Plant cellulose nanofiber antibacterial moisturizing mask and preparation method thereof

A technology of plant cellulose and nanofibrils, which is applied in the fields of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc. It can solve the problems of mask air permeability differences, user allergies, etc., achieve high nutrient solution absorption, and improve porosity Structure, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

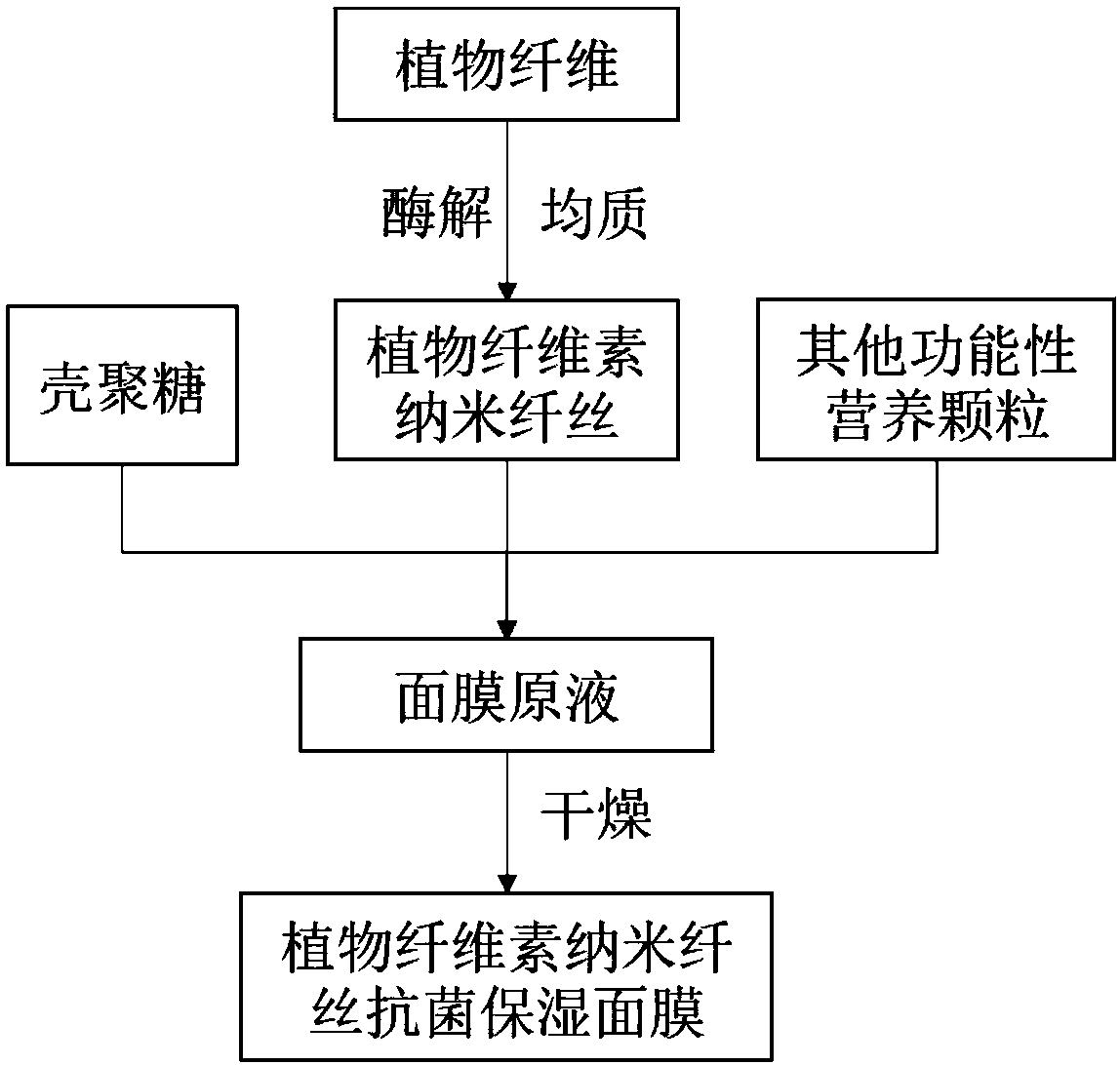

Image

Examples

Embodiment 1

[0045] A plant cellulose nanofibril antibacterial moisturizing mask, its preparation method is as follows:

[0046] (a) 10g of plant fiber (softwood pulp fiber) was enzymolyzed by 50IU of endocellulase at 50°C for 1h, then left in a water bath at 80°C for 10min to inactivate the enzyme, and then circulated under a pressure of 10000psi quality treatment 5 times to prepare plant cellulose nanofibrils with a high aspect ratio; the diameter of the plant cellulose nanofibrils is 1-50 nm, the length is greater than 1 μm, and the aspect ratio is greater than 200;

[0047] (b) Stir the plant cellulose nanofibrils and functional component particle components according to the mass ratio at a temperature of 20°C and a speed of 500r / min for 60min for blending, and then stir for 10min at a temperature of 40°C and a speed of 10000r / min for emulsification , to obtain a uniform and stable white emulsion as a mask stock solution. Plant cellulose nanofibrils and functional component particles ...

Embodiment 2

[0052] A plant cellulose nanofibril antibacterial moisturizing mask, its preparation method is as follows:

[0053] (a) 10g of plant fiber (poplar pulp fiber) was enzymolyzed by 1IU of endocellulase at 50°C for 5h, then left in a water bath at 80°C for 10min to inactivate the enzyme, and then circulated under a pressure of 30000psi quality treatment 20 times to prepare plant cellulose nanofibrils with a high aspect ratio; the diameter of the plant cellulose nanofibrils is 1-50 nm, the length is greater than 1 μm, and the aspect ratio is greater than 200;

[0054] (b) The plant cellulose nanofibrils and the functional component particle components are mixed according to the mass ratio at a temperature of 80°C and a rotation speed of 1000r / min for 30min for blending, and then stirred at a temperature of 60°C and a rotation speed of 15000r / min for 5min for emulsification , to obtain a uniform and stable white emulsion as a mask stock solution. Plant cellulose nanofibrils and fun...

Embodiment 3

[0059] A plant cellulose nanofibril antibacterial moisturizing mask, its preparation method is as follows:

[0060] (a) 10g of plant fiber (eucalyptus pulp fiber) was enzymolyzed by 100IU of endocellulase at 30°C for 10h, then left in a water bath at 80°C for 10min to inactivate the enzyme, and then circulated under a pressure of 30000psi Quality treatment once to prepare plant cellulose nanofibrils with a high aspect ratio; the diameter of the plant cellulose nanofibrils is 1-50 nm, the length is greater than 1 μm, and the aspect ratio is greater than 200;

[0061] (b) Stir the plant cellulose nanofibrils and functional component particle components according to the mass ratio at a temperature of 50°C and a speed of 800r / min for 30min for blending, and then stir for 10min at a temperature of 50°C and a speed of 10000r / min for emulsification , to obtain a uniform and stable white emulsion as a mask stock solution. Plant cellulose nanofibrils and functional component particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com