Preparing method of engineering machine final drive gear

A technology for transmission gears and construction machinery, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem of mechanical matching PVD coating with high hardness, low coating performance, unsatisfactory coating performance, coating and substrate. Problems such as poor bonding force, to achieve the effect of improving physical and mechanical properties, reducing friction coefficient, and enhancing adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

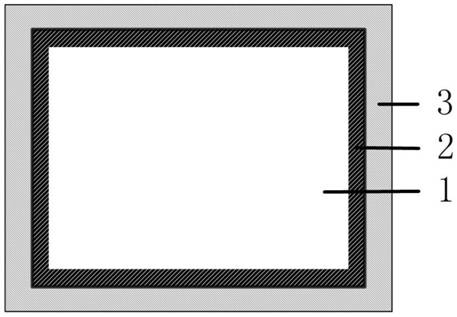

Image

Examples

Embodiment 1

[0028] In the preparation method of engineering machinery final drive gear parts according to the present invention, the base material of the gear parts is 22CrNi2MoNb, and the base body of the gear parts is subjected to quenching, high temperature tempering, rough and fine machining, and then carburized by ion plating, and then ion plating The NbHfMoC gradient coating on the surface is deposited by a combined method with magnetron sputtering. Two C ion plating targets, one Nb magnetron sputtering target, one Hf magnetron sputtering target and one Mo magnetron sputtering target are used for deposition. target;

[0029] Specifically include the following steps:

[0030] (1) Parts processing: parts blank→quenching (830~880℃, water cooling)→high temperature tempering (520~550℃, water cooling)→rough machining→semi-finishing→stress relief tempering (500~550℃, air cooling) → Finishing (surface roughness Ra 1.6μm, processing size: lower limit of tolerance);

[0031] (2) Part surfac...

Embodiment 2

[0041] In the preparation method of engineering machinery final drive gear parts described in the present invention, the base material of the final drive gear parts is 20CrMnTi, and the gear part base is subjected to carburizing treatment by ion plating after quenching, high temperature tempering, and rough and fine machining, and then through The NbHfMoC gradient coating on the surface is deposited by the combined method of ion plating and magnetron sputtering. Two C ion plating targets, one Nb magnetron sputtering target, one Hf magnetron sputtering target and one Mo magnetron are used for deposition. sputtering target;

[0042] Specifically include the following steps:

[0043] (1) Parts processing: parts blank→quenching (910~950℃, oil quenching)→high temperature tempering (535~600℃, air cooling)→rough machining→semi-finishing→stress relief tempering (565~590℃, oil quenching) Cold)→finishing (surface roughness Ra 0.8μm, processing size: lower limit of tolerance);

[0044]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com