Fermented grain treatment method of multi-grain aged white spirit flavor type white spirit

A processing method, the technology of Laobaigan, is applied in the preparation of alcoholic beverages, etc., to achieve the effects of simple process operation, improved product quality, and increased water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

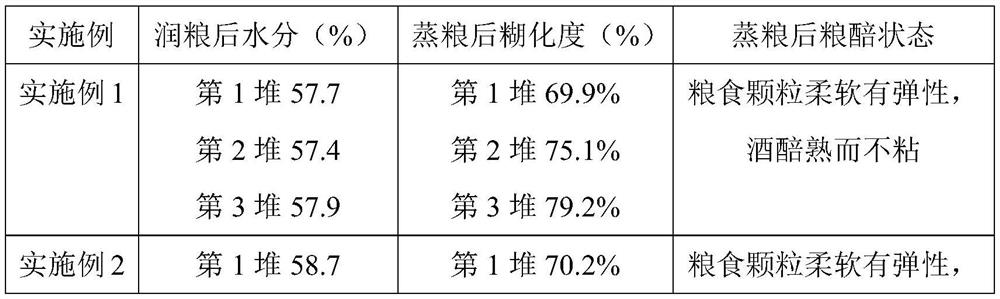

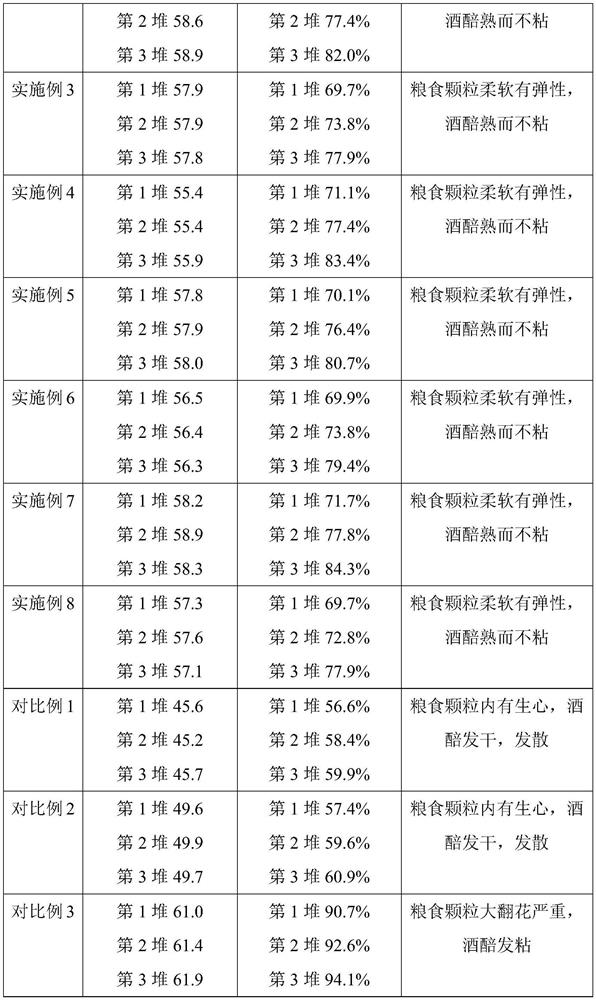

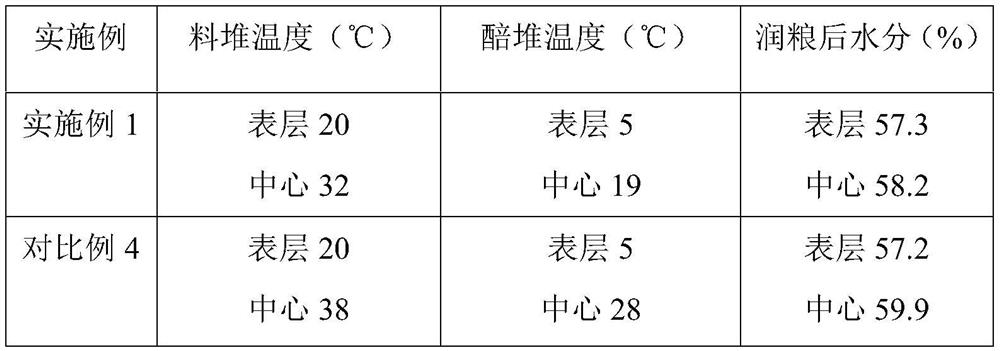

Embodiment 1

[0035] An operation method of grain fermented grains for brewing multi-grain Laobaigan-flavor liquor, comprising the following steps:

[0036] (1) 40 parts of glutinous sorghum, 8 parts of rice, 15 parts of glutinous rice, 7 parts of corn, 30 parts of japonica sorghum, and a total feeding amount of 900 kg are mixed evenly, and it is required to stir at least 2 times;

[0037] (2) Use 40°C water to moisten the above-mentioned grains evenly, add water for moistening grains to the grains several times, and stir quickly while adding water to prevent the loss of moistening grain water if it is not absorbed in time; the amount of moistening grain water is 1 / 2 of the grain weight 50%;

[0038] (3) divide the grain moistened in the step (2) into three piles, wherein the first pile is 30%, the second pile is 33%, the third pile is 37%. The lower side is 150cm long, the upper bottom is flat, each side line is straight, each side is smoothed, piled up for 20 minutes, then mixed with win...

Embodiment 2

[0045] The difference between Example 2 and Example 1 is that the water temperature for moistening grain is 45°C, the amount of water for moistening grain is 55% of the grain weight, and the grain is divided into three piles, wherein the first pile is 31%, the second pile is 34%, and the third pile is 35%. , the height of the pile is 75cm, the length of the upper side is 80cm, the length of the lower side is 150cm, and the stacking time is 25min. After moistening the grain, mix it with wine grains 3.6 times the raw material and rice husk with 18% of the raw material. The first stacking time of the mixed grain grains is 15 minutes, the second stacking time is 75 minutes, the third stacking time is 135 minutes, and the square pile height is 105 cm. The length of the upper side is 80cm, and the length of the lower side is 150cm. When layering into the tank, the bottom layer: the middle layer: the upper layer = 31:34:35, and the implementation season is summer. All the other are i...

Embodiment 3

[0047] The difference between embodiment 3 and embodiment 1 is that the water temperature for moistening grain is 50°C, the amount of water for moistening grain is 60% of the grain weight, and the grain is divided into three piles, wherein the first pile is 32%, the second pile is 34%, and the third pile is 34%. , The height of the pile is 80cm, the length of the upper side is 85cm, the length of the lower side is 150cm, and the stacking time is 20min. After moistening the grain, mix it with wine grains 3.7 times the raw material and rice husk with 17% of the raw material. The first stacking time of the mixed grain grains is 20 minutes, the second stacking time is 80 minutes, the third stacking time is 140 minutes, and the square pile height is 110 cm. The length of the upper side is 85cm, and the length of the lower side is 150cm. When layering into the tank, the bottom layer: the middle layer: the upper layer = 32:34:34, and the implementation season is autumn. All the other a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com