Composite component containing amorphous alloy and preparation method of composite component

A technology of amorphous alloys and composite components, which is applied in the field of composite components containing amorphous alloys and its preparation, can solve the problems of good fluidity, high failure risk, and high requirements of amorphous alloys, and achieve simple and easy preparation methods and reduce The effect of high overall weight and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

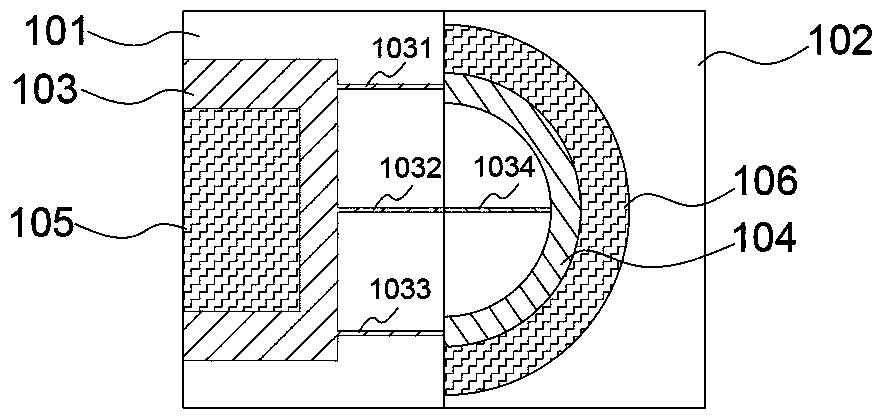

[0033] as attached figure 1 Shown is a schematic diagram of the molding cavity of the composite component in Example 1, so as to further describe the molding method and structure of the composite component in the present invention in detail.

[0034] In this embodiment, a mold is used to extrude the composite member. Specifically, the mold includes a punch 101 and a die 102 with matching shapes. The punch 101 is provided with a melt extrusion cavity 103. The melt extrusion cavity is a feeding cavity for low melting point materials. Similar to a common mold system, the melt extrusion cavity One side of the push rod structure matching the shape of its feed channel is used as a structure for pushing the molten raw material of low melting point material into the molding cavity. Although this structure is not marked in the accompanying drawings of the present invention, it does not Hinder the understanding of the core technical points in the present invention. A molding cavity 10...

Embodiment 2

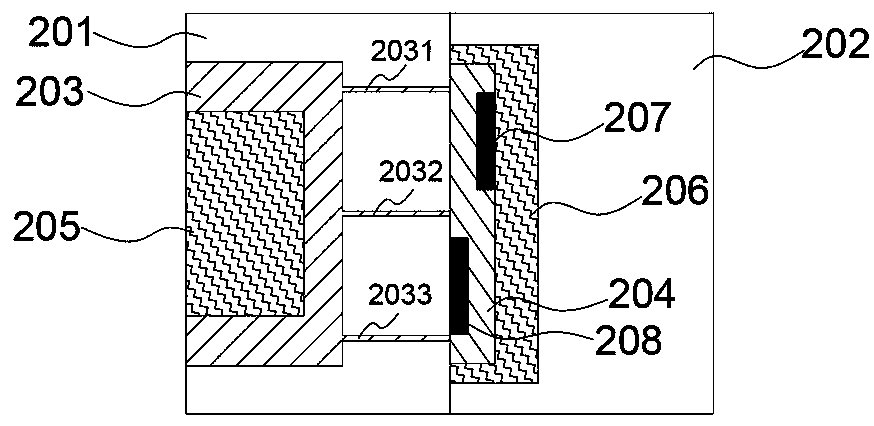

[0042] The schematic diagram of the molding cavity of the composite component in this embodiment is as attached figure 2 As shown, its structure is substantially similar to that in Example 1. Specifically:

[0043] A mold is used to extrude the composite member. The mold includes a punch 201 and a die 202 with matching shapes. The punch 201 is provided with a melting extrusion chamber 203, which is a feeding chamber for low melting point materials, which is different from ordinary The mold system is similar. The push rod structure on one side of the melt-extrusion cavity matched with the shape of the feed channel is used to push the molten raw material of the low-melting point material into the forming cavity. Cavity 204 is the final shaped cavity of the composite component. The extrusion cavity 203 communicates with the molding cavity 204 through runners 2031 , 2032 , 2033 , and the punch 201 is provided with an induction heating device 205 , and the concave die is provide...

Embodiment 3

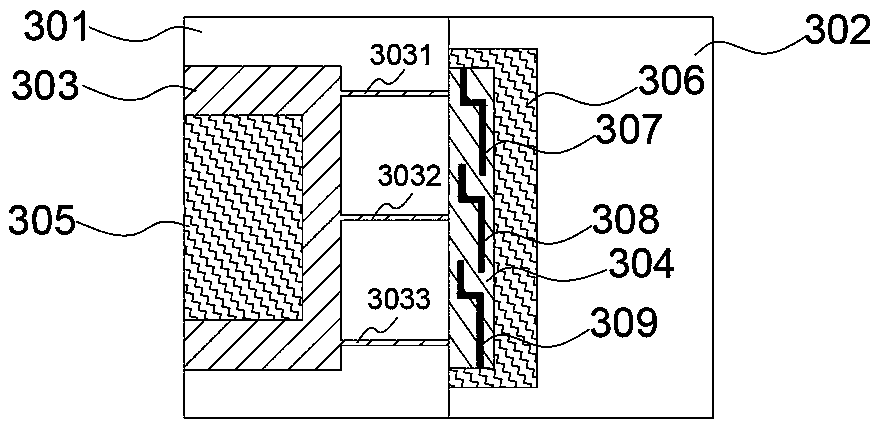

[0048] The schematic diagram of the molding cavity of the composite component in this embodiment is as attached image 3 As shown, its structure is substantially similar to that in Example 1. Specifically:

[0049] A mold is used to extrude the composite member. The mold includes a punch 301 and a die 302 with matching shapes. The punch 301 is provided with a melting extrusion chamber 303, which is a feeding chamber for low melting point materials, which is different from ordinary The mold system is similar. The push rod structure on one side of the melt-extrusion cavity matched with the shape of the feed channel is used to push the molten raw material of the low-melting point material into the forming cavity. Cavity 304 is the final shaped cavity of the composite component. The extrusion chamber 303 communicates with the molding chamber 304 through flow channels 3031 , 3032 , 3033 , and the punch 301 is provided with an induction heating device 305 , and the concave die 302...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com