Zeolite imidazate framework nanoparticle composite fiber film and preparation method thereof

A technology of zeolite imidazolate and composite fiber membrane, which is applied in the field of composite materials, can solve problems such as poor operability, aggregation of nanocrystalline fillers, uneven dispersion, etc., to solve uniform composite problems, improve gas adsorption capacity, The effect of improving the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

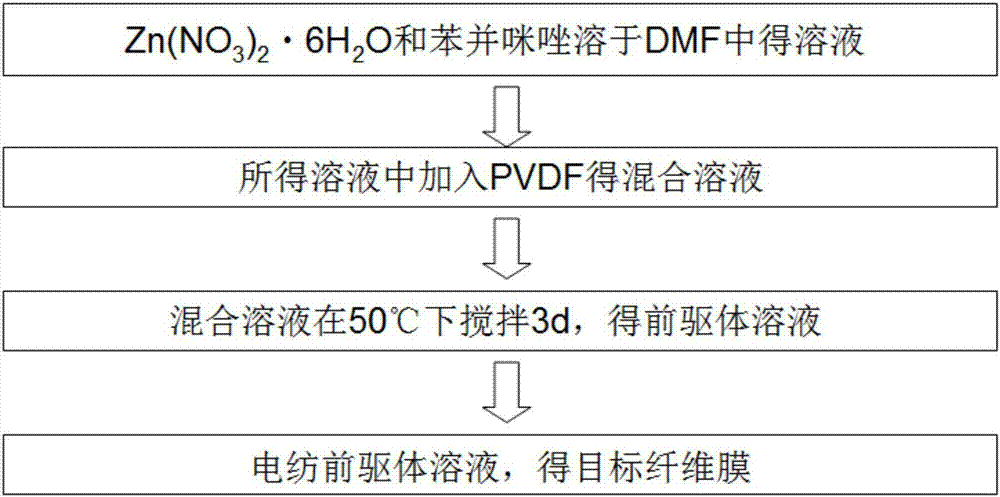

[0031] A preparation method for a zeolite imidazolate framework nanoparticle composite fiber membrane, comprising the following steps:

[0032] (1) Mix Zn(NO 3 ) 2 ·6H 2 O and benzimidazole solution, the Zn(NO 3 ) 2 ·6H 2 The content of O in the solution is 8wt%, and the content of the benzimidazole in the solution is 4wt%;

[0033] (2) Immediately add polyvinylidene fluoride (PVDF, Mw=120kDa) powder to the solution in step (1) to obtain a mixed solution, the content of which is 6wt%;

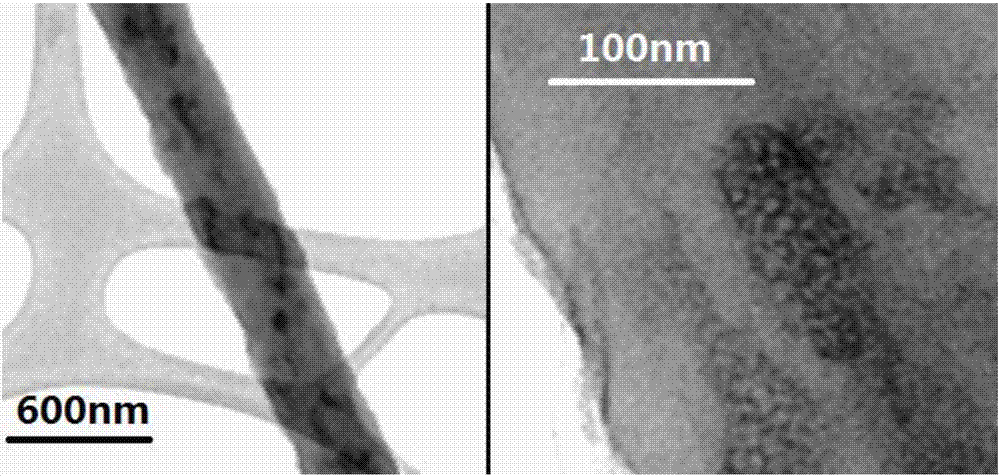

[0034] (3) Stir the mixed solution obtained in step (2) at 50° C. for 3 days to crystallize the zeolite imidazolate framework complex into nanoparticles to obtain a precursor solution;

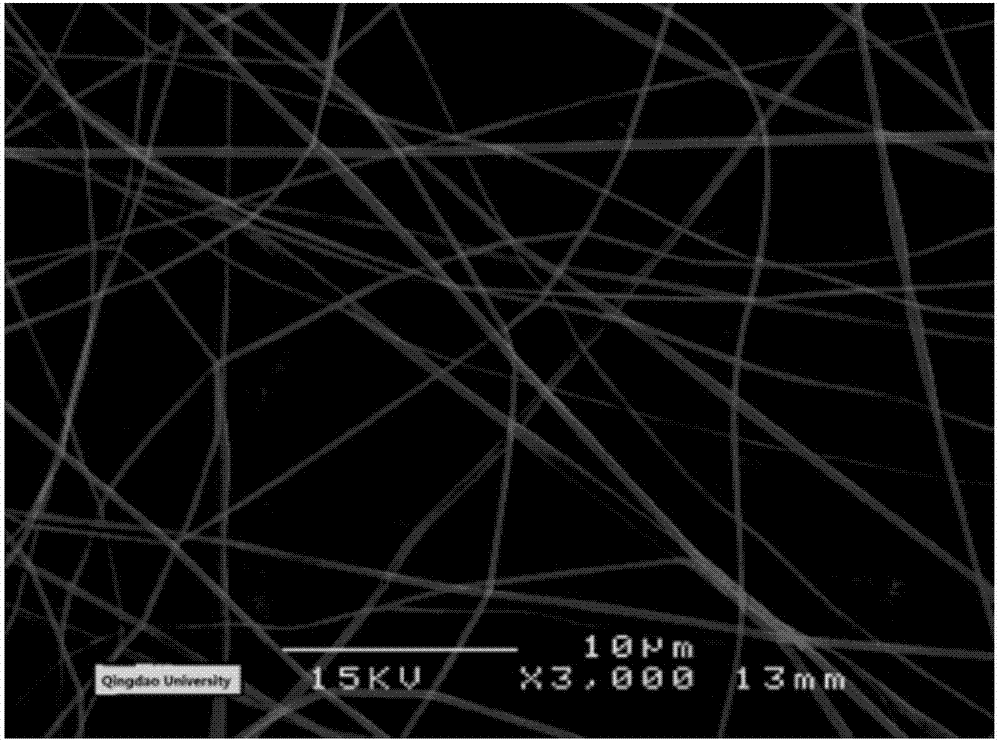

[0035] (4) Add the electrospinning precursor solution obtained in step (3) into the liquid storage mechanism of the electrospinning device, and the electrospinning precursor solution obtains a zeolite imidazolate framework nanoparticle composite fiber membrane, and the electrospinning experimental conditi...

Embodiment 2

[0037] Example 2 Absorption capacity test of carbon dioxide

[0038] Test and compare the carbon dioxide adsorption rate of the composite fiber membrane obtained by PVDF nanofiber membrane and embodiment 1 under different air pressures, wherein, the preparation method of PVDF nanofiber membrane comprises the following steps: (1) polyvinylidene fluoride (PVDF, Mw= 120kDa) powder into DMF, fully stirred at 50°C to obtain a mixed solution, the resulting mixed solution is a precursor solution; (2) Add the precursor solution obtained in step (1) to the liquid storage mechanism of the electrospinning device, and electrospin The PVDF nanofiber membrane was obtained from the precursor solution. The electrospinning experimental conditions were room temperature, humidity 35-40%, the propulsion speed of the propulsion pump of the liquid storage mechanism was 0.25μL / min, the spinning voltage was 8KV, and the spinning distance was 10cm. The inner diameter of the nozzle is 0.84mm.

[0039]...

Embodiment 3

[0044] A preparation method for a zeolite imidazolate framework nanoparticle composite fiber membrane, comprising the following steps:

[0045] (1) Mix Zn(NO 3 ) 2 ·6H 2 O and benzimidazole solution, the Zn(NO 3 ) 2 ·6H 2 The content of O in the solution is 8wt%, and the content of the benzimidazole in the solution is 4wt%;

[0046] (2) immediately add polyacrylonitrile (PAN, Mw=150kDa) powder to the solution of step (1), the content of PAN in the mixed solution is 6wt%;

[0047] (3) Stir the mixed solution obtained in step (2) at 50° C. for 3 days to crystallize the zeolite imidazolate framework complex into nanoparticles to obtain a precursor solution;

[0048] (4) Add the electrospinning precursor solution obtained in step (3) into the liquid storage mechanism of the electrospinning device, and the electrospinning precursor solution obtains a zeolite imidazolate framework nanoparticle composite fiber membrane, and the electrospinning experimental condition is room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com