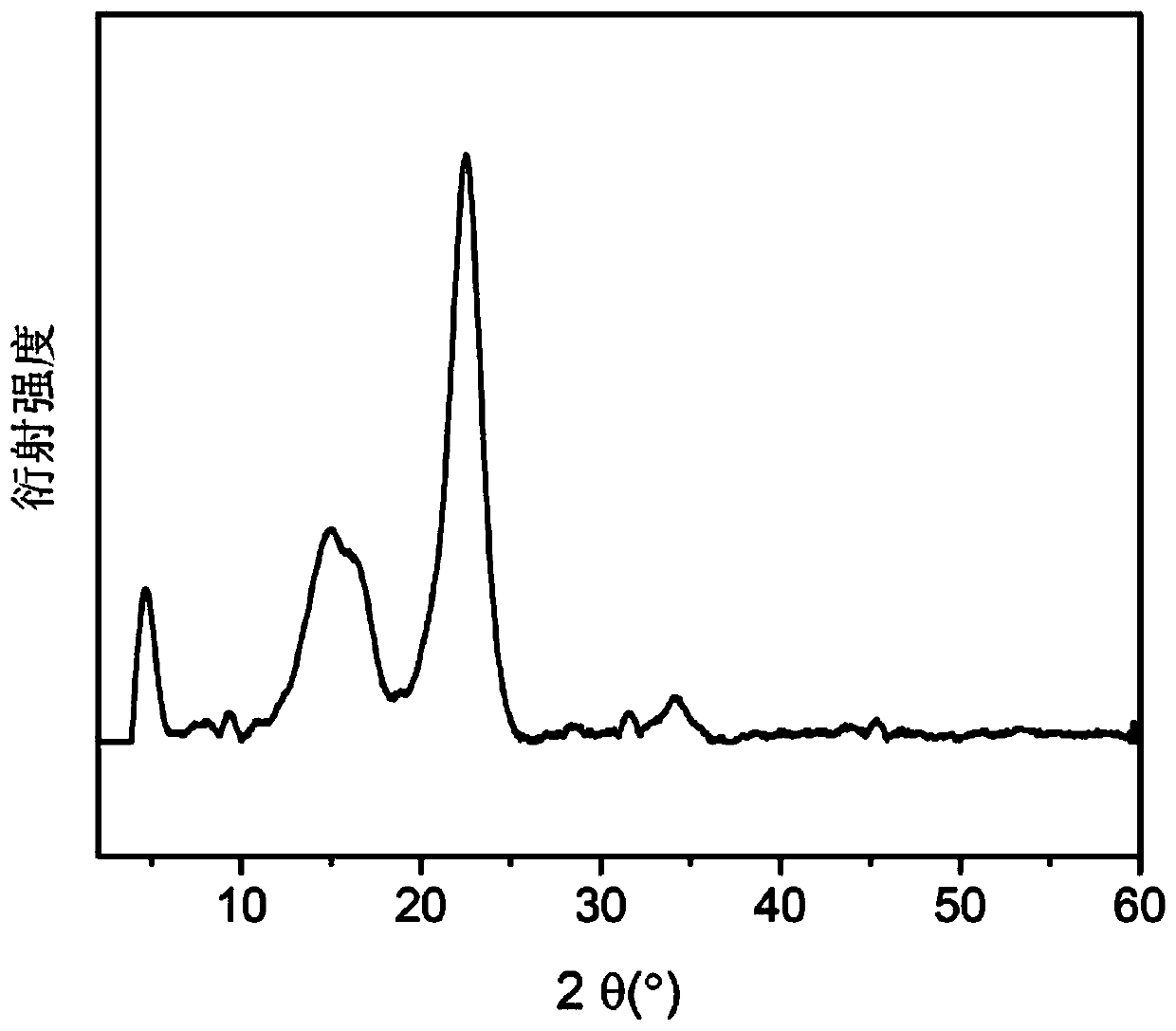

Flexible cuttable nanocellulose/covalent organic framework composite film and preparation method thereof

A covalent organic framework and nanocellulose technology, applied in the field of composite membrane science, can solve the problems of difficult control of film growth direction, low strength of COFs film, uneven film growth, etc., achieve green raw materials, increase universality, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

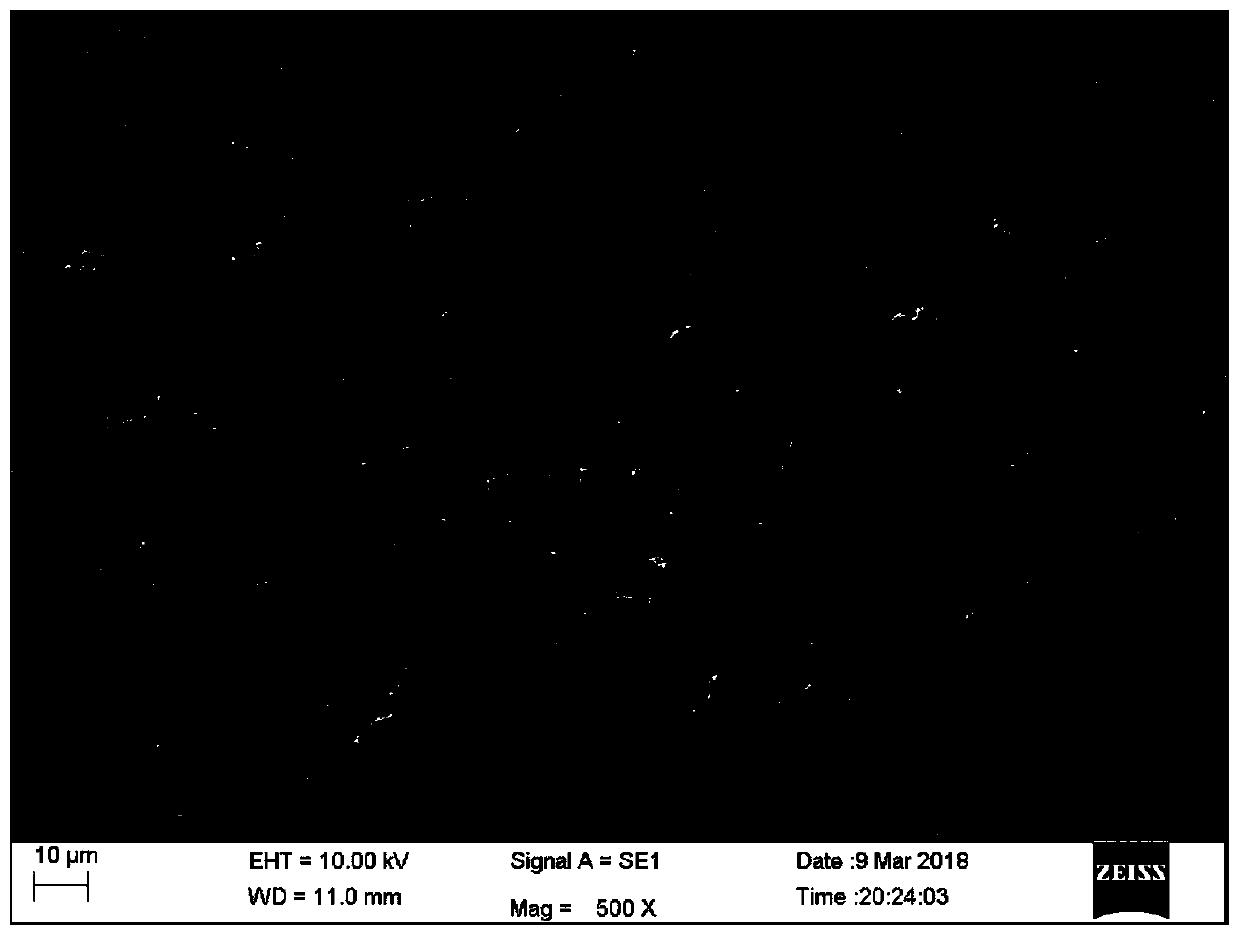

Embodiment 1

[0045] A method for preparing a flexible and tailorable nanocellulose / covalent organic framework composite membrane, comprising the following steps:

[0046] (1) Take 0.015 g of absolute dry NFC (the C6 position is a carboxyl group, and cellulose nanocrystals are used in Example 1) and place it in a conical flask, add 30 mL of deionized water, and dissolve it evenly by ultrasonication at 40 W for 5 minutes , adjust the pH to 3, then add 60 mg of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride, 0.9 g of N-hydroxysuccinimide, stir evenly and then drop by drop Add p-phenylenediamine 75 mg; in N 2 Under the protection of the atmosphere, react at room temperature for 2 h, wash it with deionized water; finally use a sand core suction filter device to perform suction filtration, and after the suction filtration is completed, remove the microporous filter membrane with a pore size of 0.25 μm, and in the micropore The front of the filter membrane continued to be covered wit...

Embodiment 2

[0050] A method for preparing a flexible and tailorable nanocellulose / covalent organic framework composite membrane, comprising the following steps:

[0051] (1) Take 0.08 g of dry NFC (the C6 position is a carboxyl group, and cellulose nanofibers are used in Example 2) and place it in a conical flask, add 30 mL of deionized water, and ultrasonically dissolve it at 40 W for 5 minutes , adjust the pH to 5.5, then add 200 mg of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride, 1.5 g of N-hydroxysuccinimide, stir evenly and then drop by drop Add 16 mg p-phenylenediamine; in N 2 Under the protection of the atmosphere, react at room temperature for 4 hours, and wash it with deionized water; finally, use a sand core suction filter device to perform suction filtration. After the suction filtration is completed, remove the microporous filter membrane with a pore size of 3 μm. The front of the membrane is continuously covered with a layer of microporous filter membrane with ...

Embodiment 3

[0055] A method for preparing a flexible and tailorable nanocellulose / covalent organic framework composite membrane, comprising the following steps:

[0056] (1) Take 0.08 g of absolute dry NFC (the C6 position is a carboxyl group, and bacterial cellulose is used in Example 3) and place it in a conical flask, add 30 mL of deionized water, and dissolve it evenly by ultrasonication at 40 W for 5 minutes. Adjust the pH to 7, then add 200 mg of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride and 1.5 g of N-hydroxysuccinimide, stir evenly with a magnetic force and then add dropwise p-Phenylenediamine 0.4 g; in N 2 Under the protection of the atmosphere, react for 4 hours, wash it with deionized water; finally use a sand core suction filter device to perform suction filtration, and after the suction filtration is completed, remove the microporous filter membrane with a pore size of 1 μm, and put it on the microporous filter membrane. Continue to cover a layer of micropor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com