Automatic pole helical reinforcement winding system

A technology of winding device and spiral rib, applied in the field of automatic spiral rib winding device, can solve the problem of not developing an automatic winding device for electric pole spiral rib, etc., and achieve the effects of easy operation, high production efficiency and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further described below through the accompanying drawings and examples.

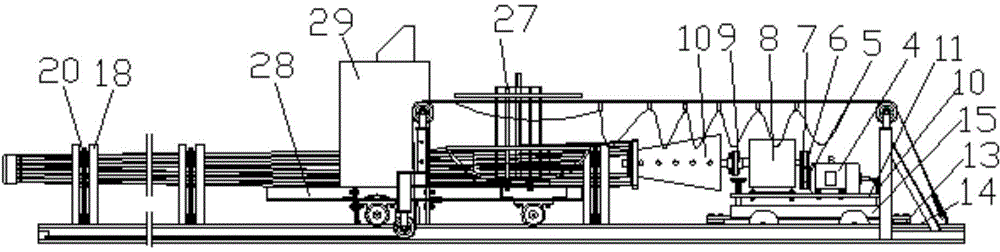

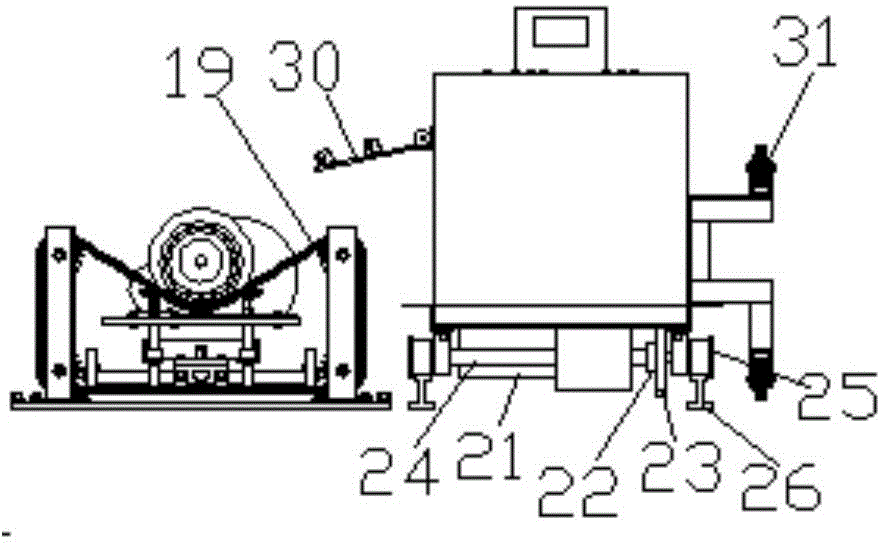

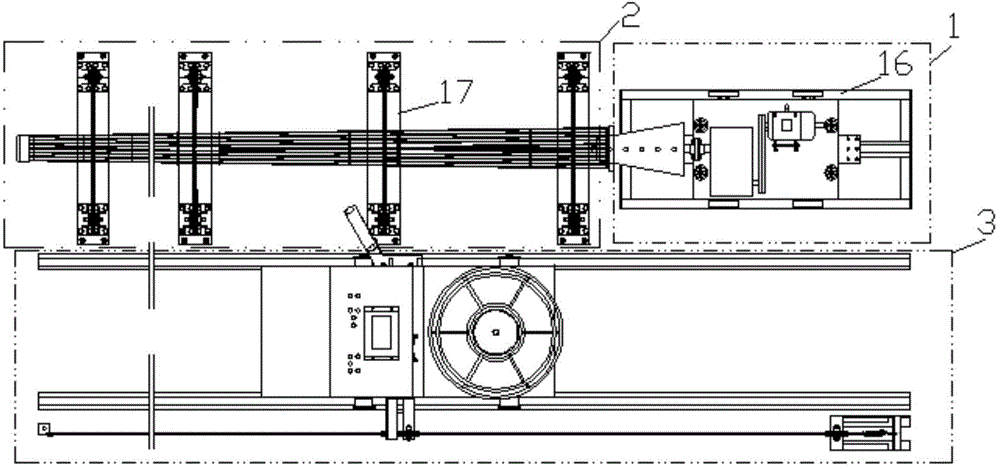

[0033] Such as figure 1 , figure 2 , image 3 As shown, the automatic pole spiral tendon winding device according to the present invention includes a carriage mechanism 1 , a bracket mechanism 2 and a trolley mechanism 3 . The specific structure and connection method are:

[0034] Such as Figure 4 , Figure 5 , Image 6 As shown, the carriage mechanism 1 includes a main motor 4, a motor pulley 5, a belt 6, a gearbox pulley 7, a gearbox 8, a coupling 9, a cone 10, a motor supporting plate 11, an adjusting screw 12, a slide Block 13, guide rail 14, four-wheel dolly 15 and guide groove 16. The motor pulley 5 is fastened on the output shaft of the main motor 4, and is connected with the transmission pulley 7 through the belt 6. The transmission pulley 7 is fastened on the input shaft of the transmission 8, and one end of the coupling 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com