Oil and gas well fracturing construction method

A construction method and technology for oil and gas wells, which is applied in earthwork drilling, wellbore/well components, production fluids, etc., can solve the problems of high drilling and grinding risks, long operation time, high cost, etc., and achieve the effect of reducing the risk of bridge plug construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055]An oil and gas well fracturing construction method, the first paragraph uses a bore of the oil or toe-ended slide, and the sleeve deformation section is used as follows:

[0056]Step (1), the continuous tube is completed 48 shots under the sleeve deformation section of the horizontal well.

[0057]Step (2), according to the number of cellular holes, 48 biological knots and 1 square strong chemical fluids are prepared, and the previous segment segments are blocked;

[0058]Step (3), use a continuous tube to incident a hole gun, complete 48 shots construction;

[0059]Step (4), repeat steps (2) and (3), complete 3 segment adhesive;

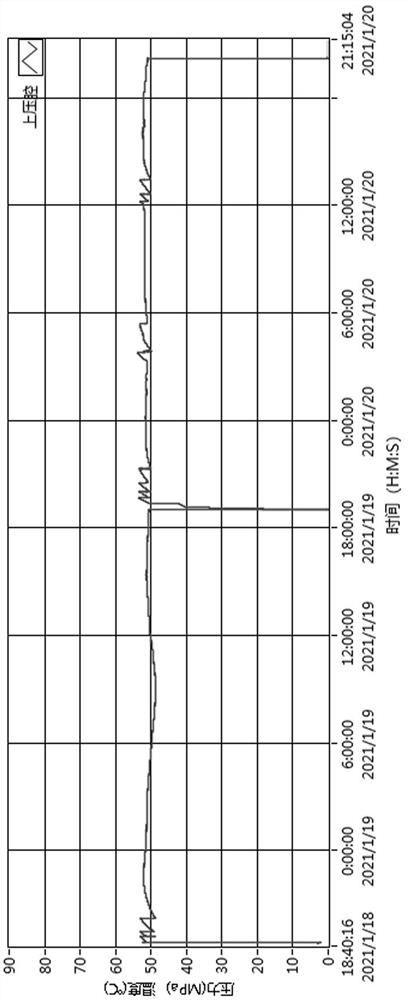

[0060]Step (5), the pump is fed into the reinforcing liquid, blocking the first / 2 layers, the biological junction will slowly dissolve in the reinforcing liquid, block the biological finolution and slit, keep the sealing status of 15-20 days;

[0061]Step (6), repeat the above steps to complete the entire casing deformation section;

[0062]Step (7), using a continu...

Embodiment 2

[0064]With the same method as in Example 1, the particles were added to the pumped reinforcing liquid, and the hydration agent was added, and after entering the formation, the capsule was broken, and the reinforcing liquid was subjected to water. Can't harm the formation.

Embodiment 3

[0066]The preparation of the biological junction in Examples 1 and 2 selects a molecular weight of the tensile strength of 120 MPa having a molecular weight of 80 W, which is spinned, woven from a rope, and then uses this polyorol material. A rope junction in a diameter of 17-20 mm, and the diameter of the rope can be adjusted according to the eyegles to be blocked, and the two ends of the rope have a woven wire having a length of 20-25 mm.

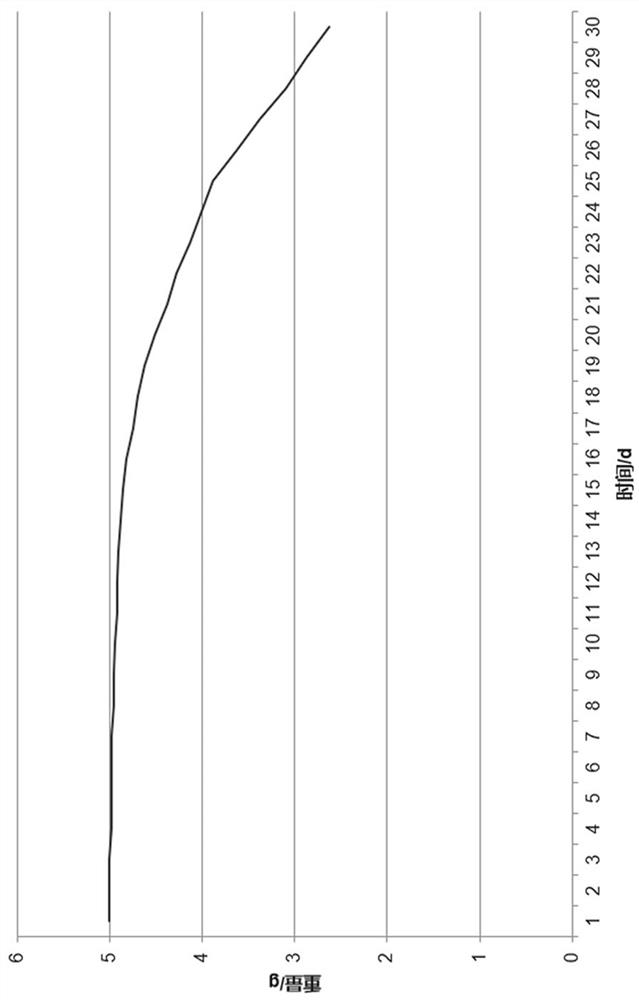

[0067]The biological knot was dissolved, the test temperature was 90 ° C, the medium was purified.

[0068]Test results: under 90 ° C, under water conditions, 4 days began to dissolve, 6 days of rope finish completely broken, completely dissolved on day 11. After drying, weighhed, and the overall dissolution rate was 98.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com