Breast pad with better water absorption performance

A technology for water absorption and breast pads, which is applied in breast bandages, abdominal bandages, etc., can solve the problems of small room for expansion, the absorption layer cannot fully absorb water, and cannot reach a saturated state, and achieves the effect of increasing water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

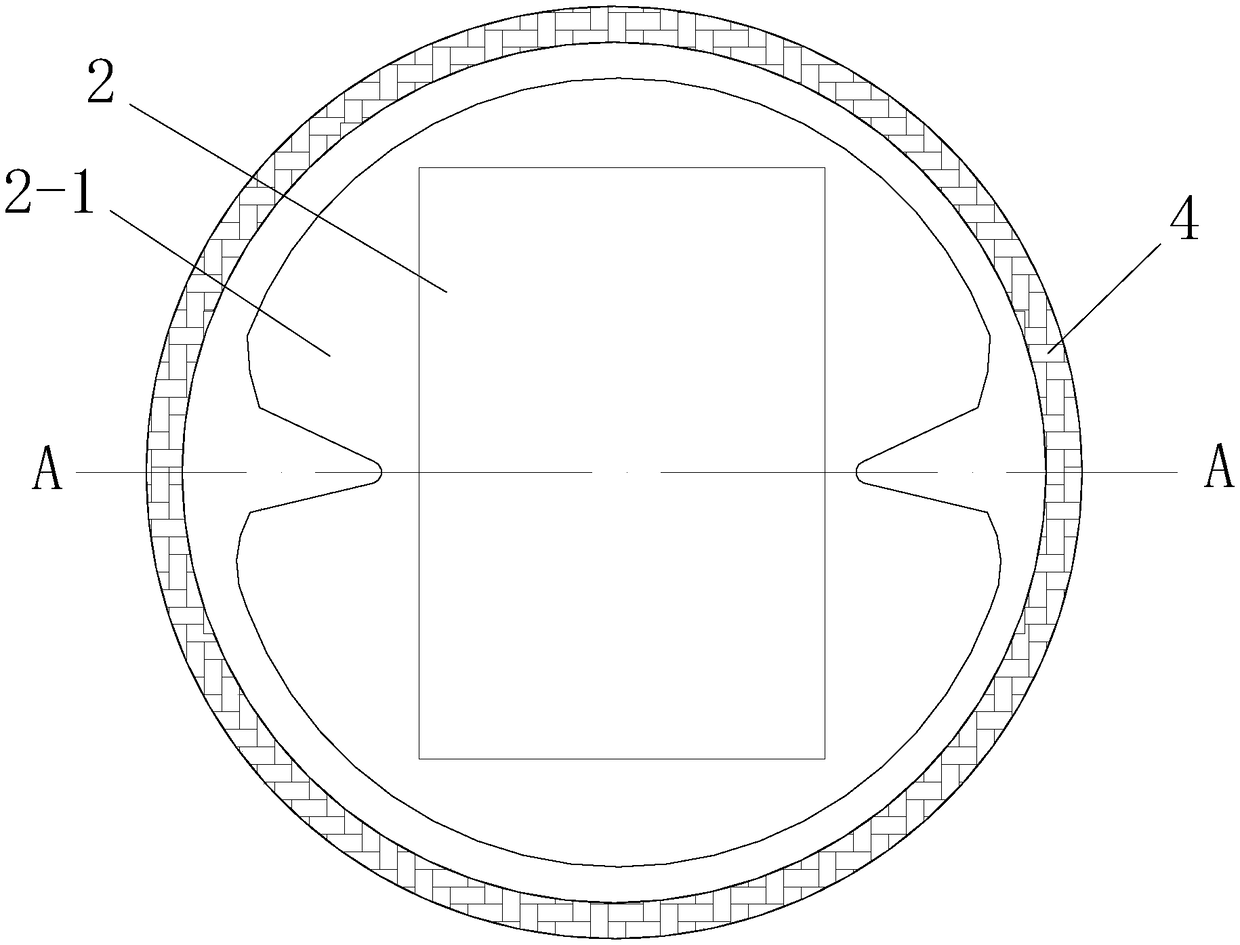

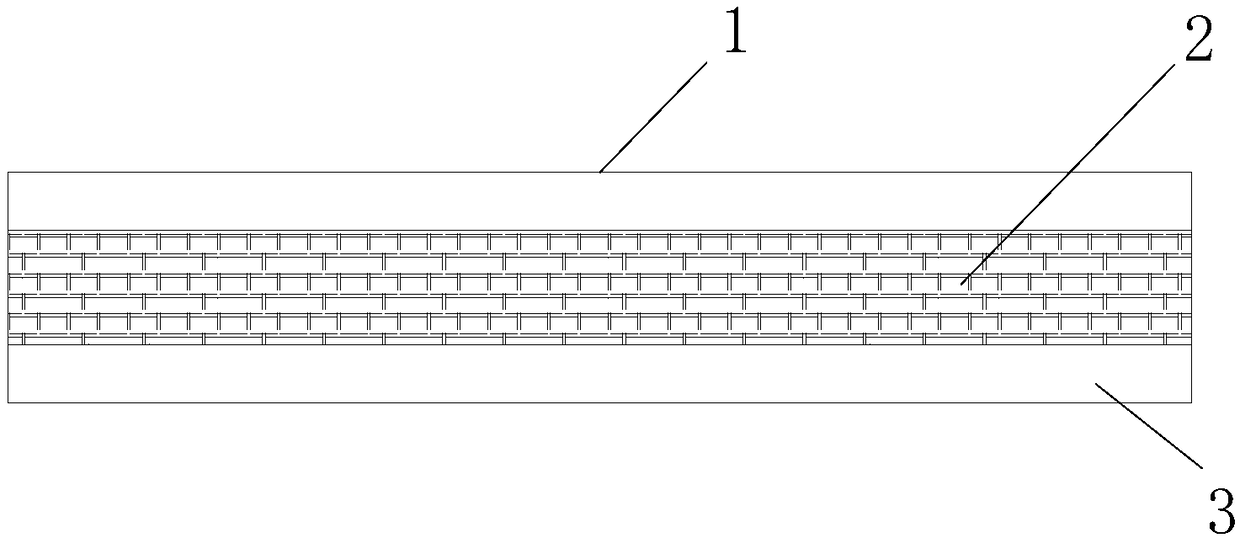

[0024] Such as Figure 1-2 As shown, the breast pad with better water absorption performance in this embodiment comprises a hydrophilic layer 1, an absorbent layer 2 and a waterproof layer 3 which are sequentially stacked. The hydrophilic layer 1 and the waterproof layer 3 are symmetrical up and down, and the surrounding edges are heated by heat The pressure rollers are fused or ultrasonically welded to form a welded ring 4; the absorbing layer 2 is bonded between the hydrophilic layer 1 and the waterproof layer 3; the area occupied by the absorbing layer 2 in the welded ring 4 is 85%, or 82%, or 80%, or 77% of the area of the inner ring of the fusion ring 4.

[0025] The absorption layer 2 is located in the center of the fusion ring 4, and the absorption layer 2 is rectangular, oval or circular; the upper and lower sides of the absorption layer 2 are bonded with butterfly-shaped dust-free paper, and / or Toilet paper, and / or fluff pulp layer 2-1, to guide the water on the ou...

Embodiment 2

[0033] On the basis of Embodiment 1, the breast pad in this embodiment has the following modifications:

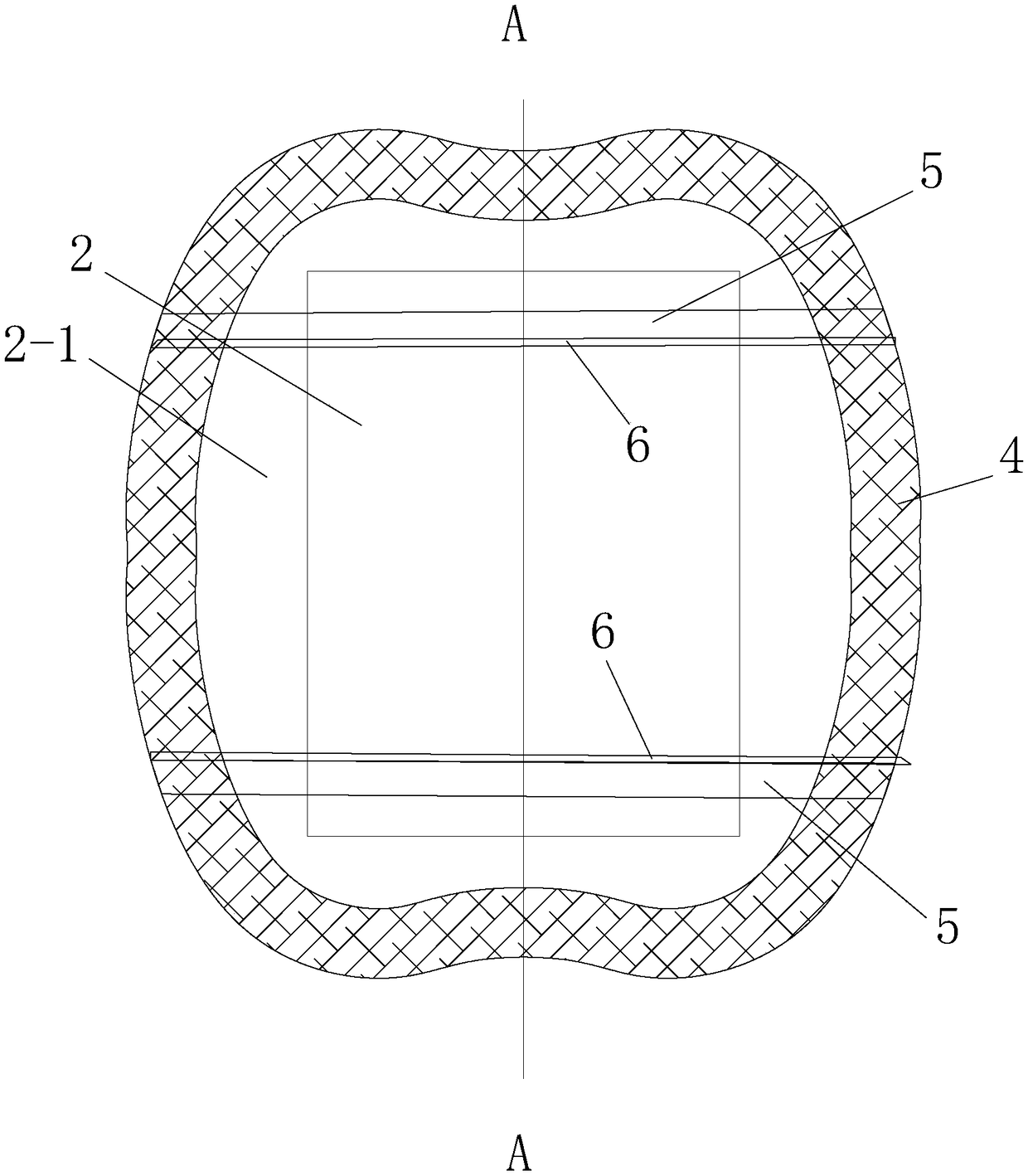

[0034] Such as image 3 The end of the hydrophilic layer 1 adjacent to the absorbent layer 2 is respectively provided with a water-retaining strip 5 perpendicular to the folded center line A-A, and the water-retaining strip 5 is folded and formed by the material of the absorbent layer 2. The two ends of the water bar 5 are welded or ultrasonically welded on the welding ring 4 by hot pressing rollers; when a pair of water retaining bars are used, they are arranged in parallel up and down to avoid overflow of milk.

[0035] The outer edge of the water-retaining strip 5 is pierced with elastic or elastic fiber 6 in a shrinking state, so that the product shrinks into an arc that fits the breast of a human body.

[0036] The elastic or elastic fiber 6 is bonded in the water retaining strip 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com