Carbon fiber-wound graphite bearing

A carbon-graphite bearing and graphite bearing technology, used in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of poor corrosion resistance, impossible corrosion resistance, and carbon-graphite material falling off. The effect of improving strength, reducing work wear, and easy machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

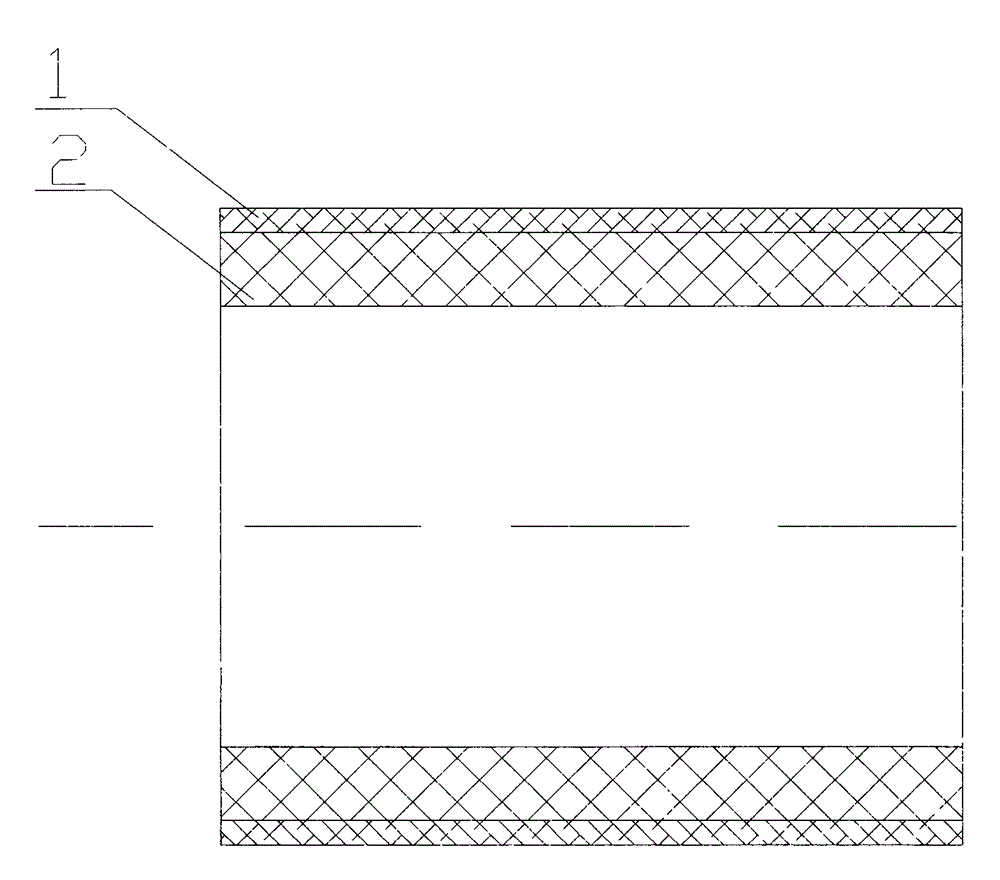

[0011] refer to figure 1 . In the embodiments described below, the carbon fiber wound carbon graphite bearing includes a graphite mandrel 2 that is processed first, and at least one layer of braided carbon fiber layer 1 is wound on the surface of the graphite mandrel. The thickness of the surface carbon fiber winding layer 1 is at least 5-10mm, and its thickness increases according to the increase of the finished product. For example, put the wound graphite bearing into the reactor to impregnate the resin, vacuumize, pressurize at least 0.8MPa, and heat up to 200°C for curing. After the curing is completed, the inner and outer circles and inner holes are roughly turned, and finally the inner and outer circles and end faces are ground according to the requirements of the drawings. The size of the carbon fiber wound graphite bearing required is Its shaft size is (Ensure that after the processing is completed, the carbon fiber layer on the surface of the finished product is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com