PVC passenger car air duct board

A technology for air duct panels and passenger cars, applied in the field of PVC passenger car air duct panels, can solve the problems of flame retardant effect (poor light and thermal stability, poor photo-oxidation and photoaging effects, large volume of finished air duct panels, etc.) Improved physical and chemical properties, good high and low temperature resistance, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

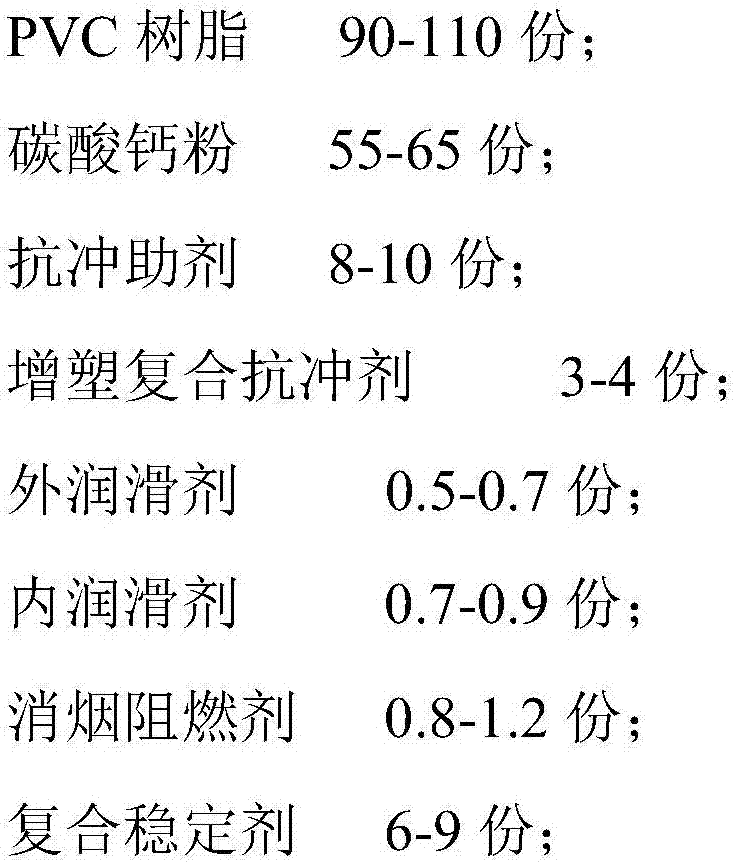

[0027] Embodiment 1, a kind of PVC passenger car air duct plate, by weight, the raw material composition is:

[0028]

[0029] The following table is the product related test data comparison table described in embodiment 1:

[0030]

Embodiment 2

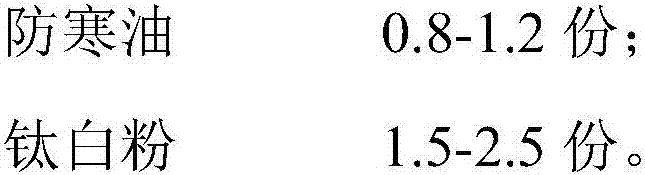

[0031] Embodiment 2, a PVC passenger car air duct plate, in parts by weight, the raw material composition is:

[0032]

[0033] The following table is the product related test data comparison table described in embodiment 2:

[0034]

Embodiment 3

[0035] Embodiment 3, a kind of PVC passenger car air duct plate, by weight, the raw material composition is:

[0036]

[0037] The following table is the product related test data comparison table described in embodiment 3:

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com