Method for adding carbon substance in the preparation of electric contact material

A technology of electrical contact materials and carbon, which is applied in the field of adding carbon materials in the preparation of electrical contact materials, can solve the problems of prolonging ball milling time, affecting material performance, pollution, etc., to avoid uneven particle agglomeration and improve comprehensive performance , The effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

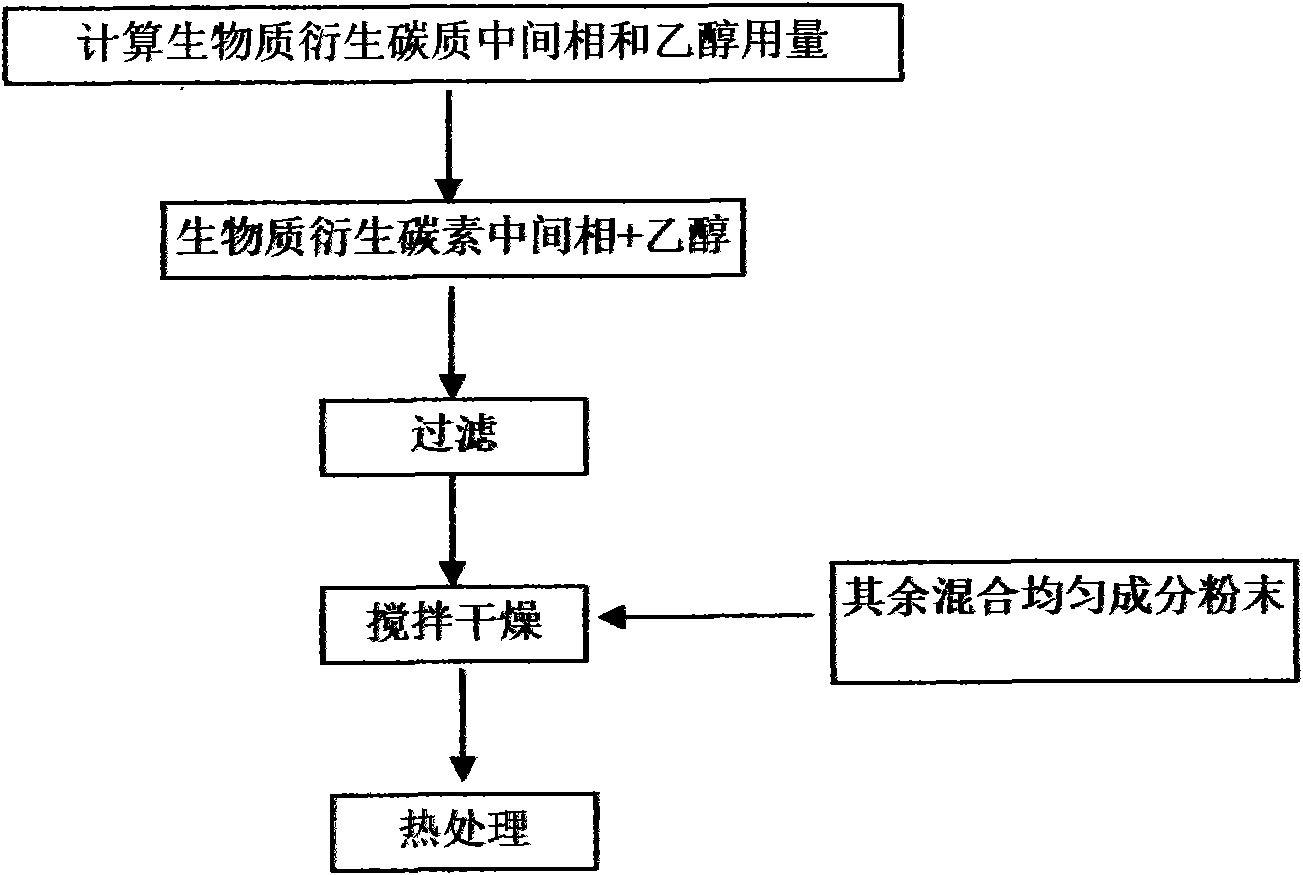

Method used

Image

Examples

Embodiment 1

[0025] Take 100g of silver tungsten carbide graphite (Ag: 84wt%, graphite: 2.5wt%, WC: 13.5wt%) electrical contact material as an example.

[0026] The first step is to calculate the amount of biomass-derived carbonaceous mesophase and ethanol required. According to the ratio of 40:1, the biomass-derived carbonaceous mesophase needs 100g×2.5%×40=100g, and the biomass-derived carbonaceous mesophase and The ratio of ethanol is 1:20: that is, 100g×20=2000g ethanol.

[0027] In the second step, the above-mentioned biomass-derived carbonaceous mesophase was dissolved in ethanol, stirred and dissolved for 15 minutes, and then the dissolved product and impurities were filtered to obtain solution A. The mesh number of the filter cloth is 100 mesh.

[0028] In the third step, the remaining 84g of Ag powder and 13.5g of WC powder were uniformly mixed to obtain mixed powder B. Add powder B into solution A and stir while heating until the ethanol evaporates completely and the temperatur...

Embodiment 2

[0031] Take 100g of silver graphite (Ag-96wt%, graphite-4wt%) electrical contact material as an example.

[0032] The first step is to calculate the amount of biomass-derived carbonaceous mesophase and ethanol required. According to the ratio of 40:1, the biomass-derived carbonaceous mesophase needs 100g×4%×40=160g, and the biomass-derived carbonaceous mesophase and ethanol Take the ratio of 1:10: 160g×10=1600g.

[0033] In the second step, the above-mentioned biomass-derived carbonaceous mesophase was dissolved in ethanol, stirred and dissolved for 60 minutes, and then the dissolved product and impurities were filtered to obtain solution A. The mesh number of the filter cloth is 200 mesh.

[0034] In the third step, add the remaining 96g of Ag powder (since the remaining component is a single component, that is, no mixing is required) into the solution A and stir, while heating until the ethanol is completely volatilized, and the temperature is 100°C.

[0035] In the fourth...

Embodiment 3

[0037] Take 100g copper tungsten carbide graphite (Cu-84wt%, graphite-2.5wt%, WC-13.5wt%) electrical contact material as an example.

[0038] The first step is to calculate the amount of biomass-derived carbonaceous mesophase and ethanol required. According to the ratio of 40:1, the biomass-derived carbonaceous mesophase needs 100g×2.5%×40=100g, and the biomass-derived carbonaceous mesophase and The ratio of ethanol is 1:5: that is, 100g×5=500g ethanol.

[0039] In the second step, the above-mentioned biomass-derived carbonaceous mesophase was dissolved in ethanol, stirred and dissolved for 30 minutes, and then the dissolved product and impurities were filtered to obtain solution A. The mesh number of the filter cloth is 300 mesh.

[0040] In the third step, the remaining Cu powder 84g and WC powder 13.5g were uniformly mixed to obtain mixed powder B. Add the powder B into the solution A and stir, while heating until the ethanol volatilizes completely, and the heating temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com