Earthquake protective clothing and production method thereof

A technology of protective clothing and fireproof cloth, which is applied in the direction of protective clothing, clothing, clothing, etc., and can solve problems such as leakage, easy deformation of the ring, and influence on fast movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

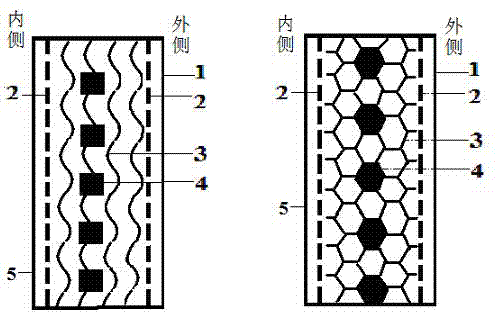

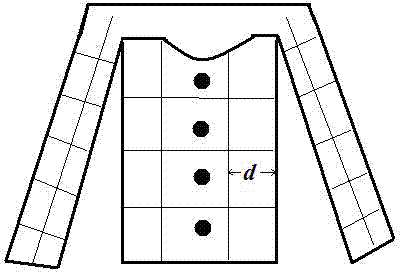

[0032] Example 1: SM series, choose silicon rubber damping material (Silicon), magnesium alloy mesh metal bracket (Magnetism alloy).

[0033] The materials are selected from the outside to the inside in order of refractory aramid fabric, corrugated silicone rubber damping material, D30 impact velocity hard material, magnesium alloy bracket and inner thickened cotton fabric. The total thickness of the fabric is 10.5mm, of which: inner , The thickness of the outer layer fabric is 0.5mm, the thickness of the inner and outer metal support nets is 1mm, and the thickness of the damping material is 7.5mm. A square hole is opened on the damping material. D30 impact speed-hard material is arranged in the square hole, and the side length of the square hole is 35mm, depth 7mm, D30 impact velocity hard material is designed into a square cylinder with a side length of 35.2mm and a depth of 7mm, mainly used for key parts of the limbs.

[0034] The total weight of the size L garment is 2.1kg...

Embodiment 2

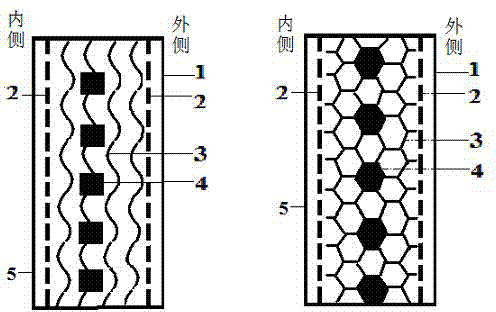

[0035] Example 2: SA series, choose sponge rubber damping material (Sponge), aluminum alloy mesh metal bracket (Aluminum alloy).

[0036] The materials are selected from the outside to the inside in order of resistant aramid fabric, sponge rubber damping material designed into a honeycomb shape, local use of D30 impact speed hard material, 2024 aluminum alloy bracket and inner thickened cotton fabric. The total thickness of the fabric is 12.5mm, of which: The thickness of the inner layer fabric is 0.6mm, the thickness of the outer layer fabric is 0.7mm, the thickness of the inner and outer metal support nets is 1.1mm, the thickness of the damping material is 9mm, the honeycomb hole is a regular hexagon, the side length of the hole is 17mm, and the depth is 8mm. D30 impact speed hard material The two ends are designed as regular hexagons, the side length of the hole is 17.5mm, and the depth is 8mm. It is mainly used for key parts of the limbs.

[0037] The total weight of the...

Embodiment 3

[0038] Embodiment 3: ST series, choose silicon rubber damping material and titanium alloy (Titanium alloy) mesh metal bracket.

[0039] The materials are selected from the outside to the inside in order of resistant aramid fabric, corrugated silicon rubber damping material, local use of D30 impact velocity hard material, titanium alloy bracket and inner thickened cotton fabric, the total thickness of the fabric is 14.5mm, of which: inner The thickness of the layer fabric is 0.8mm, the thickness of the outer layer fabric is 0.8mm, the thickness of the inner and outer metal support nets is 1.2mm, and the thickness of the damping material is 10.5mm. A square hole is opened on the damping material, and D30 impact speed hard material is installed in the square hole. The side length of the hole is 40mm and the depth is 10mm. The D30 impact velocity hard material is designed as a square cylinder with a side length of 40.3mm and a depth of 10mm. It is mainly used for key parts of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com