Cobalt-nickel-double-metal-hydroxide-nanosheet/carbon-nitride-coated nitrogen-doped hollow graphene sphere composite material and preparation method thereof and application

A graphene ball and hydroxide technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of easy deformation or collapse of the structure, unsafe hidden dangers, etc., and achieve the effects of not easy to deform or collapse, high stability, and good flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

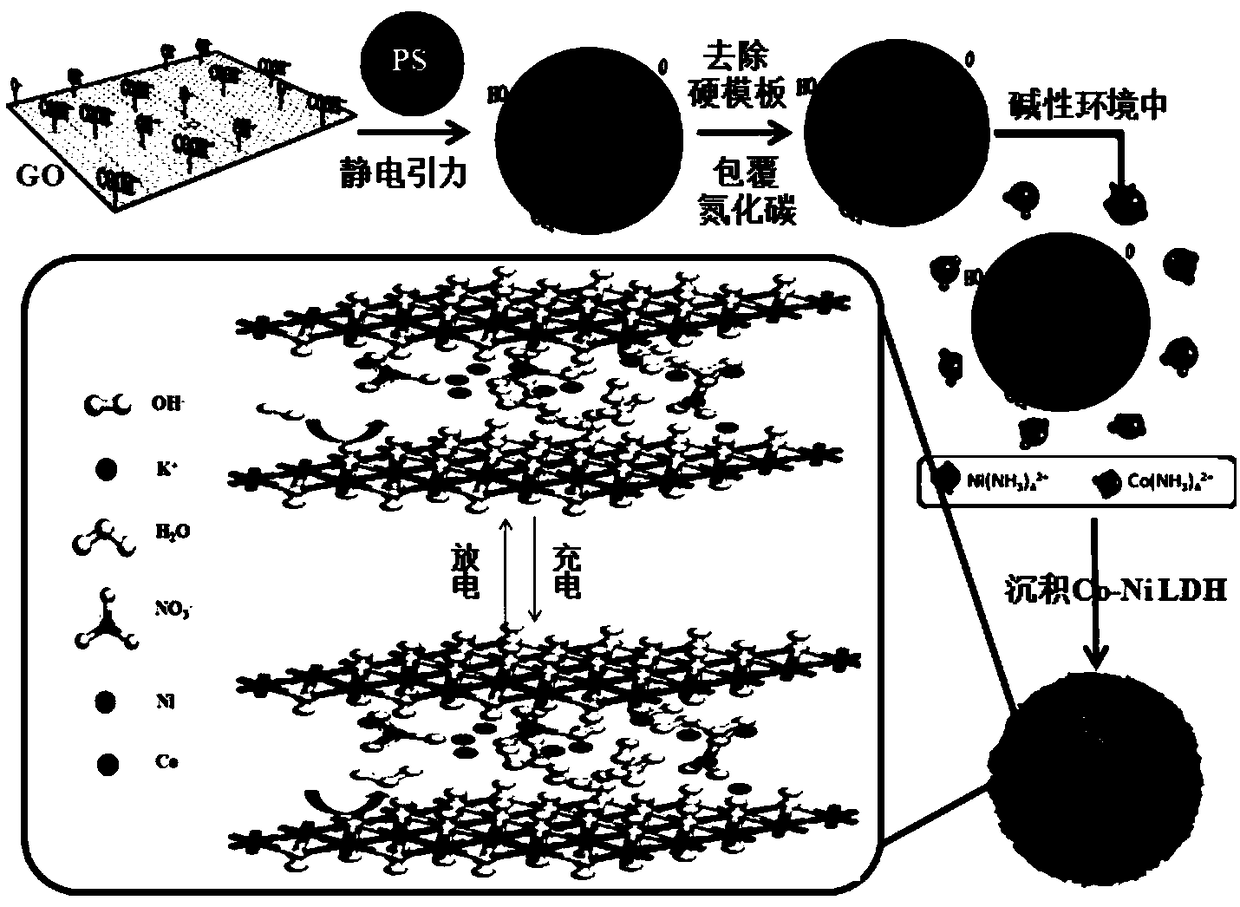

[0034] Example 1: Synthesis of cobalt-nickel double metal hydroxide nanosheets / carbon nitride-coated nitrogen-doped hollow graphene ball composite material (Co 1 Ni 1 LDH / CN x @NGHSs). The preparation process is like figure 1 As shown, including the following steps:

[0035] 1. Positively charged polystyrene beads made from styrene and polyvinylpyrrolidone;

[0036] 2. Polyaniline coated graphene spheres are prepared from polystyrene beads, graphene oxide, transition metal salts of iron and cobalt, melamine and aniline;

[0037] 3. Nitrogen-doped hollow graphene balls coated with carbon nitride are prepared from polyaniline coated graphene balls and melamine;

[0038] 4. Nitrogen-doped hollow graphene spheres coated with cobalt, nickel transition metal salts, urea and carbon nitride to prepare cobalt-nickel bimetal hydroxide nanosheets / nitrogen-doped hollow graphene spheres coated with carbon nitride Composite materials.

[0039] The specific preparation process is as follows:

[0040]...

Embodiment 2

[0052] The method is the same as in Example 1, except that: 2mL 2M Ni(NO 3 ) 2 And 0mL 2MCo(NO 3 ) 2 . Its Ni(OH) 2 / CN x @NGHSs specific surface area is 299m 2 / g such as Figure 5 As shown, the specific capacity at 1A / g current density is 1247F / g as Figure 4 Shown in curve 1.

Embodiment 3

[0054] The method is the same as in Example 1, except that: 1.34mL 2M Ni(NO 3 ) 2 And 0.67mL2M Co(NO 3 ) 2 . Co 1 Ni 2 LDH / CN x @NGHSs specific surface area is 281m 2 / g such as Figure 5 As shown, the specific capacity at 1A / g current density is 1631F / g as Figure 4 Curve 2 is shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com