Fiber reinforced hose and manufacturing method thereof

A technology of fiber reinforcement and manufacturing method, which is applied in the field of fiber reinforced hose for high-pressure fluid transportation and its manufacturing field, can solve the problems of low production efficiency, achieve the effects of improving production efficiency, improving overall strength, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

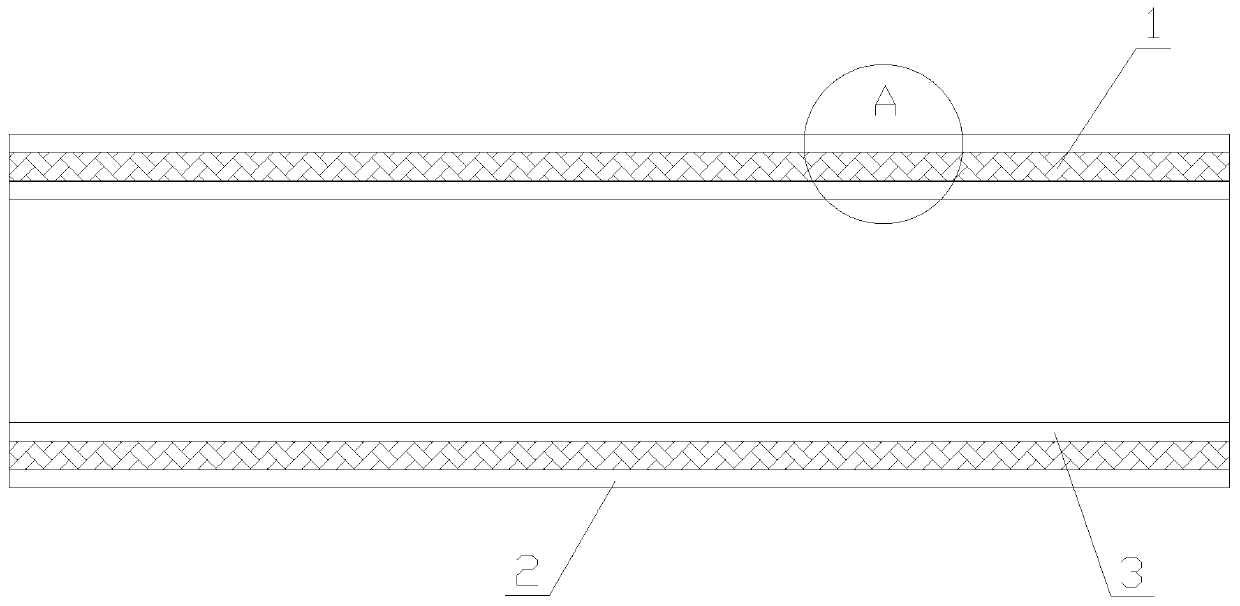

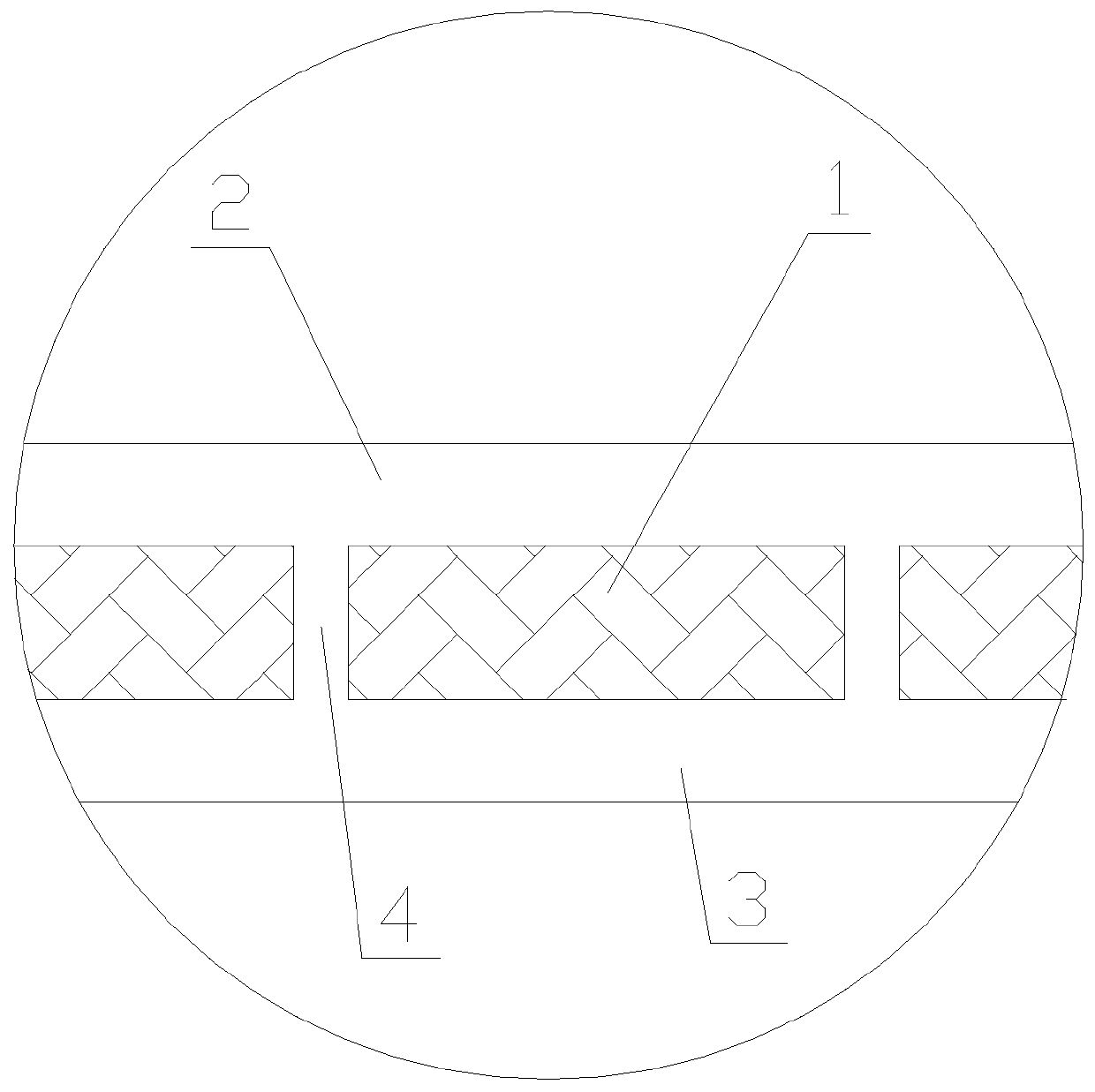

[0033] Such as figure 1 with figure 2 As shown, a fiber-reinforced hose is composed of a fiber-reinforced braided layer 1, an outer rubber layer 2 and an inner rubber layer 3. The fiber-reinforced braided layer 1 is tubular and woven from warp and weft threads. The inner rubber Layer 3 and cover layer 2 are respectively coated on the inner surface and the outer surface of braided layer 1, and several columnar adhesives 4 are permeated in the fiber gap of hose fiber reinforced braided layer 1, and the outer rubber layer 2 passes through the gap of braided layer The columnar rubber 4 is connected with the inner rubber layer 3 and forms an integral structure.

[0034] In this embodiment, the warp includes nylon fiber, polyester fiber and PEN fiber; or, the warp is twisted from nylon fiber and polyester fiber or PEN fiber; the weft is twisted from aramid fiber ; The tensile strength of the weft is 1 to 5 times that of the warp. The inner rubber layer 3, the outer rubber layer ...

Embodiment 2

[0036] A method for manufacturing a fiber-reinforced hose, comprising the following steps: 1. Material selection: According to the working pressure, caliber and length required by the fiber-reinforced hose, calculate the specifications and quantities of the warp and weft, use nylon fibers for the warp, and use nylon fibers for the weft. Using aramid fiber, the tensile force that the weft can withstand is 0.8 times that of the warp; 2. Twisting: use a twisting machine to twist the warp and weft respectively and make warp and weft spindles; 3. Upper line: Put the warp thread spindle and the weft thread spindle on the circular loom; 4, weaving: use the circular loom to weave the warp thread and the weft thread into a tubular fiber braided reinforcing layer, and set uniform gaps on the fiber braided reinforcing layer; 5, bake: Transfer the fiber-reinforced braided layer to an oven for full baking; 6. Coating: transfer the baked fiber braided layer to the die head, which is divided ...

Embodiment 3

[0039] A method for manufacturing a fiber-reinforced hose, comprising the following steps: 1. Material selection: According to the working pressure, caliber and length required by the fiber-reinforced hose, calculate the specification and quantity of the warp and weft, use polyester fiber for the warp, The weft thread uses aramid fiber, and the tensile force that the weft thread can withstand is the same as that of the warp thread; 2. Twisting: use a twisting machine to twist the warp thread and weft thread respectively and make a warp thread spindle and a weft thread spindle; Warp yarn spindles and weft yarn spindles are put on the circular loom; 4, weaving: use circular loom to weave the warp and weft threads into a tubular fiber-reinforced braided layer, and set uniform gaps on the fiber braided layer; 5, bake: the fiber The braided layer is transferred to the oven for full baking; 6. Coating: transfer the baked fiber braided layer to the die head, the die head is divided in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com