Polyethyleneimine modified biomass charcoal material and preparation method thereof, and application of polyethyleneimine modified biomass charcoal material to modification of lithium-sulfur battery diaphragm

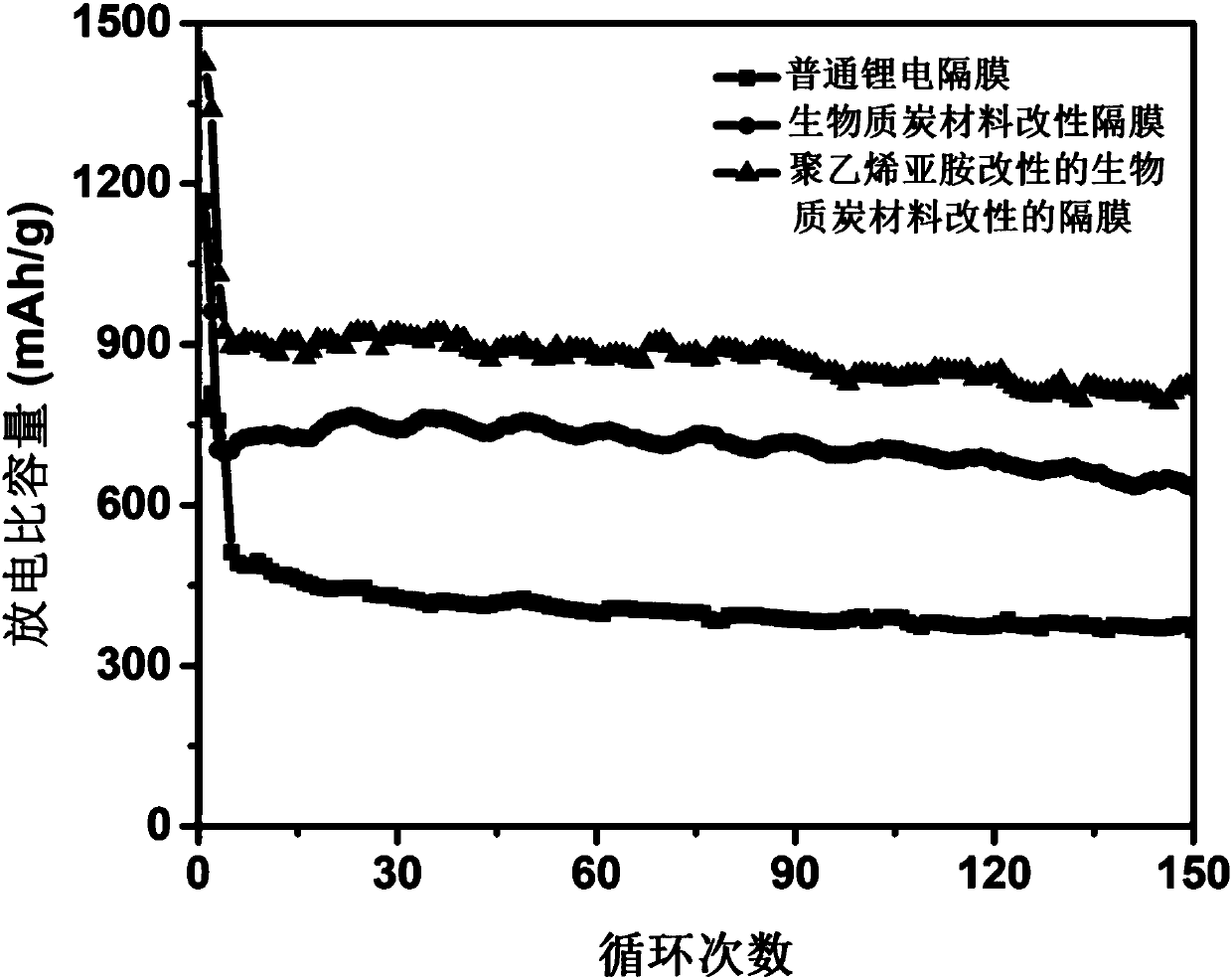

A technology of polyethyleneimine and biochar, which is applied to battery components, chemical instruments and methods, circuits, etc., can solve the problems of complex synthesis methods, high prices, and difficulty in commercial application, and achieve excellent adsorption performance, Effect of improving adsorption performance and increasing cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Add biochar to 3 mol / L KOH solution, stir and react, then separate solid from liquid, wash biochar with deionized water until neutral, and dry to obtain pretreated biochar. Immerse 1 g of the pretreated biochar in a methanol solution of 5wt.% polyethyleneimine, stir well, and separate the solid from the liquid. The obtained reaction product was washed several times with methanol, and dried at 65° C. to obtain a polyethyleneimine-modified biochar material. Mix polyethyleneimine-modified biochar material with conductive carbon black and gelatin solution at a mass ratio of 8:1:1, and obtain a viscous slurry after ball milling, and coat the slurry on the diaphragm , the coating thickness was controlled at 90 μm; the modified separator was dried and sliced for later use.

[0062] The positive electrode sheet, modified separator, lithium sheet, and nickel foam were assembled into a button battery in a glove box, and the cycle performance test was carried out in the LANDdt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com