Nano composite anti-aging anti-cancer multifunctional worsted fabric

A technology of nano-composite materials and worsted fabrics, applied in the field of textiles-worsted fabrics, can solve the problems of no nano-textile materials-worsted fabrics, etc., to enhance human immunity, good elasticity and water repellency, and improve human body functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

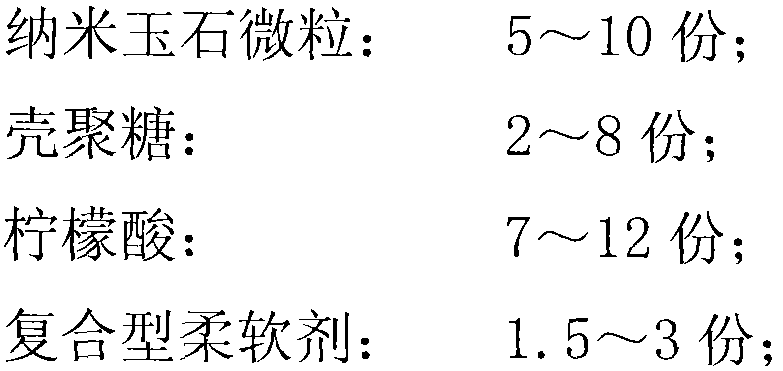

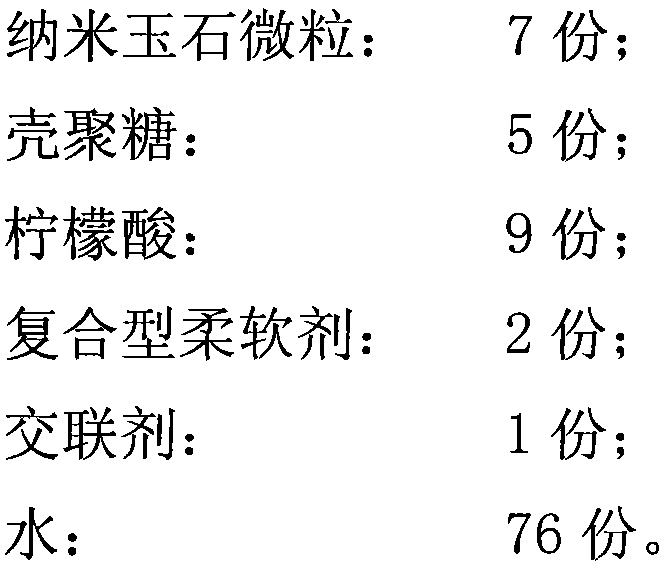

Method used

Image

Examples

preparation example Construction

[0032] The preparation methods of nano jade particles include:

[0033] (1) Vacuum condensation method: Use vacuum evaporation, heating, high-frequency induction and other methods to vaporize raw materials or form plasma, and then quench. It is characterized by high purity, good crystal structure, and controllable particle size, but high technical equipment requirements.

[0034] (2) Physical crushing method: Nano particles are obtained by mechanical crushing, electric spark explosion and other methods. It is characterized by simple operation and low cost, but the product purity is low and the particle distribution is uneven.

[0035] (3) Mechanical ball milling method: the ball milling method is used to obtain pure element nanoparticles, alloy nanoparticles or composite nanoparticles by controlling appropriate conditions. It is characterized by simple operation and low cost, but the product purity is low and the particle distribution is uneven.

example 1

[0037] [Process example 1] Plant fiber cotton worsted fabric; 9 parts of nano jade particles, 6 parts of chitosan, 12 parts of citric acid, 3 parts of composite softener, 1.5 parts of cross-linking agent, 78 parts of water; process flow: plant Fiber-cotton worsted fabric→two dip and two rolling (nano composite material, 30~70 degrees Celsius, scoring rate 60%~200%)→drying (85~95 degrees Celsius)→baking (90~120 degrees Celsius)→inspection→packaging →Product. The padding process refers to a process in which nanocomposite materials (including nano jade particles and chitosan) are treated on worsted fabrics with a printing and dyeing equipment cart, and then dried and baked. Generally, the amount of nano jade particles and chitosan treated on the fabric can be controlled by the rollover rate, usually one dip and one roll or two dip and two rolls, or multiple dips and multiple rolls as needed; Control the penetration of nano jade particles and chitosan on worsted fabrics. Drying a...

example 2

[0038] [Process example 2] Plant fiber cotton blended worsted fabric; 8 parts of nano jade particles, 5 parts of chitosan, 10 parts of citric acid, 3 parts of composite softener, 1 part of crosslinking agent, 75 parts of water; process flow: Plant fiber cotton blended worsted fabric → spray (nano composite material, 20-50 degrees Celsius, both front and back sides must be touched, so that the amount of liquid is 50% to 120% of the weight of the fabric) → accumulation (20-40 degrees Celsius) , 0.5 to 3 hours, one time in the middle) → centrifuge dewatering (make the liquid content 60% to 80% of the weight of the plant fiber cotton blended worsted fabric) → drying (hot air 85 to 95 degrees Celsius) → baking (90 ~120 degrees Celsius)→inspection→packaging→product. The spray process refers to the process of imparting nano jade particles and chitosan onto the fabric with the aid of spray equipment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dilution degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com