Electrode material of super-capacitor and preparation method thereof as well as super-capacitor manufactured by electrode material

A technology of supercapacitors and electrode materials, applied in capacitors, electrolytic capacitors, solid electrolytic capacitors, etc., can solve the problems of large device volume and high device packaging requirements, and achieve the effect of simple preparation process, low cost and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

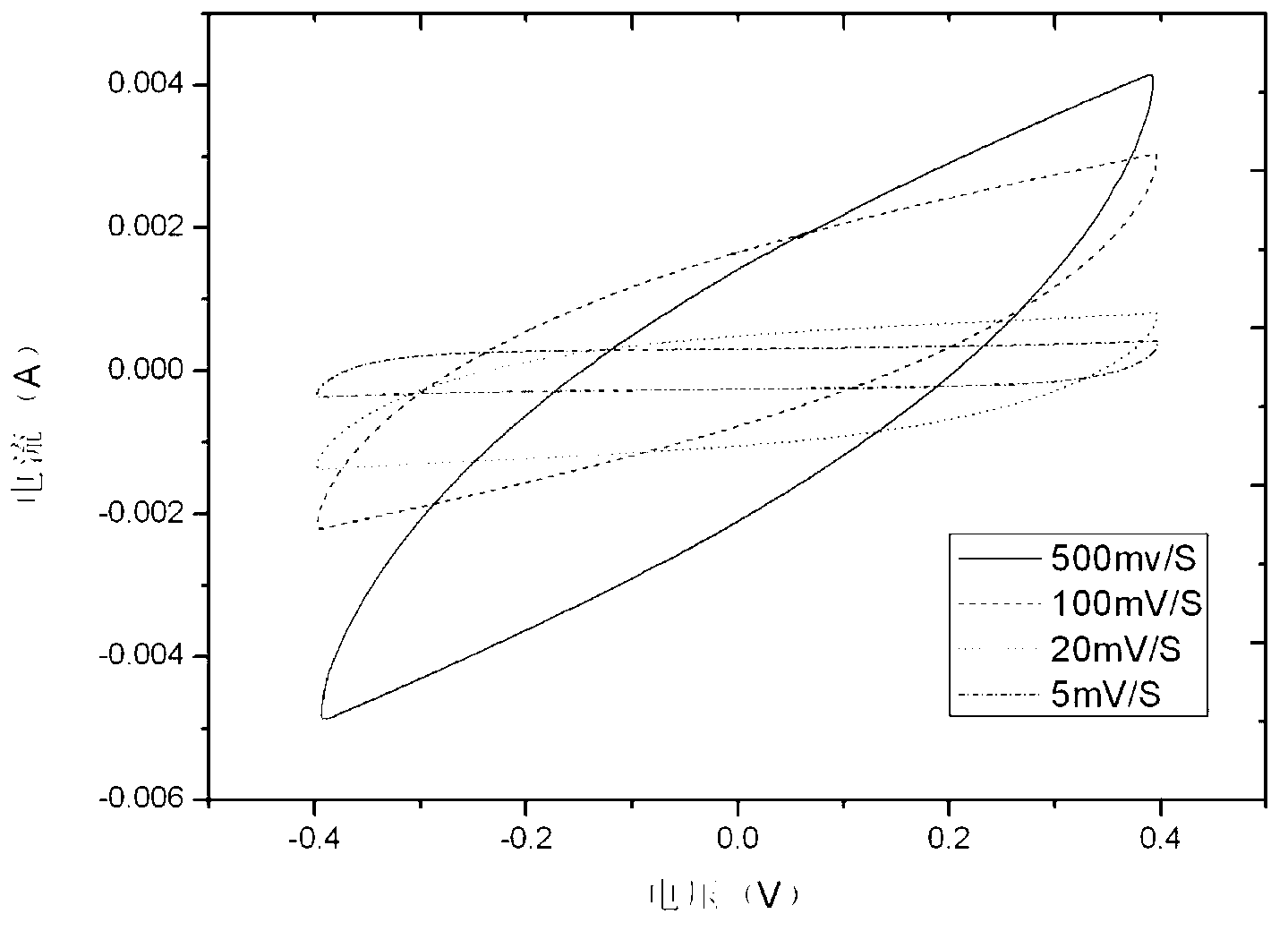

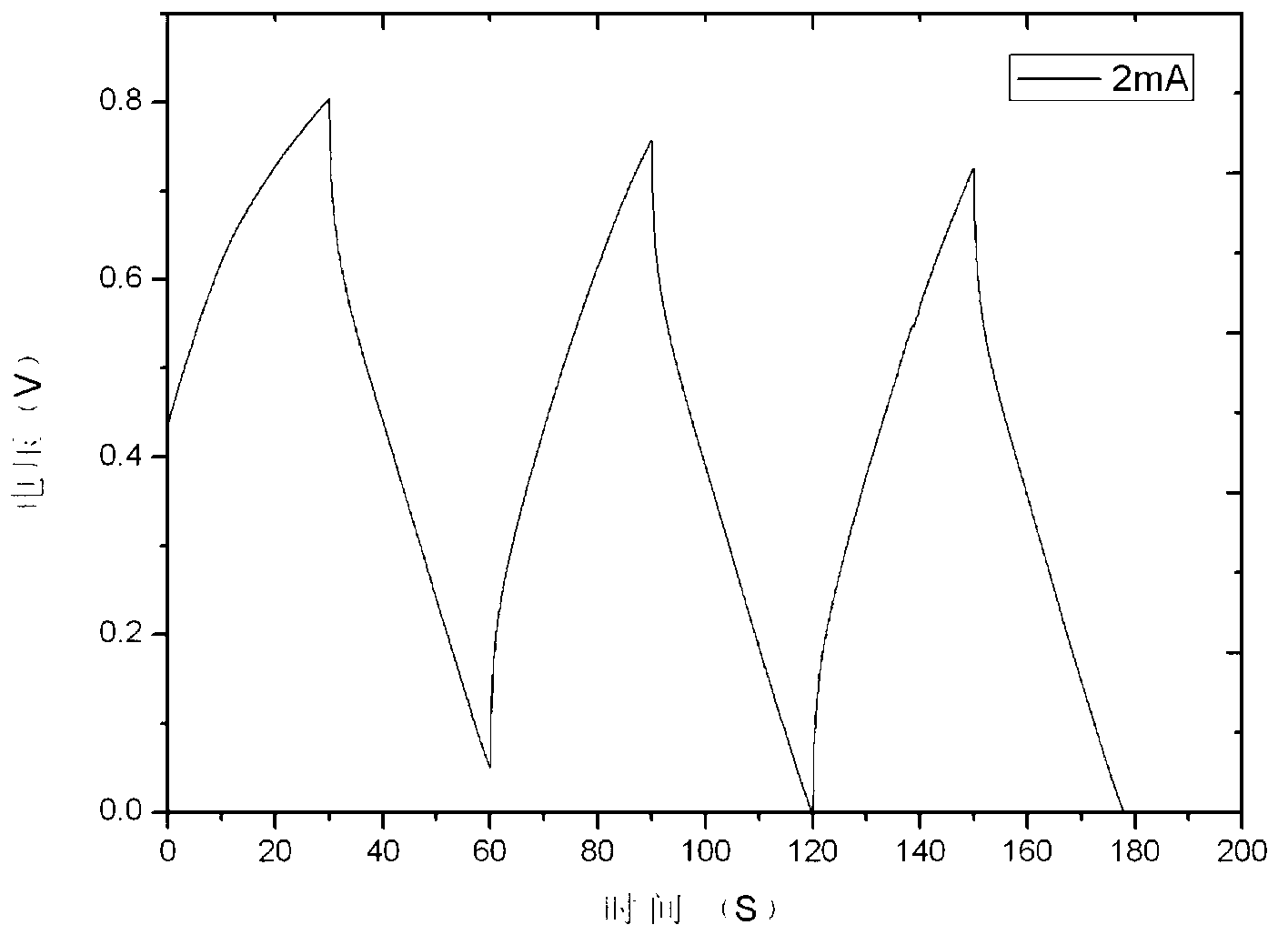

Embodiment 1

[0037]The polyvinylidene fluoride and potassium carbonate are weighed according to the ratio of 77% by mass: 23%, and the weighed raw materials are mixed uniformly, and the uniformly mixed raw materials are fully dissolved into a mixed solution with a DMF solvent to form a sol; then Evenly coat the mixed sol on the graphite paper substrate, and after drying in a constant temperature drying oven, a composite film will be formed on the graphite paper; heat treat the composite film at 220°C for 60 minutes, and heat-treat the composite Soak the film in potassium hydroxide solution for 30 minutes, take it out, and then activate the soaked composite film at 200°C for 30 minutes, thus preparing the electrode material of the flexible supercapacitor with polyvinylidene fluoride composite film ; Then use the mixed solution of polyvinyl alcohol and potassium hydroxide electrolyte as an adhesive to bond the two electrodes facing each other, that is, to prepare the graphite paper substrate ...

Embodiment 2

[0039] Weigh polyvinylidene fluoride and potassium carbonate according to the ratio of 99% by mass: 1%, mix the weighed raw materials evenly, and fully dissolve the uniformly mixed raw materials into a mixed solution with NMP solvent to form a sol; then Apply the mixed sol evenly on the aluminum foil substrate, and after drying in a constant temperature drying oven, a layer of composite film will be formed on the aluminum foil; the composite film is heat-treated at 250°C for 1 minute, and the heat-treated composite film is placed in the Soak in potassium hydroxide solution for 600 minutes, take it out, and then activate the soaked composite film at 250 ° C for 1 minute, so that the electrode material of flexible supercapacitor with polyvinylidene fluoride composite film is prepared; The mixed solution of polyvinyl alcohol and potassium hydroxide electrolyte is used as the adhesive to bond the two electrodes facing each other, that is, the aluminum foil substrate carrying the fi...

Embodiment 3

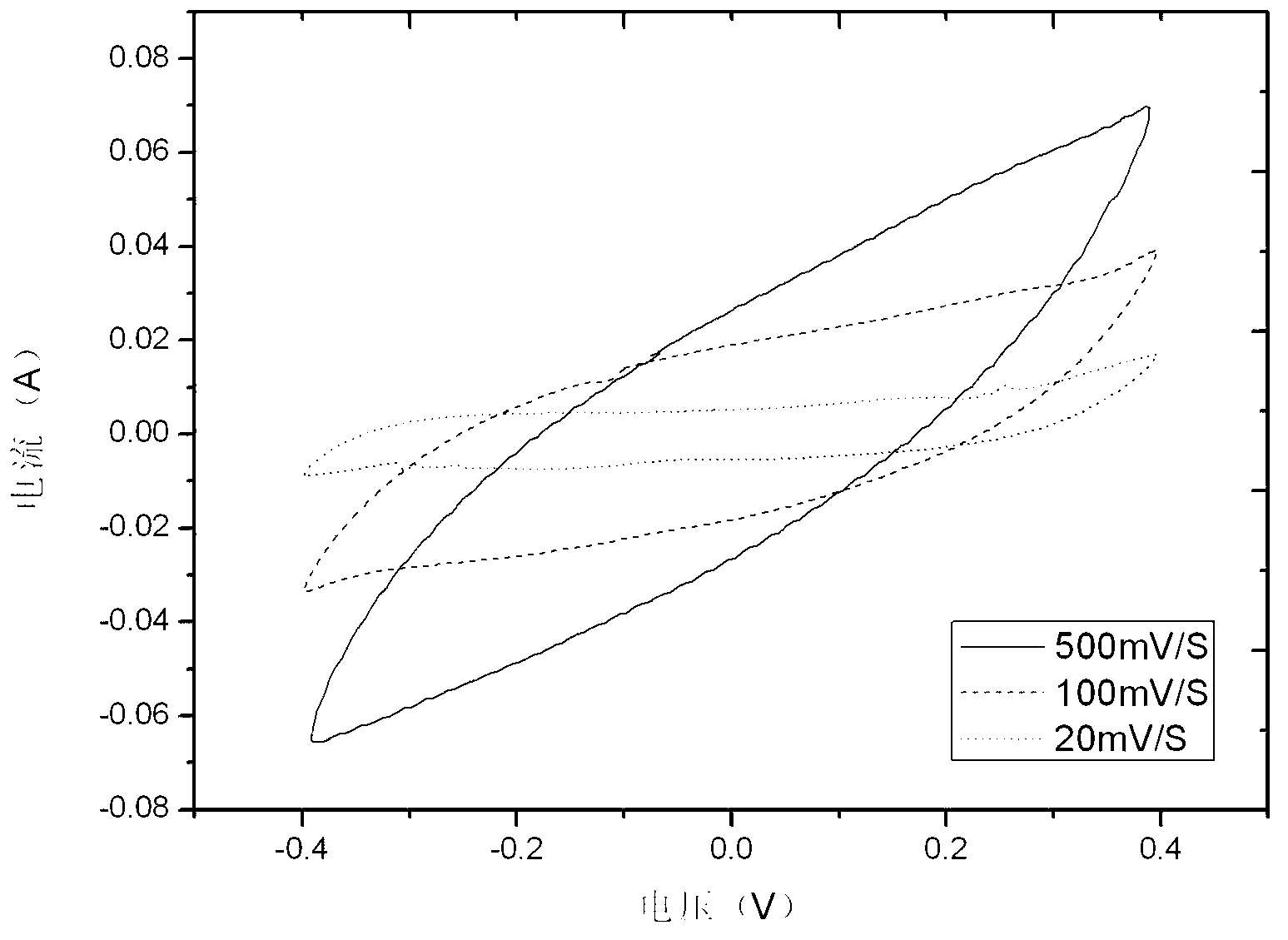

[0041] Weigh polyvinylidene fluoride and potassium carbonate according to the ratio of 50% by mass: 50%, mix the weighed raw materials evenly, fully dissolve the uniformly mixed raw materials into a mixed solution with DMSO solvent, and form a sol; then Apply the mixed sol evenly on the nickel foam substrate, and after drying in a constant temperature drying oven, a layer of composite film will be formed on the foam nickel; heat treat the composite film at 80°C for 120 minutes, and heat Soak the film in potassium hydroxide solution for 600 minutes, take it out, and then activate the soaked composite film at 80°C for 120 minutes, thus preparing the electrode material of the flexible supercapacitor with polyvinylidene fluoride composite film ; Then use the mixed solution of polyvinyl alcohol and potassium hydroxide electrolyte as an adhesive to bond the two electrodes facing each other, that is, it is prepared to use the foamed nickel substrate of the bearing film as the current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com