A fuel cell gas diffusion layer and a preparation method thereof

A gas diffusion layer, fuel cell technology, applied in fuel cells, electrical components, battery electrodes, etc., can solve the problem of no GDL preparation or quality control to provide detailed descriptions, etc., to achieve superior performance and water management capabilities, good pore structure and the effect of hydrophobic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Use commercial graphitized carbon powder, disperse the slurry with the help of a homogenizer, and then use mechanical stirring to add polytetrafluoroethylene (PTFE) solution (60% mass fraction aqueous solution) to the mixture. The total amount of PTFE added is carbon / PTFE The dry weight ratio is 60 / 40. After adding PTFE, add a thickener to adjust the viscosity of the mixture. The final carbon concentration in the slurry is 2.5-4%.

Embodiment 2

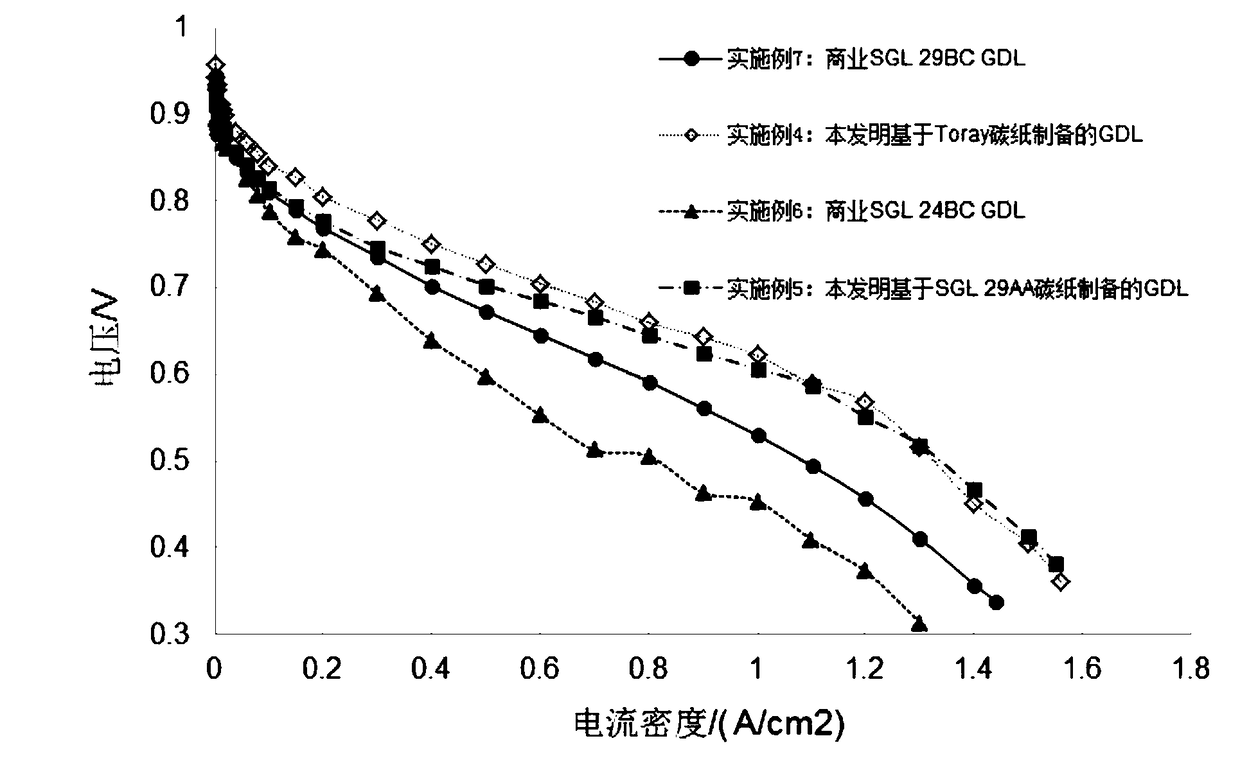

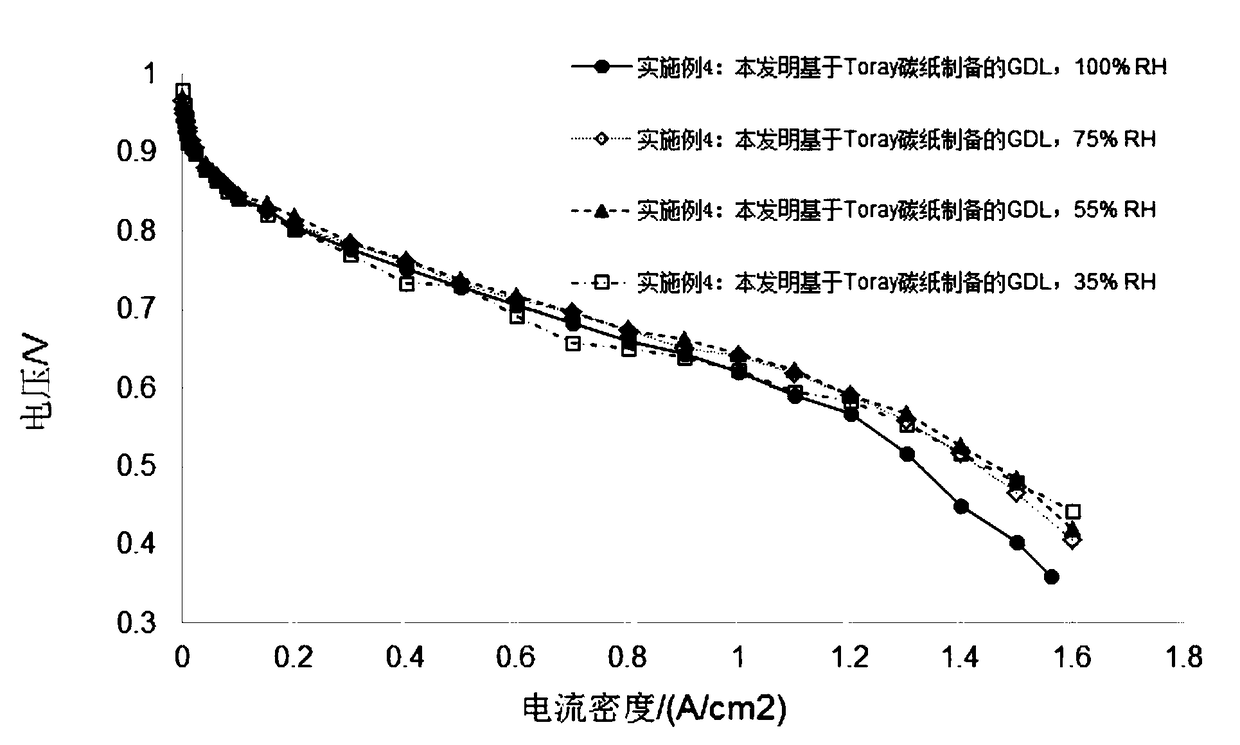

[0047] The slurry prepared in Example 1 was used to prepare a microporous layer on Toray 090 carbon paper (Toray CA Tokyo, Japan, 280um thick), and the sample was heat-treated at >300°C to remove additives and promote PTFE to form carbon and PTFE uniform The mixture was bonded and the resulting microporous layer had a loading of 22.24 grams per square meter.

Embodiment 3

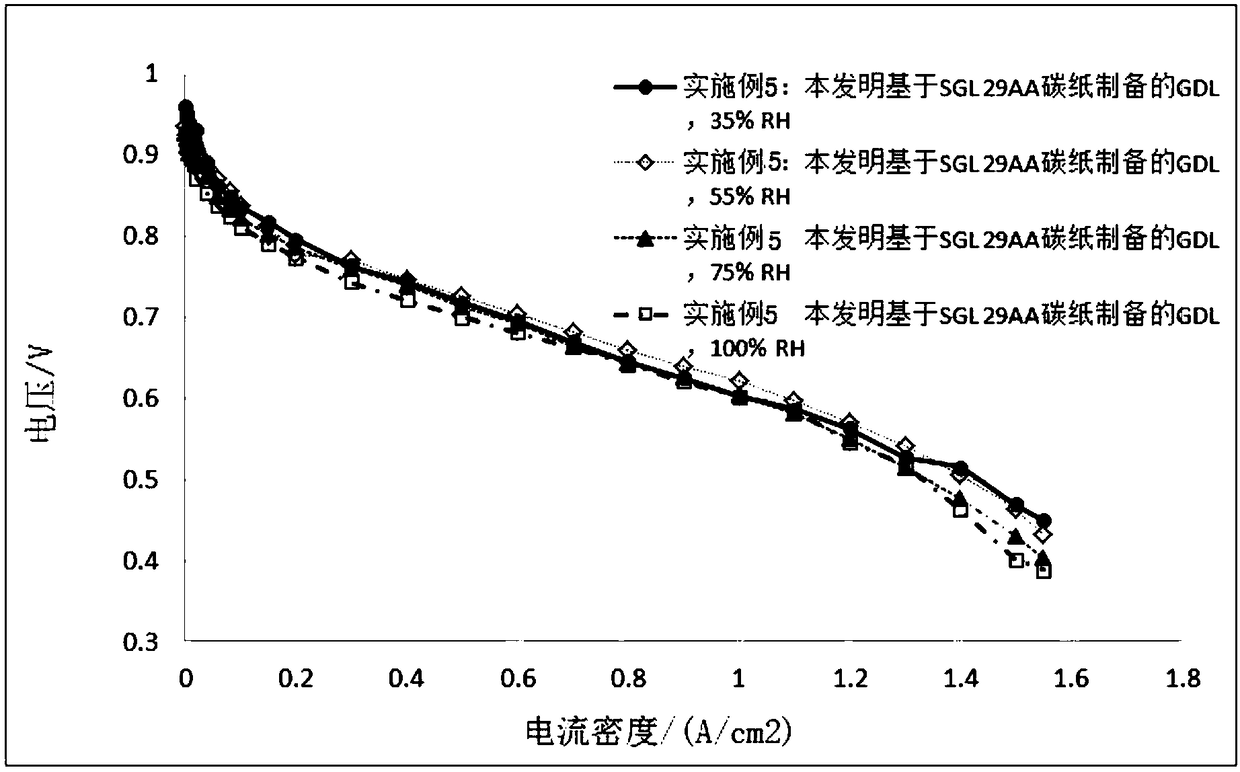

[0049] The slurry prepared in Example 1 was used to prepare a microporous layer on SGL 29AA carbon paper (SGL CARBON GmbH, Meitingen, Germany; 190 um thick) with a loading of 33.11 g / m2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com