ABS with high heat resistance and preparing process thereof

A technology with high heat resistance and heat resistance, applied in the field of polymer chemistry, it can solve the problems of difficult balance of processing performance and low introduction amount, and achieve the effect of flexible brand switching, stable product performance and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The reaction system of this embodiment adopts four reactors connected in series, and all materials are added to the process mode in the first reactor.

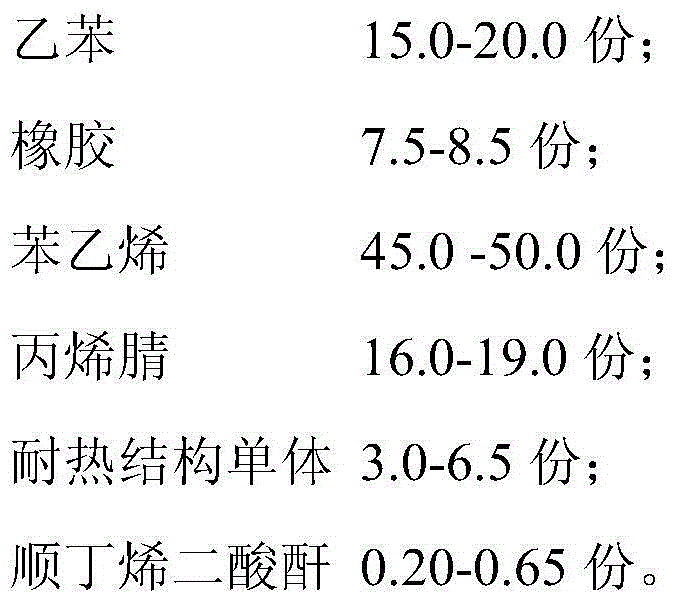

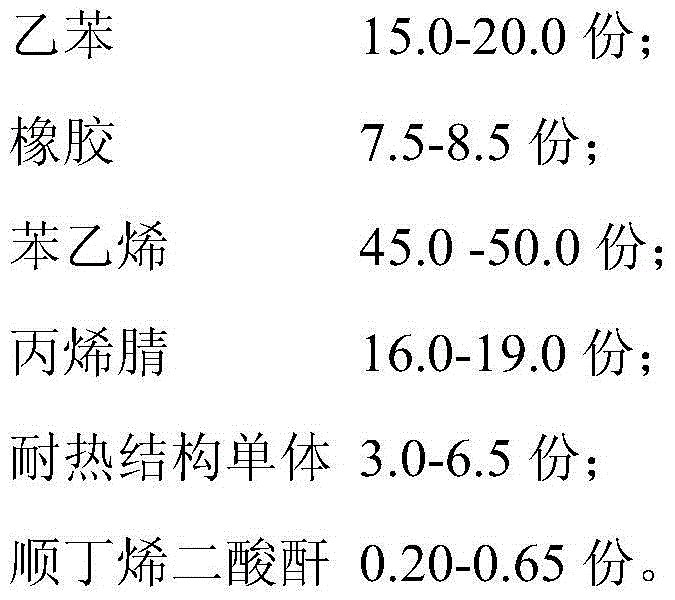

[0039] Add 20kg of ethylbenzene and 47.97kg of styrene to the rubber dissolving tank, start stirring, and add 8kg of AsahiAsapreneTM730AX rubber cut into 10×10mm into the rubber dissolving tank through the glue inlet, and stir and dissolve at room temperature for 8 hours. Then add 18.55kg of acrylonitrile, 6.5kg of N-phenylmaleimide and 0.5kg of MAH, continue to dissolve for 2 hours, then add 1.40% of white oil, 0.30% of antioxidant 3,5-tert-butyl- 4-Hydroxy-phenyl-octadecyl ester, 0.35% of chain transfer agent dimerized α-methylstyrene, 0.015% of initiator tert-butyl perbenzoate, and continued to stir and disperse for 30 minutes.

[0040] The feed rate of the reactor is 1540mL / h; the pressure of the feed system is controlled between 0.8MPa and 0.9MPa; the reaction temperature of the four reactors is 90°C; 110°C; 120°C;...

Embodiment 2

[0046] The reaction system of this embodiment adopts four reactors connected in series, and all materials are added to the process mode in the first reactor.

[0047] Add 20kg of ethylbenzene and 47.97kg of styrene to the rubber dissolving tank, start stirring, and add 8kg of AsahiAsapreneTM730AX rubber cut into 10×10mm into the rubber dissolving tank through the glue inlet, and stir and dissolve at room temperature for 8 hours. Then add 18.55kg of acrylonitrile, 5.5kg of N-phenylmaleimide and 0.27kg of MAH, continue to dissolve for 2 hours, then add 1.40% of white oil, 0.30% of antioxidant 3,5-tert-butyl- 4-Hydroxy-phenyl-octadecyl ester, 0.35% of chain transfer agent dimerized α-methylstyrene, 0.015% of initiator tert-butyl perbenzoate, and continued to stir and disperse for 30 minutes.

[0048] The feed rate of the reactor is 1540mL / h; the pressure of the feed system is controlled between 0.8MPa and 0.9MPa; the reaction temperature of the four reactors is 90°C; 110°C; 118°C...

Embodiment 3

[0054] The reaction system of this embodiment adopts four reactors connected in series, and all materials are added to the process mode in the first reactor.

[0055] Add 20kg of ethylbenzene and 47.97kg of styrene to the rubber dissolving tank, start stirring, and add 8kg of AsahiAsapreneTM730AX rubber cut into 10×10mm into the rubber dissolving tank through the glue inlet, and stir and dissolve at room temperature for 8 hours. Then add 18.55kg of acrylonitrile, 3kg of N-phenylmaleimide and 0.6kg of MAH, continue to dissolve for 2 hours, then add 1.40% of white oil, 0.30% of antioxidant 3,5-tert-butyl-4 -Hydroxy-phenyl-octadecyl ester, 0.35% chain transfer agent dimerized α-methylstyrene, 0.015% initiator tert-butyl perbenzoate, and continued to stir and disperse for 30 minutes.

[0056] The feed rate of the reactor is 1540mL / h; the system pressure is controlled between 0.8MPa and 0.9MPa; the reaction temperatures of the four reactors are 92°C; 112°C; 118°C; 150°C; It is 120...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com