Porous magnetic chitosan gel microsphere with controllable particle size and preparation method thereof

A technology of chitosan gel and chitosan, which is applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of high preparation costs, extremely high requirements for reaction preparation conditions, and unsuitable acidity Wastewater treatment and other issues, to achieve the effect of simple preparation method and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

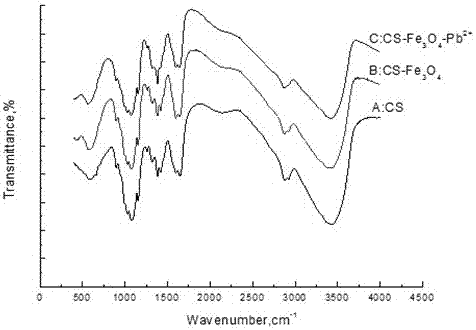

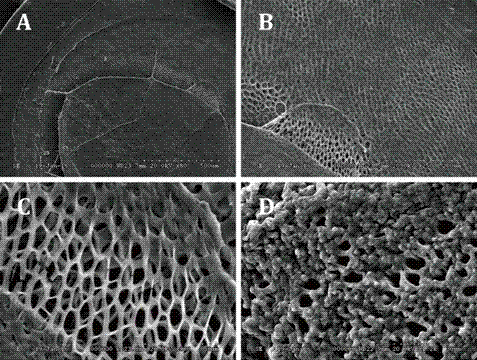

[0045] Example 1: Add 0.4g chitosan to a beaker, add 10~20ml of 2% acetic acid solution, dissolve and stir with a magnetic stirrer for 30min (3000r / min), and prepare Fe 2+ (0.5~1M), Fe 3+ (1~2M) mixed solution (molar ratio is 0.1~2.0), add chitosan solution and continue to stir for 30min (3000r / min), the solution changes from bright yellow to dark red. Prepare an alkaline soaking solution with deionized water, weigh a certain mass of sodium hydroxide and sodium citrate, so that the concentrations in the dissolved solution are 1-5M and 0.01-1M respectively. Use a peristaltic pump to drop the chitosan solution dropwise into the above-mentioned alkaline soaking solution. After soaking for 24 hours, apply a magnetic field to separate the magnetic chitosan gel microspheres, and rinse them with deionized water until they are neutral. The magnetic chitosan gel microspheres were soaked in deionized water and stored for later use. The functional groups and internal structure of the a...

example 2

[0046] Example 2: Take 1mmol / L of Pb 2+ Solution 3ml, add 0.15g magnetic chitosan gel microspheres as an adsorbent, after adsorption for 12h, measure the residual concentration of lead in the solution by flame atomic absorption spectrometry, and calculate its removal rate according to formula ①. SEM was used to compare the adsorbent before and after adsorption (see attached Figure 4 C, attached Figure 4 D).

[0047] Formula ①: removal rate = (C o -C e )*V / C o *100%

[0048] where C o is the initial concentration, C e is the adsorption equilibrium concentration, and V is the volume of the lead solution.

[0049] Calculated, the adsorbent for 1mmol / L of Pb 2+ The removal rate of the solution is over 90%.

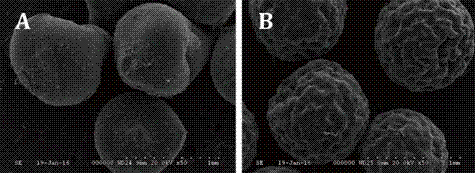

[0050] attached figure 1 Each figure in the figure is an optical photograph reflecting the different properties of porous magnetic chitosan gel microspheres, with figure 1 In figure A, the gel microspheres are scattered at the bottom of the beaker without the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com