer sheath and the shielding layer, and a second outer sheath is arranged between the first outer sheath and the inner sheath, so The second outer protective layer is a layer of metal mesh, and the surface of the metal mesh is covered with an insulating coating and a refractory coating. The wire and cable of the invention has good impact resistance and good fire resistance.

Owner:HEFEI DAHU ELECTRIC WIRE & CABLE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com