Preparation method for integral molecular sieve adsorbent for deep gas dehydration

A technology of deep dehydration and molecular sieve, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc. It can solve the problem that molecular sieve adsorbents cannot fully meet the requirements of deep gas dehydration, so as to improve the depth of dehydration and adsorption capacity and reduce dust. Yield, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

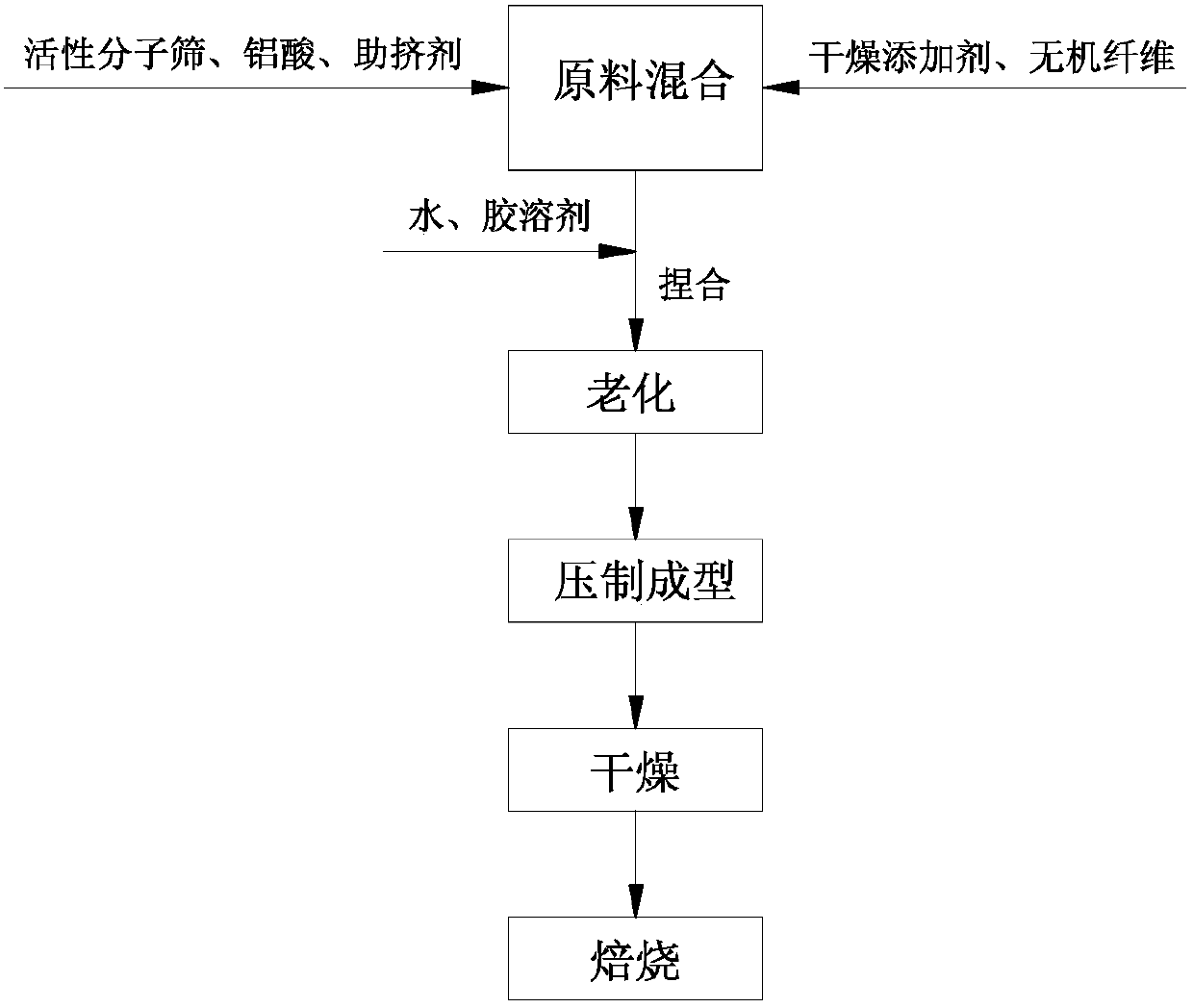

[0038] The invention provides a method for preparing a molecular sieve monolithic adsorbent, and the prepared adsorbent can be used for deep removal of trace moisture in the air. Such as figure 1 As shown, the present invention mainly includes several major processes of raw material mixing, aging, compression molding, drying and roasting.

[0039] 1. Raw material mixing

[0040] The active molecular sieve with a particle size of less than 60 mesh, aluminum acid (for binding), extrusion aid, drying additive and inorganic fiber are uniformly mixed in a mixer to obtain a mixed dry powder. The mass percentages of active molecular sieve and alumina acid, extrusion aid, drying additive and inorganic fiber are: active molecular sieve 40%-90%, alumina acid 10%-60%, extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com