Aluminum and aluminum alloy surface treatment method

A technology of aluminum alloy surface and treatment method, which is applied in the direction of surface reaction electrolytic coating, anodic oxidation, electrolytic coating, etc., can solve the problems of low surface hardness, intergranular corrosion and corrosion of aluminum and aluminum alloy, and achieve the reduction of friction coefficient, Enhanced corrosion ability and improved porous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

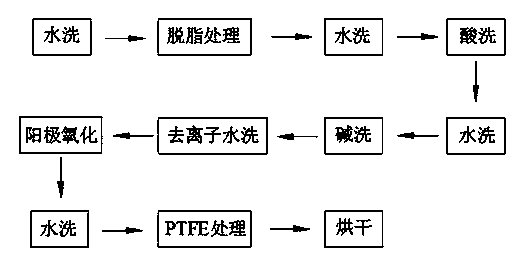

[0025] Such as figure 1 As mentioned above, take the aluminum alloy base material and process it according to the following steps:

[0026] (1) Water washing: wash the aluminum alloy substrate with tap water for 2 minutes, and perform impurity and dust removal treatment;

[0027] (2) Degreasing treatment: put the aluminum alloy base material into a degreasing solution for degreasing treatment, wherein the degreasing solution is an aqueous cleaning solution with a weight content of 15%, and the degreasing solution contains sodium salt, surfactant and cleaning agent; sodium salt, surface The weight percentage of active agent and cleaning agent is 2:10:50; the sodium salt is trisodium phosphate and sodium silicate; the surfactant is sodium dodecylbenzenesulfonate, alkylphenol polyoxyethylene ether and dioctyl Sodium sulfosuccinate; The cleaning agent is trichlorethylene;

[0028] (3) Water washing: spray and wash the degreased aluminum alloy substrate for 2 minutes;

[0029] (...

Embodiment 2

[0038] Take the pure aluminum substrate and process it according to the following steps:

[0039] (1) Water washing: wash the pure aluminum substrate with tap water for 2 minutes, and perform impurity and dust removal treatment;

[0040] (2) Degreasing treatment: put the pure aluminum base material into a degreasing solution for degreasing treatment, wherein the degreasing solution is an aqueous cleaning solution with a weight content of 8%, and the degreasing solution contains sodium salt, surfactant and cleaning agent; sodium salt, surface The weight percentage of active agent and cleaning agent is 48:12:52; the sodium salt is trisodium phosphate and sodium silicate; the surfactant is sodium dodecylbenzenesulfonate and alkylphenol polyoxyethylene ether; cleaning The agent is trichloroethane;

[0041] (3) Water washing: spray and wash the degreased pure aluminum substrate for 2 minutes;

[0042] (4) Pickling: Soak the pure aluminum base material after step 3 in the acid sol...

Embodiment 3

[0051] Take the aluminum alloy substrate and process it according to the following steps:

[0052] (1) Water washing: wash the aluminum alloy substrate with tap water for 2 minutes, and perform impurity and dust removal treatment;

[0053] (2) Degreasing treatment: put the aluminum alloy base material into a degreasing solution for degreasing treatment, wherein the degreasing solution is an aqueous cleaning agent solution with a weight content of 10%, and the degreasing solution contains sodium salt, surfactant and cleaning agent; sodium salt, surface active agent The weight percentage of active agent and cleaning agent is 6:14:58; the sodium salt is trisodium phosphate, sodium silicate; the surfactant is sodium dodecylbenzenesulfonate, alkylphenol polyoxyethylene ether and di Sodium octyl sulfosuccinate; cleaning agents are trichloroethylene and trichloroethane.

[0054] (3) Water washing: spray and wash the degreased aluminum alloy substrate for 2 minutes;

[0055] (4) Pickl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com