Method for constructing green and energy-saving building

A construction method and construction technology, applied in the direction of building, building roof, building structure, etc., can solve the problems of insufficient heat radiation restriction, insufficient flame retardant ability to release harmful substances, insufficient restriction and comprehensive, etc., and achieve high conversion and appreciation. effect, optimized effect, effect of good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

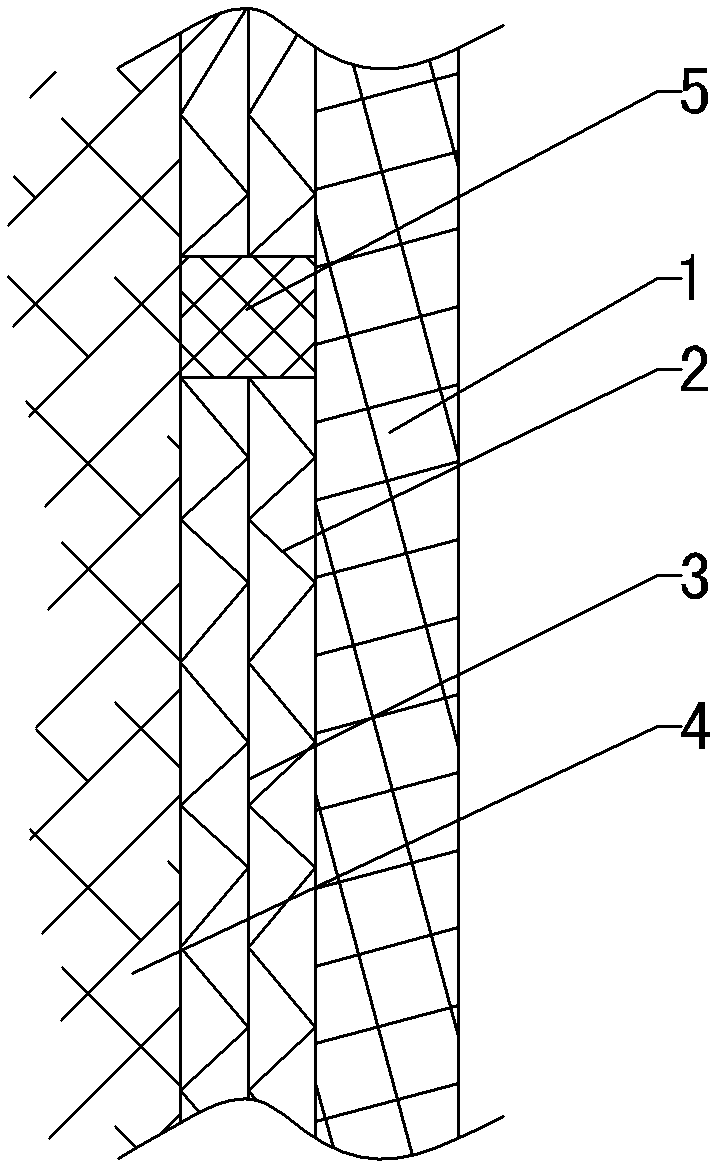

[0030] Refer to attached figure 1 :

[0031] The construction method of the green energy-saving building, the wall or the roof construction layer has a layer of supporting surface layer and multi-layer intervals for blocking heat transfer, including the following steps,

[0032] 1.1. Make the support surface layer 1 installed on the construction layer of the building. First, crush and sieve the fly ash from the landfill and put it into the mixer. Use short strips or small blocks with low thermal conductivity The material is made of coarse aggregate, and quicklime powder, cement and process water are used to form a binder, and then harmless organic or inorganic waste filamentary or strip-shaped fibers are used as mechanical performance strengthening components, and process additives are used to improve workability , and finally these ingredients are fully stirred and mixed to make the support surface layer 1 of different shapes and structures. The support surface layer 1 inclu...

Embodiment 2

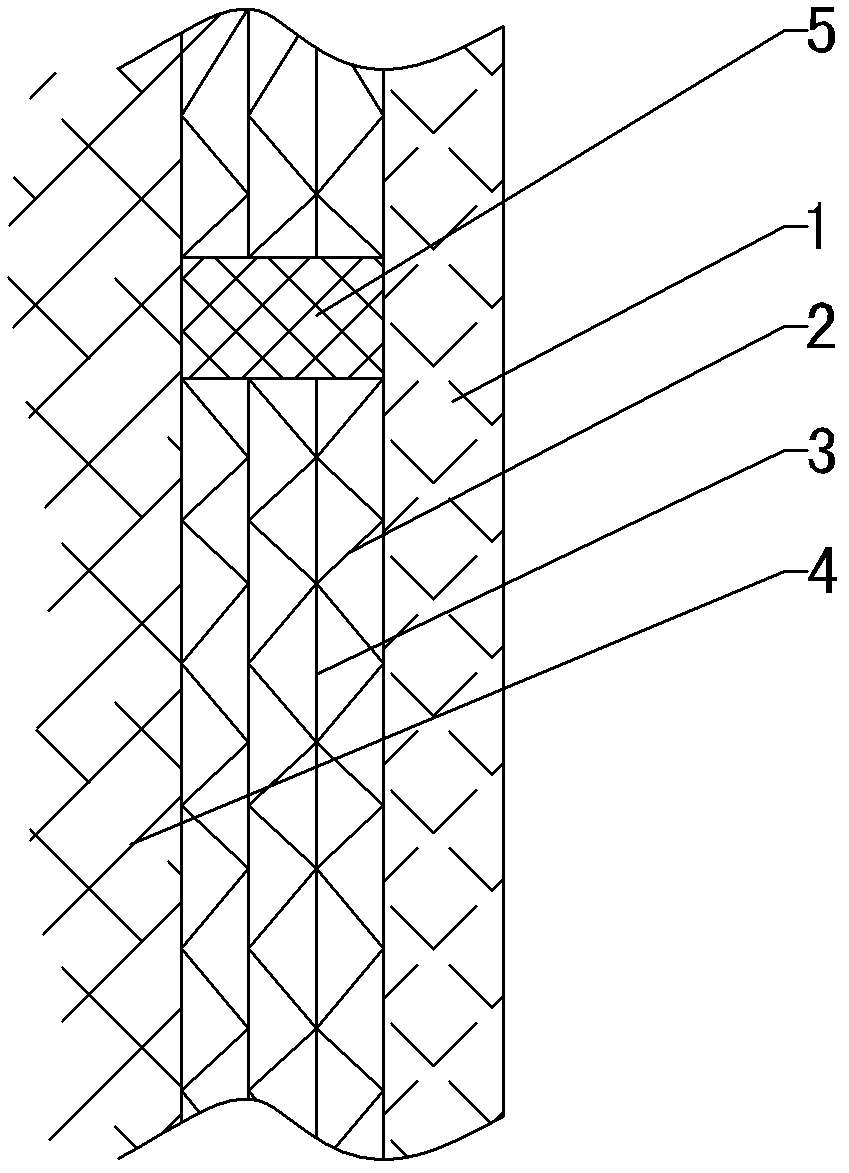

[0039] Refer to attached figure 2 :

[0040] There are three layers of grids 2 and two layers of reflective layers 3, which form three intervals that block heat transfer. Among them, the intervals between the supporting surface layer 1 and the adjacent reflective layer 3 are relatively closed, and heat convection can be effectively obtained. The heat conduction is generated by the air in the interval and the warp 14 or weft 15 of the grid, so its magnitude is small; when the temperature of the protective surface layer 1 is higher than that of the wall 4, the reflective layer 3. More than 90% of the radiant heat of the heat radiation is reflected back to the direction of the armor surface layer 1, and a small amount is absorbed, so the gap effectively blocks heat transfer.

[0041]In the same way, the space between the two reflective layers 3 is also similarly and effectively blocked the heat transfer. Similarly, the space between the wall body 4 and the adjacent reflective l...

Embodiment 3

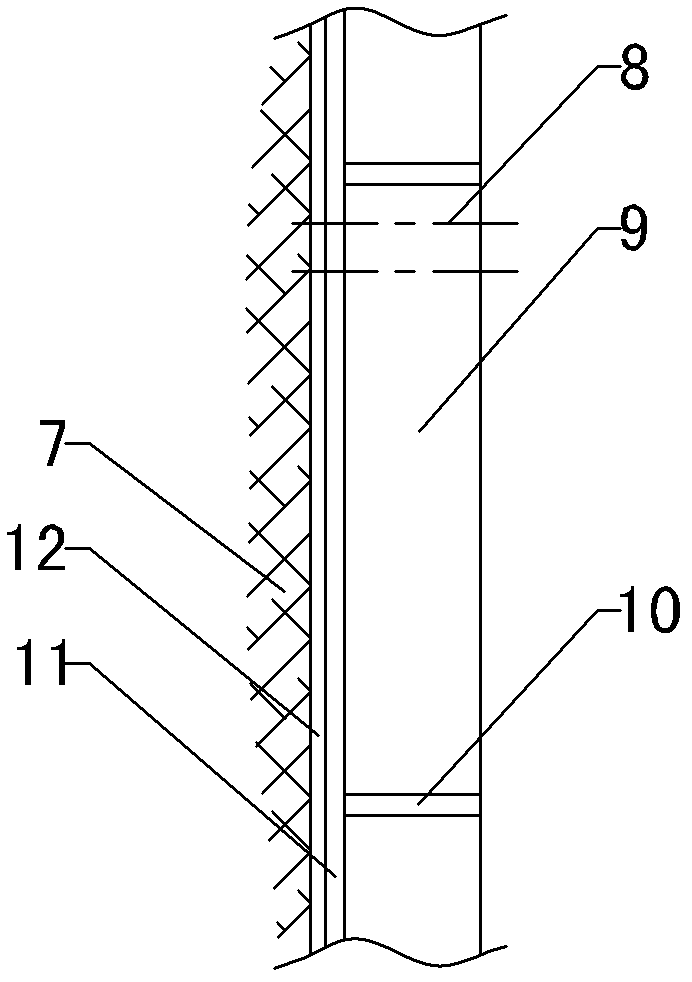

[0045] Refer to attached image 3 :

[0046] The wall body 4 is the exterior wall of the building, and the supporting surface layer 1 is provided with two layers, and the supporting surface layer 1, the mesh grid 2, the reflective layer 3, the cement-based composite profiles blocked around the surroundings, the spacer 5 and the liner are made into one Composite layer components 9 of formula structure, and each gap between the composite layer components 9 is blocked with cement-based adhesive.

[0047] Composite layer components 9 are provided in multiple pieces, and are directly fastened to the wall body 4 by splicing through fixed embedded parts 8 , and the gaps formed between composite layer components 9 are filled with filler to form filler gaps 10 .

[0048] The bracing surface layer 1, grid 2, reflective layer 3 and cement-based composite material are directly made into an integrated finished product, which is directly fixed and installed on the wall body 4, which saves ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com