Patents

Literature

223results about How to "Increased porous structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

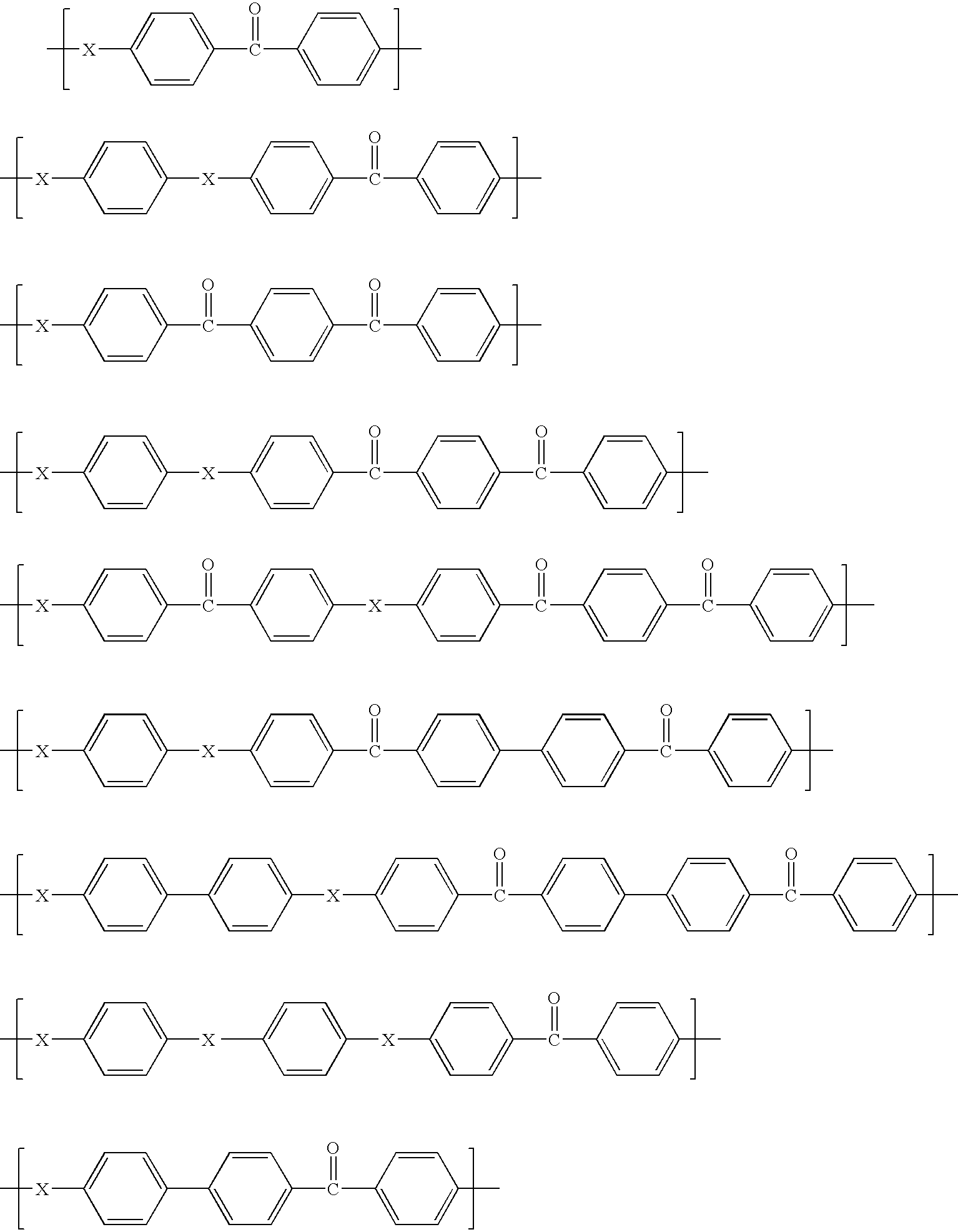

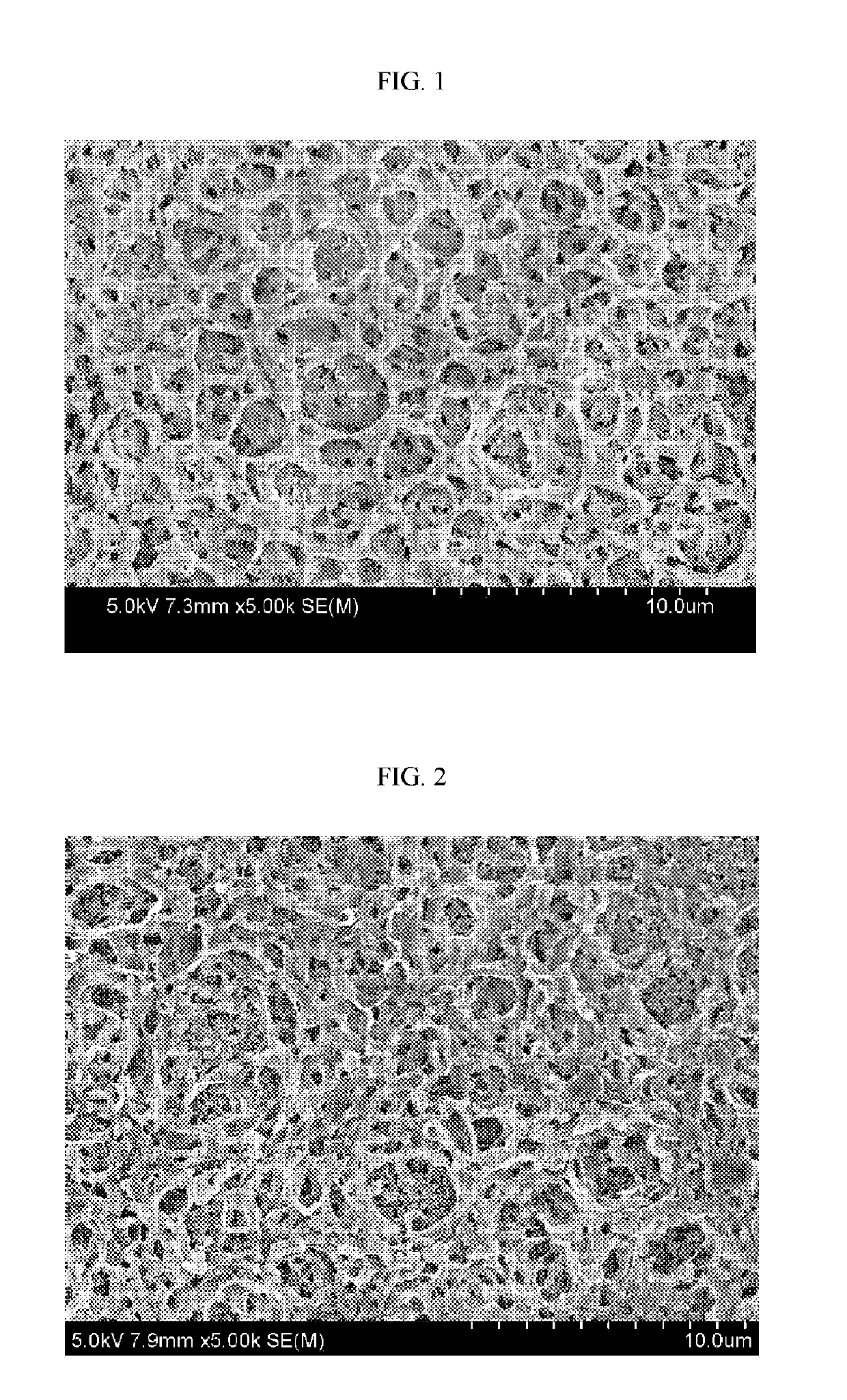

Porous poly(aryl ether ketone) membranes, processes for their preparation and use thereof

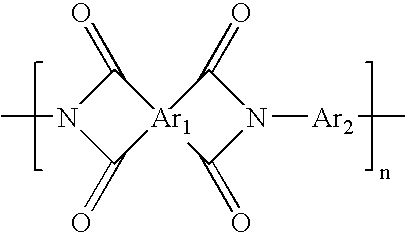

ActiveUS6887408B2Simple and cost-effective and industrially feasibleIncreased porous structureMembranesSemi-permeable membranesArylPorous medium

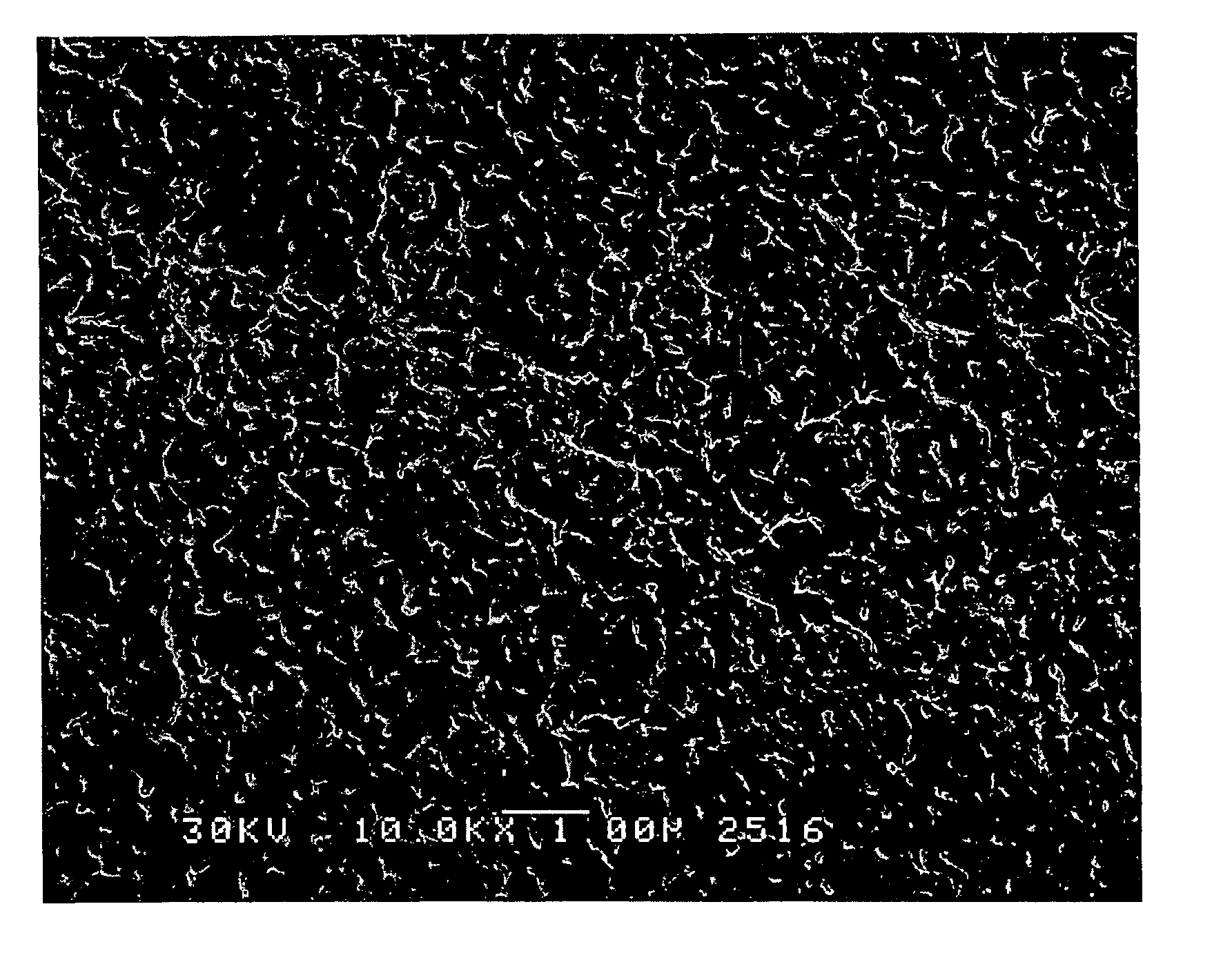

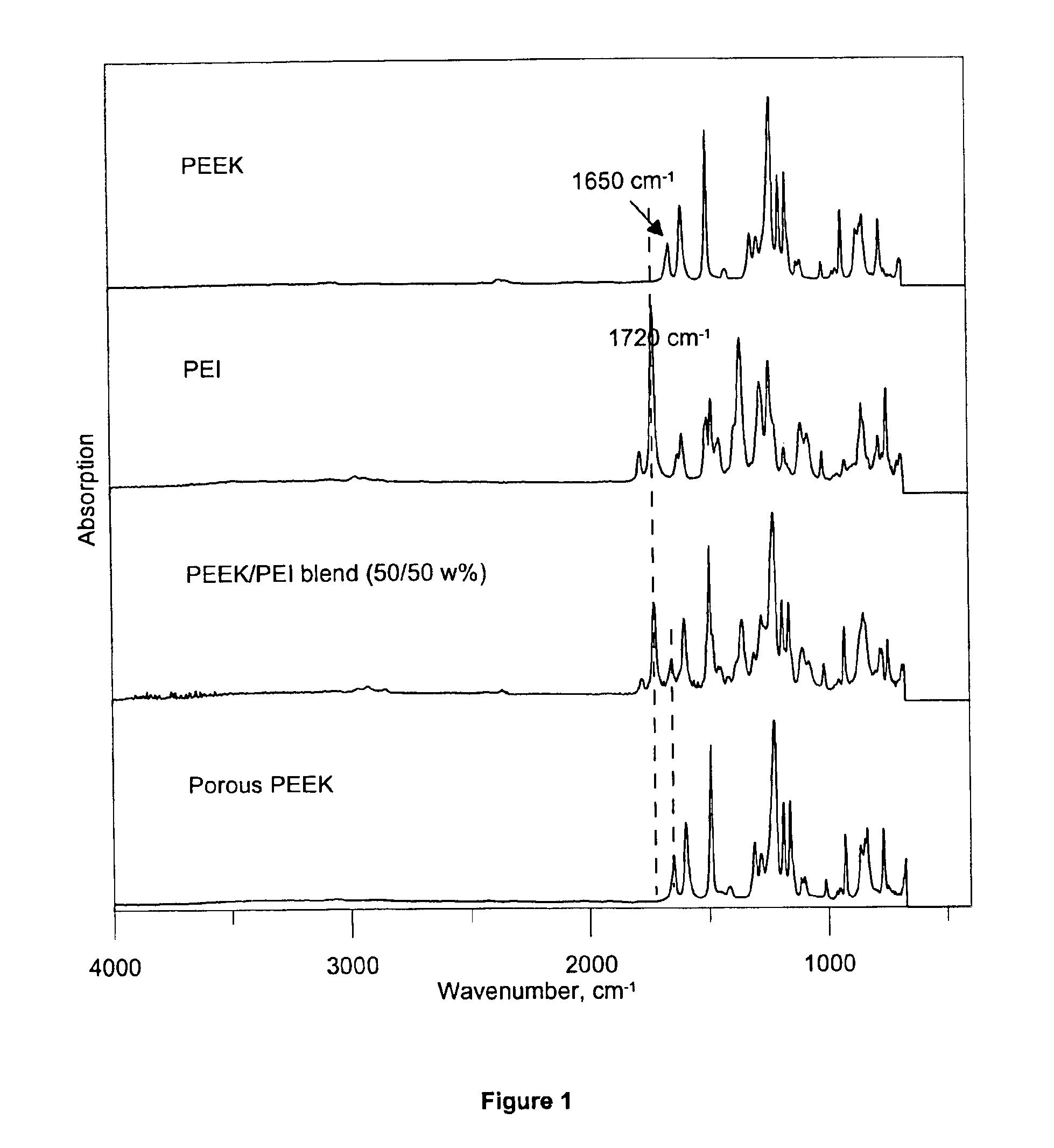

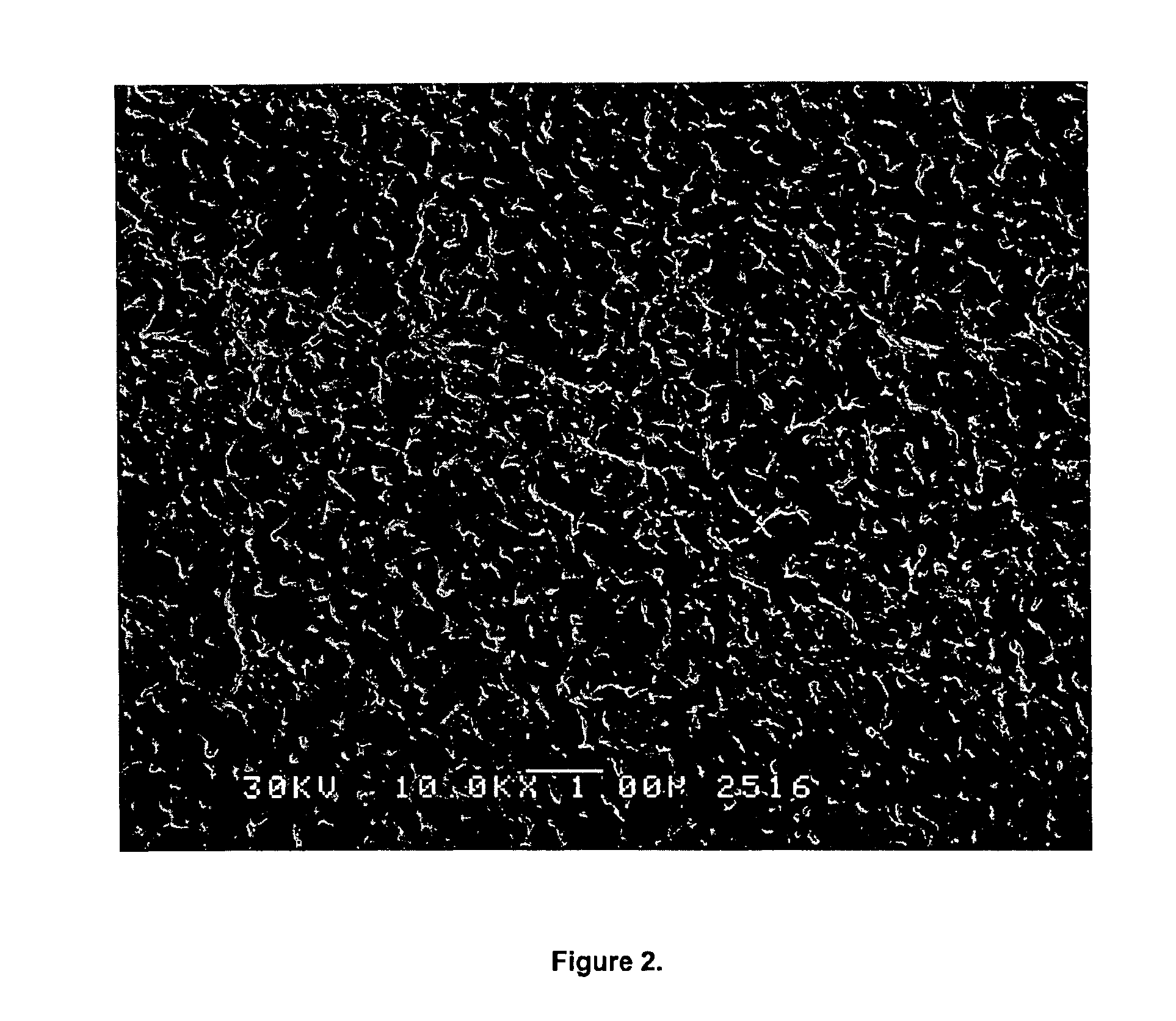

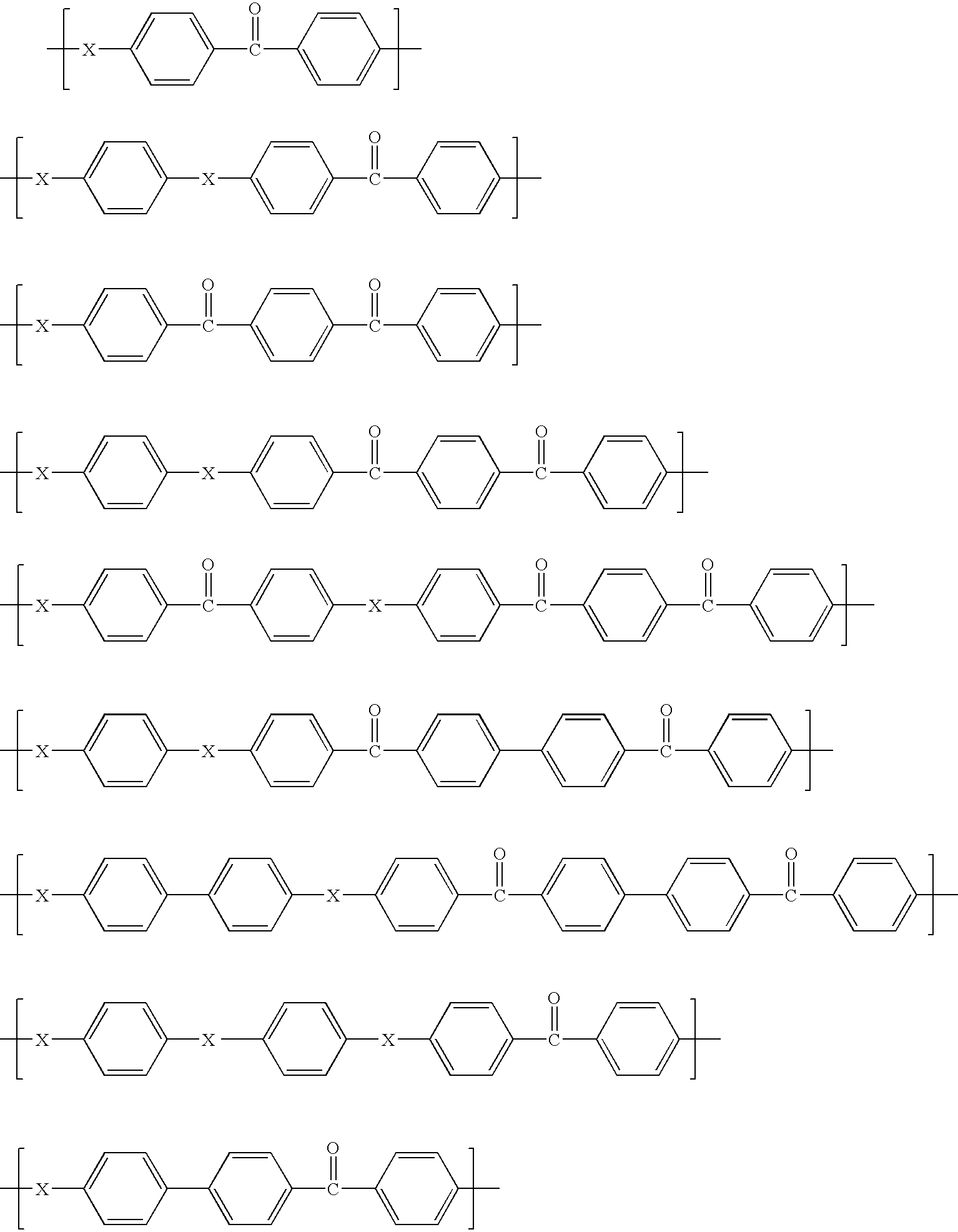

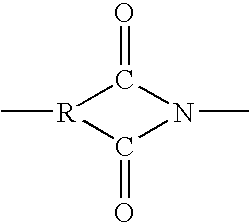

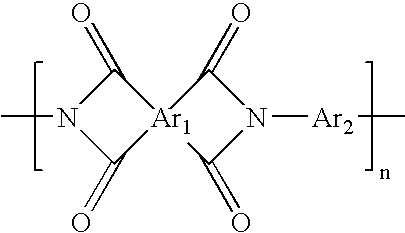

Porous poly(aryl ether ketone) (PAEK) articles are prepared from PAEK / polyimide blends by selective chemical decomposition and subsequent removal of the polyimide phase. Porous PAEK articles exhibit highly interconnected pore structure and a narrow pore size distribution. The porous PAEK articles of the present invention can be utilized as a porous media for a broad range of applications, including membranes for fluid separations, such as microfiltration, ultrafiltration, nanofiltration, and as a sorption media.

Owner:MASSACHUSETTS DEV FINANCE AGENCY

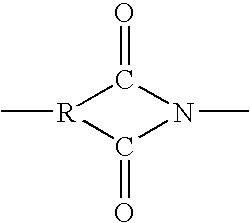

Functionalized porous poly(aryl ether ketone) materials and their use

ActiveUS20060094852A1Good chemical resistanceSimple and cost-effective and industrially feasibleMembranesSemi-permeable membranesPolymer scienceHydrazine compound

Functionalized porous poly(aryl ether ketone) articles are prepared by reacting ketone groups in the backbone of poly(aryl ether ketone) polymer with a primary amine reagent. Preferred functional primary amines are primary aliphatic amines or substituted hydrazines containing one or more target functional groups including polar groups, such as hydroxyl groups, ˜OH, amino groups, ˜NH2, ˜NHR, ˜NRR′, and ethylene oxide groups, ˜OCH2CH2—, negatively or positively charged ionic groups, such as ˜SO3−, ˜COO−, and ˜NH4+ groups, hydrophobic groups such as siloxane or perfluorcarbone groups, and non-polar groups, such as linear or branched hydrocarbon groups. The functionalized porous poly(aryl ether ketone) article can be prepared by reacting primary amine with a pre-formed, shaped porous poly(aryl ether ketone) article or by functionalizing the surface of a non-porous precursor article that is subsequently converted into a porous article.

Owner:MASSACHUSETTS DEV FINANCE AGENCY

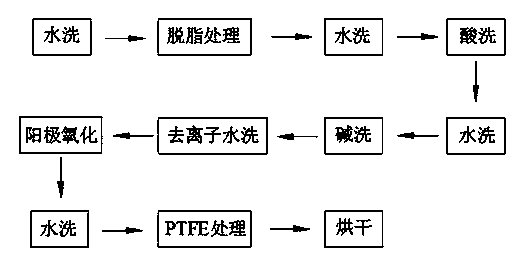

Aluminum and aluminum alloy surface treatment method

The invention discloses an aluminum and aluminum alloy surface treatment method which is characterized by comprising steps as follows: water washing, degreasing treatment, water washing, pickling, water washing, alkali washing, deionized water washing, anodic oxidation, water washing, PTFE (polytetrafluoroethylene) treatment, and drying. According to the aluminum and aluminum alloy surface treatment method, an aluminum and aluminum alloy oxide film with good uniformity can be obtained, and the film is high in hardness, abrasion-resistant, corrosion-resistant and the like.

Owner:GUANGXI POLYTECHNIC VOCATIONAL & TECHN COLLEGE

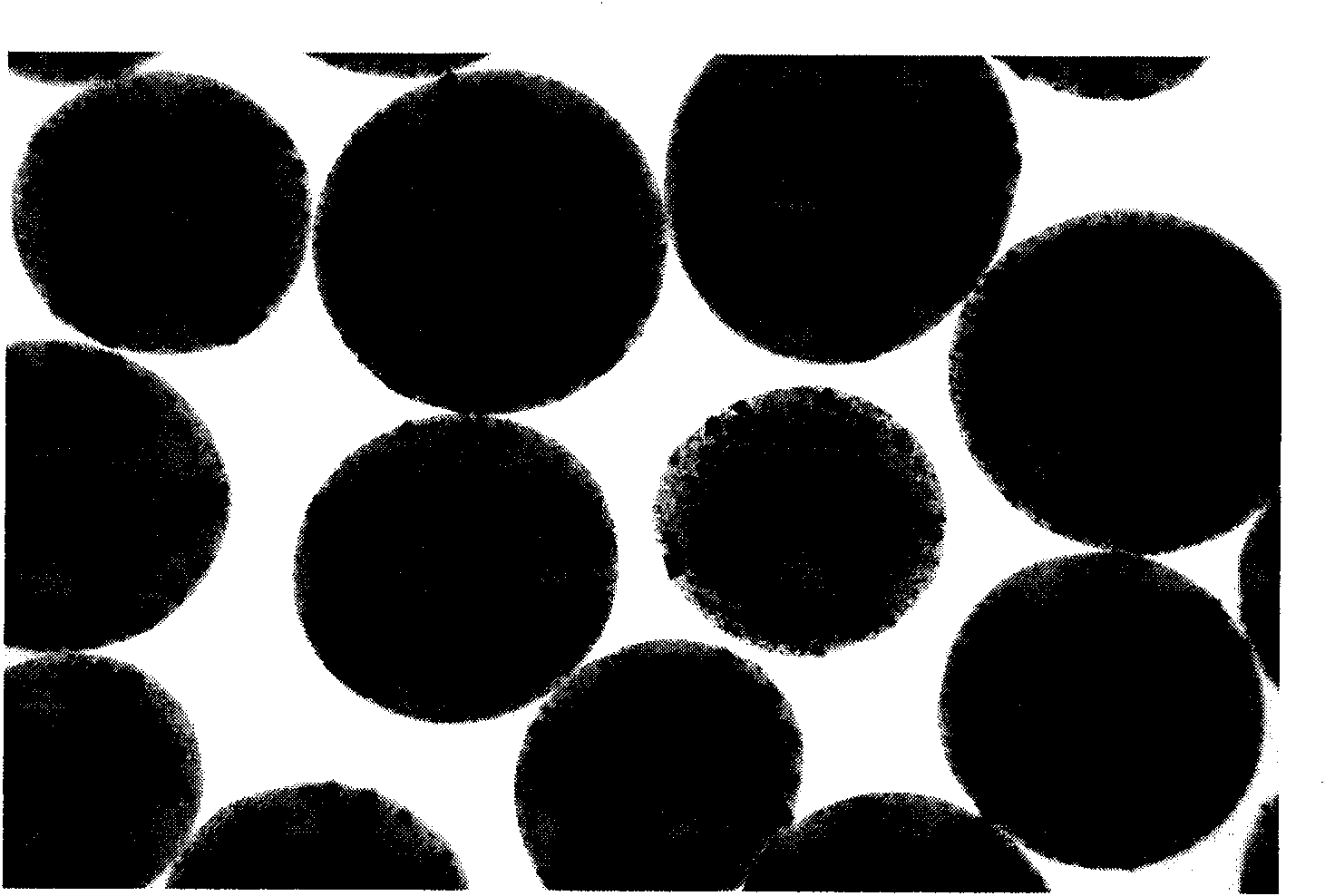

Method for preparing cellulose microsphere by taking ionic liquid as solvent

InactiveCN101612540ASolve forming problemsSolve the problem of sphericityOther chemical processesAlkali metal oxides/hydroxidesCelluloseLow speed

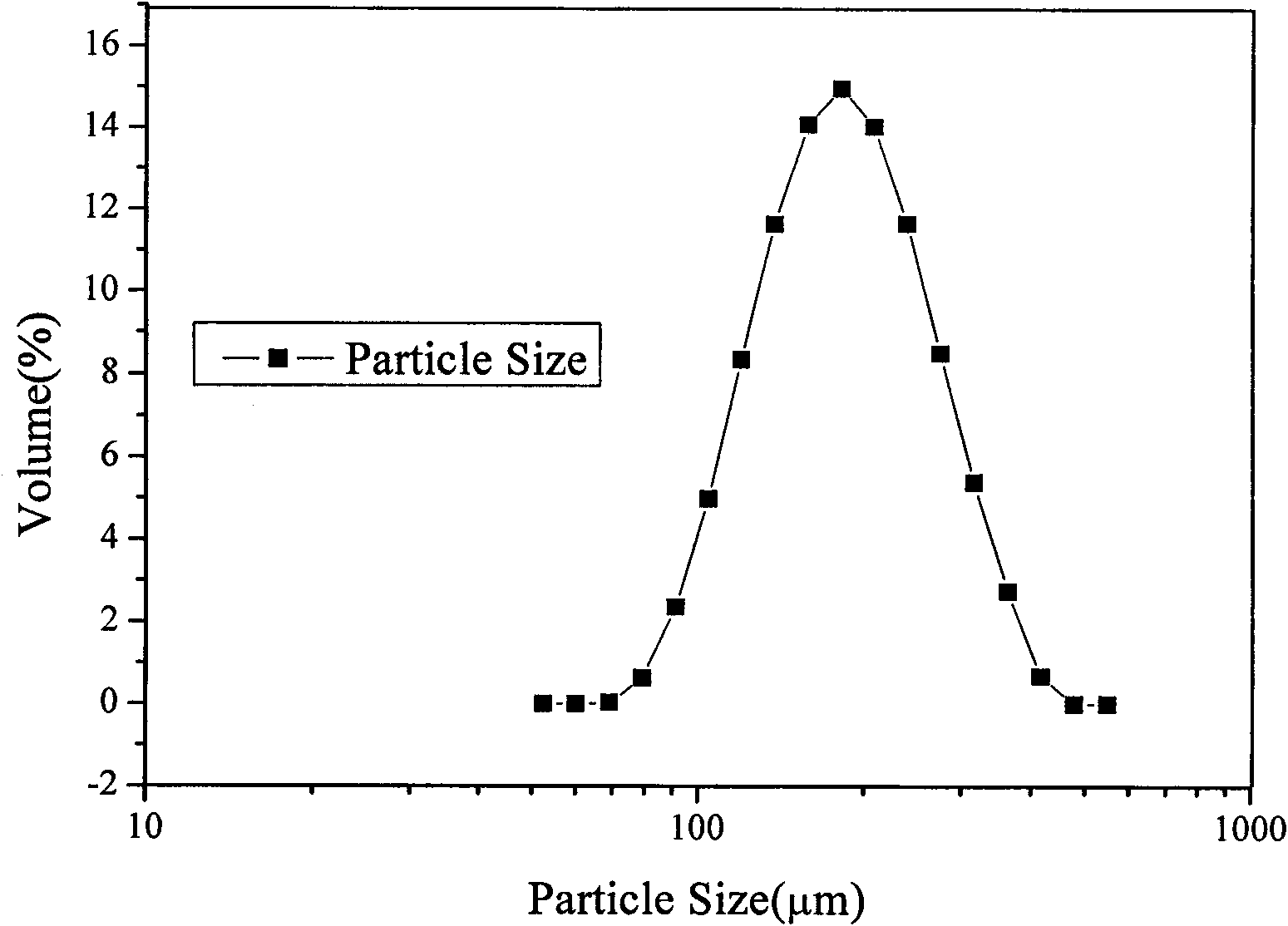

The invention discloses a method for preparing cellulose microspheres by taking ionic liquid as a solvent. The method comprises the steps of: 1) preparing cellulose solution as follows: dissolving the cellulose into the ionic liquid under low-speed stirring and proper temperature; 2) adding inert particles: adding proper amount of inert particles, and stirring evenly; 3) forming spheres by reversed phase suspension: adding oil phase and a surface active agent, leading the cellulose solution to be condensed into spheres by reversed phase suspension and program temperature reduction; 4) curving microspheres: adding a curving agent and curving to form the cellulose microspheres; 5) washing: using deionized water to wash and soak so as to obtain the cellulose microspheres; and 6) screening: screening in a wet state and obtaining the cellulose microspheres with a certain particle size range. The developed preparation process is simple and convenient, the used solvent is safe and non-toxic, the prepared cellulose micrsphere has porous structure and proper particle size, high sphericity and good hydropathy, can adjust density, can be used as substrate of an absorbent and has good biocompatibility.

Owner:ZHEJIANG UNIV

High-performance variable-pressure adsorption 5A molecular sieve and preparing method thereof

InactiveCN1530167AReduce dosageHigh adsorption capacityOther chemical processesMolecular sieveKaolinite

A high-performance 5A molecular sieve with pressure-variable adsorption function is prepared through proportionally mixing the raw powder of 4A molecular sieve with kaolinite-type clay, adding plant fibres, granulating, sieving, baking, calcining at 200-1000 deg.C, immersing in the solution of sodium hydroxide, washing, Ca ion exchanging in CaCl2 solution, washing, baking, and calcining at 100-800 deg.C. Its advantages are high adsorption capacity, diffusing speed, and mechanical strength.

Owner:江苏洁欧康科技有限公司

Sintered porous structure and method of making same

InactiveUS20110033772A1Simple and low cost methodLow costFinal product manufactureLayered productsOptoelectronicsSpherical shaped

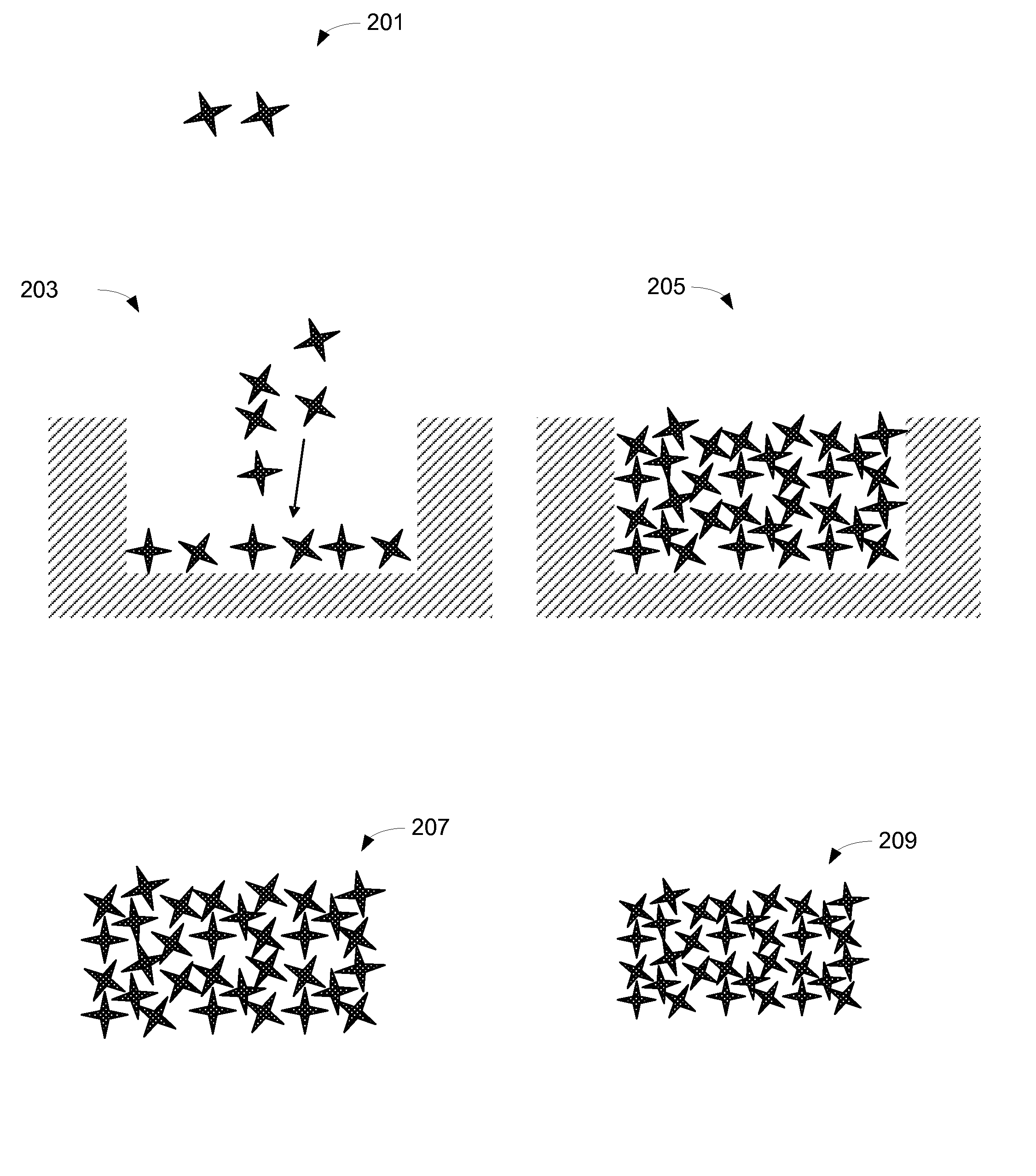

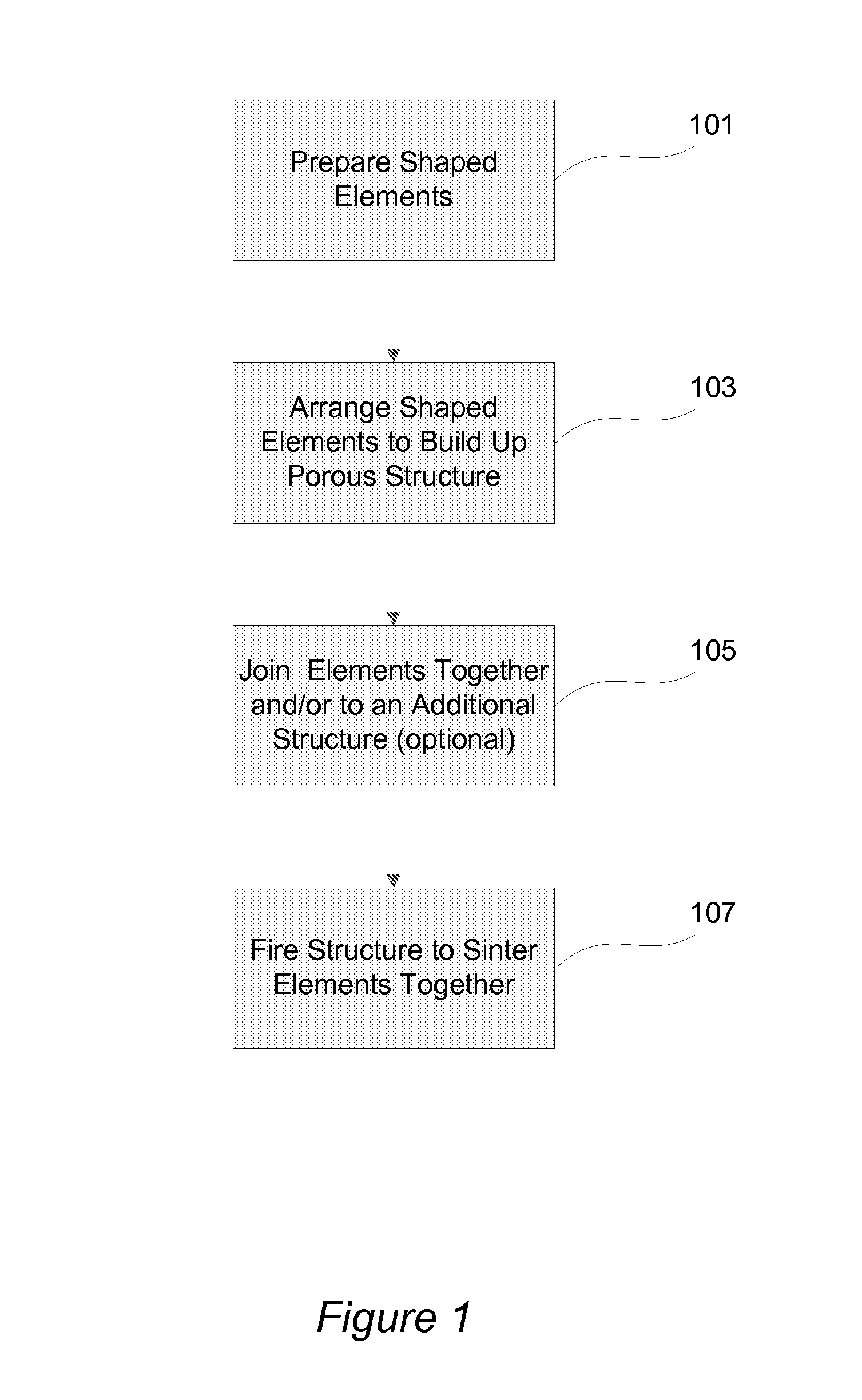

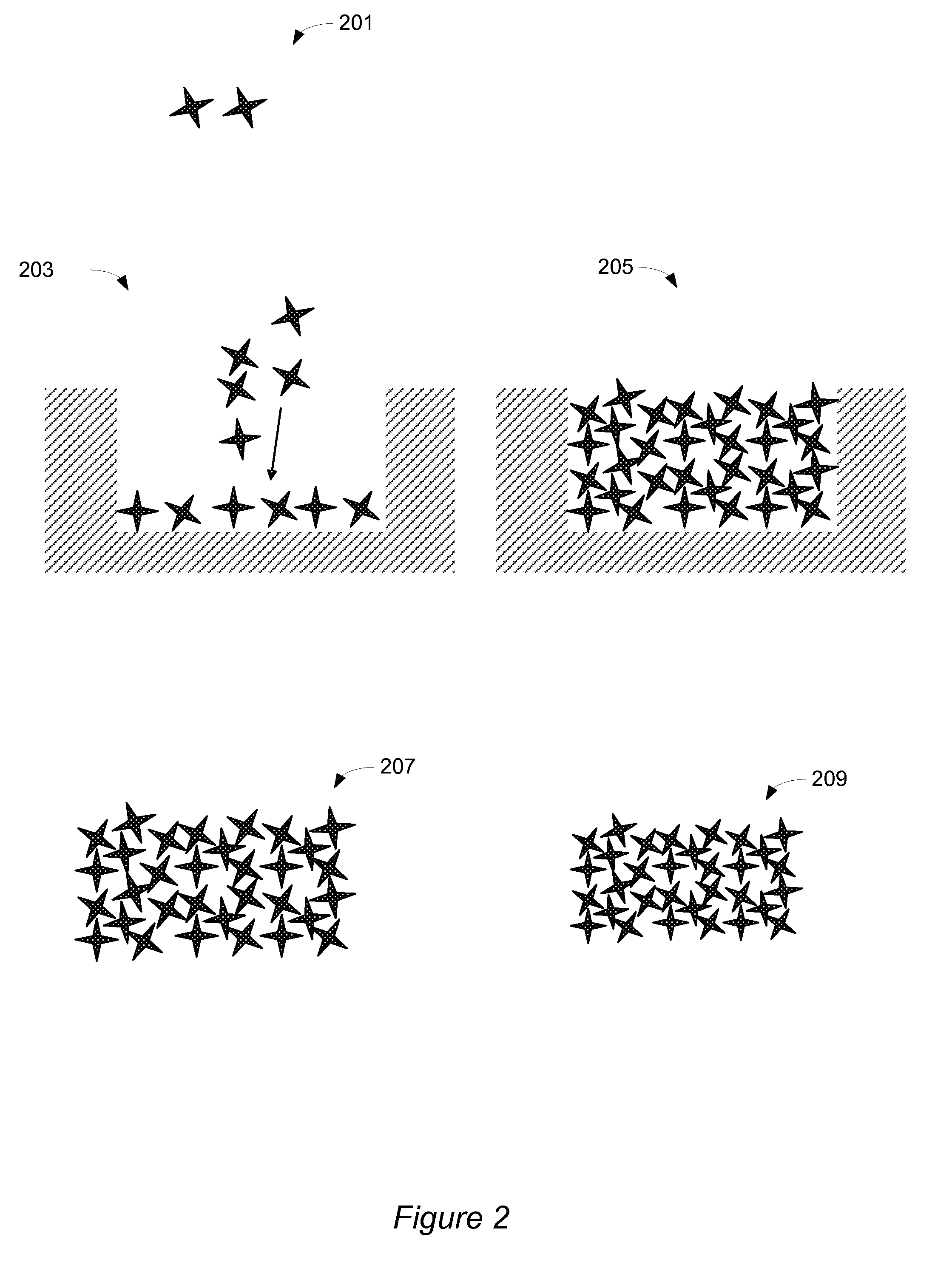

Simple, low cost methods of manufacturing highly porous structures are provided. The methods involve building up porous structures with elements shaped to provide the desired strength, porosity and pore structure of the porous structure and then sintering the elements together to form the structure. Also provided are novel sintered porous structures made up of sintered non-spherical elements. In certain embodiments, the shaped green elements and the porous structure are simultaneously sintered. Also provided are novel sintered porous structures made up of sintered non-spherical elements.

Owner:RGT UNIV OF CALIFORNIA

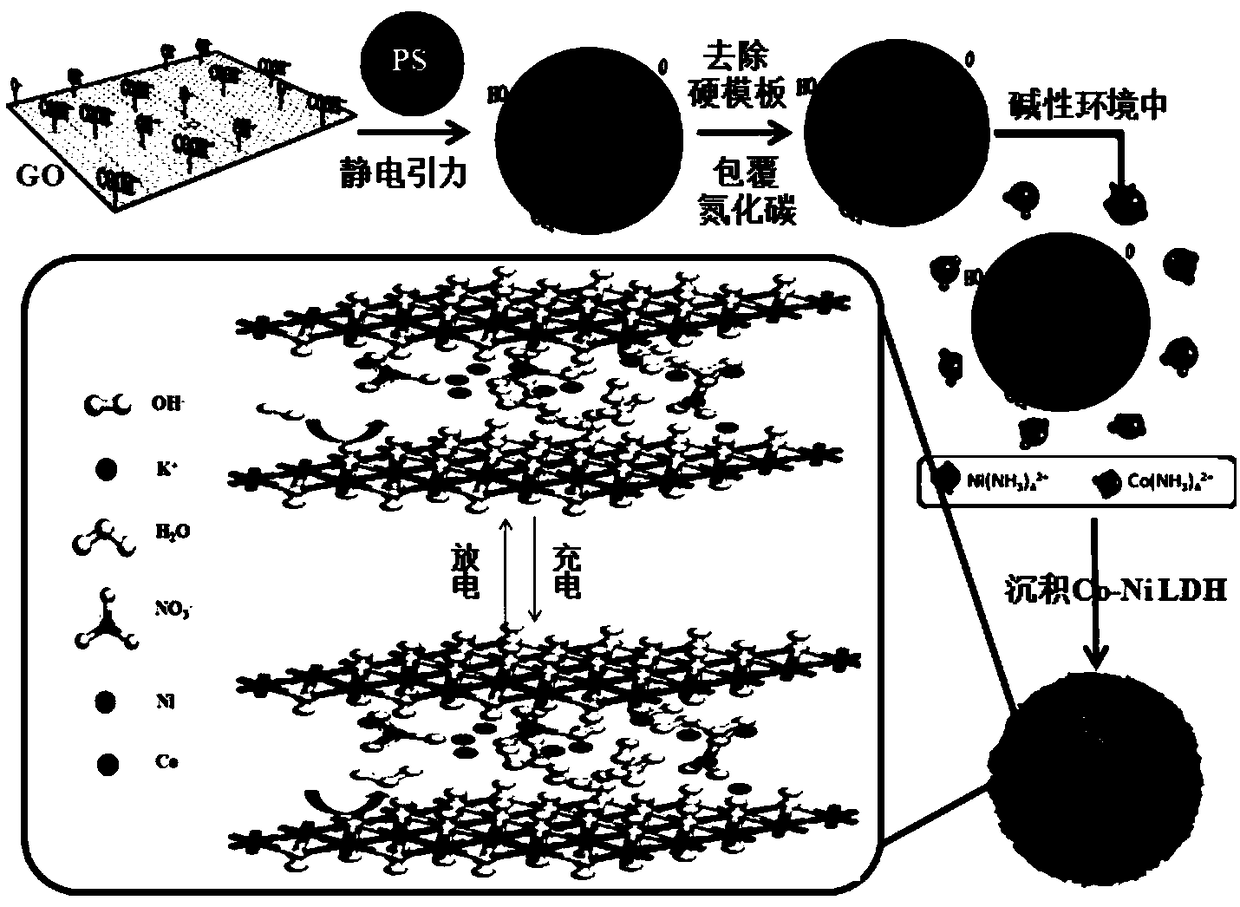

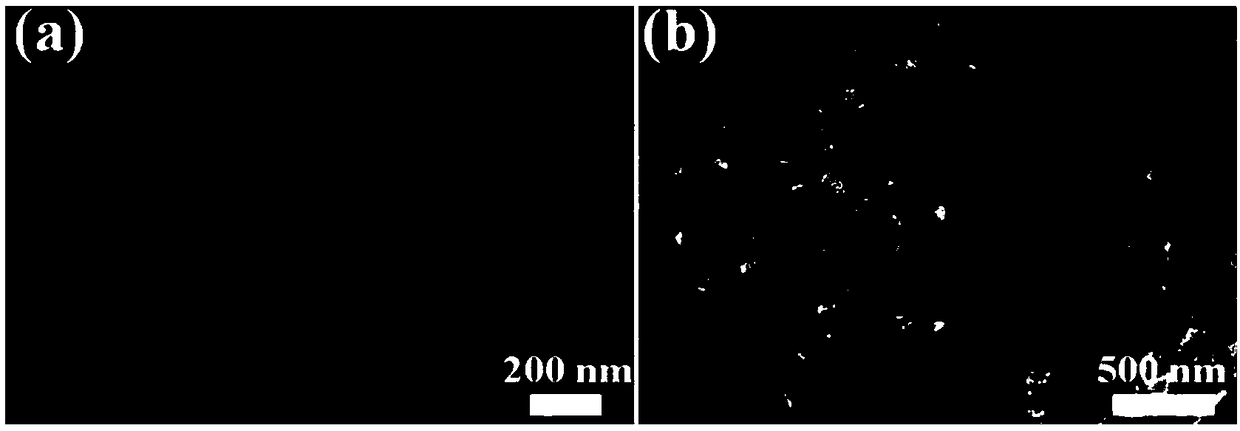

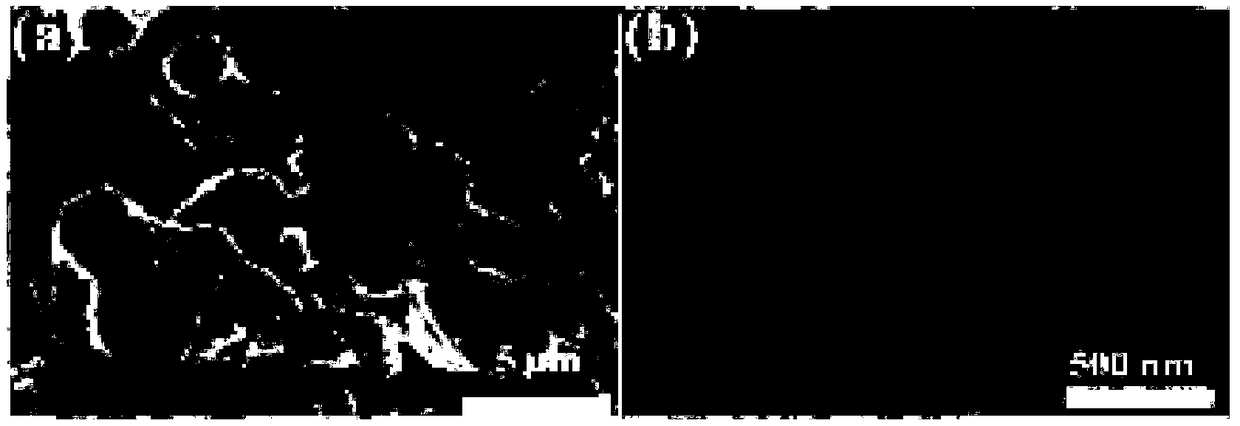

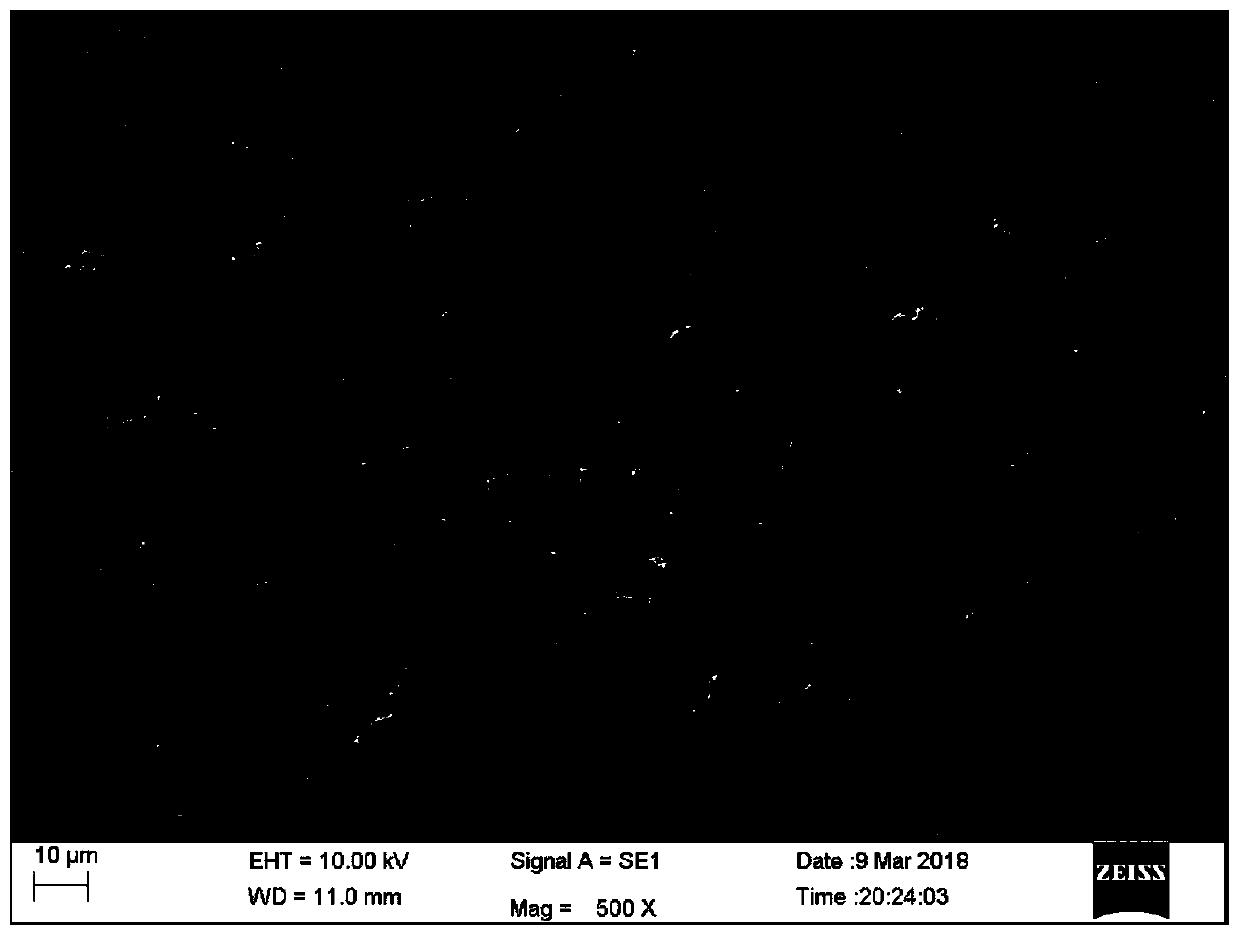

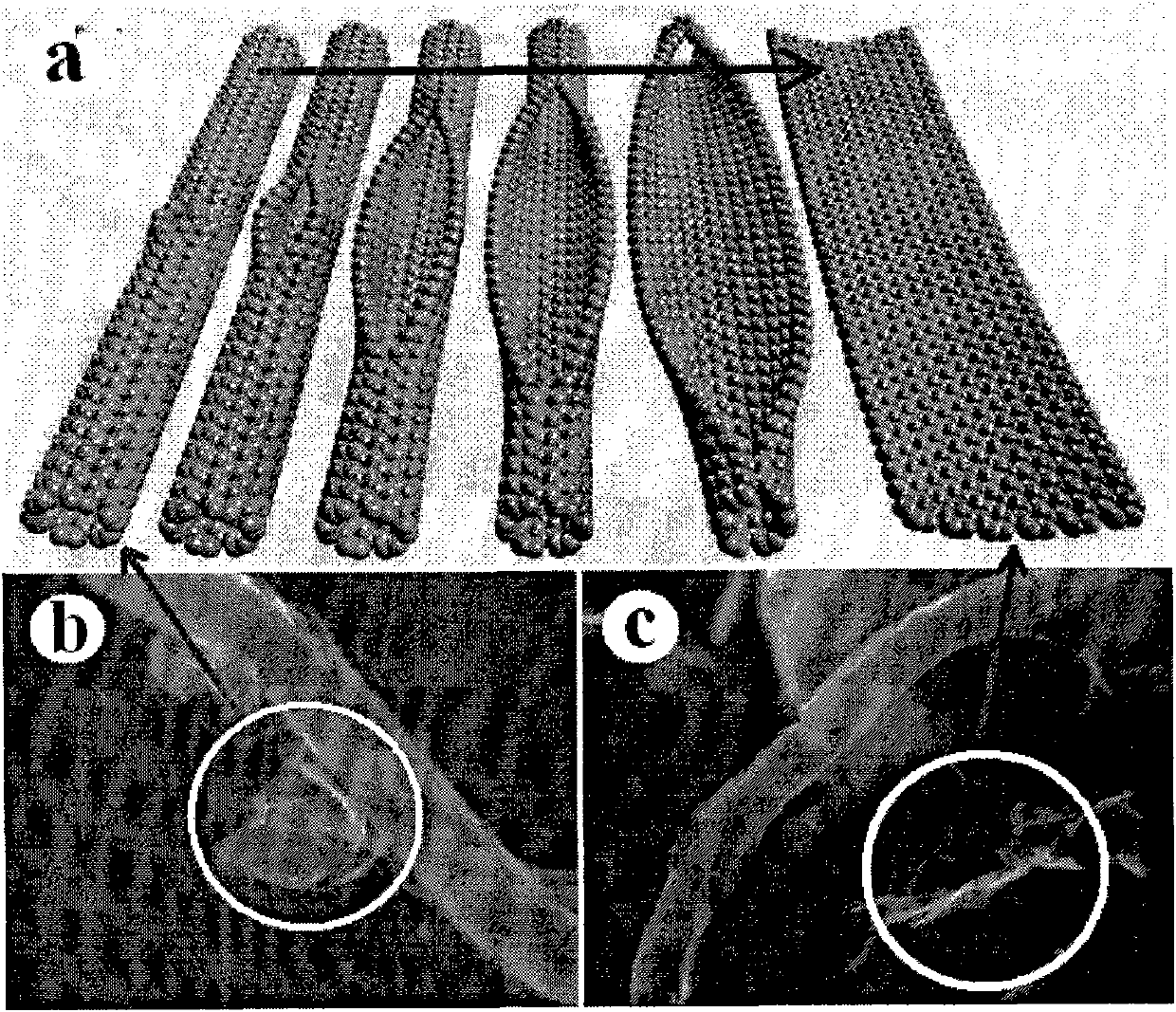

Cobalt-nickel-double-metal-hydroxide-nanosheet/carbon-nitride-coated nitrogen-doped hollow graphene sphere composite material and preparation method thereof and application

InactiveCN109300703AImprove stabilityAvoid deformationHybrid capacitor electrodesElectric capacityUnit structure

The invention discloses a cobalt-nickel-double-metal-hydroxide-nanosheet / carbon-nitride-coated nitrogen-doped hollow graphene sphere composite material and a preparation method thereof, and application as a supercapacitor electrode material. The composite material comprises a cobalt-nickel-double-metal-hydroxide-nanosheet / carbon-nitride-coated nitrogen-doped hollow graphene sphere has a 3D spherical appearance; and the specific surface area is 100 to 1000m<2> / g and the average pore diameter of 1 to 200mm. In addition, the preparation method includes the following steps: preparing a small polystyrene sphere; preparing a polyaniline-coated graphene sphere; preparing a carbon-nitride-coated nitrogen-doped hollow graphene sphere; and preparing a cobalt-nickel-double-metal-hydroxide-nanosheet / carbon-nitride-coated nitrogen-doped hollow graphene sphere composite material. Therefore, a problem of series agglomeration of the cobalt-nickel double-metal hydroxide unit structure during the traditional preparation technology process is solved effectively; and a novel method is provided for preparing an electrode material with advantages of large specific surface area, high flexibility, high electric capacity, and high stability.

Owner:ZHEJIANG SCI-TECH UNIV

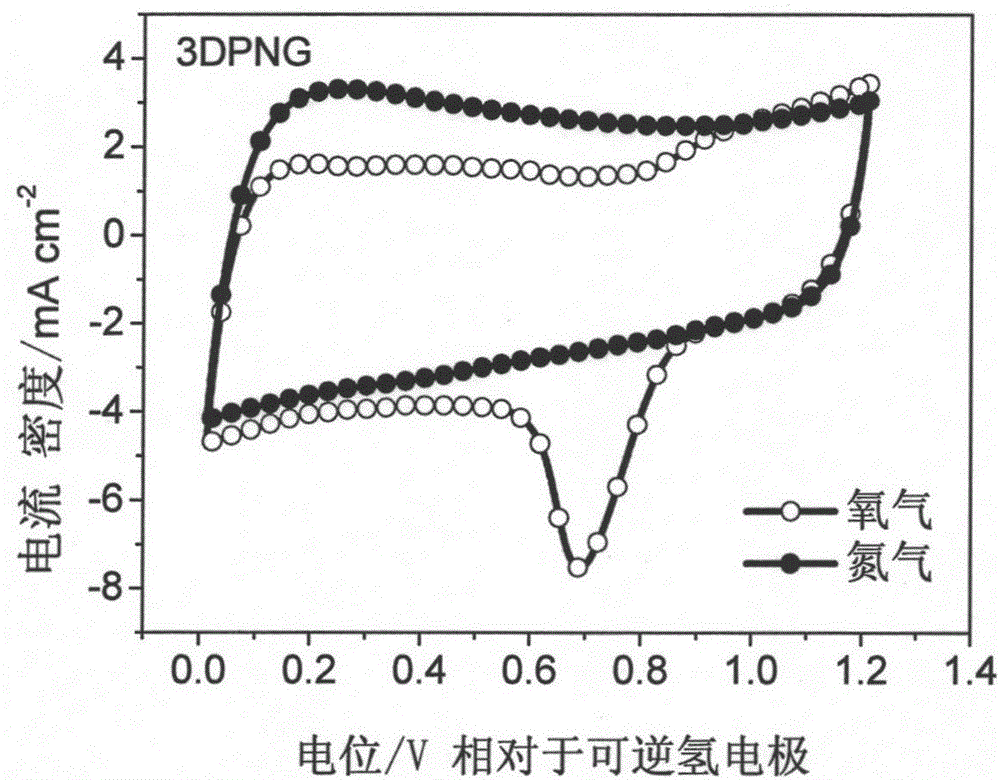

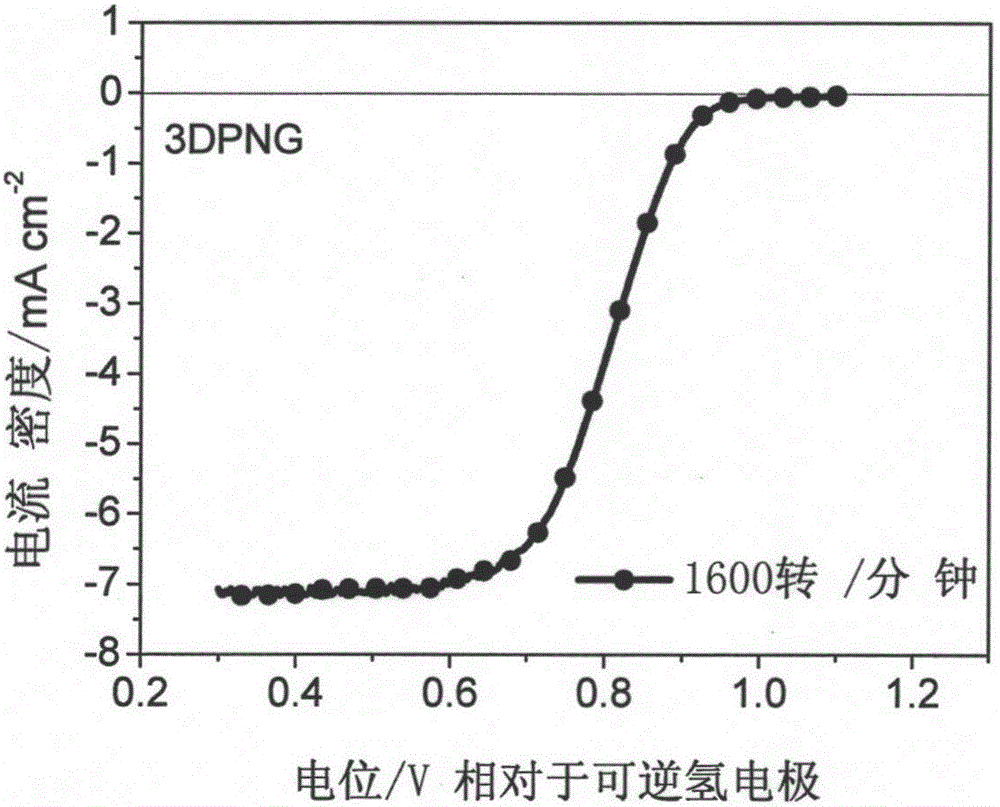

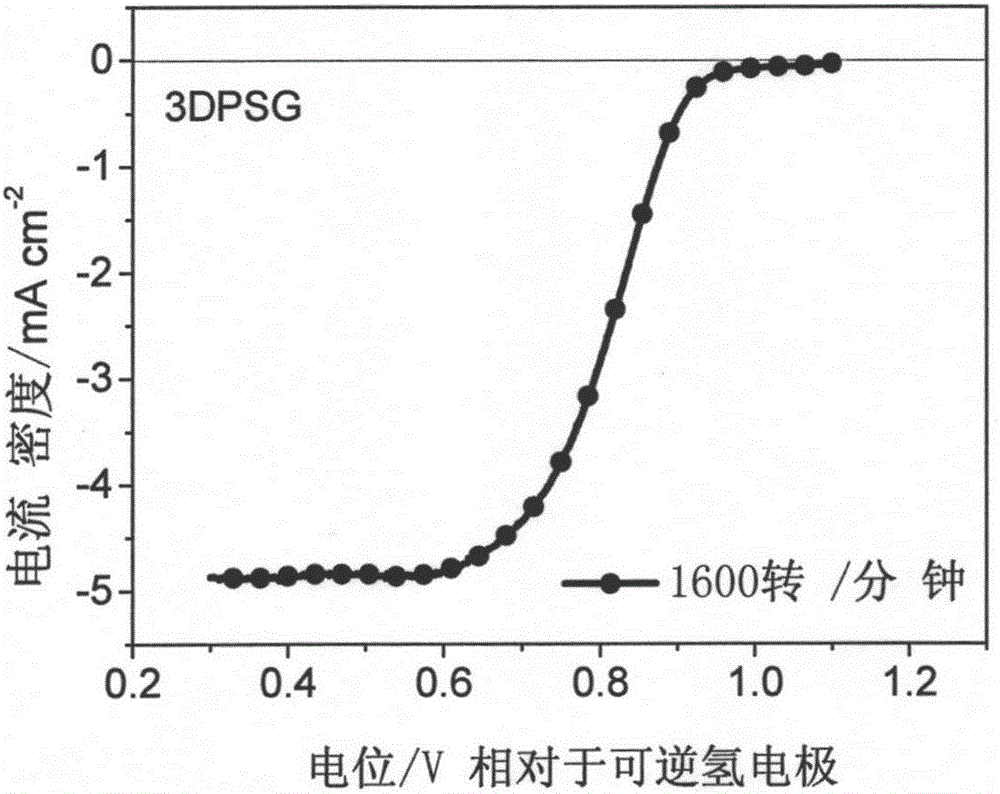

Preparation and application of nitrogen, sulphur or chlorine-doped three-dimensional porous graphene catalyst

InactiveCN105680060AIncrease the areaIncreased porous structureCell electrodesPorous grapheneReduction treatment

The invention provides a preparation and an application of a nitrogen, sulphur or chlorine-doped three-dimensional porous graphene catalyst. The preparation comprises the following steps: dissolving graphene oxide, an alkyl compound, a transition metal salt containing nitrogen, sulphur or chlorine and hydrochloric acid into a solvent, and carrying out ultrasonic treatment and drying to obtain a precursor; heating the precursor to 600-1,000 DEG C under inert gas protection and carrying out roasting reduction treatment for 1-3 hours to obtain primary carbide; carrying out pickling treatment on the obtained primary carbide with a mixed solution of hydrofluoric acid and hydrochloric acid at a room temperature for 12-24 hours, centrifuging the primary carbide, cleaning the primary carbide with deionized water and then drying the primary carbide to obtain the three-dimensional porous graphene material containing nitrogen, sulphur or chlorine; and heating the three-dimensional porous graphene material to 600-1,000 DEG C under inert gas protection, and carrying out roasting reduction treatment for 1-3 hours to obtain the nitrogen, sulphur or chlorine-doped three-dimensional porous graphene catalyst. The nitrogen, sulphur or chlorine-doped three-dimensional porous graphene catalyst has the characteristics of being high in stability, not easy to poison and the like, and has a good application prospect in the fields of wastewater treatment of a fuel cell, a metal-air cell, a super capacitor, an energy storage battery and a microbial fuel cell and the like.

Owner:DONGHUA UNIV

Functionalized porous poly(aryl ether ketone) materials and their use

ActiveUS7176273B2Simple and cost-effective and industrially feasibleIncrease concentrationSemi-permeable membranesMembranesArylPolymer science

Functionalized porous poly(aryl ether ketone) articles are prepared by reacting ketone groups in the backbone of poly(aryl ether ketone) polymer with a primary amine reagent. Preferred functional primary amines are primary aliphatic amines or substituted hydrazines containing one or more target functional groups including polar groups, such as hydroxyl groups, ˜OH, amino groups, ˜NH2, ˜NHR, ˜NRR′, and ethylene oxide groups, ˜OCH2CH2—, negatively or positively charged ionic groups, such as ˜SO3−, ˜COO−, and ˜NH4+ groups, hydrophobic groups such as siloxane or perfluorcarbone groups, and non-polar groups, such as linear or branched hydrocarbon groups. The functionalized porous poly(aryl ether ketone) article can be prepared by reacting primary amine with a pre-formed, shaped porous poly(aryl ether ketone) article or by functionalizing the surface of a non-porous precursor article that is subsequently converted into a porous article.

Owner:MASSACHUSETTS DEV FINANCE AGENCY

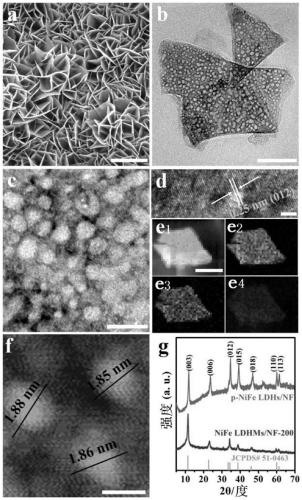

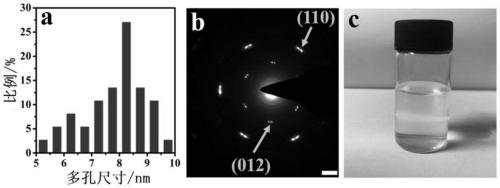

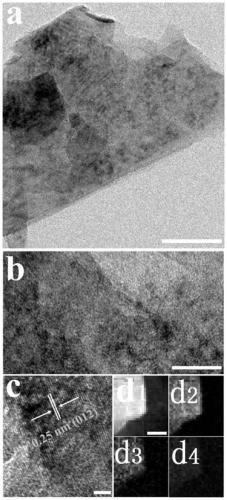

Foamed nickel-based porous NiFe hydrotalcite nanosheet as well as preparation and application thereof

PendingCN111229232AEasy to operateLow costCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNickel saltHydrotalcite

The invention relates to a foamed nickel-based porous NiFe hydrotalcite nanosheet as well as preparation and application thereof. The invention discloses a preparation method of a foamed nickel-basedporous NiFe hydrotalcite nanosheet. The preparation method comprises the following steps that foamed nickel is immersed into a reaction solution, wherein the reaction solution comprises bivalent nickel salt, trivalent iron salt, urea, ammonium fluoride, hydrogen peroxide and water; then a reaction is conducted at the temperature of 100-120 DEG C under the closed condition, so that the foamed nickel-based porous NiFe hydrotalcite nanosheet is obtained after the reaction is completed.

Owner:SUZHOU UNIV

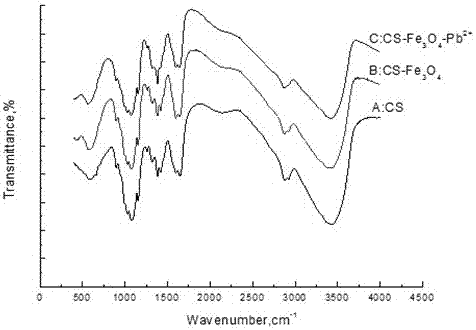

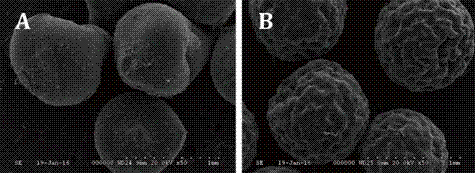

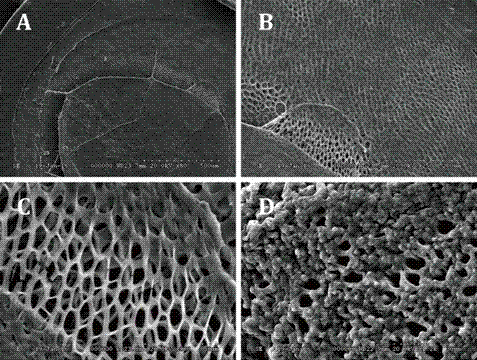

Porous magnetic chitosan gel microsphere with controllable particle size and preparation method thereof

PendingCN107282013AEasy to prepareReduce manufacturing costOther chemical processesWater contaminantsPeristaltic pumpStrong acids

The invention provides a porous magnetic chitosan gel microsphere with controllable particle size based on an in-situ co-precipitation principle and a preparation method thereof. The preparation method comprises the following main steps: firstly, carrying out a complexation reaction on a mixed solution of Fe<2+>, Fe<3+> and chitosan to prepare precursor-induced pre-sol; secondly, dropwise dripping the pre-sol into an alkaline soaking solution containing NaOH, sodium citrate and the like for coprecipitating to generate nano-Fe3O4; thirdly, carrying out a crosslinking reaction on the pre-sol and then curing, wherein the crosslinked chitosan gel microsphere is of a porous reticular structure and the Fe3O4 is uniformly distributed in the chitosan gel microsphere. The particle size of the chitosan gel microsphere is controlled by adjusting the rotating speed of a peristaltic pump and the concentration of the solution. The chitosan gel microsphere prepared by the method has the advantages of abundant pores, large specific surface area, and high adsorption and acid resistance; in addition, the preparation method has the characteristics of simplicity, wide source in raw materials, low cost, easiness in separation and recovery, no secondary pollution and the like. The porous magnetic chitosan gel microsphere disclosed by the invention can be used for enrichment, recovery and contamination remediation of metals in mines, smelting plants, electronic factories, electroplating plants and radioactive wastewater.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY +1

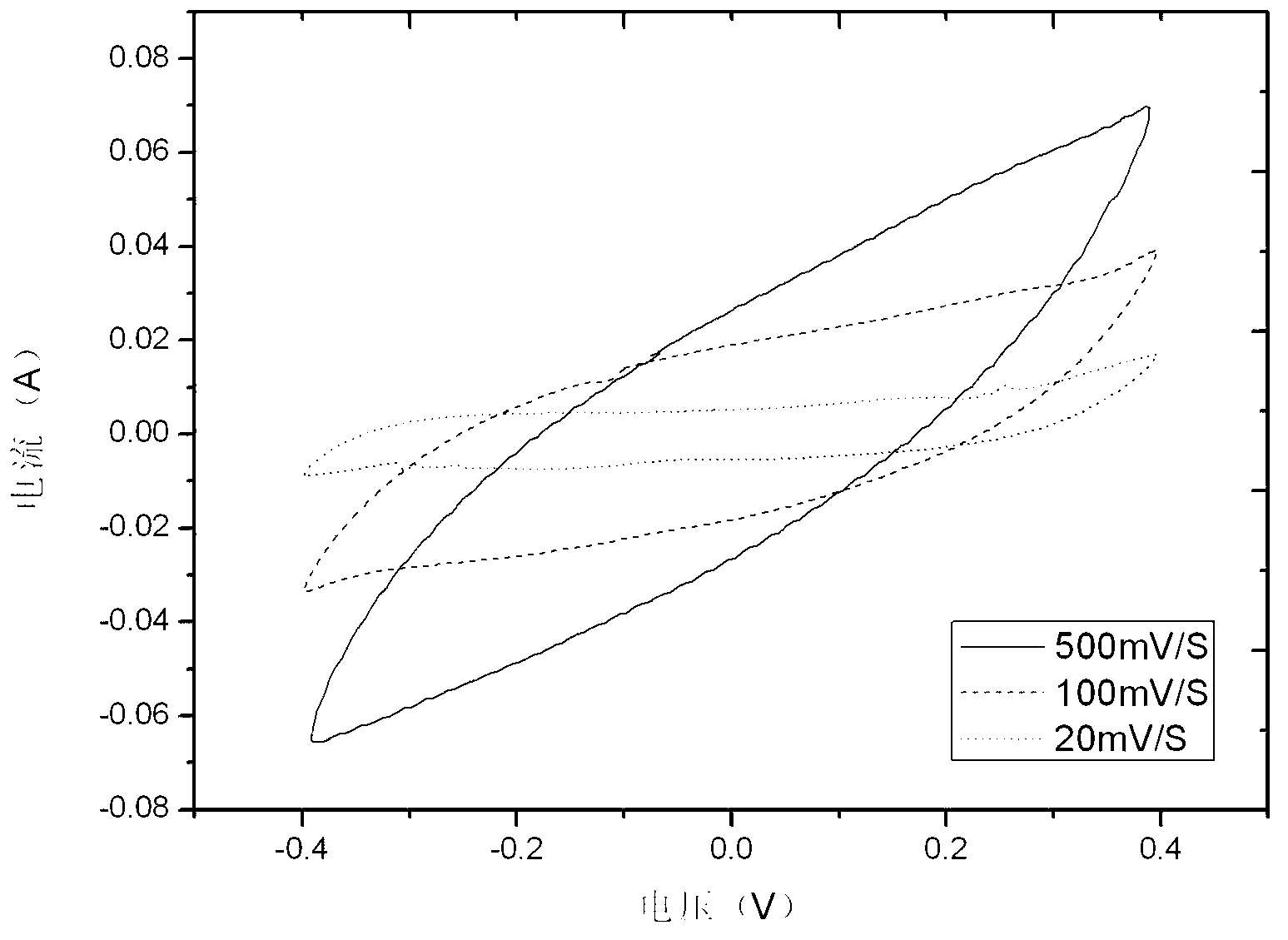

Preparation method of GO (Graphene Oxide)/NiCO LDHs catalytic material for detecting glucose and electrochemical sensor

InactiveCN109507271AIncreased porous structureImprove adsorption capacityMaterial electrochemical variablesGraphite oxideMethanol

The invention discloses a preparation method of a GO (Graphene Oxide) / NiCO LDHs catalytic material for detecting glucose and an electrochemical sensor. The preparation method comprises the following steps: firstly, dispersing graphene oxide (GO) into absolute methanol to obtain a graphene oxide dispersion solution; synthesizing GO@ZIF-67 by utilizing cobalt nitrate hexahydrate and dimethylimidazole; then carrying out hydrothermal synthesis on the GO@ZIF-67 and the nickel nitrate hexahydrate to obtain the GO / NiCO LDHs catalytic material; finally, dropwise adding a catalytic material solution onto a cleaned bare glass carbon electrode, so as to obtain a GO / NiCO LDHs modified electrochemical sensor. According to the preparation method, good electrochemical performance of the graphene oxide, and a porous structure and a regular shape of an MOFs (Metal Organic Frameworks) material are combined; ZIF-67 is used as a sacrificial template and oriented growth of the NiCO LDHs catalytic materialis realized; the stability of the glucose electrochemical sensor is enhanced, a detection range is expanded, the detection cost is reduced and the sensitivity of detection is improved. An enzyme-freeelectrochemical sensor makes a breakthrough of improving the analytical performance including high stability, high sensitivity and high catalytic performance and.

Owner:TIANJIN POLYTECHNIC UNIV

Chromium poisoning-resistant doped CeO2-coated LaNi0.6Fe0.4O3-delta cathode of solid oxide fuel cell and preparation method thereof

InactiveCN102420332AImprove anti-chromium poisoning performanceImprove electrochemical performanceCell electrodesFuel cellsThree-phase

The invention relates to a chromium poisoning-resistant doped CeO2-coated LaNi0.6Fe0.4O3-delta cathode of a solid oxide fuel cell and a preparation method thereof. The doped CeO2 comprises foreign ions of Gd<3+>and Sm<3+>. The preparation method is characterized in that a doped CeO2 particle layer is coated on the surface of a sintered LaNi0.6Fe0.4O3-delta cathode aperture. Therefore, a cathode pore structure and conductive performances are not influenced; deposition of chromium of highly volatile CrO3 and CrO2(OH)2 on a LaNi0.6Fe0.4O3-delta / electrolyte interface is reduced; LaNi0.6Fe0.4O3-delta / electrolyte three-phase interface length is prolonged; and LaNi0.6Fe0.4O3-delta cathode oxygen reduction reaction dynamic performances are improved so that solid oxide fuel cell (SOFC) performances are improved.

Owner:SHANGHAI JIAO TONG UNIV

Separator and electrochemical device including the same

ActiveUS20190131604A1Improve adhesionIncreased porous structureSolid electrolytesFinal product manufactureNon solventPorous coating

Disclosed are a separator and an electrochemical device including the same. The separator includes: a porous polymer substrate having a plurality of pores; a separator base including a porous coating layer formed on at least one surface of the porous polymer substrate, and including a plurality of inorganic particles and a binder polymer disposed partially or totally on the surface of the inorganic particles to connect and fix the inorganic particles with each other; and an adhesive porous layer formed on at least one surface of the separator base and including an adhesive resin which shows adhesive property through heating at a temperature lower than the melting point of the porous polymer substrate, wherein the adhesive porous layer is provided with a porous structure formed by phase separation caused by the evaporation rate of a solvent and that of a non-solvent, when applying and drying a coating composition including the adhesive resin, the solvent and the non-solvent on at least one surface of the separator base.

Owner:LG ENERGY SOLUTION LTD

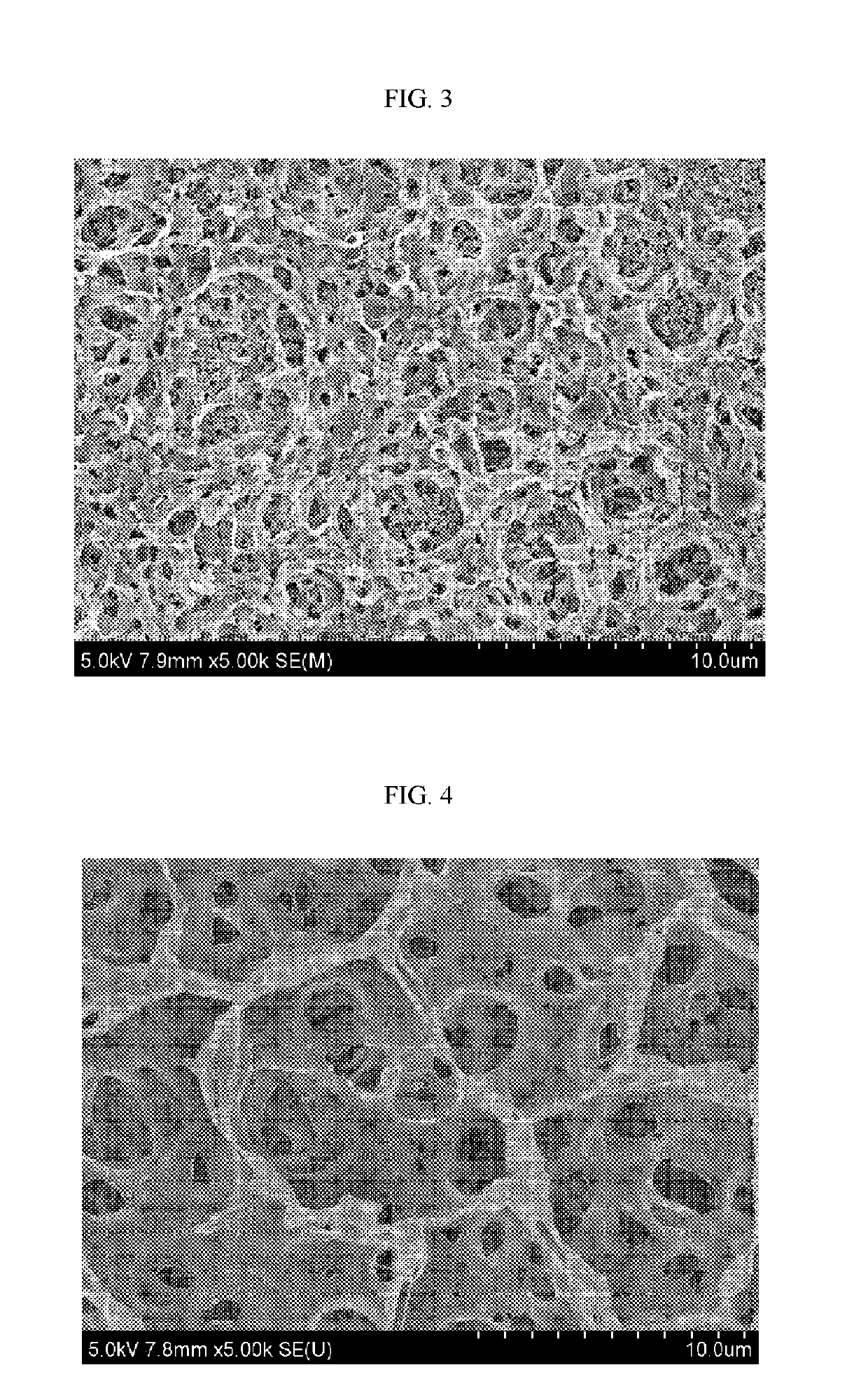

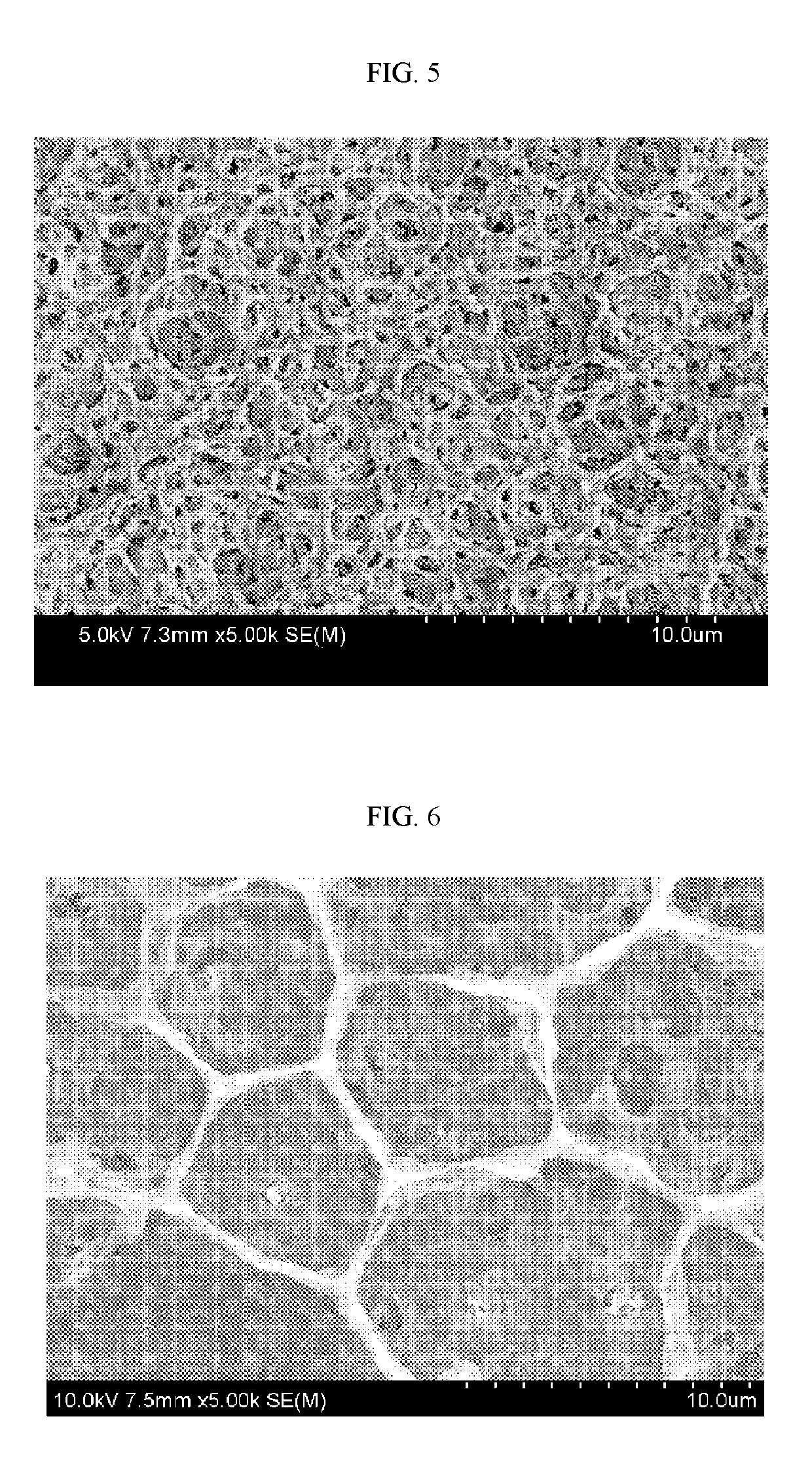

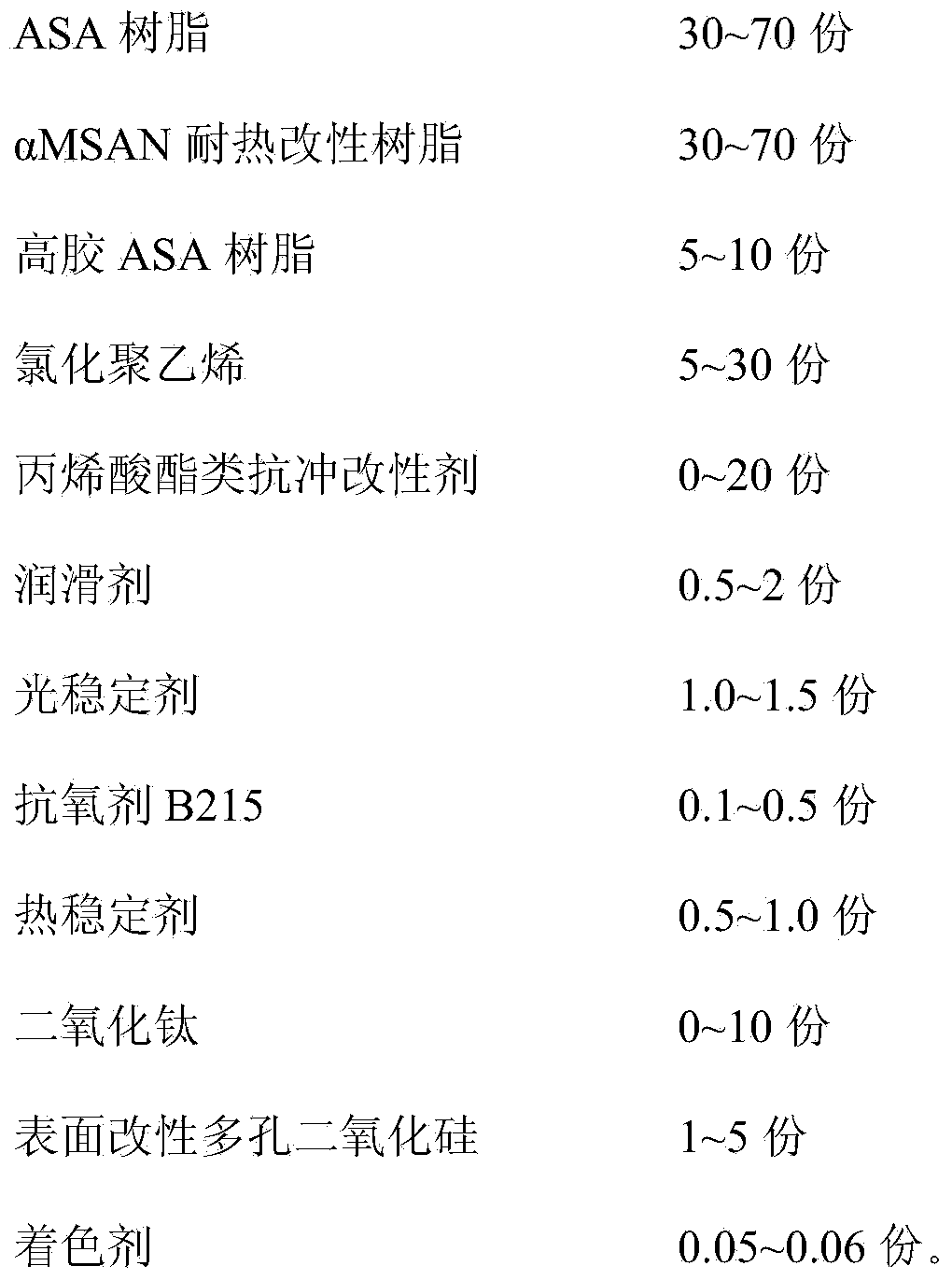

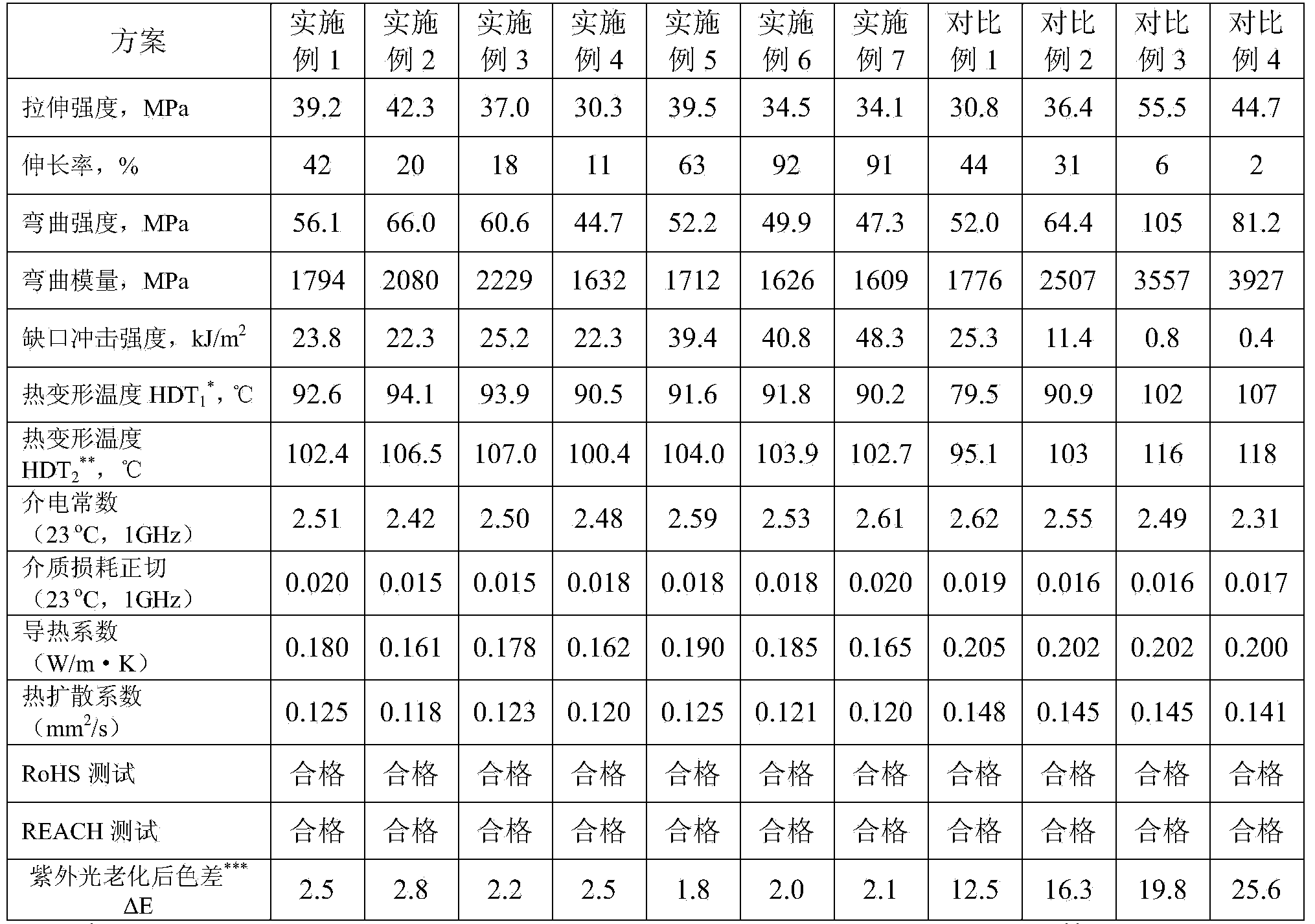

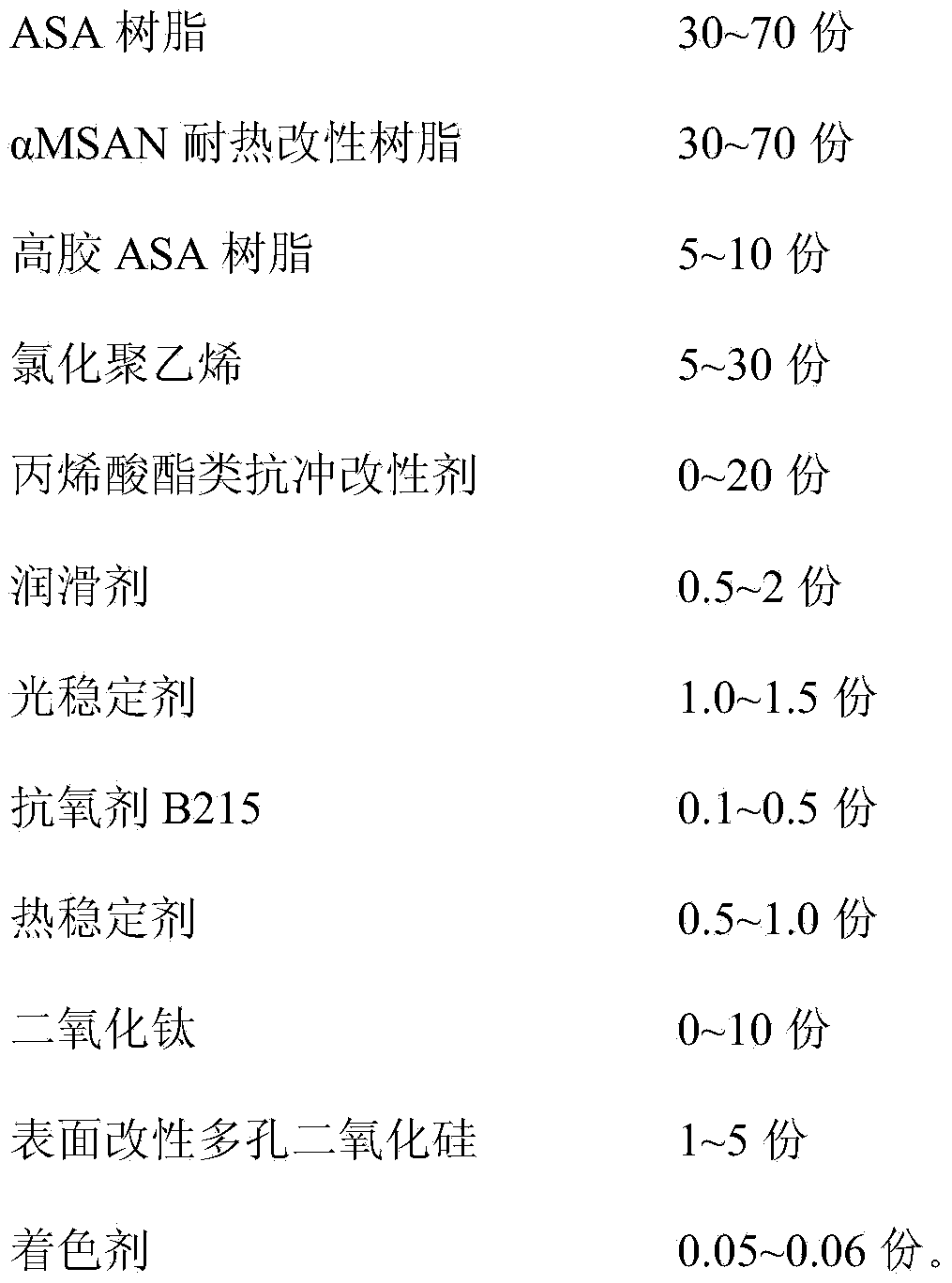

Environment-friendly modified ASA (Acrylonitrile Styrene Acrylate) profiled bar base station antenna outer cover and preparation method thereof

The invention discloses an environment-friendly modified ASA (Acrylonitrile Styrene Acrylate) profiled bar base station antenna outer cover and a preparation method thereof. The modified ASA profiled bar base station antenna outer cover has multifunctionality and is environment-friendly, excellent in mechanical property, highly heat-resistant, excellent in dielectric properties, excellent in ultraviolet irradiation resistance and low in heat conductivity coefficient. The environment-friendly modified ASA profiled bar base station antenna outer cover disclosed by the invention is prepared from the following raw materials in parts by weight: 30-70 parts of ASA resin, 30-70 parts of alphaMSAN heat-resistant modified resin, 5-10 parts of high-rubber ASA resin, 5-30 parts of chlorinated polyethylene, 0-20 parts of acrylate impact modifier, 0.5-2 parts of lubricating agent, 1.0-1.5 parts of light stabilizer, 0.1-0.5 part of antioxidant B215, 0.5-1.0 part of heat stabilizer, 0-10 parts of titanium dioxide, 1-5 parts of surface modified porous silicon dioxide and 0.05-0.06 part of coloring agent.

Owner:NANJING UNIV OF TECH +1

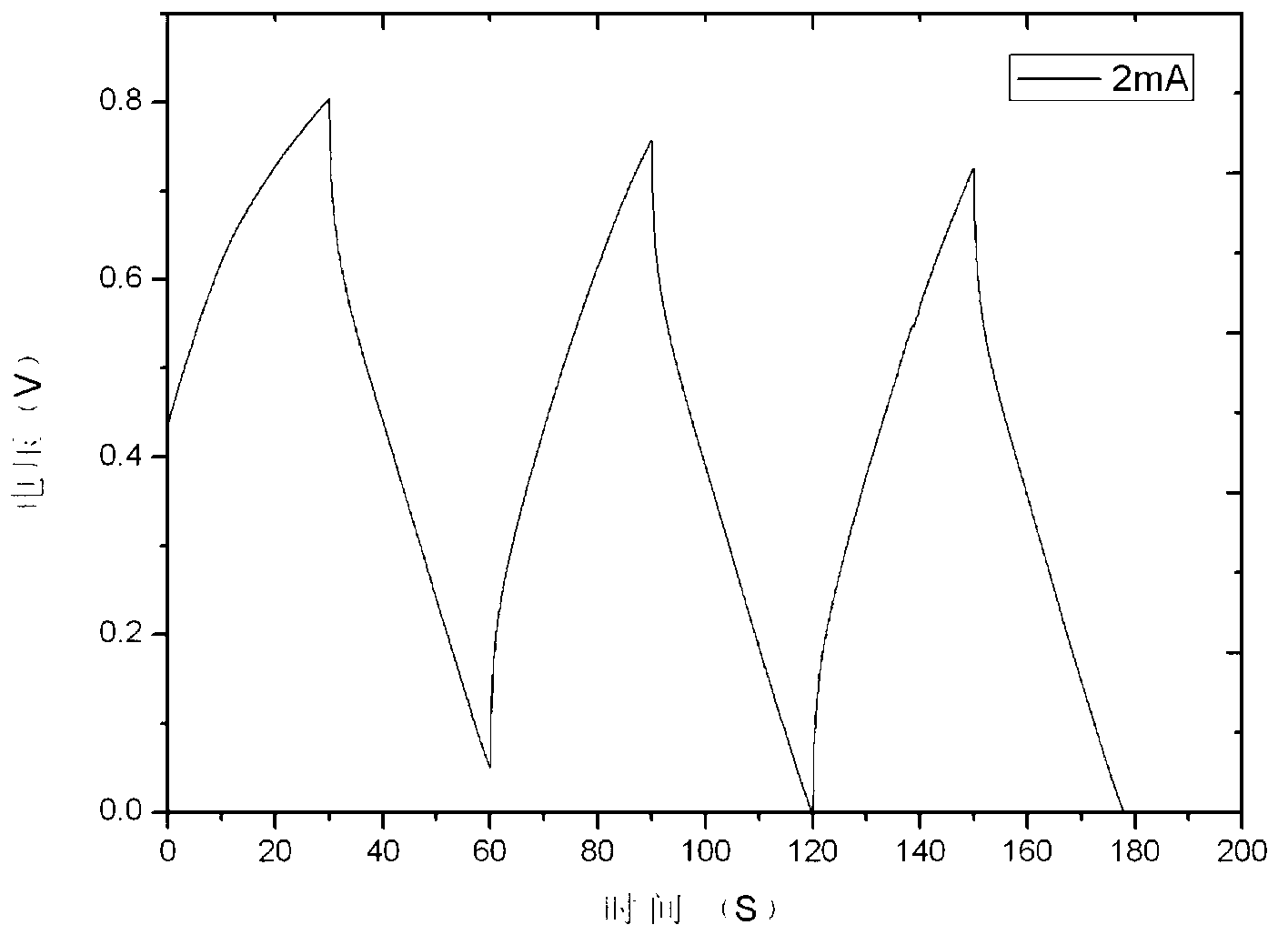

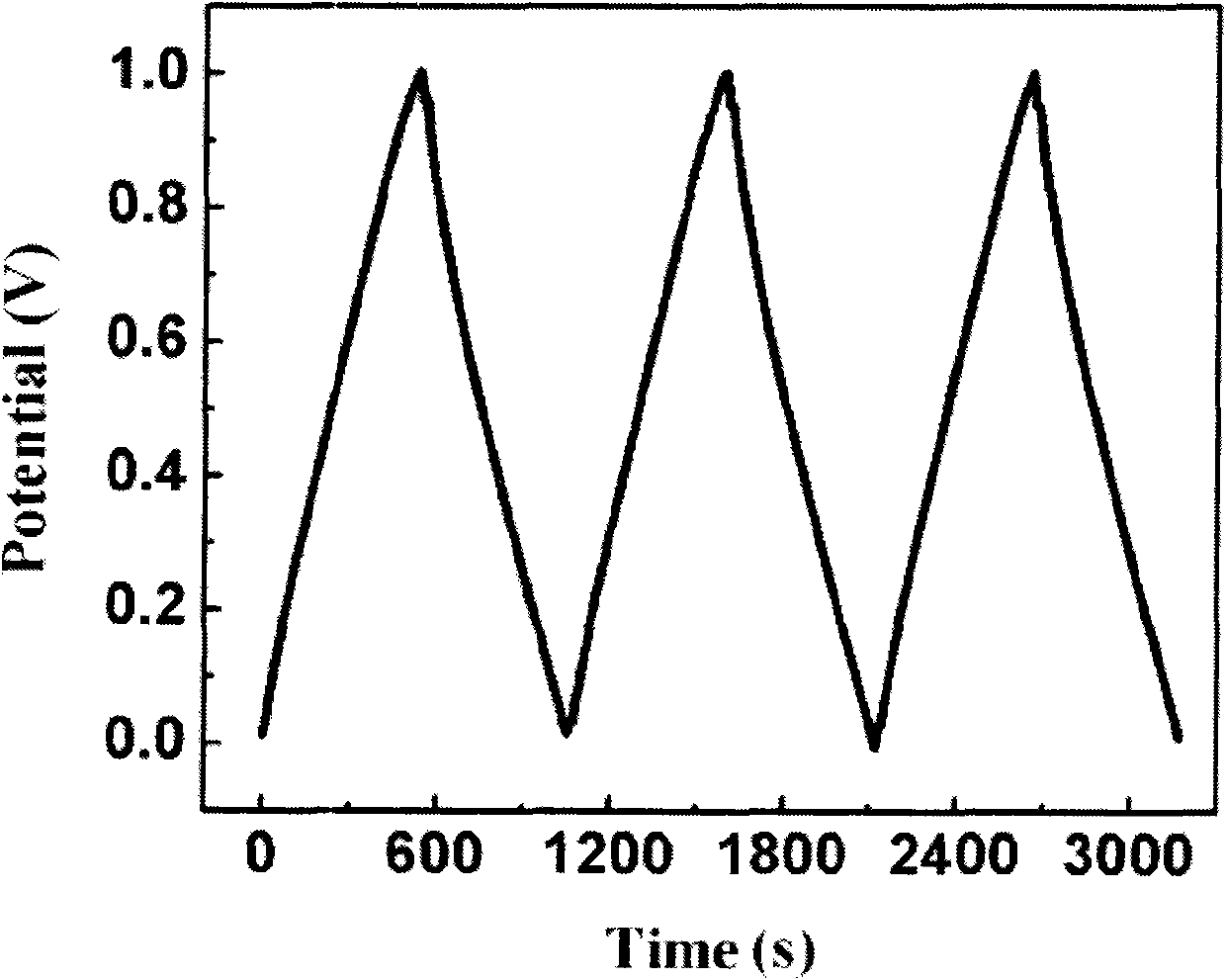

Preparation method and application for delta-MnO2 thick film pseudocapacitor electrode

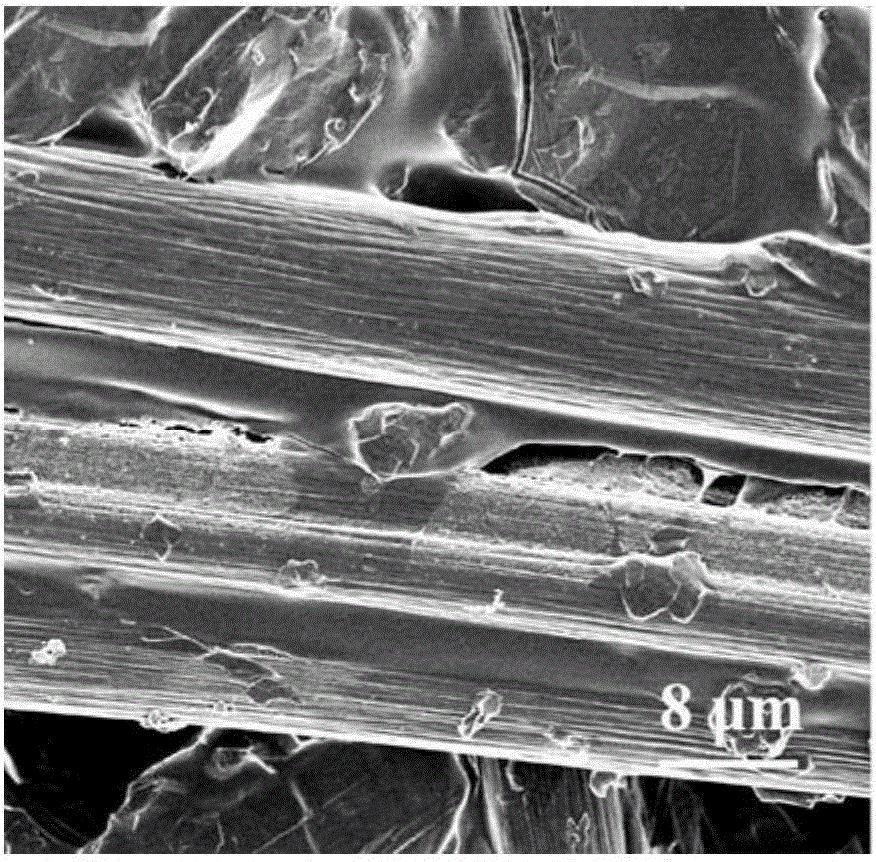

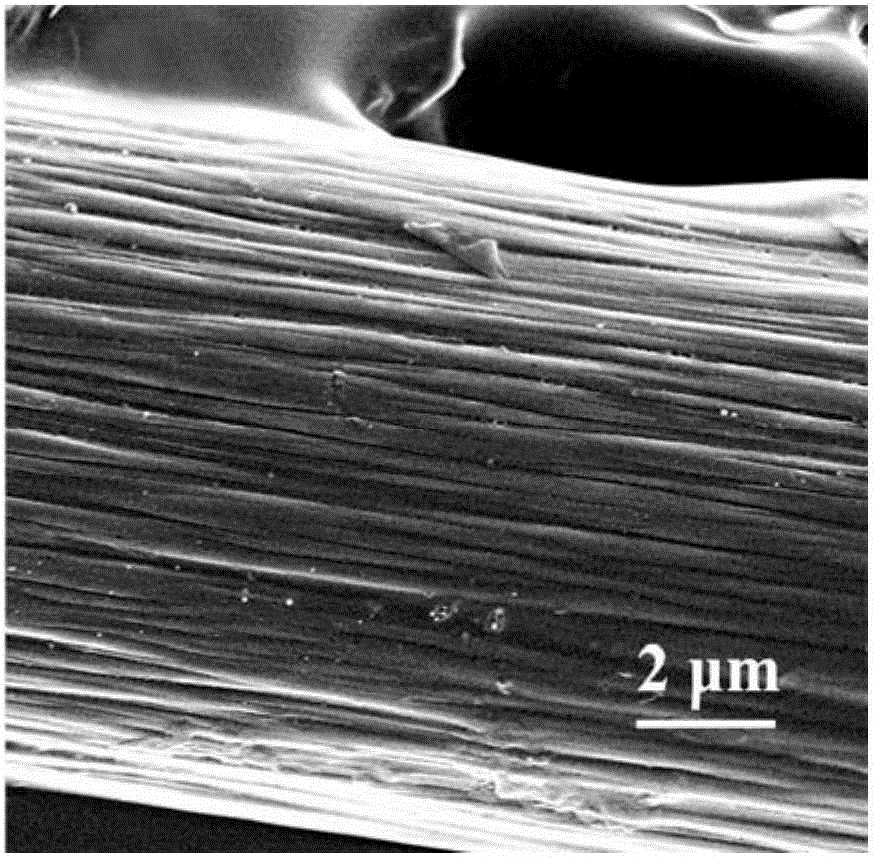

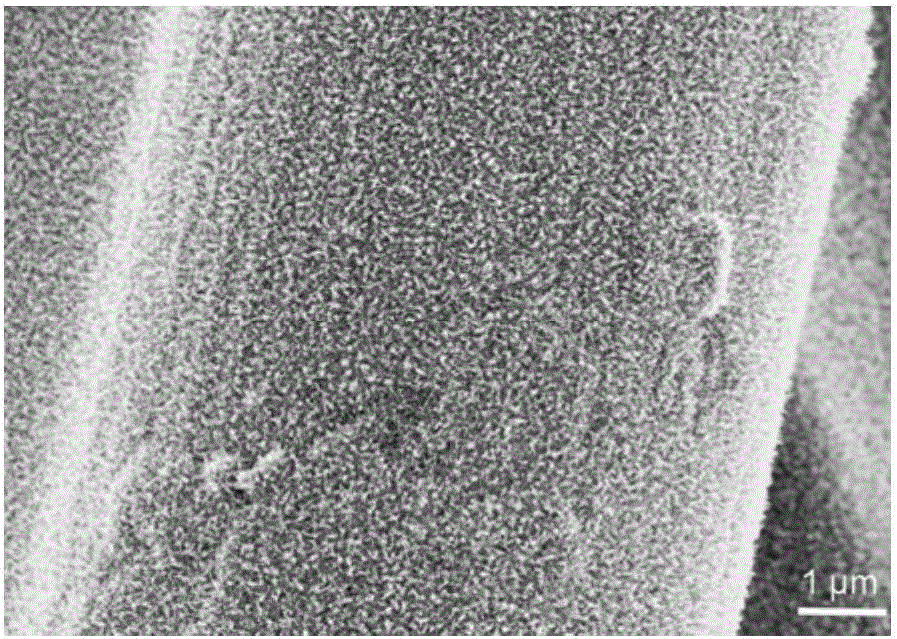

InactiveCN105355462AIncrease loadIncrease surface areaHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceFiber

The invention discloses a preparation method for a delta-MnO2 thick film pseudocapacitor electrode. The preparation method comprises the following steps of immersing carbon fiber paper into a potassium permanganate solution for 0.5 hour, then performing hydrothermal growth to form a GZO nanowire array to be used as a three-dimensional framework, and finally performing positive electrode disposition in different times on the framework with high conductivity to obtain the delta-MnO2 thick film. The synthetic method provided by the invention is simple, and low in cost; and the obtained pseudocapacitor electrode is high in quality specific capacitance and area specific capacitance, relatively high in potential window and high in the cycling stability.

Owner:SOUTH CHINA UNIV OF TECH

Solid oxide fuel cell and functional gradient composite cathode and preparation method thereof

ActiveCN102683721AImproving the Kinetic Performance of Oxygen Reduction ReactionHigh catalytic activityCell electrodesSolid electrolyte fuel cellsComposite cathodeFuel cells

The invention relates to a solid oxide fuel cell and a functional gradient composite cathode and a preparation method thereof. The functional gradient composite cathode for the solid oxide fuel cell comprises a chromium poisoning resistant layer, an activation layer and a current collection layer, wherein the chromium poisoning resistant layer is made of LNF (LaNi0.6Fe0.4O3) and doped CeO2, the activation layer is positioned above the chromium poisoning resistant layer and made of LSM (La0.8Sr0.2MnO3) and doped CeO2, and the current collection layer is positioned above the activation layer and made of LSM. The preparation method of the functional gradient composite cathode for the solid oxide fuel cell includes the steps: a, attaching paste of the chromium poisoning resistant layer onto an electrolyte layer and drying to obtain the chromium poisoning resistant layer; b, attaching paste of the activation layer onto the chromium poisoning resistant layer and drying to obtain the activation layer; c, attaching paste of the current collection layer to the activation layer and drying to obtain the current collection layer, so that a blank is obtained; and d, sintering the blank to obtain the functional gradient composite cathode. Chromium deposition of high-volatility CrO3 and CrO2 (OH)2 on cathode / electrolyte interfaces is reduced.

Owner:中氢新能源(江苏)有限公司

Separator for a non-aqueous secondary battery and non-aqueous secondary battery

ActiveUS20140242444A1Increased porous structureImprove ion permeabilityLi-accumulatorsCell component detailsPorous substrateHexafluoropropylene

A separator for a non-aqueous secondary battery including a porous substrate, and an adhesive porous layer that is formed on one side or both sides of the porous substrate and contains the following polyvinylidene fluoride resin A and the following polyvinylidene fluoride resin B:Polyvinylidene fluoride resin A: a polyvinylidene fluoride resin containing structural units derived from vinylidene fluoride and structural units derived from hexafluoropropylene, a total content ratio of structural units derived from hexafluoropropylene in each of the vinylidene fluoride copolymers being from 0.5 mol % to 1.5 mol % of a total content of structural units in each of the vinylidene fluoride copolymers; andPolyvinylidene fluoride resin B: a polyvinylidene fluoride resin containing structural units derived from vinylidene fluoride and structural units derived from hexafluoropropylene, a total content ratio of structural units derived from hexafluoropropylene in each of the vinylidene fluoride copolymers being greater than 1.5 mol % of a total content of structural units in each of the vinylidene fluoride copolymers.

Owner:TEIJIN LTD

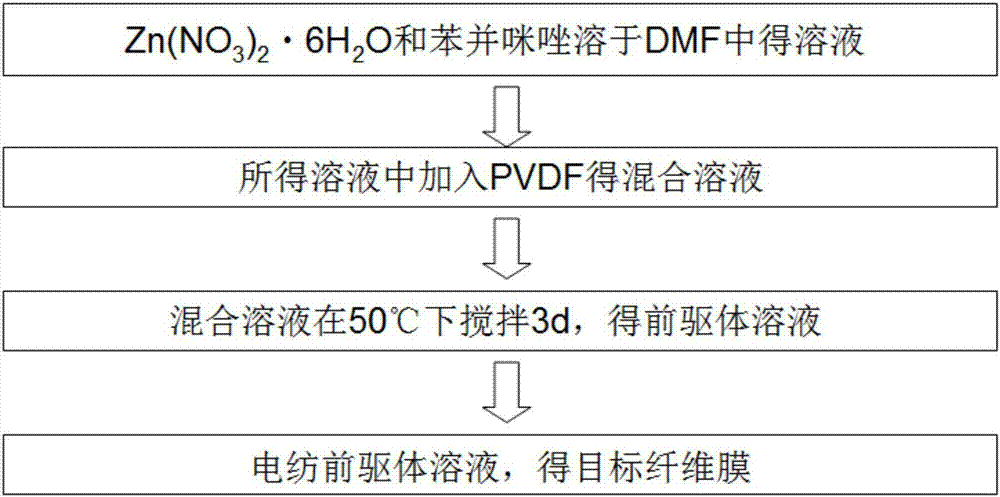

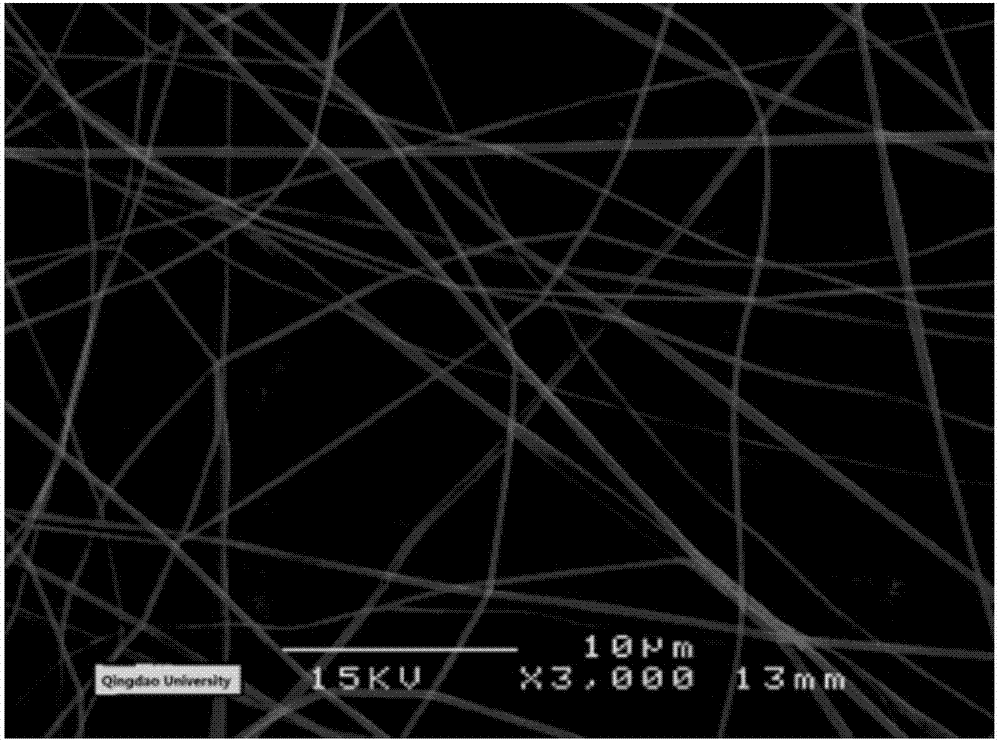

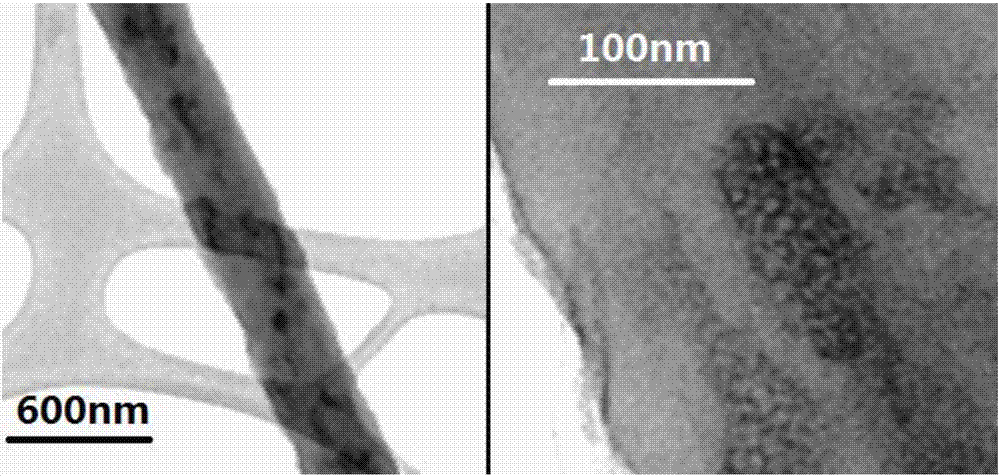

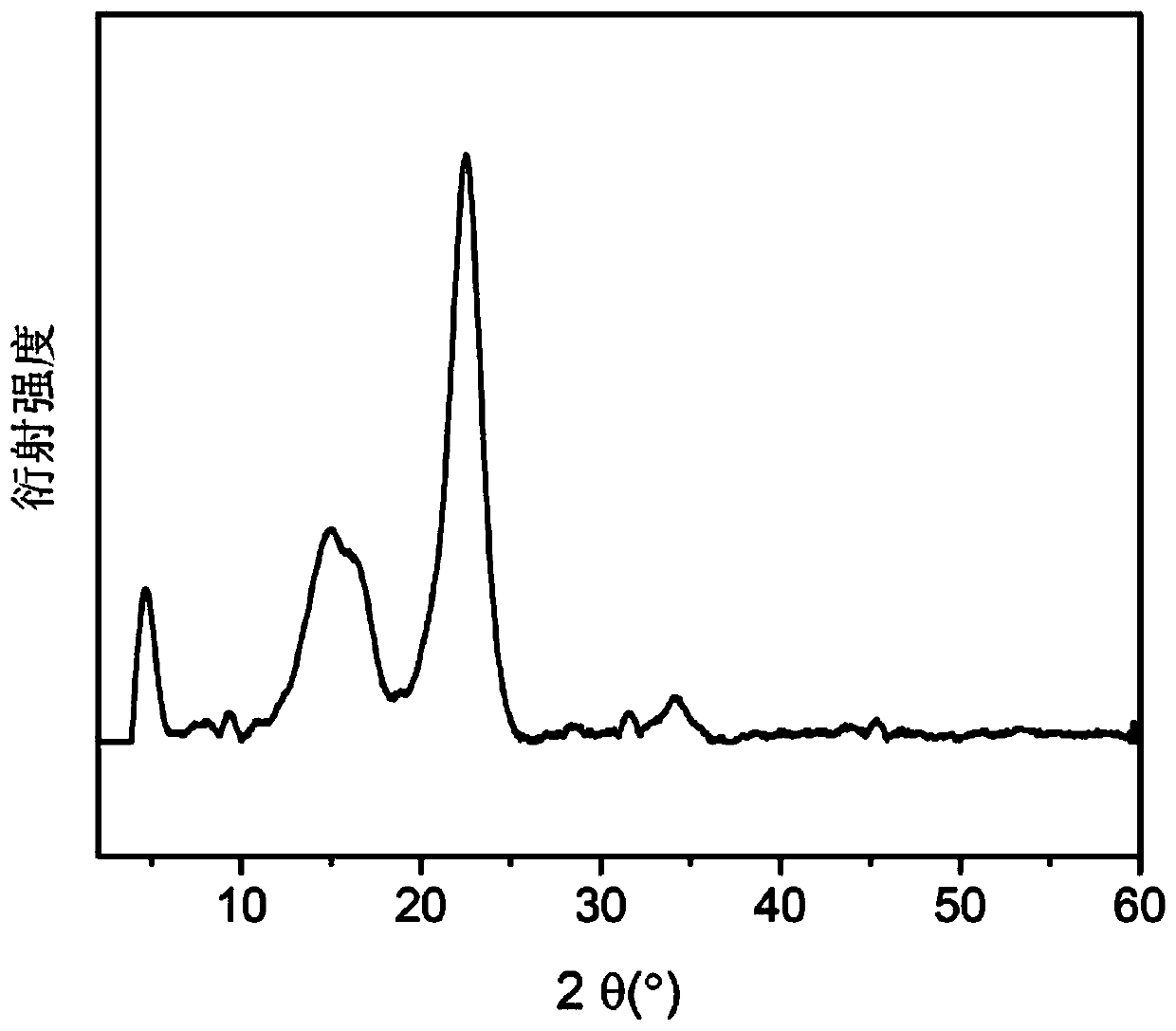

Zeolite imidazate framework nanoparticle composite fiber film and preparation method thereof

InactiveCN106948087AEvenly dispersedKeep the inherent characteristicsProductsGas treatmentFiberElectrospinning

The invention discloses a zeolite imidazate framework nanoparticle composite fiber film and a preparation method thereof; the method uses the static spinning technology to carry out in-situ preparation of the polymer composite fiber film containing the zeolite imidazate framework nanoparticles; the zeolite imidazate framework nanoparticles are evenly distributed in the composite fiber film, and the zeolite imidazate framework nanoparticle content in the composite fiber film is 10-15wt%; the composite fiber film has strong gas adsorption capability, and the zeolite imidazate framework nanoparticles are evenly composited in the high-molecular matrix, thus improving the application values of same in real life.

Owner:QINGDAO UNIV

Nuclear-grade ion-exchange resin-based composite material and preparation method thereof

ActiveCN106824272AImprove efficiencyGood recycling performanceCation exchanger materialsOrganic-compounds/hydrides/coordination-complexes catalystsNuclear gradeIon exchange

The invention discloses a nuclear-grade ion-exchange resin-based composite material and a preparation method thereof. The composite material is prepared by the steps: firstly reducing a platinum precursor into polymer-packaged nano platinum particles by using a reducing agent in existence of a polymer packaging agent; adding a silicon source and an aluminum source and then carrying out hydrothermal reaction employing a polymer as a structure-directing agent to obtain a platinum-silicon aluminum molecular sieve core-shell structure compound, wherein the inner core is nano platinum particles and the shell layer is a silicon-aluminum molecular sieve; and finally assembling the platinum-silicon aluminum molecular sieve core-shell structure compound to nuclear-grade ion-exchange resin to obtain the nuclear-grade ion-exchange resin-based composite material. The composite material has relatively high ion exchange property, relatively high catalytic removal efficiency, relatively high environment durability and extremely high recycling property, and has a good application prospect in the field of nuclear industry circulating water treatment.

Owner:NANJING INST OF TECH

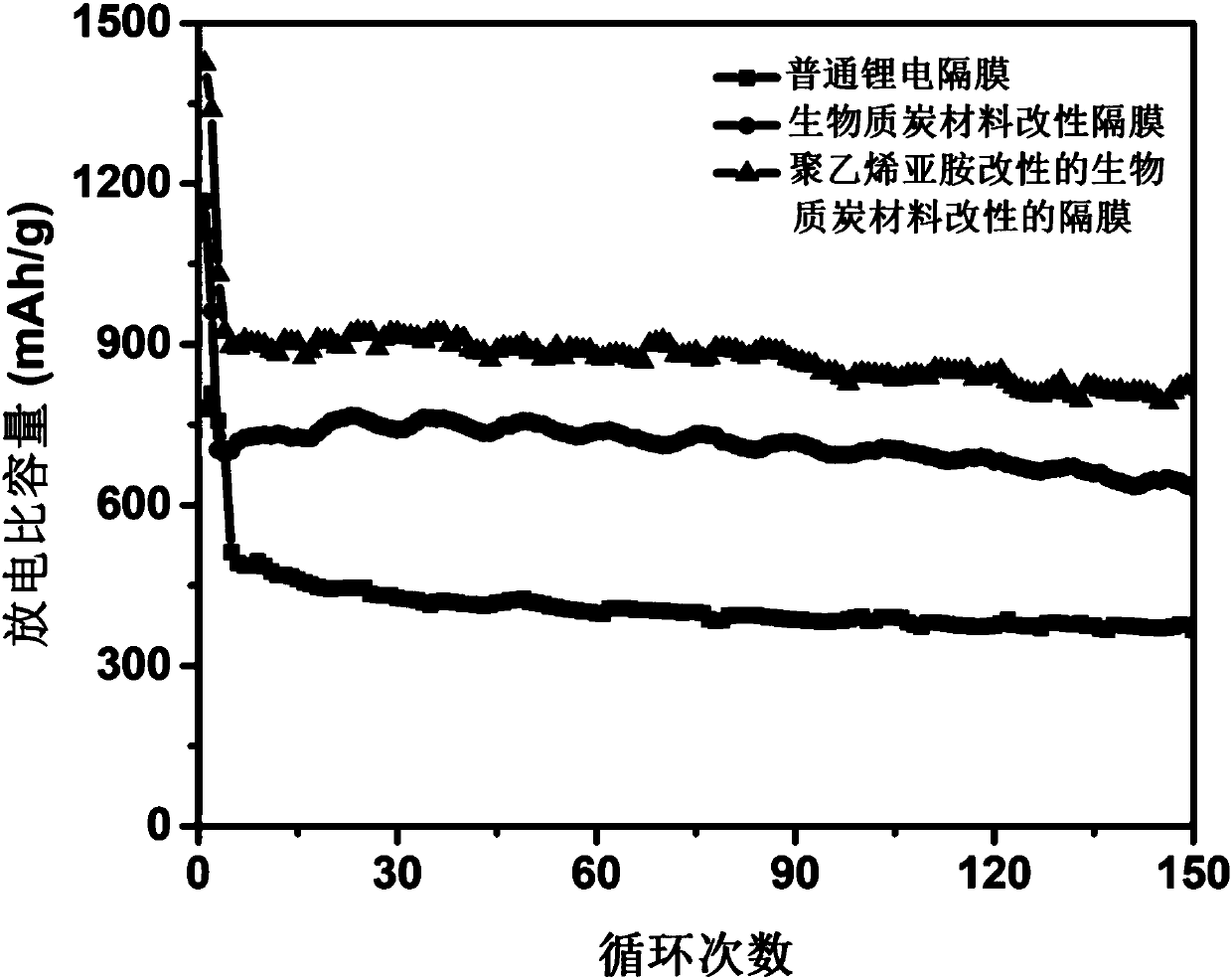

Polyethyleneimine modified biomass charcoal material and preparation method thereof, and application of polyethyleneimine modified biomass charcoal material to modification of lithium-sulfur battery diaphragm

InactiveCN107673350AIncreased porous structureConducive to loadCarbon compoundsCell component detailsLithium–sulfur batteryLithium sulfur

The invention provides a polyethyleneimine modified biomass charcoal material and a preparation method thereof, and application of the polyethyleneimine modified biomass charcoal material to modification of a lithium-sulfur battery diaphragm, belonging to the technical field of lithium-sulfur batteries. The polyethyleneimine modified biomass charcoal material is prepared by reacting a biomass charcoal material with polyethyleneimine at room temperature in virtue of an impregnation process and then carrying out washing and drying. Polyethyleneimine has rich amino group and shows powerful capacity in capturing lithium polysulfide. Biomass charcoal has a hierarchical pore structure and a specific surface area of 2000-3000 m<2> / g and can adsorb and store lithium polysulfide. When applied to modification of the lithium-sulfur battery diaphragm, the modified biomass charcoal material can effectively inhibit polysulfide from shuttling back and forth between the positive and negative electrodes of a battery, thereby enhancing the cycle performance of the battery. The invention also discloses a lithium-sulfur battery with a modified diaphragm. The actual specific capacity of the lithium-sulfur battery is obviously improved.

Owner:BEIJING UNIV OF CHEM TECH

Lightweight aluminum oxide castable and preparation method thereof

InactiveCN103044044AGood medium and low temperature performanceImprove high temperature performanceCeramicwareFoaming agentSlag

The invention relates to a lightweight aluminum oxide castable and a preparation method thereof. According to the technical scheme, the preparation method comprises the following steps of: uniformly mixing 80wt%-90wt% of alpha-Al2O3 fine powder and 10wt%-20wt% of rho-Al2O3 micro-powder or 80wt%-90wt% of commercial alumina fine powder and 10wt%-20wt% of rho-Al2O3 micro-powder, 1wt%-5wt% of pseudo-boehmite micro-powder and 5wt%-10wt% of an expanding agent, which are taken as raw materials, and adding 0.1wt%-1wt% of a water reducer and 15wt%-30wt% of water into the mixture to mix for 3-15 minutes, thus obtaining a mixed material; adding foam prepared from 0.1wt%-1wt% of a foaming agent to the mixed material to stir for 3-5 minutes; and pouring and vibrating the mixed material for molding, and drying the mixed material at 110-150 DEG C for 12-36 hours to obtain the lightweight aluminum oxide castable. The lightweight aluminum oxide castable has the advantages of low production cost, simple process, energy conservation, environment protection, and easiness for large-scale production; and the lightweight aluminum oxide castable is high in porosity, small in mean aperture, high in refractoriness, high in high-temperature strength, low in thermal conductivity and high in resistance to steel slag erosion.

Owner:WUHAN UNIV OF SCI & TECH

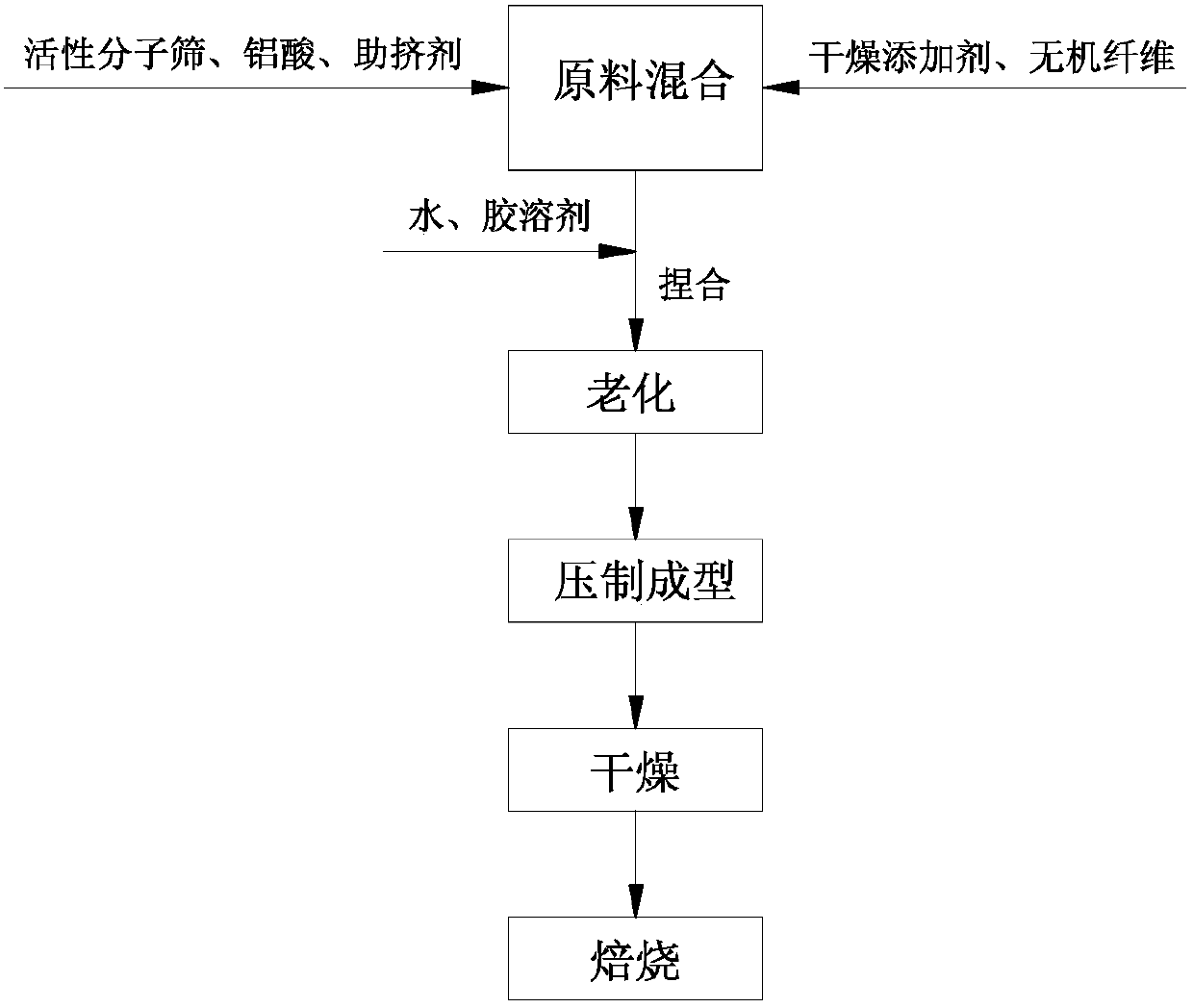

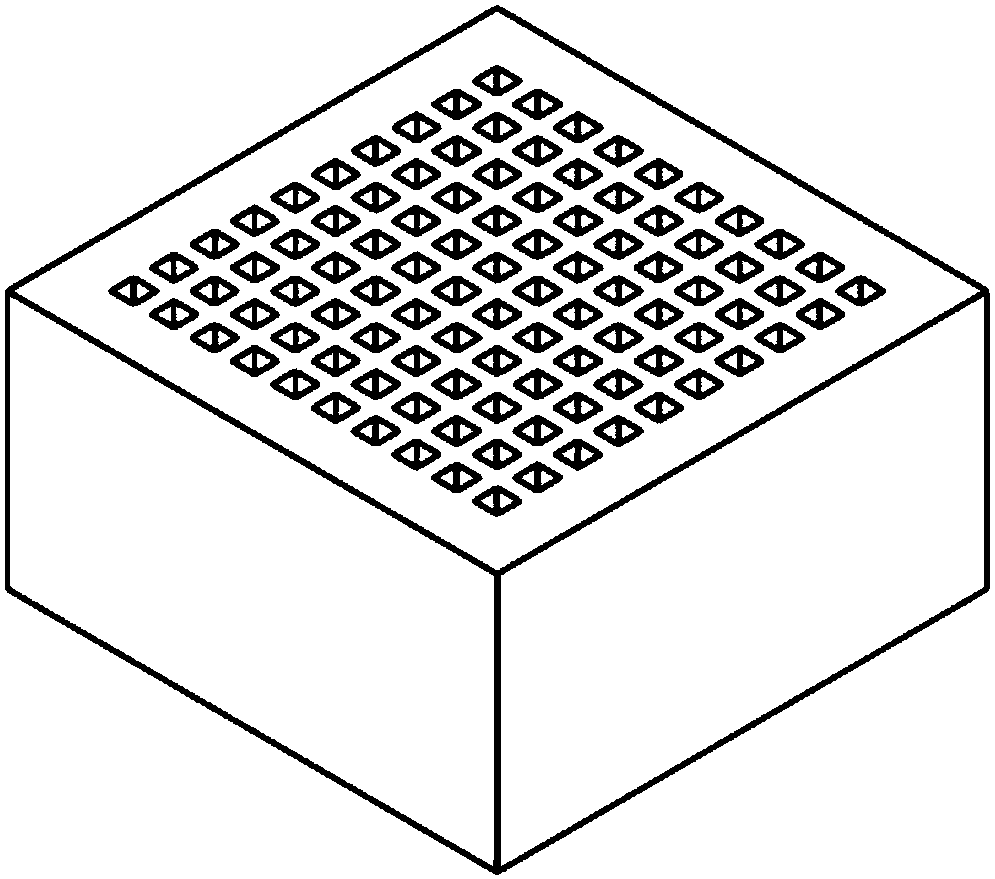

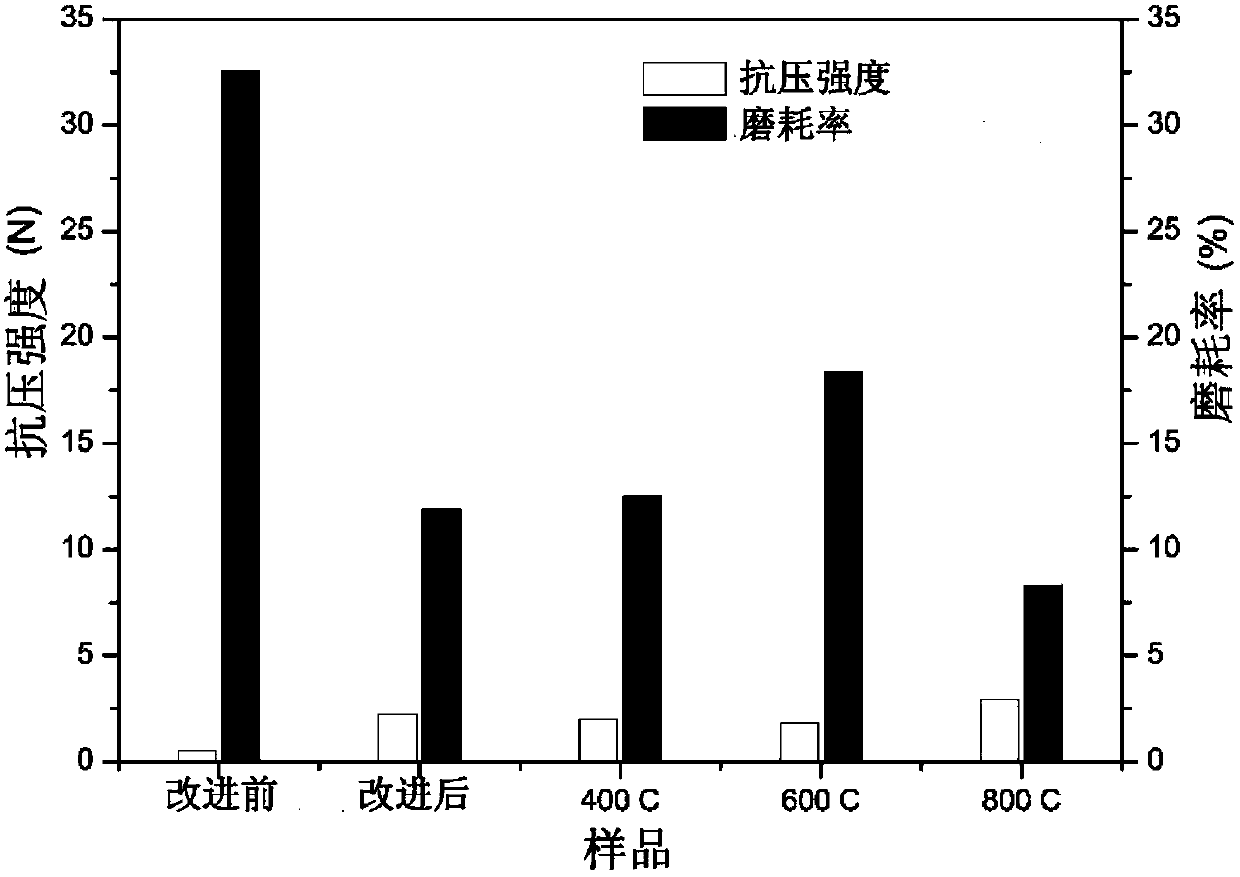

Preparation method for integral molecular sieve adsorbent for deep gas dehydration

InactiveCN105944663AAvoid relative motionSmall pressure dropOther chemical processesAluminium silicatesFiberSorbent

The invention discloses a preparation method for an integral molecular sieve adsorbent for deep gas dehydration. The problem of difficulty of a molecular sieve adsorbent in meeting a deep gas dehydration requirement is solved. The preparation method comprises the following steps: (1) uniformly mixing an active molecular sieve, aluminic acid, an extrusion assistant, a drying additive and inorganic fibers; (2) mixing mixed dry powder and water, and kneading a green body; (3) aging the green body to obtain a prepared body; (4) performing compression molding on the prepared body to obtain a cellular blank; (5) shaping, drying and aging the cellular blank; (6) performing secondary drying on the shaped, dried and aged cellular blank; (7) performing calcination and furnace cooling on the secondarily dried cellular blank to obtain the adsorbent. The adsorbent has the characteristics of strong compressive strength, high abrasion resistance, low gas passing pressure drop and high dehydration depth, and is low in cost and suitable for popularization and application, and the preparation method is simple.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

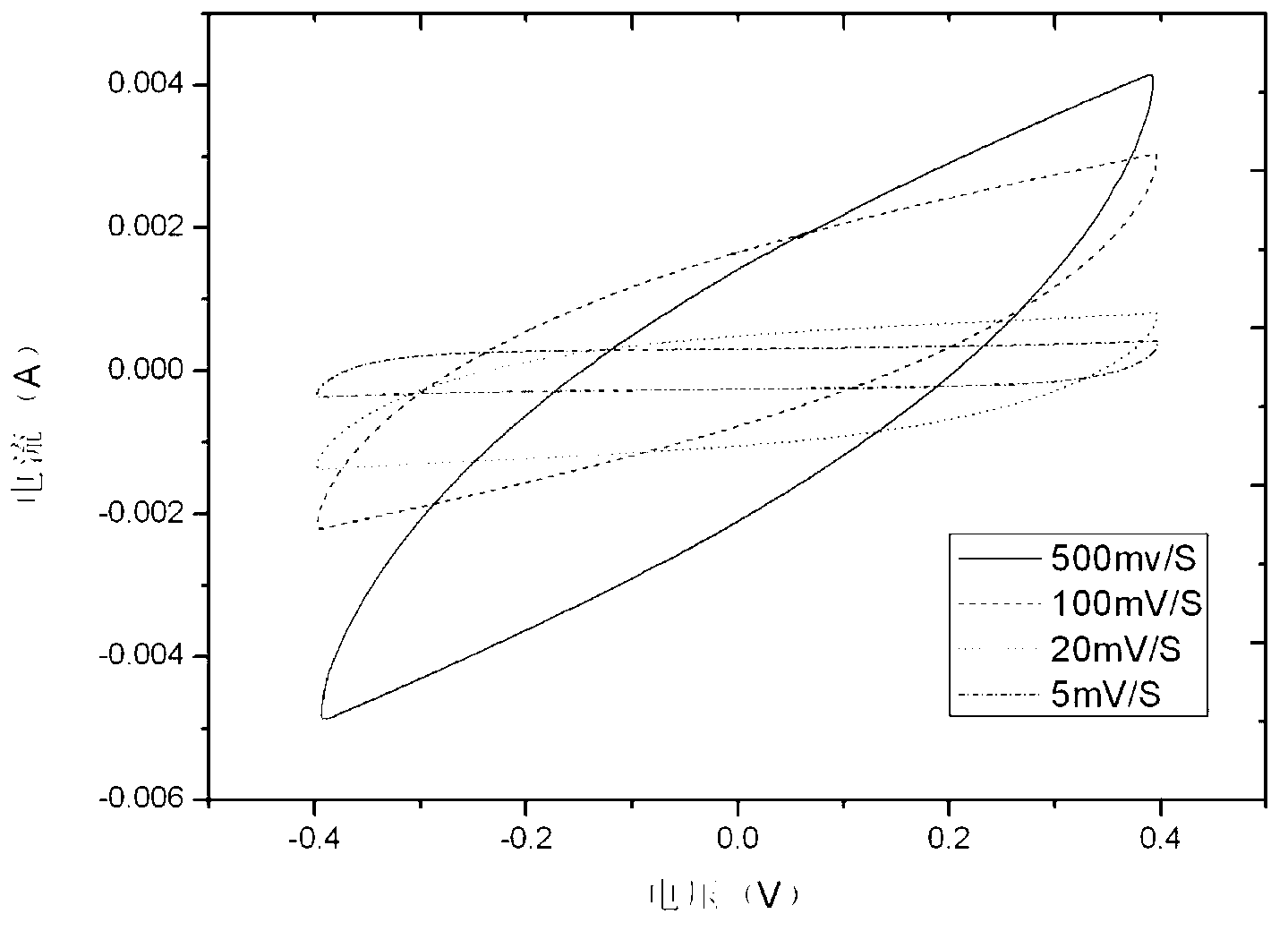

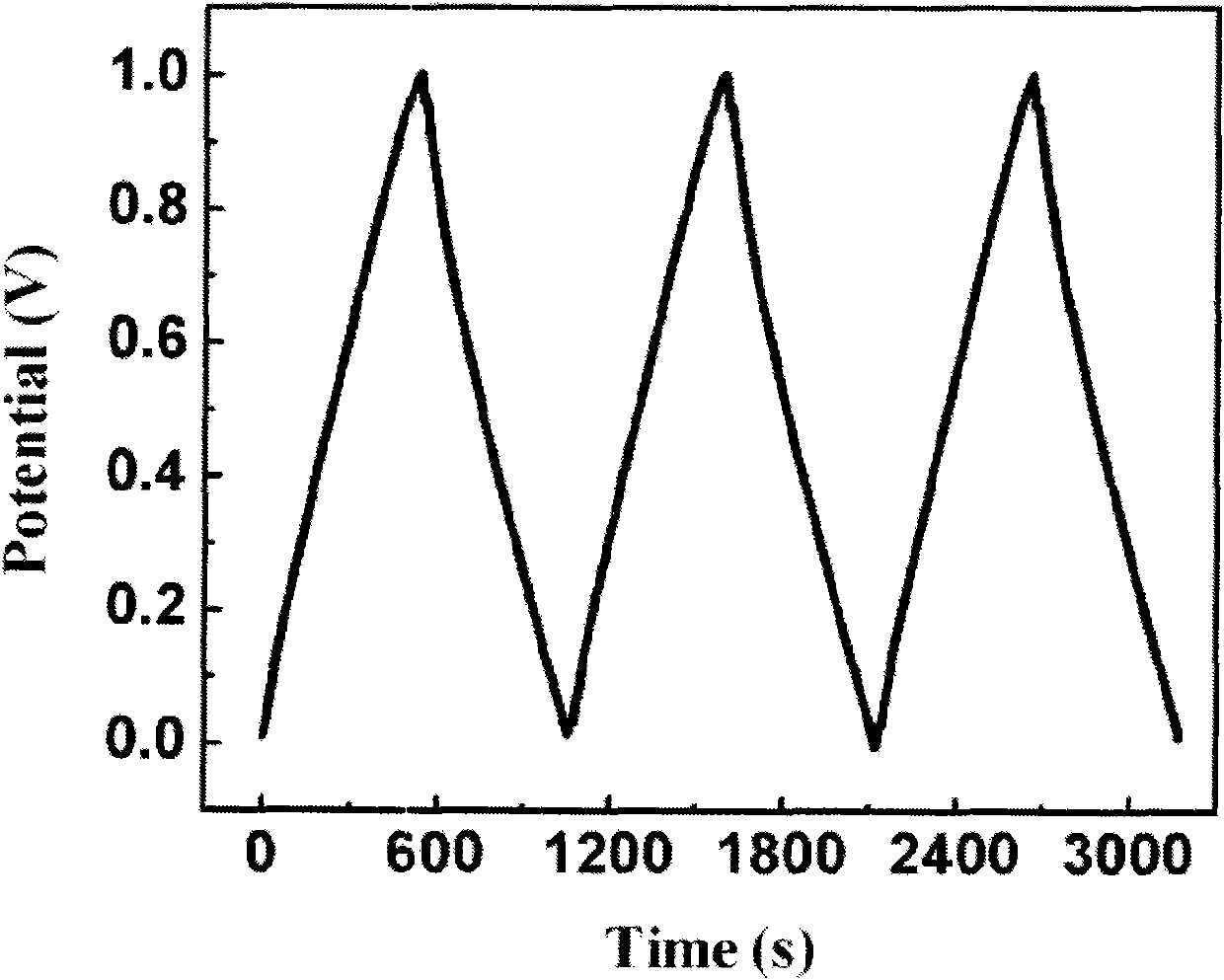

Electrode material of super-capacitor and preparation method thereof as well as super-capacitor manufactured by electrode material

InactiveCN102842433AReduce thicknessImprove power densitySolid electrolytic capacitorsComposite filmOrganic solvent

The invention relates to an electrode material of a super-capacitor and a preparation method of the electrode material as well as a super-capacitor manufactured by the electrode material. The electrode material comprises the following components in percentage by weight: 50-99% of polyvinylidene fluoride groups and 1-50% of additives. The preparation method comprises the following steps of: mixing the polyvinylidene fluoride groups with the additives in percentage by weight and dissolving the obtained mixture by using an organic solvent; coating and drying the dissolved solution on a carrier film substrate to obtain a composite film; activating the composite film by a physiochemical process to obtain an electrode material made from the polyvinylidene fluoride groups; and preparing the obtain electrode material into a flexible super-capacitor. The electrode material prepared from the polyvinylidene fluoride groups without adding active substances, low in cost and fast in charge-discharge speed; the flexible super-capacitor manufactured by the electrode material is good in charge-discharge performance and long in cycle life; and the flexible super-capacitor can be bent and folded, and is 200 mu m in the thinnest thickness, thus meeting a miniaturization development trend of a device and expanding an application scope of the super-capacitor.

Owner:SICHUAN UNIV

Flexible cuttable nanocellulose/covalent organic framework composite film and preparation method thereof

ActiveCN110227357AHigh crystallinityIncreased porous structureSemi-permeable membranesComposite filmFiltration

The invention discloses a flexible cuttable nanocellulose / covalent organic framework composite film and a preparation method thereof. The method comprises the following steps: chemically modifying nanocellulose (the carboxyl group is located at the C6 position) by using an amide condensation reaction to make an amino active group located at the C6 position of the nanocellulose, and carrying out vacuum suction filtration and drying on the obtained product to obtain a modified nanocellulose film; immersing the modified nanocellulose film in a 1,3,5-triformylphloroglucinol and p-phenylenediaminecovalent organic framework material precursor solution, and carrying out a solvothermal reaction in the presence of a catalyst; and ultrasonically washing the obtained reaction product with an organicsolvent, and carrying out high temperature activation in an oven to obtain the flexible cuttable nanocellulose / covalent organic framework composite film. The obtained flexible and cuttable compositefilm has the advantages of good film forming quality, compact, continuous, uniform and flat surface and good repeatability, and greatly maintains the crystallinity of the covalent organic framework material.

Owner:SOUTH CHINA UNIV OF TECH

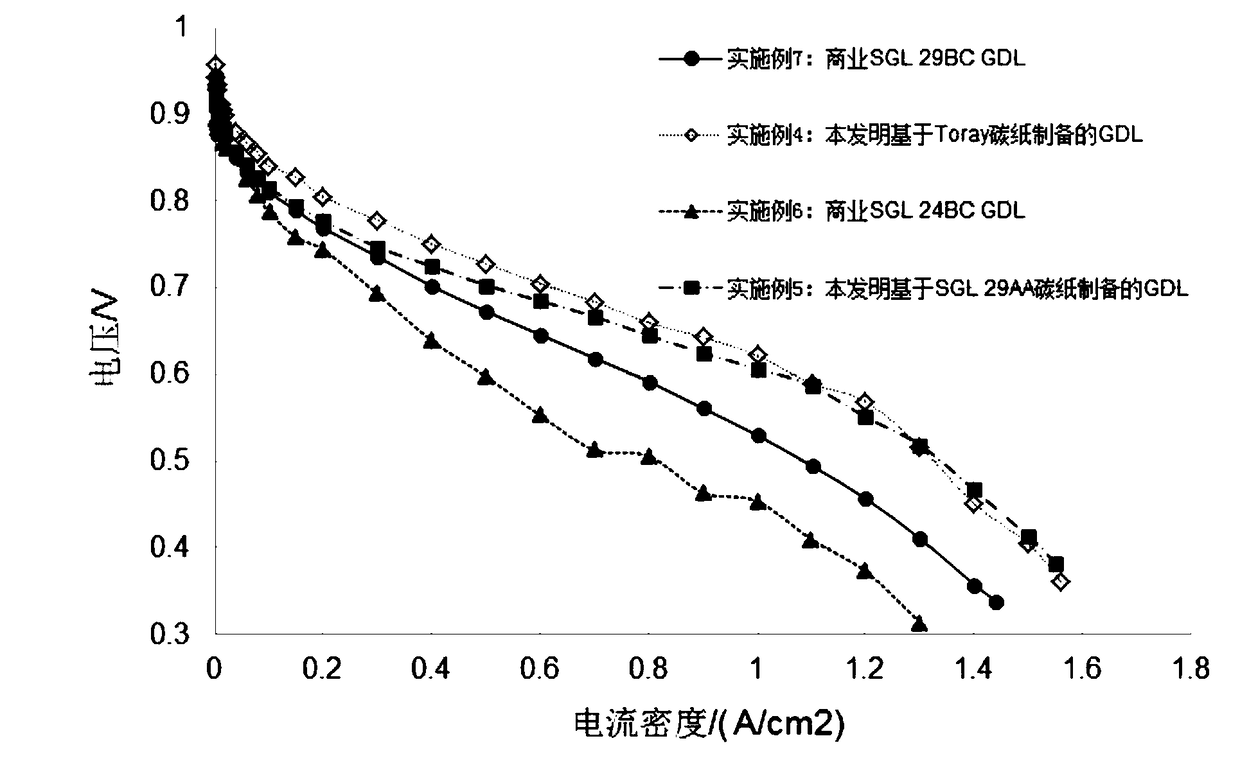

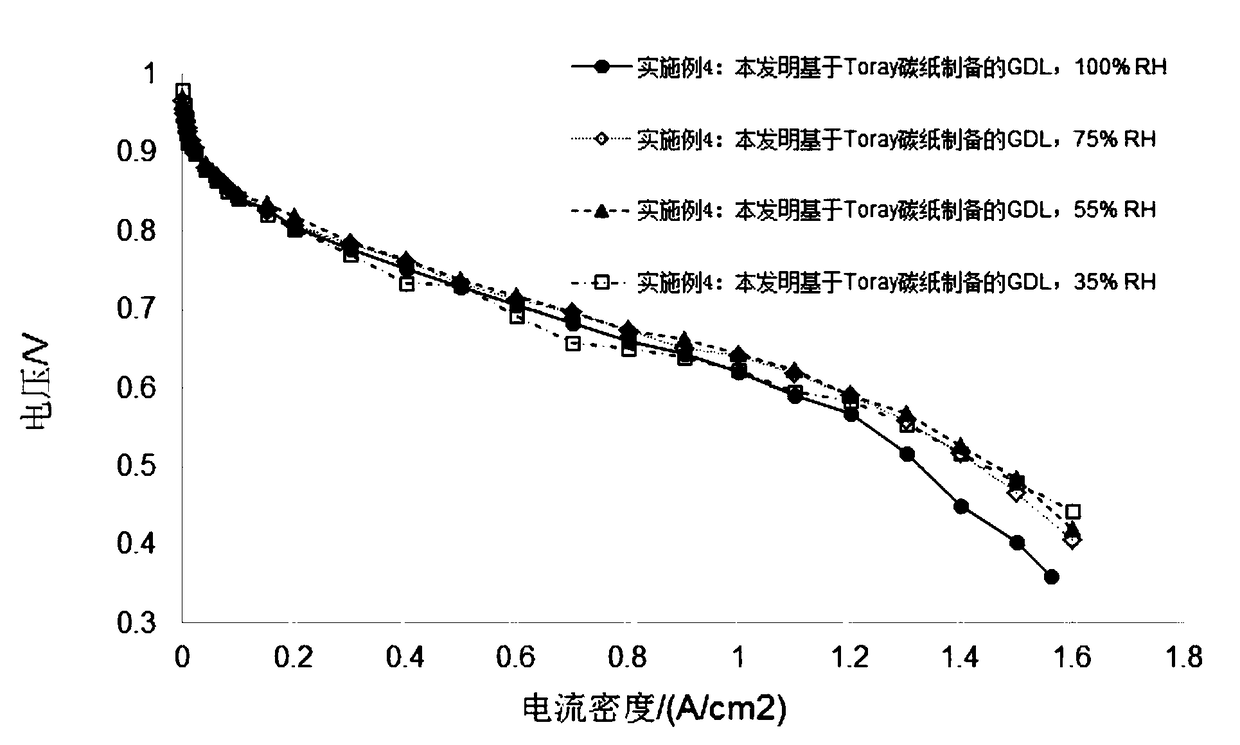

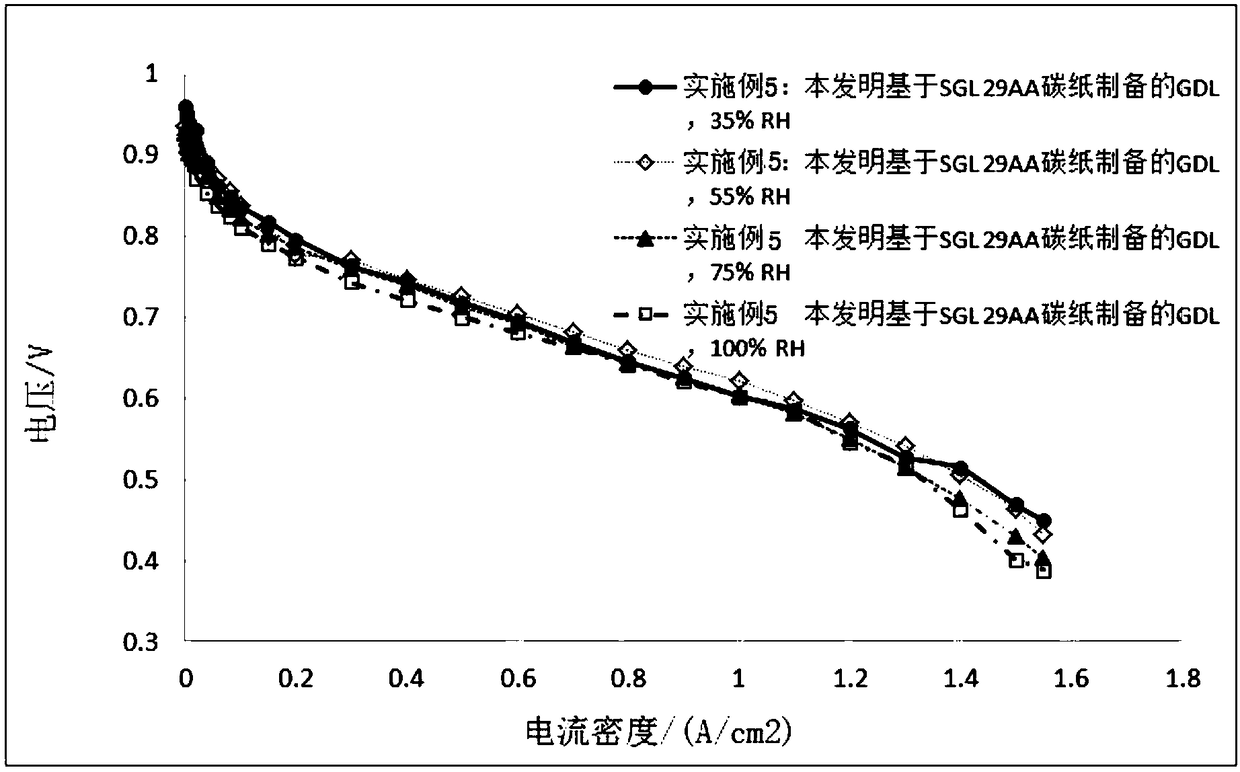

A fuel cell gas diffusion layer and a preparation method thereof

The invention relates to a fuel cell gas diffusion layer and a preparation method thereof. The gas diffusion layer includes an electrically conductive mesh structure serving as a carrier and a coatingcoated on one or both sides of the electrically conductive mesh structure, the coating comprises carbon powder and binder, wherein the coating is a porous structure with characteristic porosity and hydrophobicity, and is prepared by dispersing the carbon powder particles into water, dispersing the slurry through a homogenizer, adding the binder, stirring the slurry mechanically, and adjusting theslurry mixture to a proper viscosity; Coating the slurry mixture onto the surface of the conductive mesh structure; The sample is heat-treated to remove the additive to form a homogeneous adhesive mixture of carbon and binder to produce the product. As compare with that prior art, the gas diffusion layer of the present invention has good pore structure and hydrophobic property, and has superior performance and water management capability when hydrogen / oxygen or hydrogen / air or other fuel cells are operated.

Owner:TONGJI UNIV

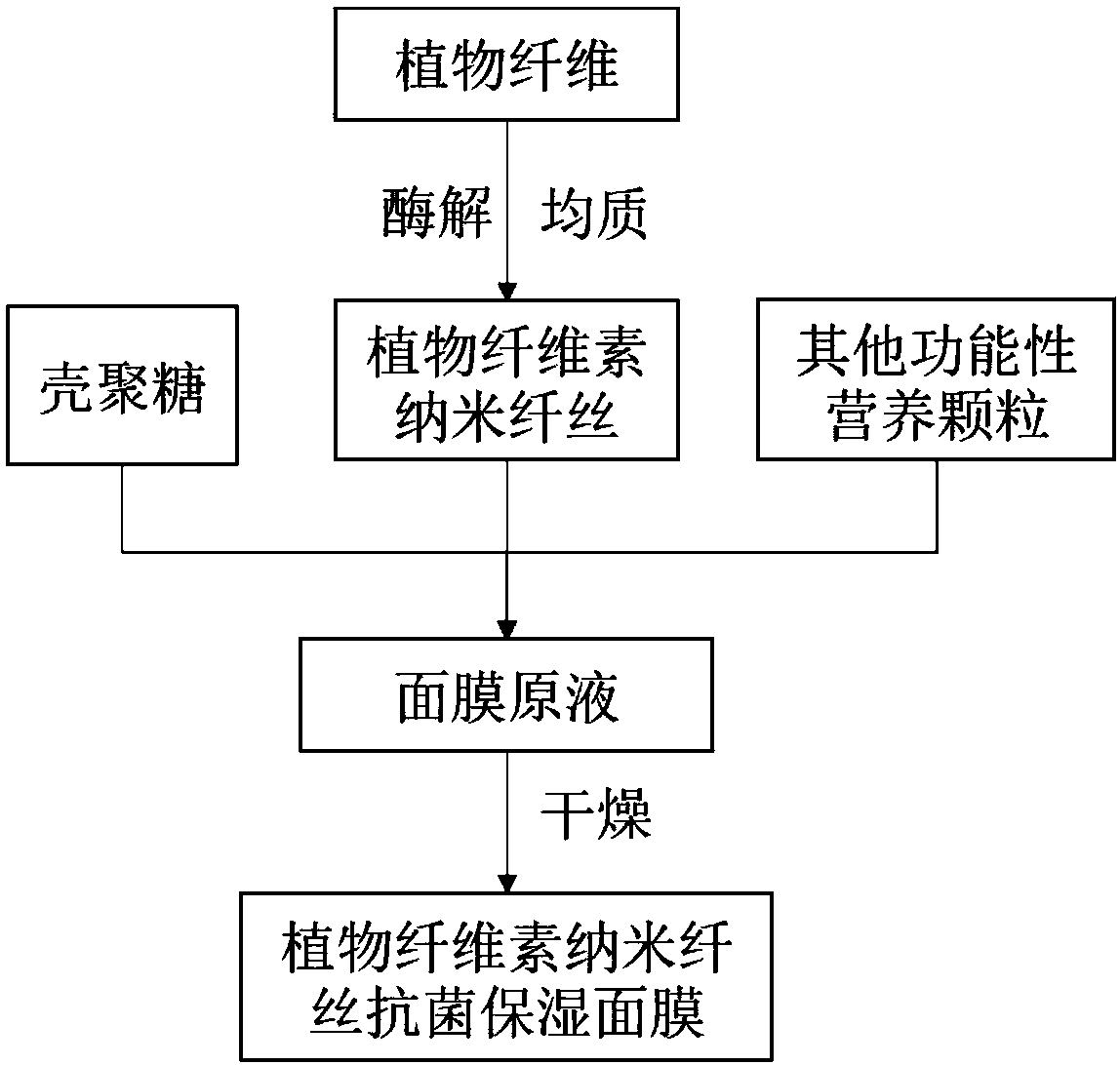

Plant cellulose nanofiber antibacterial moisturizing mask and preparation method thereof

ActiveCN108143680AIncrease water absorptionHigh nutrient absorptionCosmetic preparationsToilet preparationsEmulsionEnzyme

The invention belongs to the field of skin-care mask materials, and discloses a plant cellulose nanofiber antibacterial moisturizing mask and a preparation method thereof. The preparation method comprises the following steps of hydrolyzing plant fibers by enzyme, and mechanically treating, so as to prepare plant cellulose nanofiber with a high length-to-radius ratio; blending antibacterial chitosan, other functional ingredient particles and the plant cellulose nanofiber, emulsifying to obtain a uniform and stable white emulsion which is used as a mask raw liquid, pouring the mask raw liquid into a die, and preparing a mask sheet with a specified shape under certain conditions; finally, filling feeding a wetting agent into a package bag of the mask body containing the plant cellulose nanofiber and the functional ingredients, sealing an opening, sterilizing, and packaging. The plant cellulose nanofiber antibacterial moisturizing mask has the advantages that by adopting pure natural plantfibers, the poison and harm are avoided, the safe, economical and environment-friendly effects are realized, the water is favorably supplemented to the deep skin layer, and the absorbing speed and absorbing effect of a functional nutritional liquid are improved.

Owner:SOUTH CHINA UNIV OF TECH

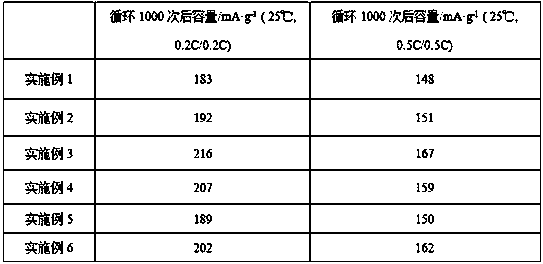

Carbon-coated vanadium pentoxide positive electrode material as well as preparation method thereof and application of carbon-coated vanadium pentoxide positive electrode material in lithium battery

InactiveCN109817943AImprove conductivityImprove structural stabilityCell electrodesSecondary cellsCarbon coatingPorous graphene

The invention provides a carbon-coated vanadium pentoxide positive electrode material, a preparation method thereof and application of the carbon-coated vanadium pentoxide positive electrode materialin a lithium battery, and belongs to the technical field of lithium batteries. The specific scheme is as follows: the carbon-coated vanadium pentoxide positive electrode material has a sandwich structure, an outer coating layer of the sandwich structure is a nitrogen-doped carbon material, an inner sandwich layer of the sandwich structure is graphene foam and vanadium pentoxide, and the preparation method comprises the following steps: (1) performing hydrothermal growth of vanadium disulfide in the graphene foam, and annealing in air; (2) self-polymerizing dopamine on the annealed graphene foam, carrying out centrifugal drying, and carrying out high-temperature annealing in an inert atmosphere; and (3) assembling the annealed material in the inert atmosphere into the lithium battery. According to the prepared vanadium pentoxide positive electrode material with the carbon-coated structure, the loading capacity of the active material is increased through the porous graphene foam, the lithium ion transport distance is shortened, the structural stability of the active material is stabilized through carbon coating, and therefore the prepared vanadium pentoxide positive electrode material shows good electrochemical performance.

Owner:ZHUHAI COSMX BATTERY CO LTD

Preparation method for activated carbon/carbon nano tube mixed electrode material, and product thereof and application

ActiveCN101908389APrevent oxidationIncrease production costElectrolytic capacitorsCarbon-silicon compound conductorsMicrosphereMetallurgy

The invention discloses a preparation method for an activated carbon / carbon nano tube mixed electrode material, and a product thereof and application. The method comprises the following steps of: 1) weighing raw materials according to the mass ratio of potassium hydroxide to mesocarbon microbeads (MCMB) of 5-10:1, and adding water for mixing to form paste; 2) placing the paste into a first stainless steel container, sealing the first stainless steel container, placing the first sealed stainless steel container into a second stainless steel container with a larger volume, filling petroleum coke powder into the second stainless steel container, and sealing the second stainless steel container; and 3) placing the second stainless steel container into a muffle furnace, raising the temperature to 900 to 1,100 DEG C, preserving the heat for 2 to 5 hours, cooling the second stainless steel container with the furnace to normal temperature, taking the reactant out, washing the reactant with a 5 to 10 percent hydrochloric acid to remove impurities, washing the reactant with deionized water till the reactant is neutral, and drying the reactant to obtain the AMCMB / CNT mixed electrode material. Compared with the prior art, the method has the advantages of no need of protecting a gas supply device, simple equipment and low production cost.

Owner:GUANGXI NORMAL UNIV

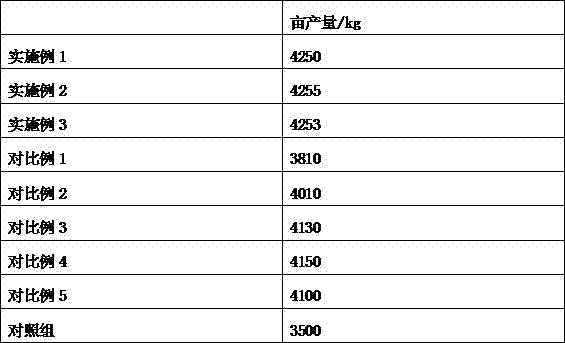

Biomass charcoal

InactiveCN107254324AHigh yieldIncrease productionBiofuelsSpecial form destructive distillationAgriculture cropsStipa capillata

The invention discloses biomass charcoal and relates to the technical field of straw application. The biomass charcoal is prepared from corn straw, wheat straw, cotton straw and stipa capillata in a mixing manner. The biomass charcoal disclosed by the invention is not only high in biomass charcoal yield and good in repairing effect on soil, but also capable of promoting absorption of fertilizer nutrients by crops, crop growth can be promoted, and the yield can be increased.

Owner:安徽省宗正农业科技开发股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com