Patents

Literature

140 results about "Collagen fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

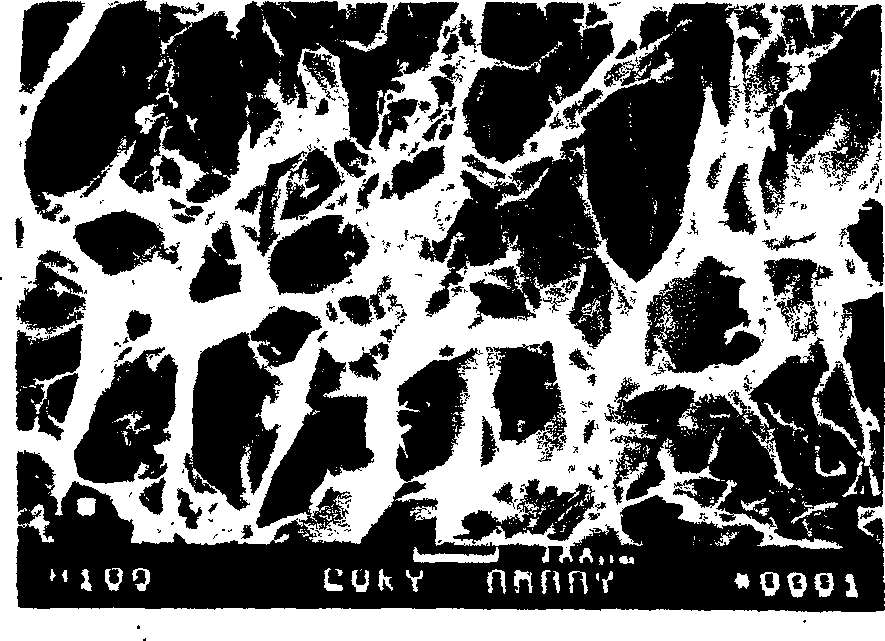

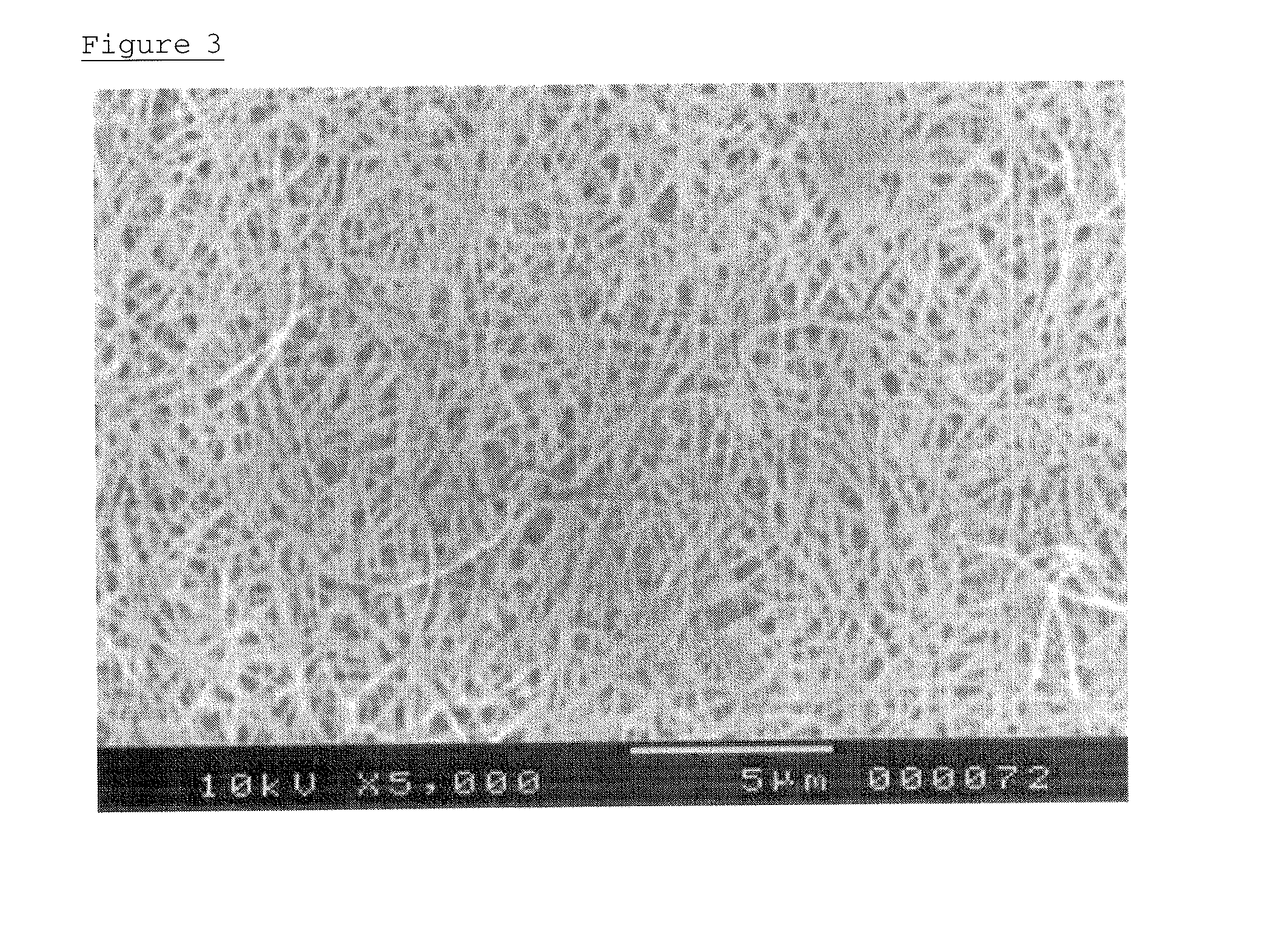

Collagen fiber is a type of biological fiber that is characteristically white and composed of collagen. It is typically arranged in branching bundles of indefinite length. It is the most predominant type of connective tissue fiber. It is a strong insoluble fiber. It occurs in skin, tendon, ligaments, bone, cartilage,...

Mineralized collagen artificial periosteum and preparation method thereof

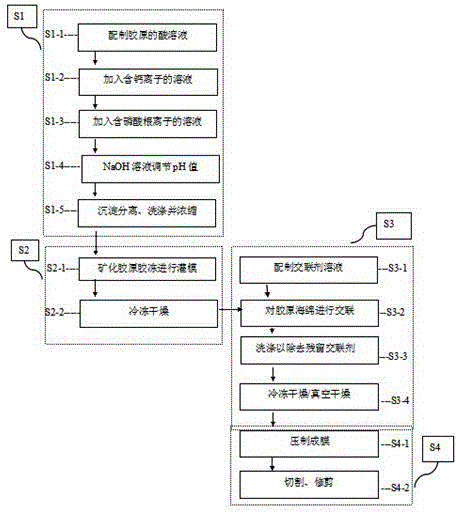

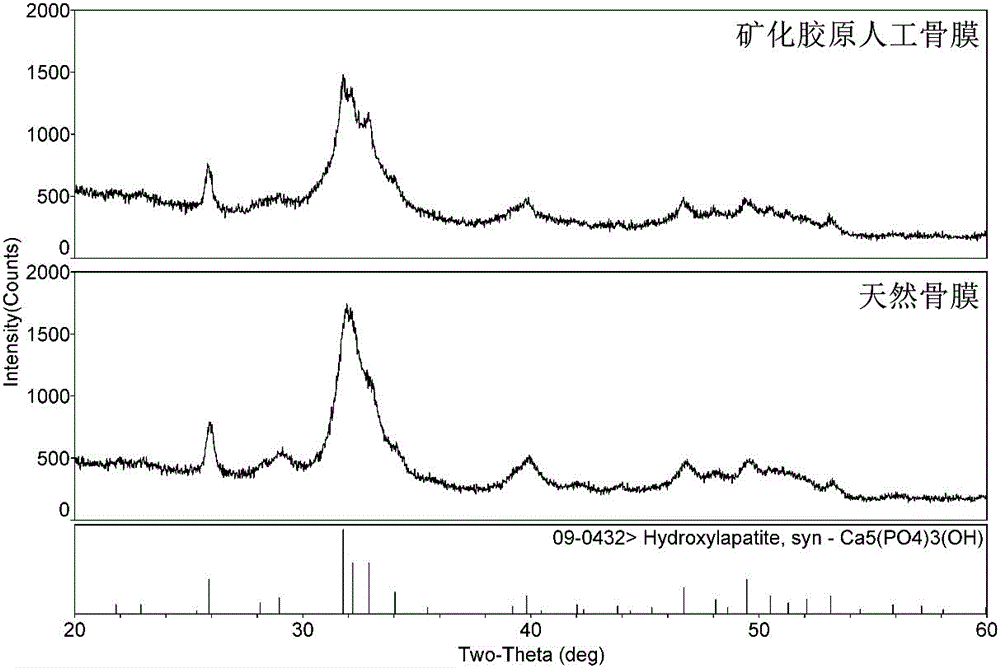

The invention provides a mineralized collagen artificial periosteum. The artificial periosteum is prepared from mineralized collagen in which nano calcium phosphonium salt and collagen fibers are arranged in order, has substances and micro and macro structures, which are the same as a natural periosteum, also has a favorable mechanical property and biodegradation properties, and can be used for replacing and restoring the periosteum. The artificial periosteum can limit other bone grafting materials in the bone fracture parts in the restoring process to prevent the bone grafting materials from coming out and muscles, fat and other tissues from being extruded into the bone fracture parts, so that the restoring effect cannot be influenced. The pore structure of the artificial periosteum facilitates revascularization and conveying of nutrient substances, thereby benefiting restoring of bone fractures. Since the mineralized collagen artificial periosteum consists of nano calcium phosphonium salt and the collagen fibers, the artificial periosteum can be gradually degraded along with regeneration of bone tissues and the periosteums in the body. The invention also provides a preparation method of the artificial periosteum.

Owner:BEIJING ALLGENS MEDICAL SCI & TECH

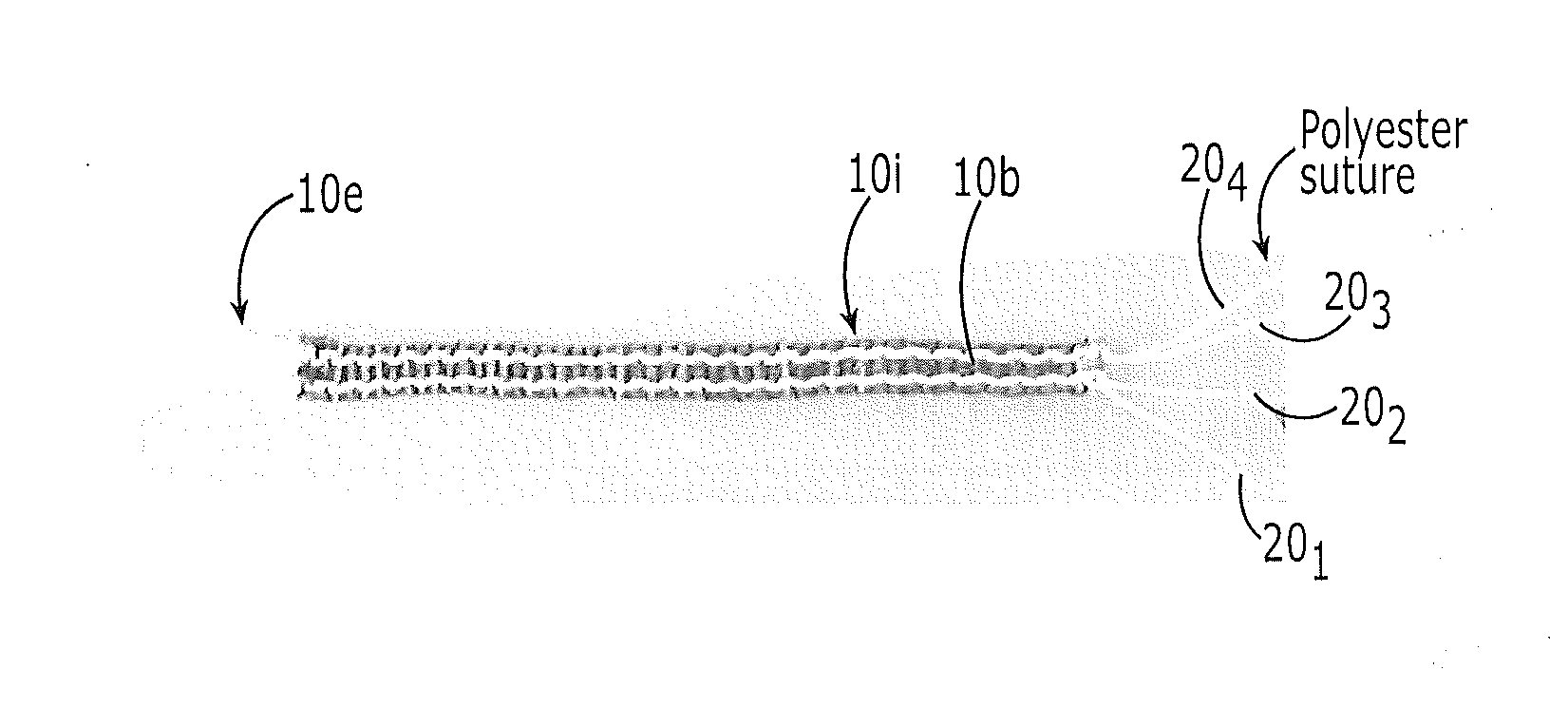

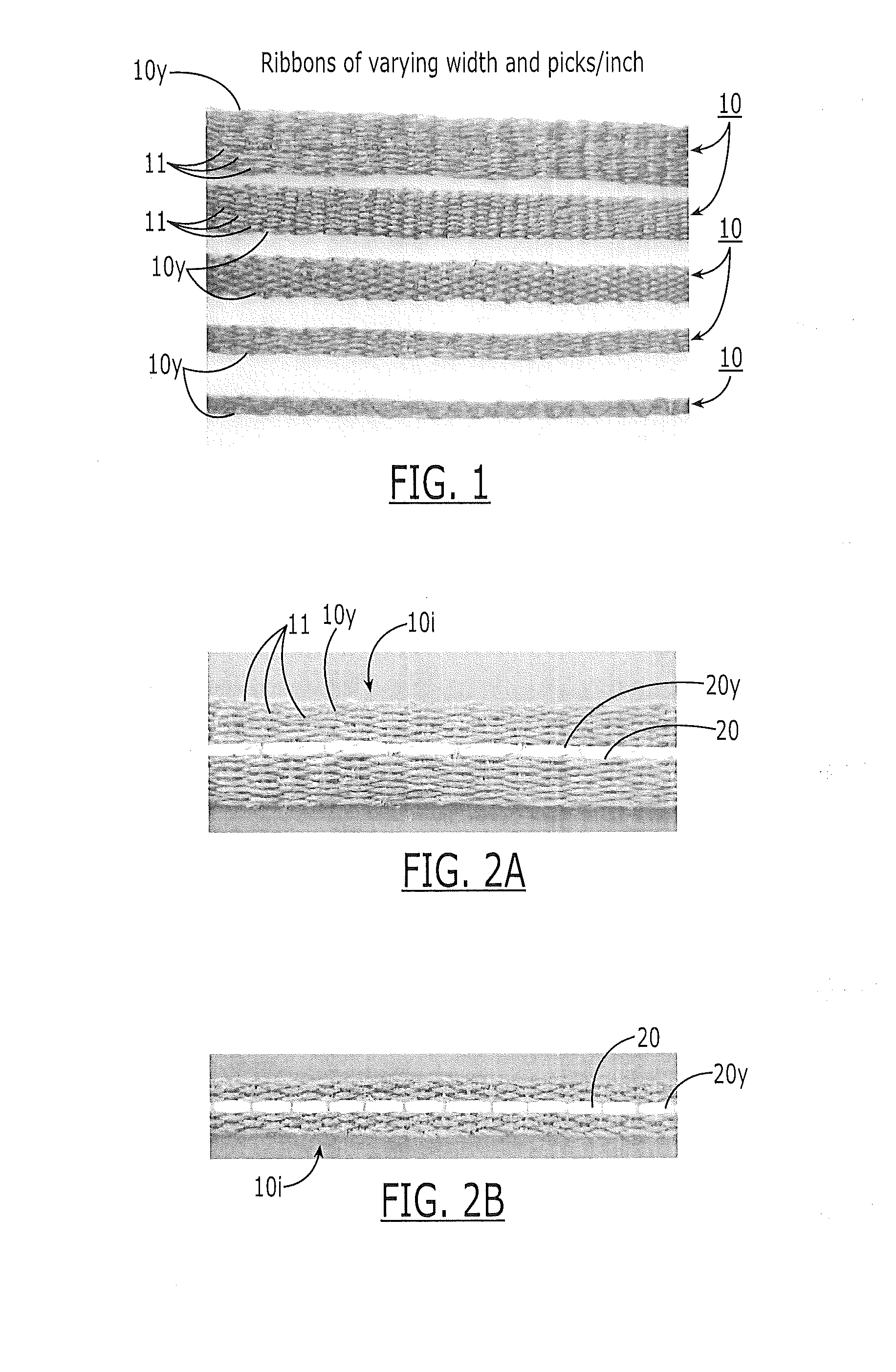

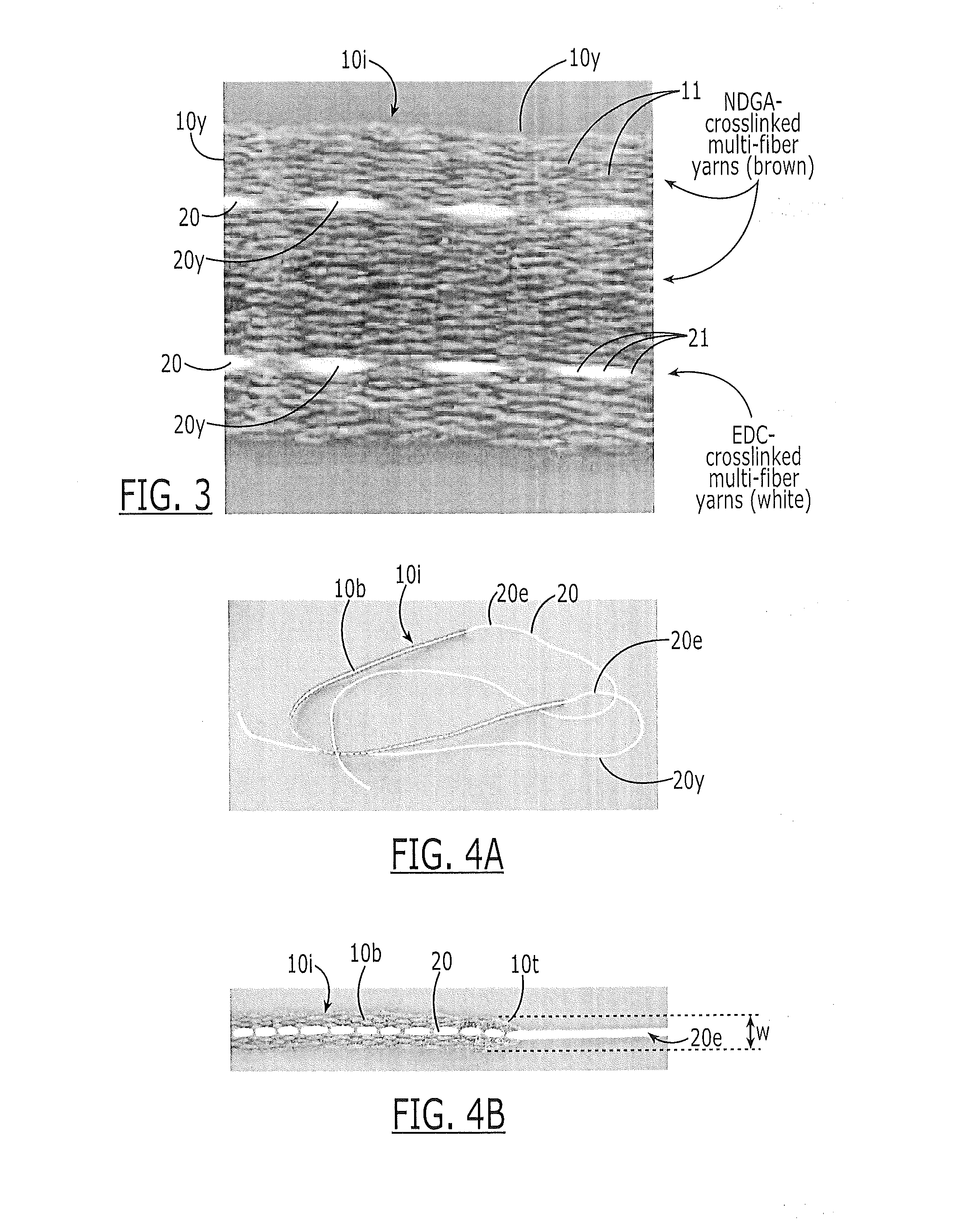

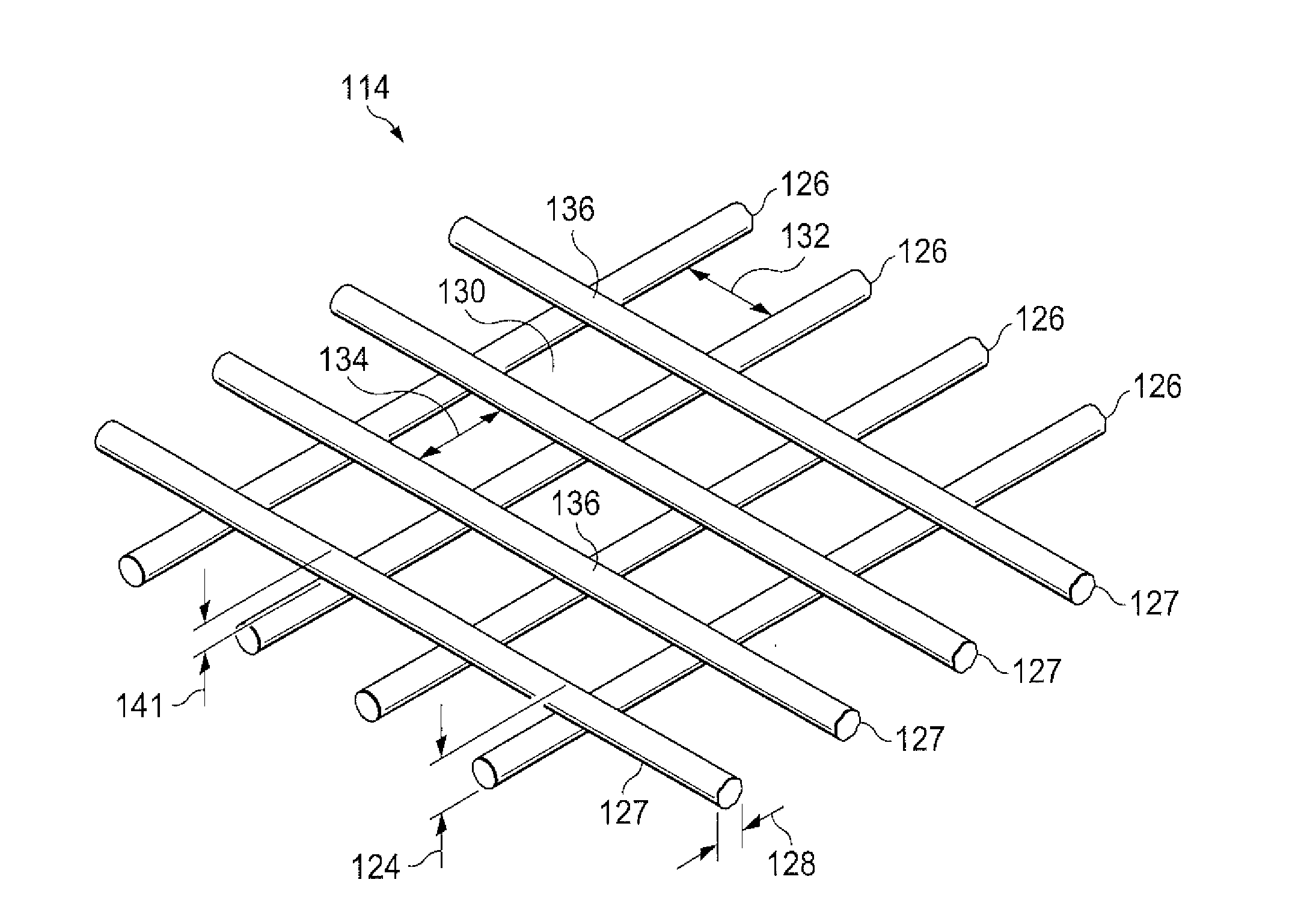

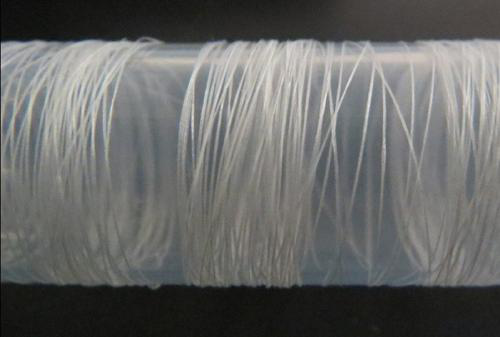

Collagen fiber ribbons with integrated fixation sutures and methods of making the same

ActiveUS20140172096A1Reduce probabilityDifferent fiber tensile strengthSuture equipmentsMonocomponent protein artificial filamentProsthesisCollagen fiber

Owner:MIMEDX GROUP

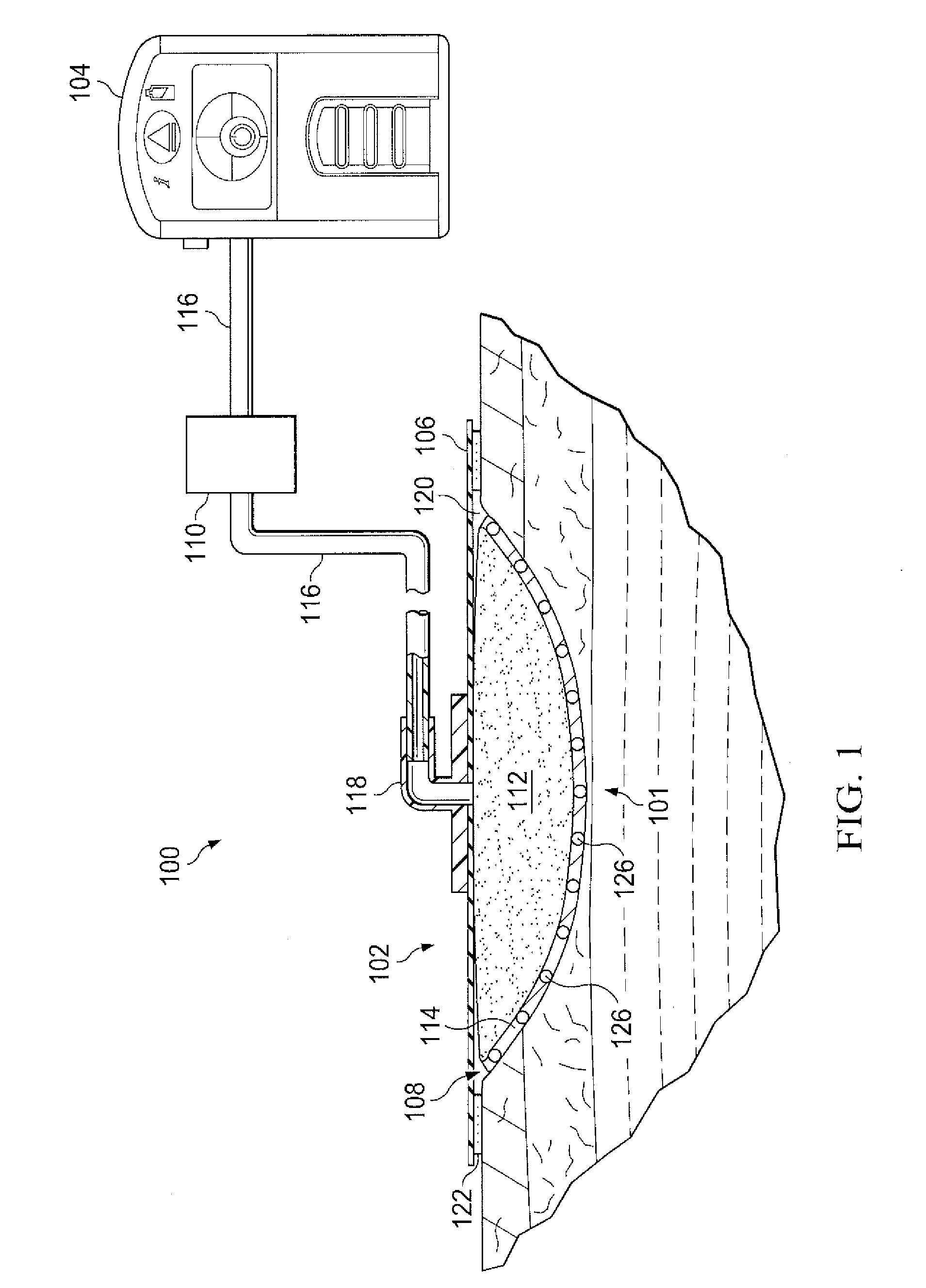

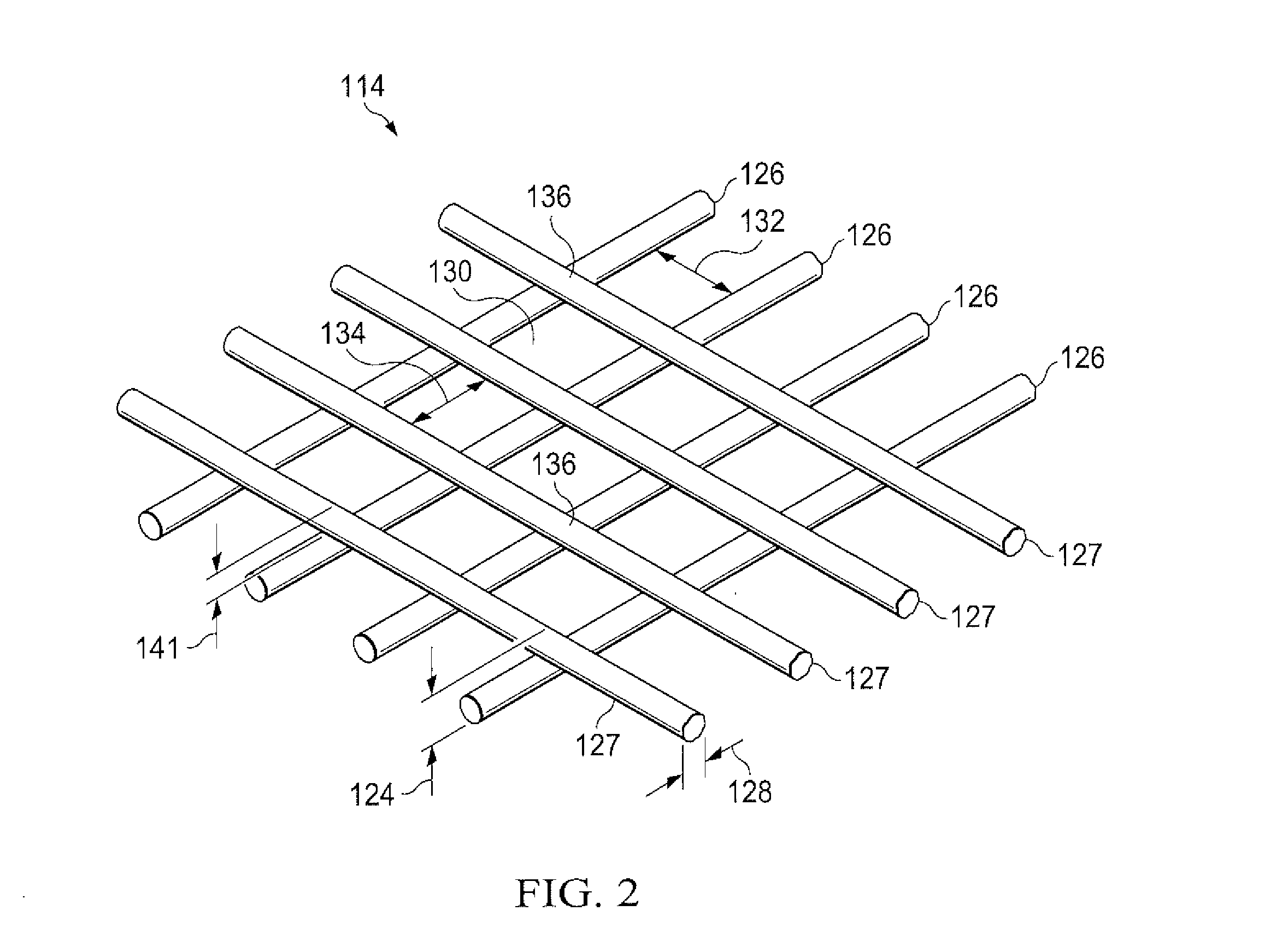

Protease modulating wound interface layer for use with negative pressure wound therapy

Systems, methods, and apparatuses for modulating proteases including matrix metalloproteinase (MMP), elastase, and bacterial protease in a negative pressure therapy system are described. A mesh having a sacrificial substrate is included. The sacrificial substrate includes a plurality of collagen fibers reinforced with a supporting material and intersecting with each other to form a network of collagen fibers having a plurality openings. The openings of the plurality of openings have an average area between about 0.5 mm2 and about 20 mm2 to permit the flow of negative pressure through the mesh. The sacrificial substrate can also include oxidized regenerated cellulose.

Owner:KCI LICENSING INC

Fiber-Containing Product for Hair and Head Dressing Product Formed Therefrom

InactiveUS20090260646A1Good shape retentionSame textureHair accessoriesMonocomponent protein artificial filamentPolyesterFiber

Disclosed is a fiber for use as hair which has touch / shine like a hair, excellent curl-retaining property and flame retardancy. Also disclosed is a head-dressing product produced using the fiber. The fiber comprises (A) 90 to 10 parts by weight of polyester fiber and (B) 10 to 90 parts by weight of a reproduced collagen fiber containing an aluminum compound. Preferably, the aluminium compound is an aluminium salt and is contained in an amount of 8 to 20% by weight in terms of aluminium oxide. The polyester fiber may contain a flame retarder.

Owner:KANEKA CORP

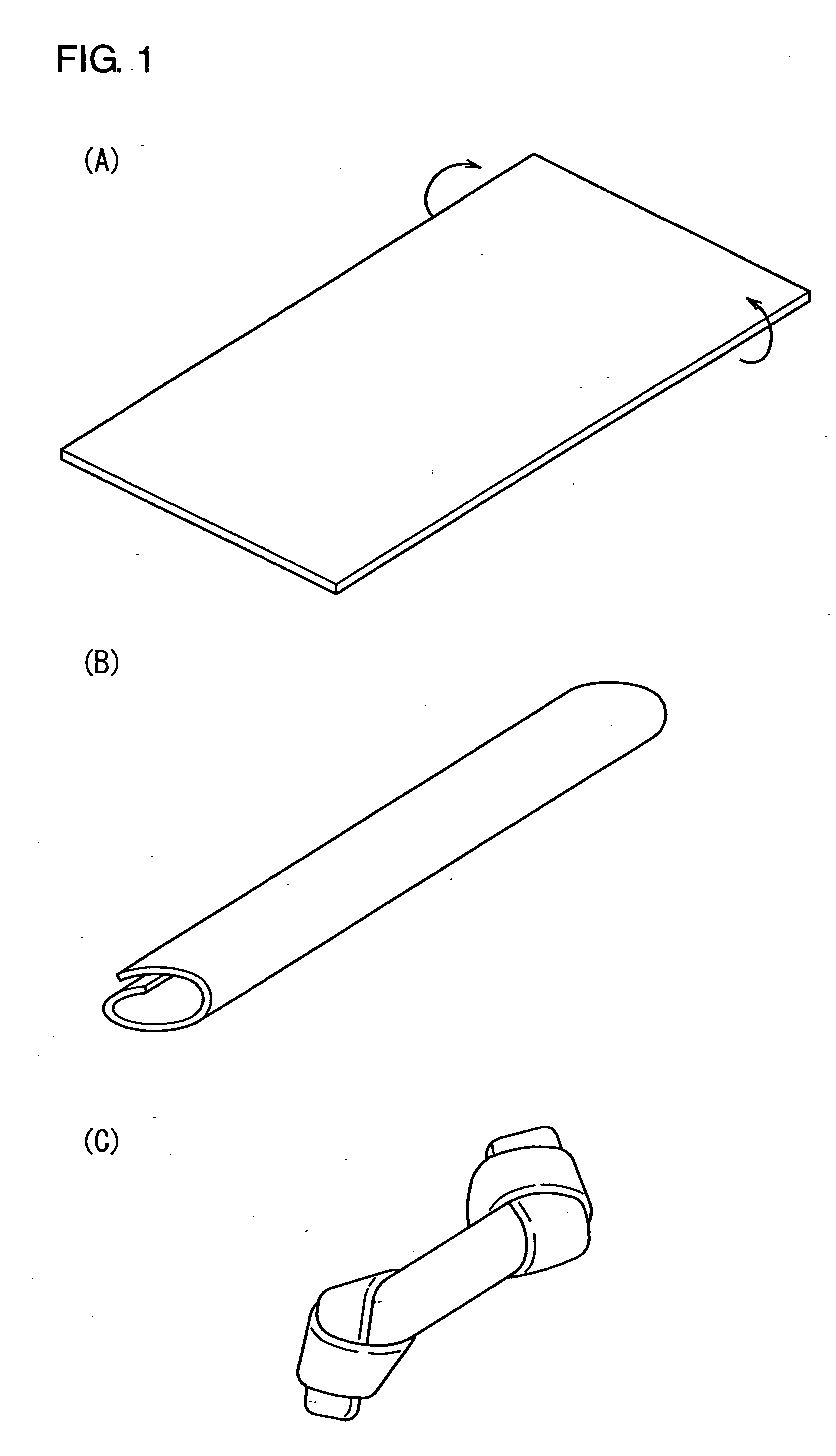

Process for producing artificial rawhide

InactiveUS20040187794A1Efficient use of resourcesCost-effectiveAnimal feeding stuffWorking-up animal fodderFiberCollagen fiber

A process whereby artificial rawhide comparable in qualities to natural rawhide can be produced. After pre-treatments such as washing with water, liming, bleaching, etc., rawhide is roughly cut into pieces (about 10 cmx10 cm) and then further finely cut with the use of a chopper and a micro-cutter to thereby prepare collagen fibers. Next, water, a collagen fiber powder and gelatin are added thereto to give a sol or a gel having a moisture content of 60 wt % to 80 wt %. Then it is extruded into a sheet, using a screw extruder at 30° C. or below and dried, thereby giving artificial rawhide. This artificial rawhide in the form of a sheet is cut into strips in a predetermined size. Then, each strip is rolled in the width direction and tied in the length direction. Thus, a bone-shape chewing gum for dogs can be obtained.

Owner:NAKATA TATSUJI

Composites comprising collagen extracted from sarcophyton sp. coral

Isolated composites are disclosed comprising collagen fibers isolated from a Sarcophyton sp. coral. An exemplary composite comprises as a first component a bundle of collagen fibers, the collagen fibers being isolated from a Sarcophyton sp. coral, and a second component selected from the group consisting of a polysaccharide, a polypeptide, polylipid, a synthetic polymer, a metal and a mineral, wherein the bundle of collagen fibers comprise woven fibers, twisted fibers, braided fibers, knitted fibers, tied fibers, or sutured fibers. Uses thereof and method of generating are also disclosed.

Owner:RAMOT AT TEL AVIV UNIV LTD

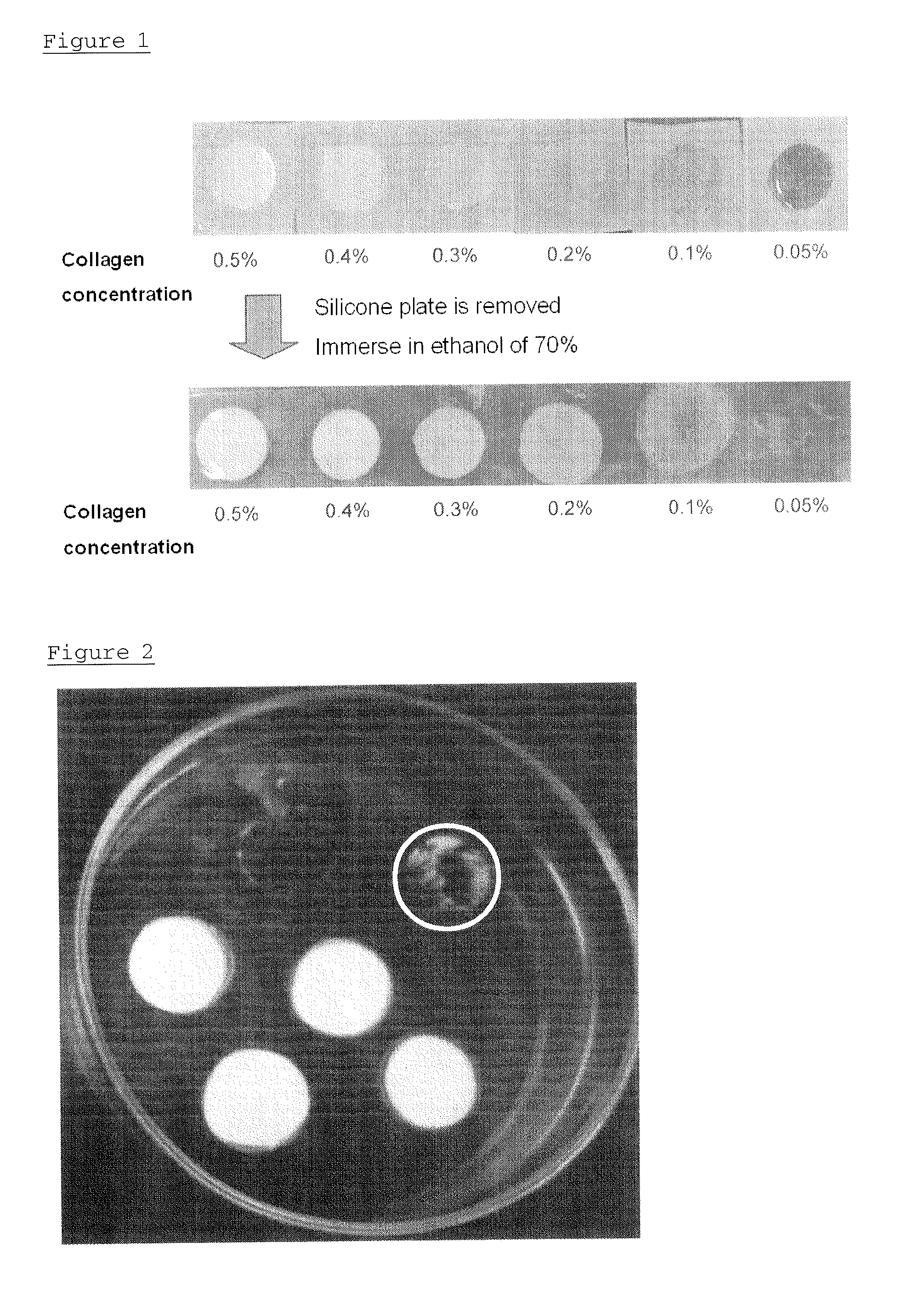

Preparation of collagen base biological medical material

InactiveCN101264337AGood biocompatibilityGood blood compatibilitySurgeryAbsorbent padsFreeze-dryingFibril

The invention discloses a preparation method for collagen-based biomedical materials, which is characterized in that: fresh animal skin and / or tendon and / or sheet-beam are adopt to make collagen fiber dispersion liquid (gel) or freeze-dry the collagen fiber materials via the enzymatic method, then are immersedly treated for 20 to 60 minutes through ethanol alcohol solution with concentration of 35 to 65 percent with 8 to 12g / L 2- sulfonic acid under the temperature of 15 to 40 DEG C, and then are immersedly treated for 4 to 24 hours through solution with 1.0 to 5.5g / L N-hydroxy amber imide and 0.8 to 4.0g / L carbodiimide hydrochloride under the temperature of 15 to 40 DEG C; the collagen raw materials are cleaned and immersed for two times through ethanol with concentration of 80 to 95 percent, each time for 10 to 30 minutes, then are immersed and cleaned for one time through Na2HPO4 solution with concentration of 1.5 to 2.0 percent and NaCl solution with concentration of 5.5 to 6.5 percent respectively, the time is 30 to 60 minutes; then are immersed and cleaned for 2 times through distilled water immersion, each time for 10 to 30 minutes, the materials after being cleaned are freeze-dried, and the collagen-based biomedical materials are obtained.

Owner:SICHUAN UNIV

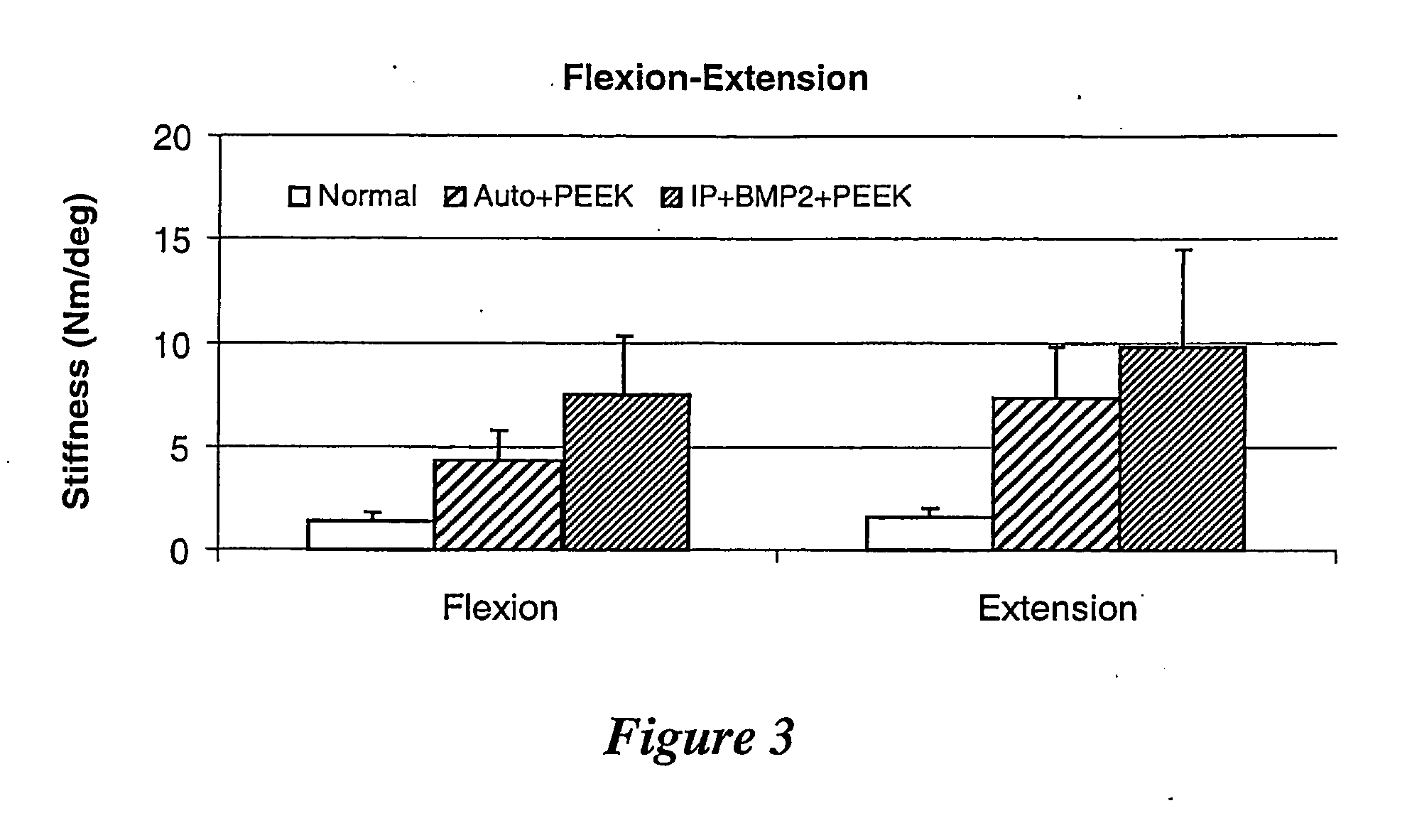

Cohesive osteogenic putty and materials therefor

Described is an implantable medical material comprising a malleable, cohesive, shape-retaining putty including mineral particles, insoluble collagen fibers and soluble collagen. The medical material can be used in conjunction with biologically active factors such as osteogenic proteins to treat bone or other tissue defects in patients.

Owner:WARSAW ORTHOPEDIC INC

Biological active bone tissue inducing regeneration film and preparation method

The present invention discloses a bioactive bone tissue induced regeneration membrane, which has two-layer composite structure, one layer is polylactic acid, and another layer is a mixture of cololagen fibre and bioactive factor recombinant human gene bone morphogenetic protein. Said membrane is made up by the steps: on the polylactic acid base membrane made up by swelling, stirring, dissolving, defoaming and moulding, making scratching and roughening treatment, coating collagen fibre solution, then coating collagen fibre and bioactive factor recombinant human gene bone morphogenetic protein mixed solution, cooling and vacuum drying. Said membrane has has the bone induced activity, can make the damaged region of bone grow new bone again.

Owner:SICHUAN UNIV

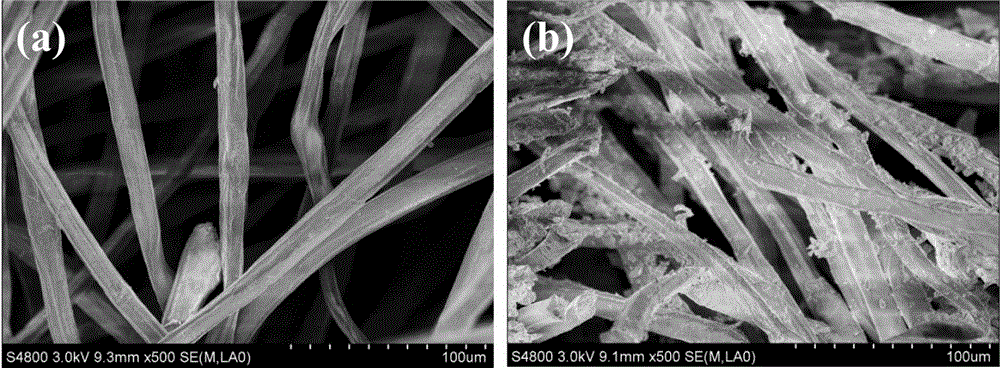

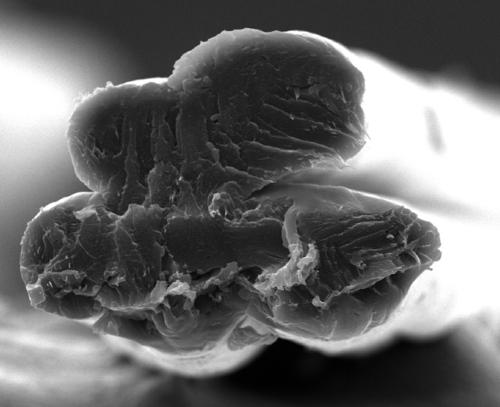

Collagenous fiber fancy yarn and preparing method thereof

The invention discloses a collagenous fiber fancy yarn and a preparing method thereof and relates to the field of textiles. The preparing method of the collagenous fiber fancy yarn comprises the steps that a wet method is adopted for extracting collagenous fibers with the length ranging from 8 mm to 40 mm from blue and wet scrap leather; short collagenous fibers and long collagenous fibers are obtained after the collagenous fibers are subjected to two opening processes and a long fiber removing and separating process; the short collagenous fibers are prepared into fiber knot balls through a pearl wool ball twisting machine; the fiber knot balls and the long collagenous fibers are fed to a carding machine together, and the collagenous fiber fancy yarn is obtained after the processes of carding, thick combining and yarn thinning. According to the preparing method of the collagenous fiber fancy yarn, the collagenous fiber with different lengths are extracted from the blue and wet scrap leather, the short collagenous fibers are prepared into the fiber knot balls and then prepared into the collagenous fiber fancy yarn together with the long collagenous fibers, the problem that the extracted short collagenous fibers cannot be well used is solved, and the purpose of fully utilizing the short collagenous fibers extracted from the blue and wet scrap leather is achieved.

Owner:JIAXING UNIV

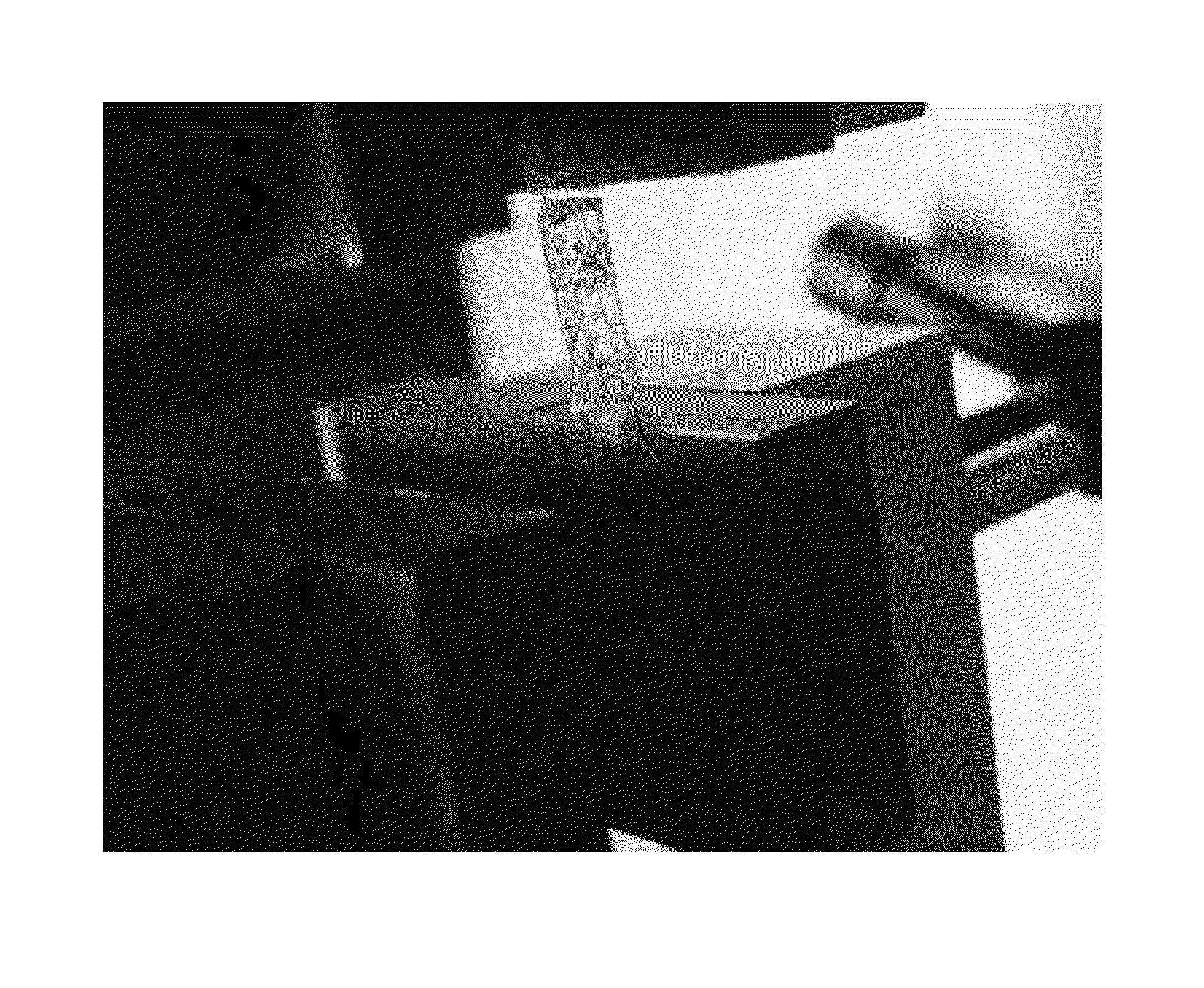

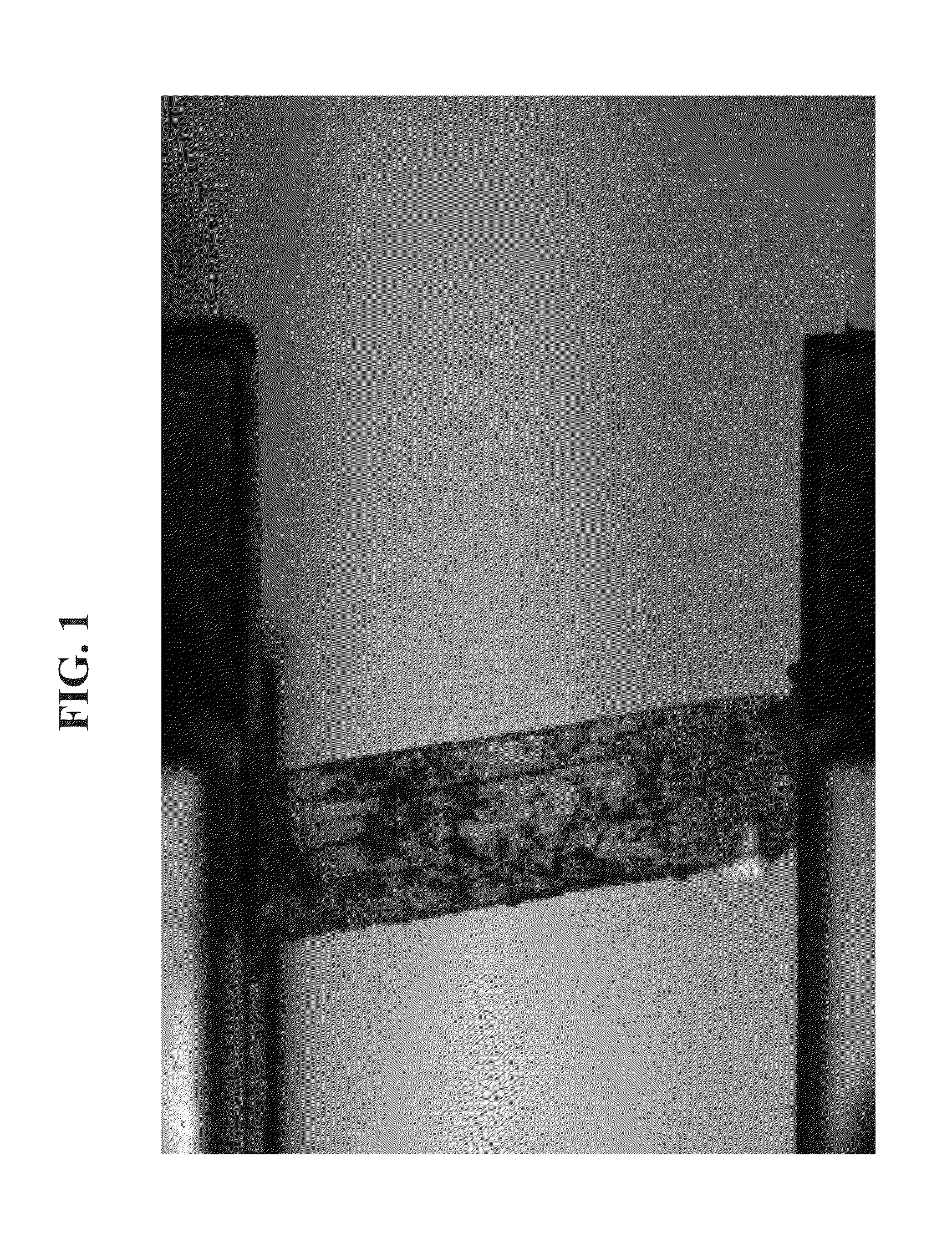

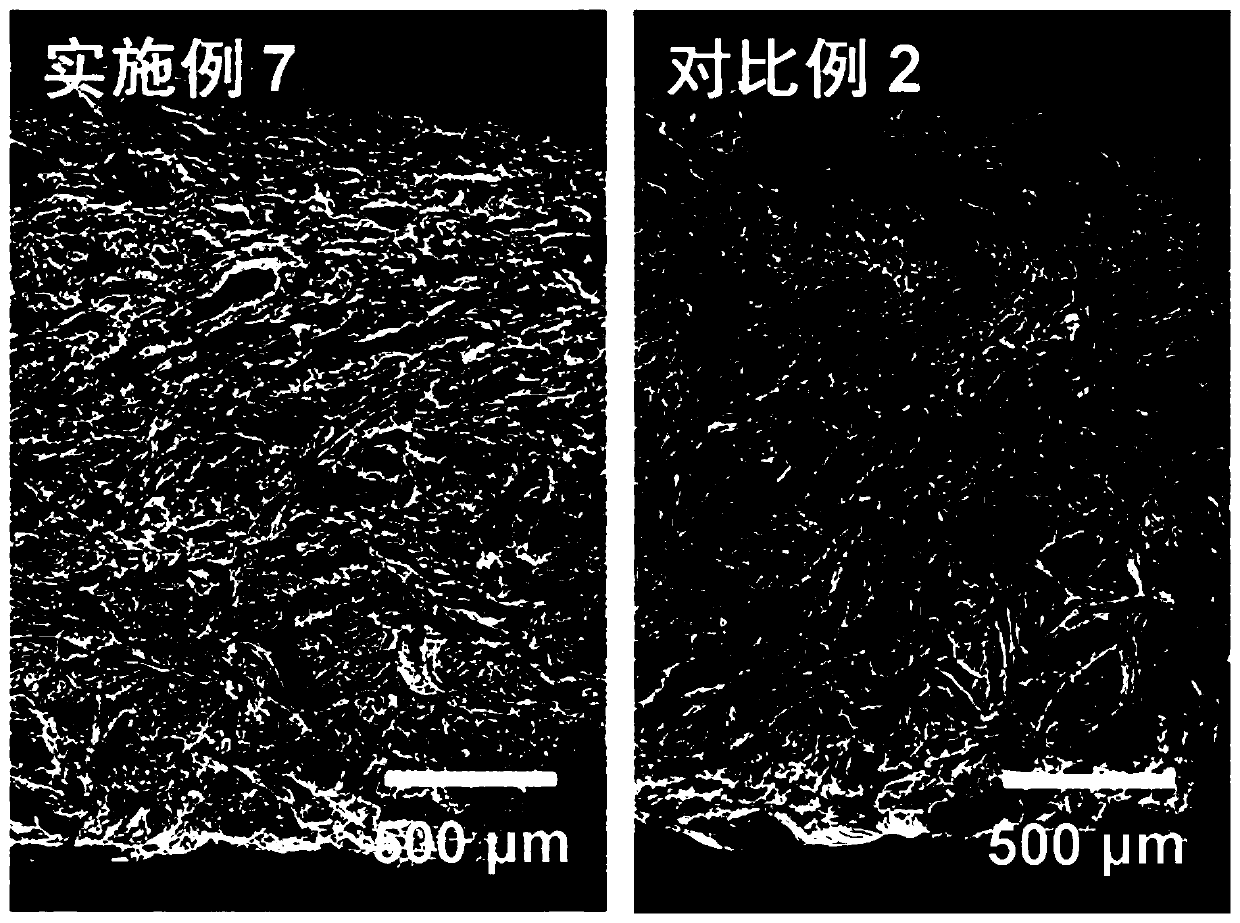

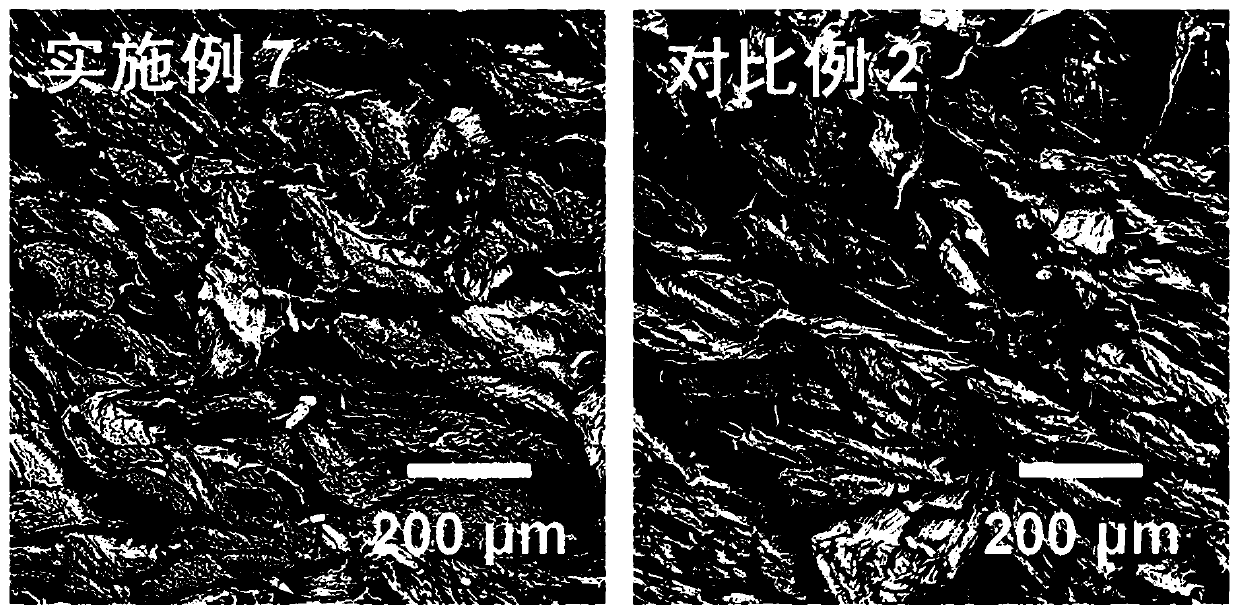

High-strength tissue regeneration membrane and preparation method thereof

The present invention provides a high-strength tissue regeneration membrane. The material includes a dense layer and a loose layer. In the preparation process, a gradient dialysis process is carried out to rearrange molecules into an ordered structure, and endow the molecules with more consistent and more extensive collagen fiber orientation, thus improving the mechanical properties of the material. The mechanical properties of the material are similar to those of human tissues, and the material can be stitched by using sutures, and can be used to guide tissue regeneration or bone tissue regeneration. The present invention provides a preparation method of the high-strength tissue regeneration membrane.

Owner:BEIJING PAISHENG BIOTECH CO LTD

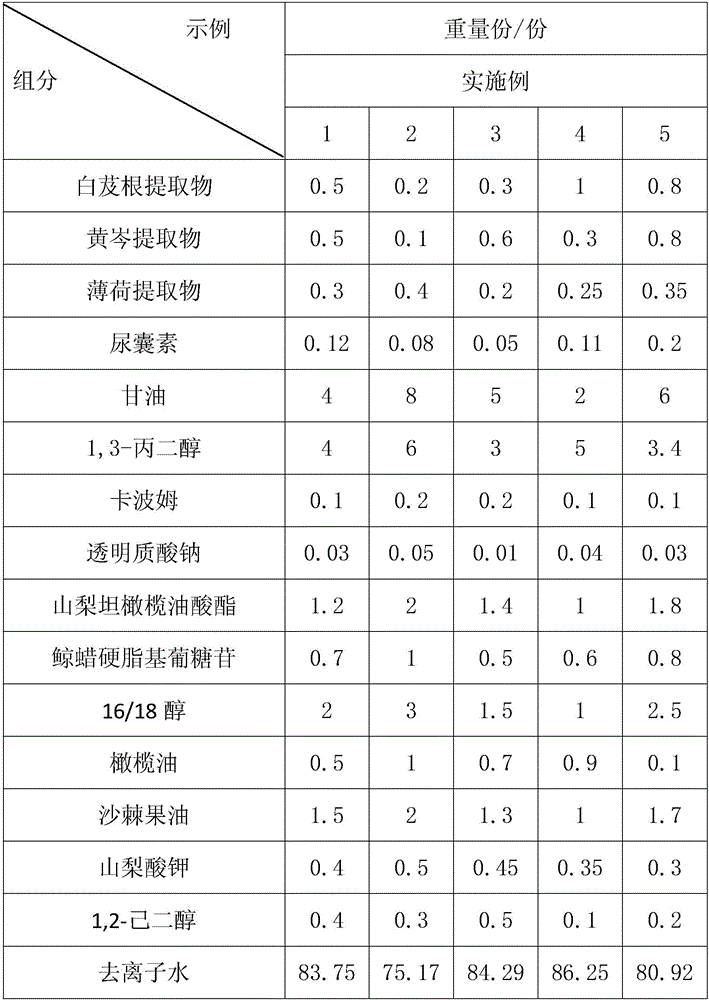

Composition for preventing stretch marks, stretch mark cream and the preparation method

InactiveCN106265310ASafeEfficientCosmetic preparationsToilet preparationsFiberCentella asiatica extract

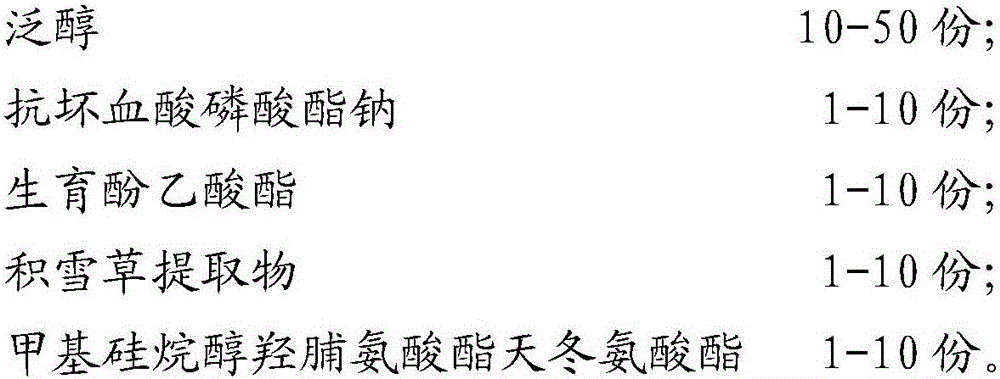

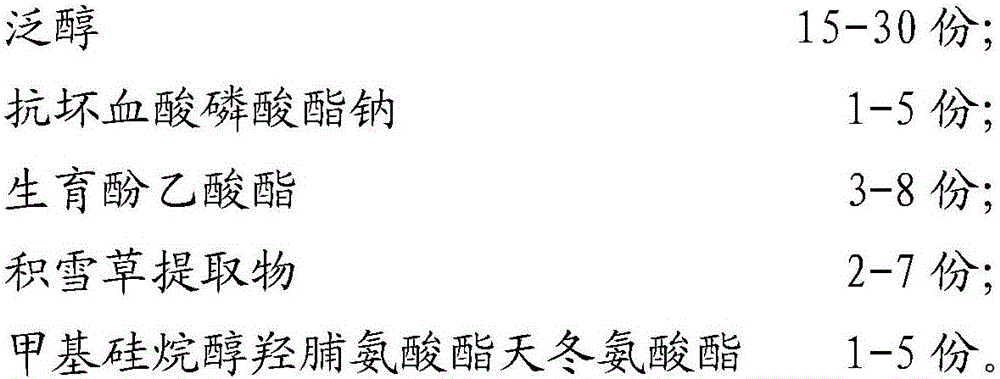

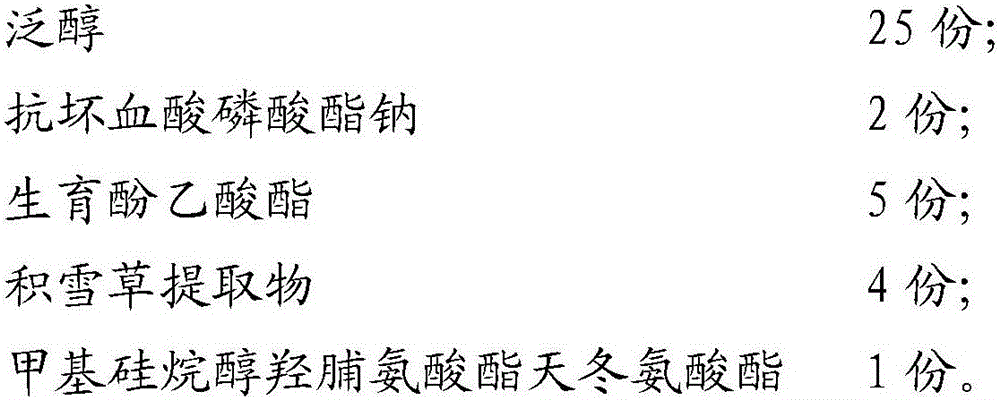

The invention relates to the field of skin care and in particular relates to a composition for preventing stretch marks, a stretch mark cream and the preparation method. The composition for preventing stretch marks, includes by weight the following constituents: panthenol 10-50 parts; ascorbic acid sodium phosphate 1-10 parts; tocopheryl acetate 1-10 parts; centella asiatica extract 1-10 parts; methylsilanol hydroxyproline ester aspartate 1-10 parts. The selected raw materials in the method are commonly used qualified cosmetic constituents, and do not contain chemical peeling agent and exfoliating ingredients, the safety is high; the formula composition is carefully designed for stretch marks and the repair, it keeps the skin elastic and soft, strengthens the skin elasticity; the composition penetrates deep into the skin, nourishes and repairs; it prevents the degeneration of elastic fibers, collagen fiber and proteoglycan, stimulates and regulates fibroblast cell division, helps the regeneration of epidermal and dermal cells, prevents stretch marks.

Owner:TIANJIN TIANSHI BIOLOGICAL DEV

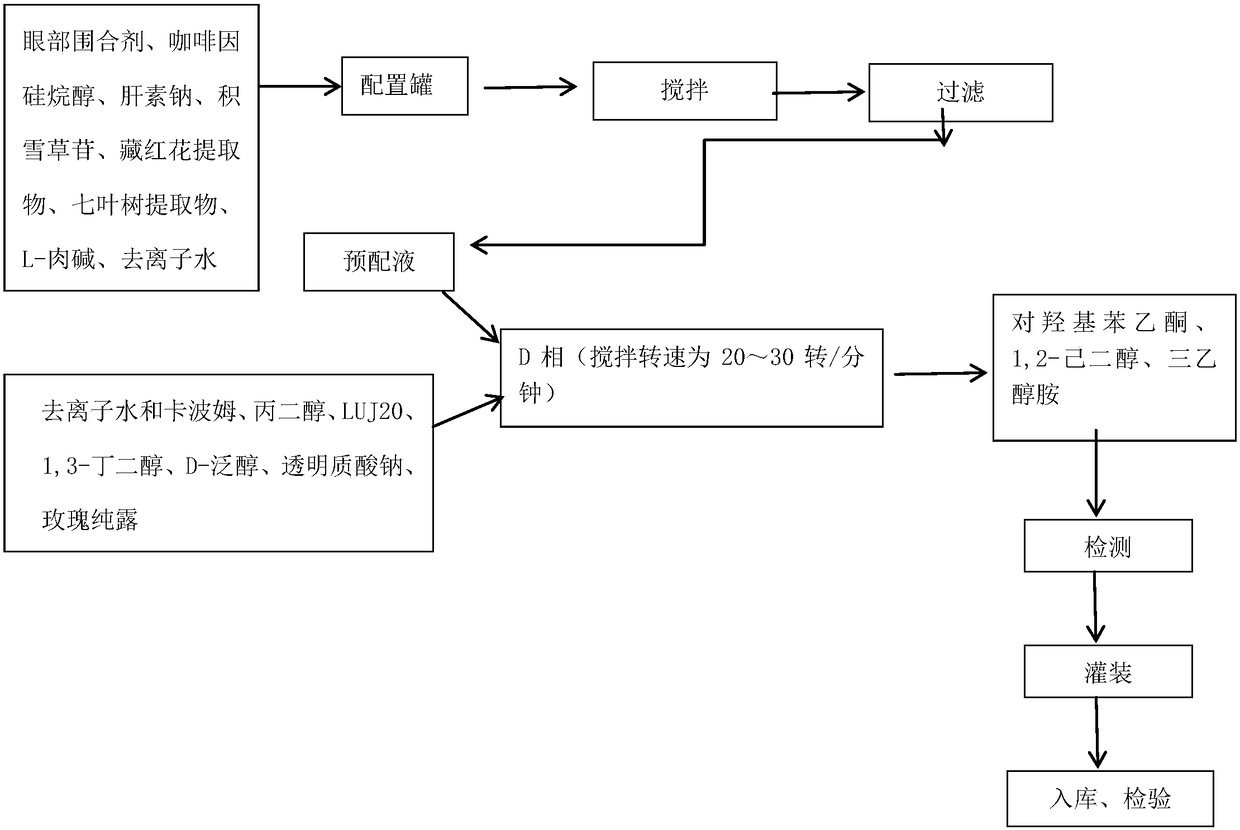

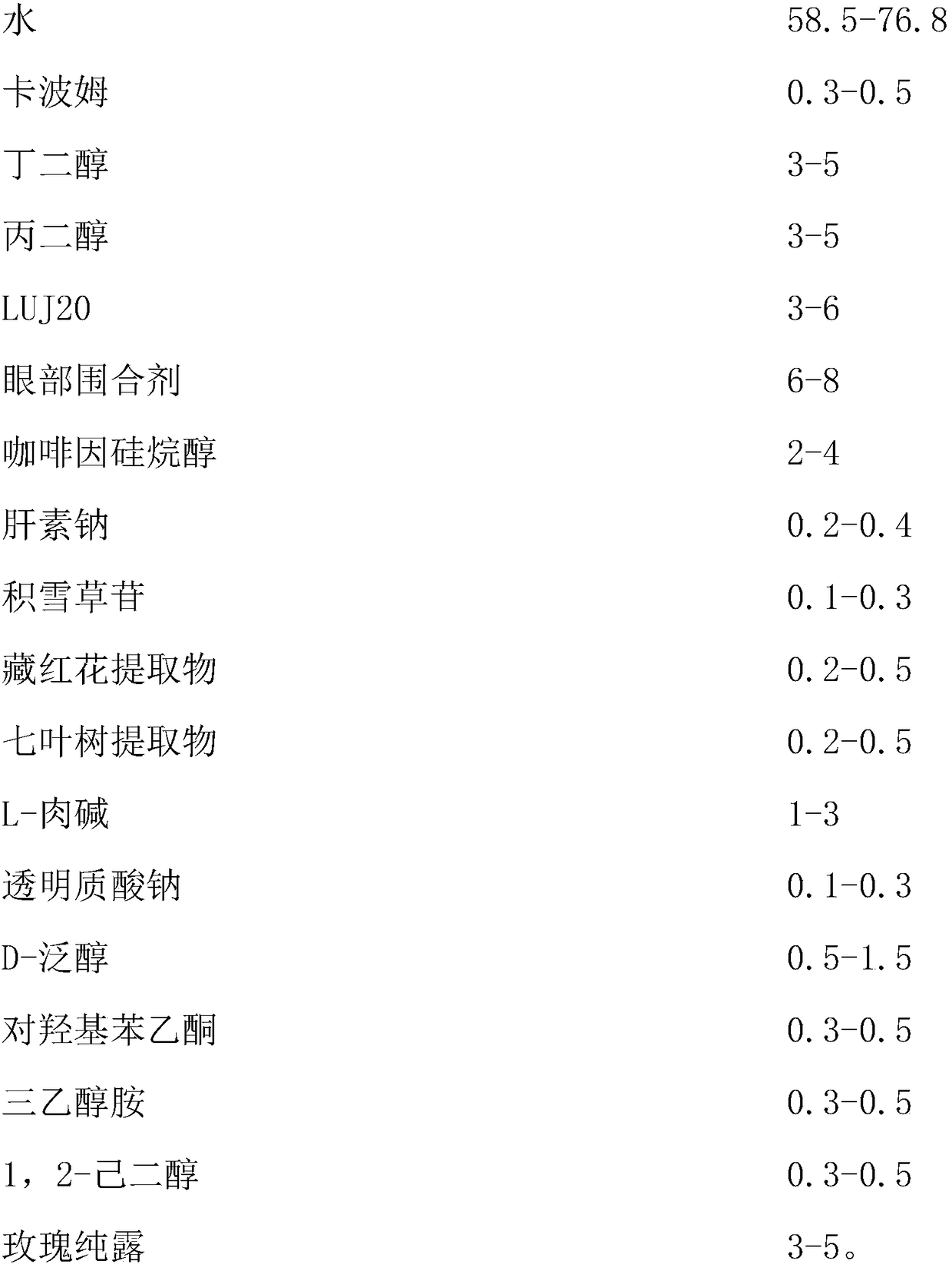

Compound eye-bag removal gel and preparation technology thereof

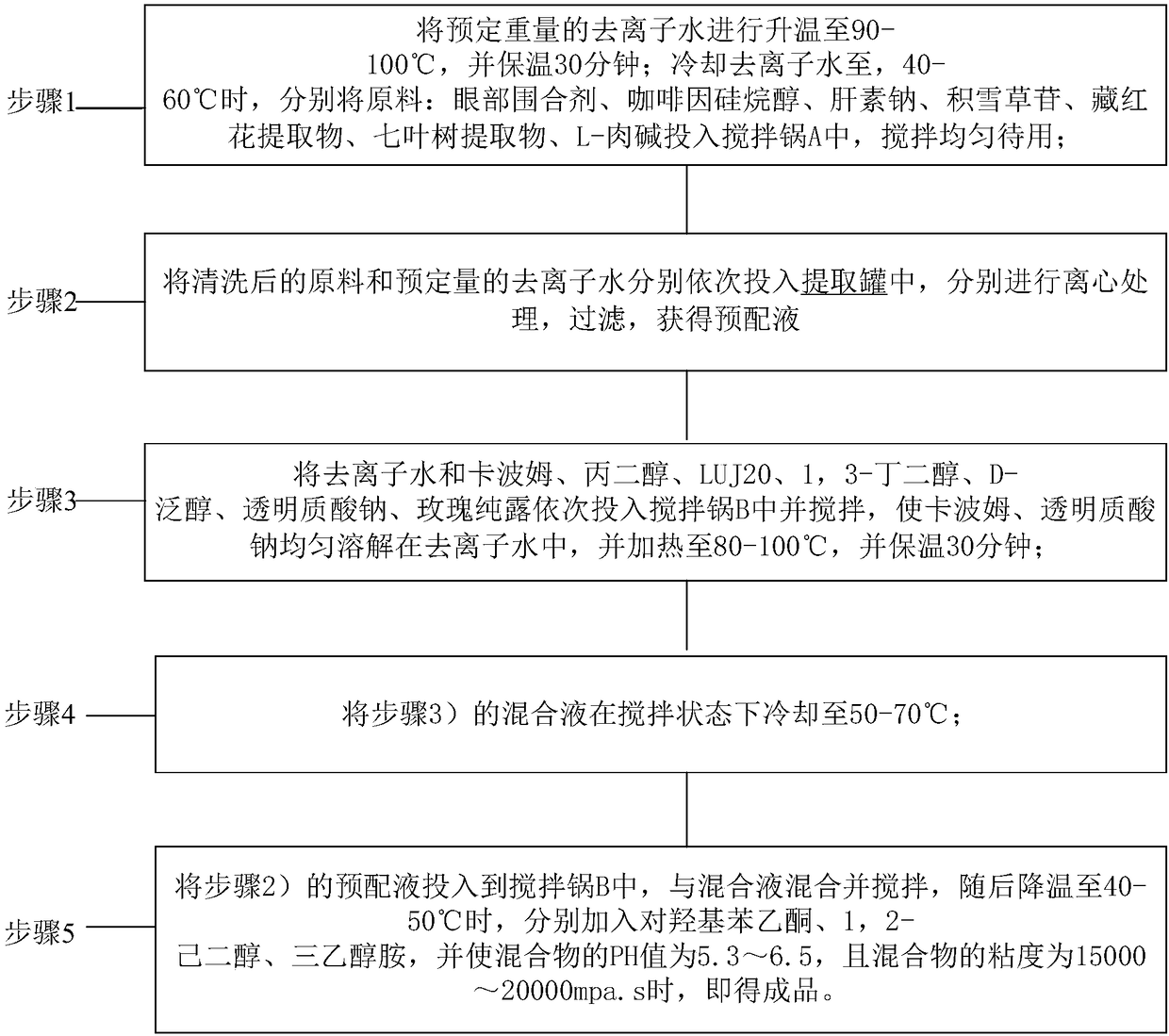

InactiveCN108261368ARelieve puffinessReduce accumulationCosmetic preparationsToilet preparationsHYDROSOLSodium hyaluronate

The invention discloses a compound eye-bag removal gel and a preparation technology thereof. The raw materials include: carbomer, butylene glycol, propylene glycol, LUJ20, an eye enclosure agent, caffeine silanol, heparin sodium, asiaticoside, a saffron extract, an aesculus chinensis extract, 1, 2-hexanediol, rose hydrosol, triethanolamine, p-hydroxyacetophenone, L-carnitine, sodium hyaluronate, and D-panthenol. The compound eye-bag removal gel can relieve periocular edema and fat accumulation, degrade fat, and ease eye-bag fat, and skin elastic fiber relaxation caused eye-bag and pigmentation, improve the compactness of eye skin, promote grease decomposition, and reach firming efficacy, has the effects of inhibiting collagen fiber, inhibiting proliferation of fibrous tissue, resisting oxidation and eliminating edema, can increase the skin finish and softness, can delay skin aging after frequent use, and has remarkable anti-aging efficacy.

Owner:广州重生化妆品实业有限公司

Method for preparing absorbable and antibacterial guided tissue regeneration membrane for bone-like structure

ActiveCN104436318AFunction as a biological barrierImprove biological activitySurgerySodium phosphatesPhosphorylation

The invention provides a method for preparing an absorbable and antibacterial guided tissue regeneration membrane for a bone-like structure, and belongs to the field of biological medical materials. The method comprises the following steps: firstly, preparing a cell free bovine pericardial collagen fiber membrane by adopting a repeated freeze-thaw method and a surface active agent TritonX-100, or preparing a demineralized cell free collagen fiber membrane of a cattle lamellar bone by using a method of EDTA decalcification by using the surfactant TritonX-100; treating by using sodium trimetaphosphate to obtain a phosphorylated collagen fiber membrane; with the assistance of a direct-current electric field, mineralizing in agar hydrogel containing calcium and phosphate, thereby obtaining a mineralized collagen membrane with a bone-like structure with certain hardness; and finally soaking the mineralized collagen membrane into a minocyline solution, and preparing an antibacterial bone-like structured composite membrane structure by virtue of the characteristics of combined minocyline and hydroxyapatite. The guided tissue regeneration membrane provided by the invention has a bone-like structure, is capable of maintaining a bone defect space, is good in operation forming property and antibacterial property, and can be applied to clinical practice for bone defect remediation and reconstruction in periodontal departments, dental implant mediation and occlusalf surfaces.

Owner:李柏霖 +1

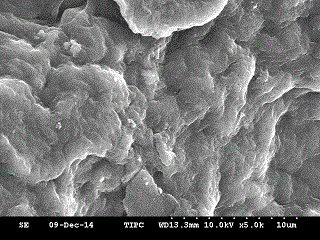

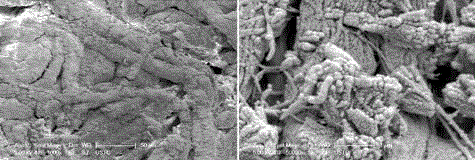

Fluffy type skin collagen hemostatic material and preparation method thereof

The invention discloses a preparation method of a fluffy type skin collagen hemostatic material. The preparation method is characterized by comprising the following steps: by taking medical purified pig dermis as a raw material, performing repeated alkaline swelling and acid swelling to ensure that the pigskin collagen fibers are moderately separated and loosened on the premise of keeping three-dimensional structures of pigskin collagen fibers unchangeable, and then performing processes such as carbodiimide modification, freeze drying, rewetting, mechanical fluffing and sterilization to finally prepare a cottony fluffy type skin collagen hemostatic material. According to the material disclosed by the invention, a three-dimensional reticular structure of natural pigskin collagen can be completely preserved; and compared with ordinary collagen materials, fluffy type skin collagen prepared by using the method disclosed by the invention has more excellent structure stability, mechanical performance and biodegradability, has good biological performance such as biocompatibility and low immunogenicity, also has the functions of promoting the healing and repair of wound surfaces, and can be applied to rapid and effective hemostasis in a wound repair process.

Owner:SICHUAN UNIV

Manufacturing method for high-strength calfskin for special purpose

ActiveCN105154594AHigh fullnessGood flexibilityTanning treatmentPre-tanning chemical treatmentTanninAldehyde formation

The invention provides a manufacturing method for high-strength calfskin for a special purpose. Calf wet blue which is evenly shaved through a conventional process is used as a raw material, the raw material is weighed, returned to water, degreased, retanned, neutralized, filled with grease and top-dyed, and then the raw material is sorted and coated according to the conventional process. In the retanning working procedure, tannin extract is used and combined with phthalidyl / peptide bonds on a polypeptide chain of skin collagen through hydrogen bonds, and therefore raw hide is changed into leather; fatty aldehyde is added in the retanning working procedure, carbonyl in the fatty aldehyde reacts with amidogen in skin collagen fiber, the skin collagen fiber is further fixed, and the defects existing in tannin extract tanning are overcome; and non-chrome retanning is performed, the fatty aldehyde is used for replacing a chrome tanning agent, and therefore chrome pollution is greatly reduced. The fatty aldehyde is added in the greasing working procedure, so that the fullness and the softness of the leather are improved, the alkali resistance and the laundering durability of the leather are improved, and the shrinkage temperature of the leather is increased. The tensile strength of the calfskin manufactured through the method is 19 N / mm<2> and the tearing strength is increased to 72 N / mm and the tensile strength and the tearing strength of the calfskin are increased by 26.7% and 10.77% compared with those of calfskin produced through an existing process.

Owner:JIHUA 3512 LEATHER & GARMENT

Strontium and iron doped hydroxyapatite collagen fiber composite scaffold material and preparation method thereof

ActiveCN105536072AHigh modulus of elasticityRetain biological propertiesIron compoundsProsthesisPhysical chemistryPharmaceutical drug

The invention discloses a strontium and iron doped hydroxyapatite collagen fiber composite scaffold material and a preparation method thereof. The scaffold material is prepared through compounding collagen fibers having a three dimensional connective porous structure with strontium and iron doped hydroxyapatite with a good drug therapy function. The preparation method mainly comprises the following steps: preparing strontium and iron doped hydroxyapatite through a co-precipitation technology; and compounding the collagen fibers through a dipping-pulling technology. The functional bone restoration scaffold material has excellent biologic performances, very good mechanical strength and toughness and a three dimensional connective macro-porous structure, can deliver drugs to a specific position under the induction of a magnetic field, can restore and treat bone defects induced by various bone diseases, and has wide application prospect in the field of bone restoration materials and biological drugs.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Method for treating slunk

ActiveCN102994657AEasy to handleImprove cleanlinessTanning treatmentPre-tanning chemical treatmentFiberSodium hydrosulfide

The invention provides a method for treating slunk. The method comprises the steps of: mainly soaking the slunk with water, coating, liming, deliming, softening, pickling and bating, wherein a coating liquor comprises the components of water, sodium sulfide, sodium hydrosulfide, a liming auxiliary agent and starch; and a liming liquor comprises the components of water, multielement mixed alkali, liming enzyme, sodium sulfide and a liming auxiliary agent. By adding the liming auxiliary agent and the starch in the coating process, the concentration of sodium sulfide is adjusted, the treatment effect on skin slunk grains can be enhanced, a smooth skin surface can be favorably obtained, and the cleanliness of the skin surface is increased; meanwhile, the multielement mixed alkali, in place of lime, can act together with the liming enzyme in the liming process, so that collagen fibers are favorably dispersed and fiber bundles are expanded. As lime is unnecessarily added to the coating and liming processes, the problems of high cost, serious pollution and equipment corrosion brought by lime can be avoided; and as the skin surface of the slunk is tender and susceptible, the problem of damage to the skin surface can be avoided due to no lime addition.

Owner:隆丰革乐美时尚有限公司

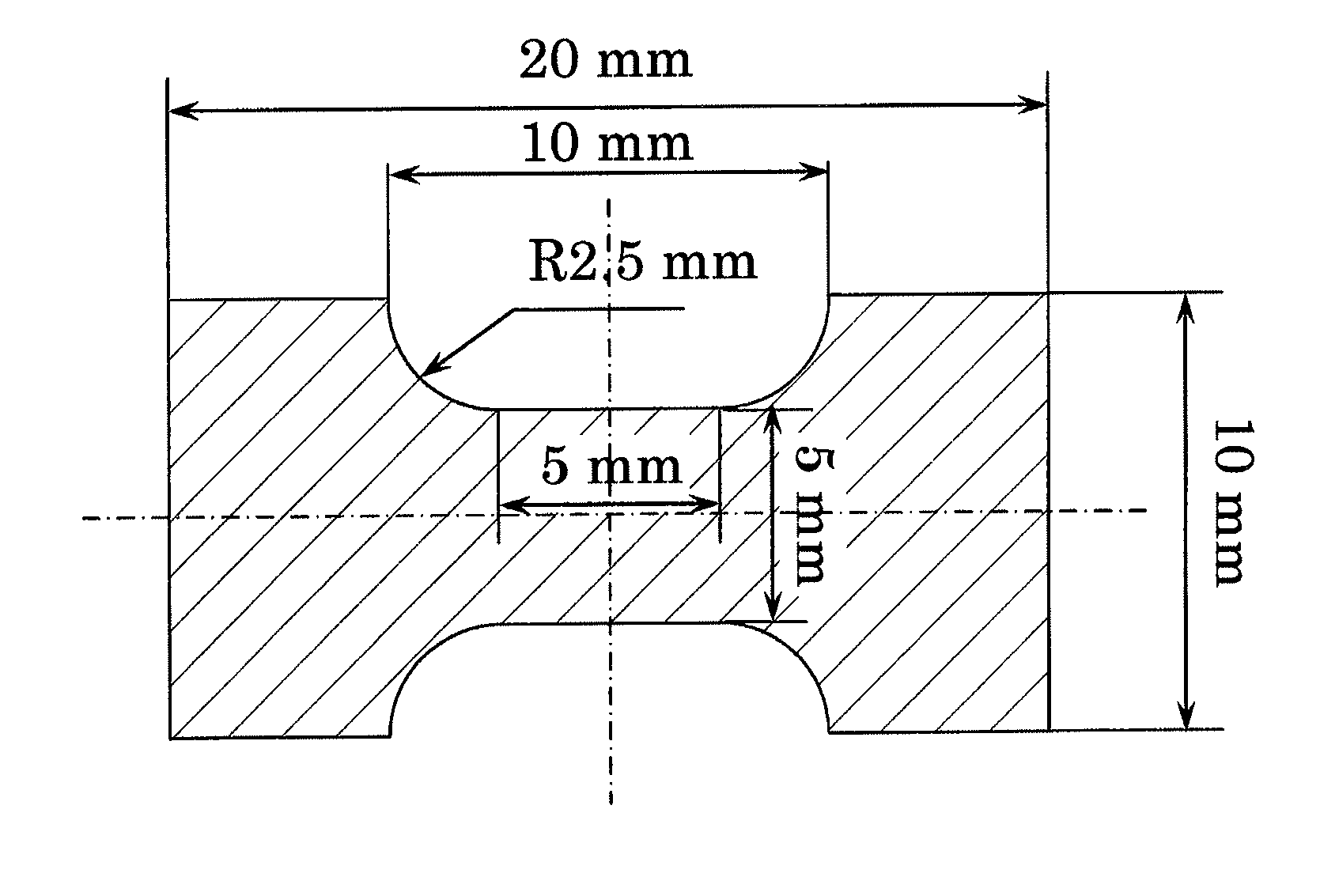

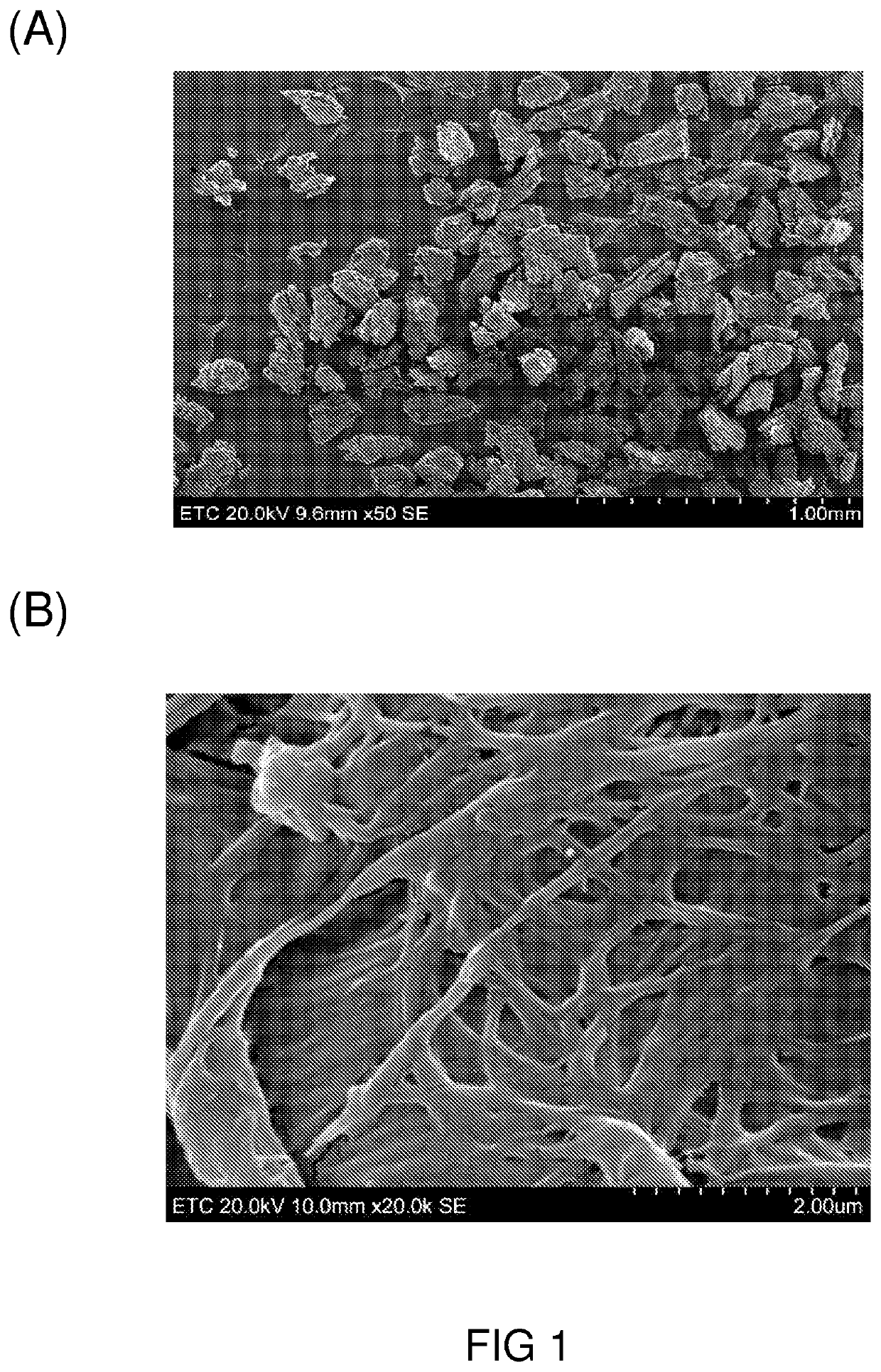

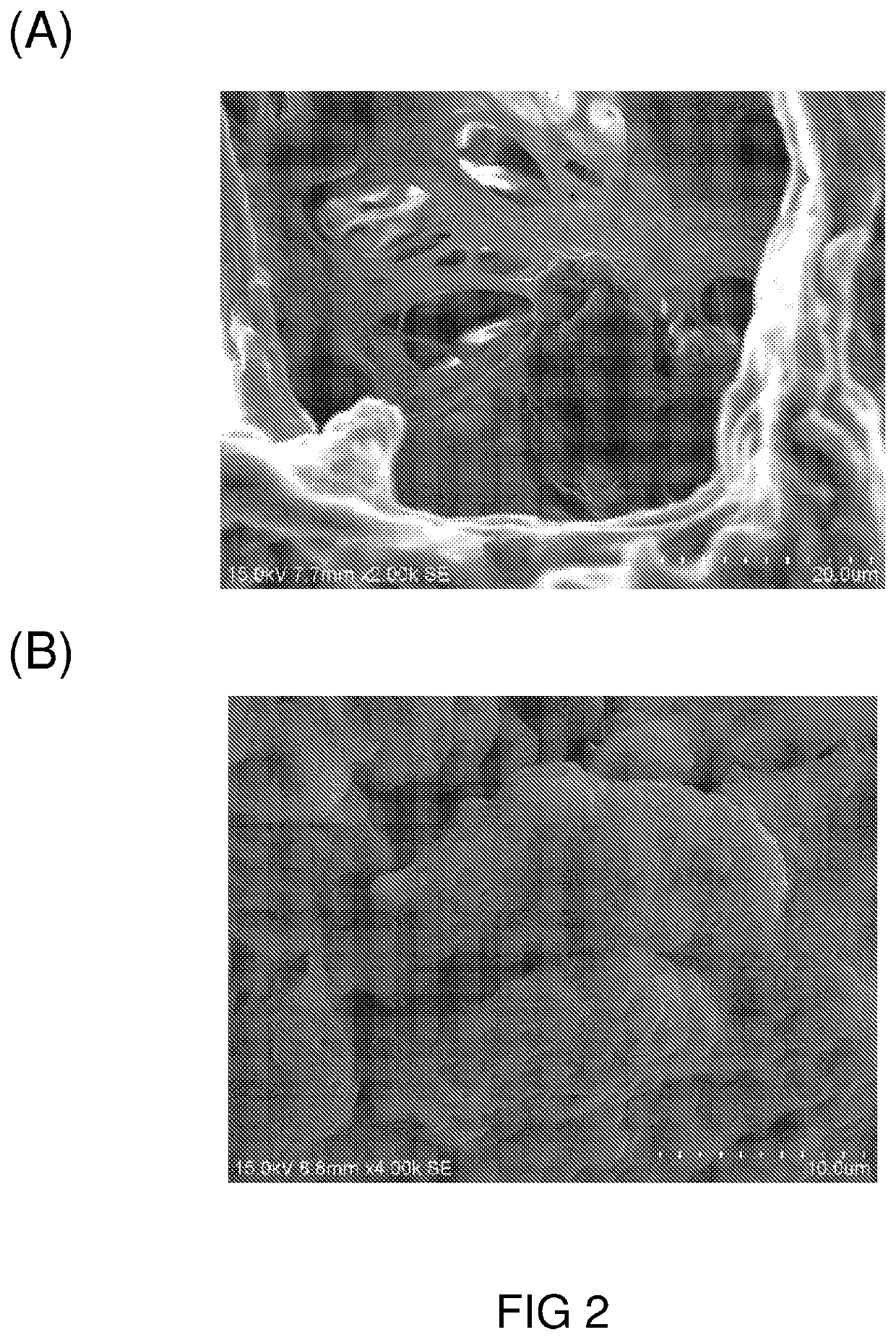

High-strength collagen fiber membrane and a manufacturing method thereof

InactiveUS20140044948A1Slow changeHigh tensile strengthPeptide/protein ingredientsSurgeryWound dressingCell culture media

The object of the present invention is to provide a collagen fiber membrane, which has sufficient strength and can be used as a cell culture substrate, a scaffold material for regenerative medicine (for example, material for tissue engineering of cartilage, bone, ligament, corneal stroma, skin, or liver), an implantation material (for example, wound dressing material, bone grafting material, hemostatic material, anti-adhesive material) or a carrier for drug delivery. The object of the present invention can be solved by a fish-derived collagen fiber membrane, characterized in that (1) a tensile strength is 30 MPa or more, (2) a density determined by the gravimetric method, is 0.4 g / cm3 or more, and (3) an average membrane thickness is 1 μm to 2 mm, and a variation in membrane thickness is plus or minus 30%, relative to the average membrane thickness.

Owner:TOKYO INST OF TECH

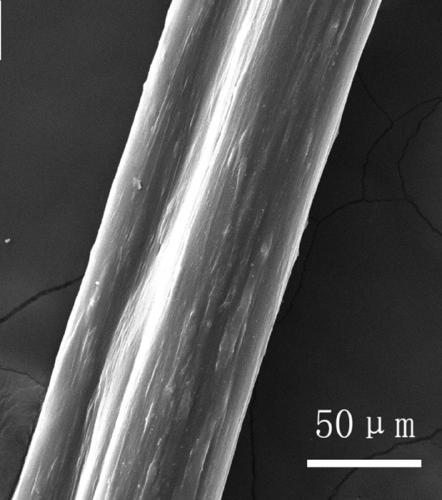

Method for preparing collagen fiber through wet spinning

PendingCN111501121AIncrease contentGood biocompatibilityMonocomponent protein artificial filamentAnimal fibresFiberHigh concentration

The invention relates to a method for preparing collagen fiber through wet spinning. Firstly, I type collagen is dissolved in a NaAc / HAc buffering solution with the pH being 3.0 at the room temperature, a high-concentration collagen content collagen solution is obtained, vacuum pumping defoaming treatment is conducted, absolute ethyl alcohol is adopted as a coagulating bath, high-content collagenfiber is prepared through a wet spinning manner, the fiber is subjected to green crosslinking treatment, and the collagen fiber good in performance is obtained. Compared with the prior art, the NaAc / HAc buffering solution is adopted as the collagen green solvent, and the content of the collagen in the fiber is greatly increased; the absolute ethyl alcohol which is the coagulating bath not commonlyused in collagen wet spinning is adopted to prepare the collagen fiber, and ethyl alcohol is volatile and free of toxicity. The whole preparing method is moderate in condition and green in technologyand is simple and convenient to conduct. The prepared collagen fiber has good biocompatibility and excellent mechanical performance, meanwhile, the purpose that the degrading rate can be regulated and controlled can be achieved, and a new path is provided for collagen-based medical composite fiber preparing and application.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

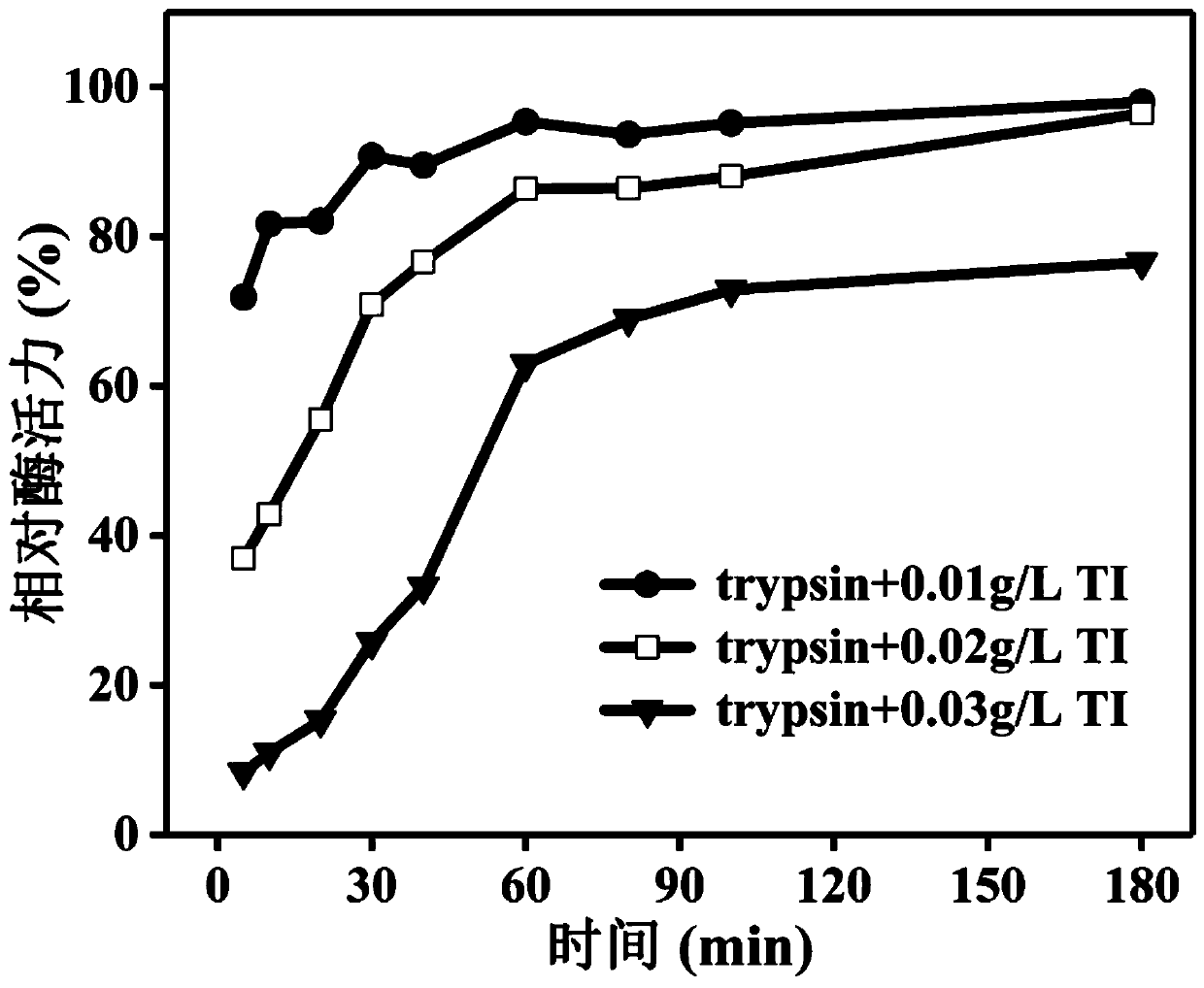

Method for regulating catalytic activity of protease in tanning process

ActiveCN110643754AShorten the timeReduce intensityPre-tanning chemical treatmentProtease preparationEngineering

The invention discloses a method for regulating the catalytic activity of protease in a tanning process. A protease reversible inhibitor and an existing protease preparation are applied to a water soaking, depilating or softening process together to achieve the purpose of firstly inhibiting and then recovering the activity of the protease. The method can reduce the rate of the initial catalytic hydrolysis reaction of the protease in the tanning process, so after the protease permeates into skins, skin proteins are hydrolyzed, the action time and strength of the protease on collagen fibers on the skin surface layer are reduced, the uniformity of the hydrolysis effect of the protease on collagen fibers in every layer in the skins is improved, and the technical problems of easy damages to theskin collagen fibers and reduction of a leather product of a tanning biotechnology based on the effect of the protease are solve. The provided protease reversible inhibitor is selected from proteins,and is an environmentally-friendly assistant.

Owner:SICHUAN UNIV

Preparation of high purity collagen particles and uses thereof

ActiveUS20200040030A1Connective tissue peptidesPharmaceutical delivery mechanismCollagenanBiochemistry

Owner:ACRO BIOMEDICAL CO LTD

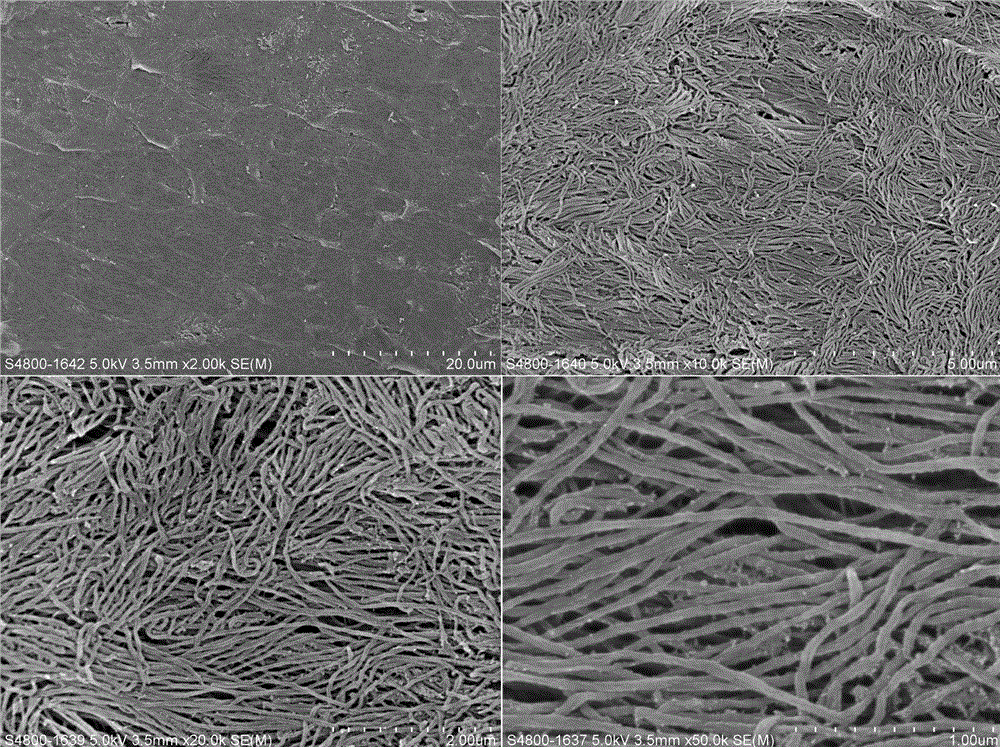

Collagen implant and preparation method thereof

ActiveCN113768815ACompact structureStrong and stable structureCosmetic preparationsConnective tissue peptidesFiberEnzyme digestion

The invention provides a collagen implant and a preparation method thereof, and relates to the field of beauty. The collagen implant comprises the following components: collagen fibers and a phosphate buffer solution with the pH value of 7. The invention also provides a preparation method of the collagen fibers, the collagen molecules obtained by adopting the method provided by the invention have a fiber structure with a clear shape after self-aggregation, each fiber is completely exposed and mutually staggered to form a fiber web, and meanwhile, the periodic cross grain D band of the collagen fiber can be clearly observed, and a better fiber form can be formed, and the molecular regularity is higher; the collagen fibers are uniform in thickness and have better elastic strength; besides, the collagen implant is the first material source which is prepared from achilles tendon collagen and can be safely traced to the source through a block chain in the whole world, a virus inactivation pretreatment technology and a precise enzyme digestion telopeptide removal technology are adopted, potential allergy risks can be completely removed, and the prepared implant has a more natural shaping filling effect and a long in-vivo degradation period.

Owner:浙江崇山生物制品有限公司

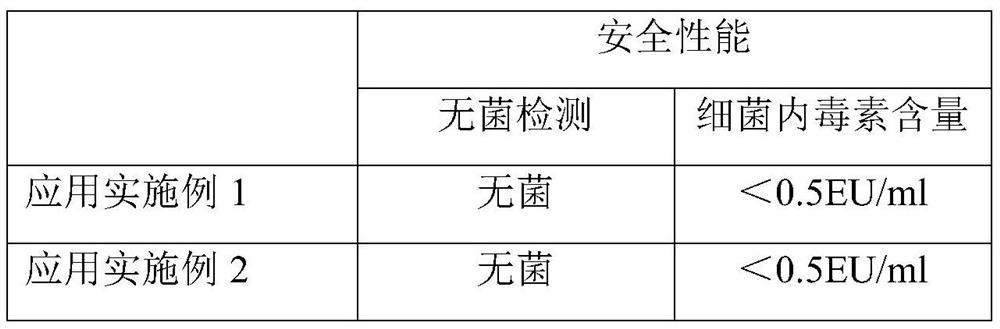

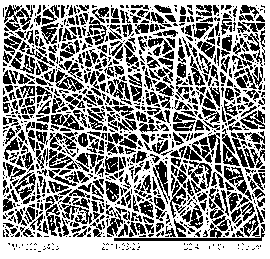

Antimicrobial haemostatic dressing and production method thereof

InactiveCN103301503AEasy to operateLow costMonocomponent protein artificial filamentAbsorbent padsSpinningElectrospinning

The invention relates to an antibacterial haemostatic dressing and a production method thereof. The production method comprises the following steps: dissolving collagen in a solvent and preparing collagen fibers through electrostatic spinning and glutaraldehyde vapor cross-linking; then soaking the collagen fibers in an Ag4O4 ammonia solution or spraying the Ag4O4 ammonia solution onto the collagen fibers; and drying the solvent to obtain the antibacterial haemostatic dressing. The antimicrobial haemostatic dressing produced in the invention has the following advantages: thickness of the collagen fibers are uniform, and a good antibacterial effect is obtained.

Owner:SHANGHAI SIXTH PEOPLES HOSPITAL +1

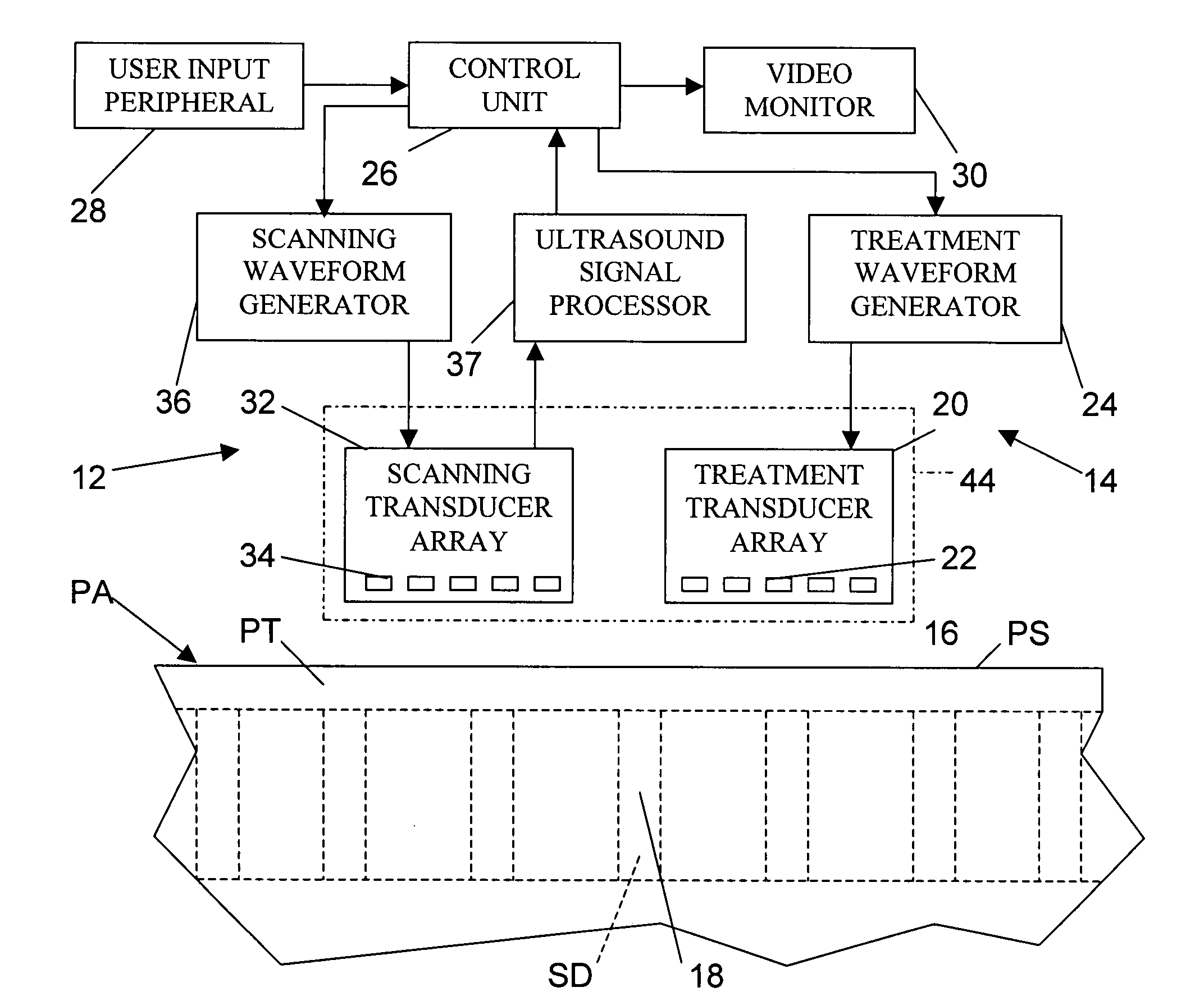

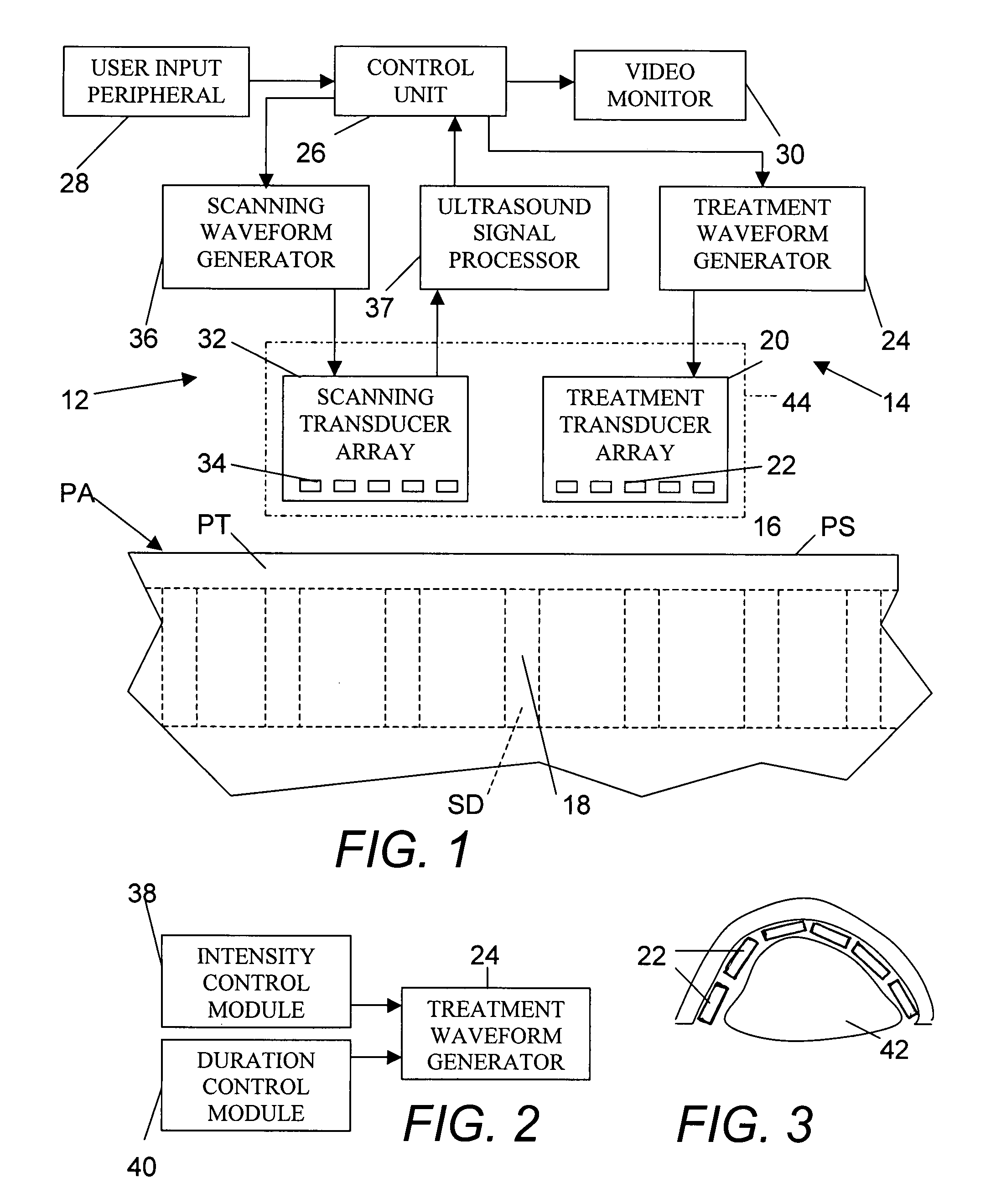

Spinal treatment method and associated apparatus

InactiveUS20080243036A1The right amountUltrasonic/sonic/infrasonic diagnosticsUltrasound therapySpinal columnIntervertebral disc

Spinal pain is treated non-invasively by operating a scanning apparatus to locate a spinal disc afflicted with cracks or fissures, and applying waveform energy to the afflicted spinal disc to heat the spinal disc sufficiently to modify collagen fibers of the spinal disc and destroy pain receptors in the spinal disc. The scanning apparatus may be an ultrasound scanner, while the treatment waveform energy may be ultrasonic waveform energy. The applying of the waveform energy includes generating ultrasonic pressure waves in the spinal disc.

Owner:US HIFU

Three-dimensional mineralized collagen scaffold material and bone regeneration application thereof

InactiveCN108926743APromote regenerationPromote growthPharmaceutical delivery mechanismTissue regenerationFiberCollagen scaffold

The invention discloses a three-dimensional mineralized collagen scaffold material and a bone regeneration application thereof. A method for preparing the three-dimensional mineralized collagen scaffold material having a strict grade structure by binary assembling comprises the following steps: preparing nano-hydroxyapatite; performing dialysis in the collagen mineralization process to make the nano-hydroxyapatite slowly enter and be deposited on the surface of collagen fibers; and controlling various parameters in vitro to complete the simulation of natural bone mineralized collagen fibers. The three-dimensional mineralized collagen scaffold prepared by completely duplicating chemical components and periodic grade structure of natural bones has a proper mechanical strength, and can recruit host cells to realize osteogenic differentiation. The three-dimensional mineralized collagen scaffold material having the strict grade structure has excellent angiogenesis ability, and can be individually used to realize bone defect repair in in vivo animal test without adding any biological preparation, such osteogenic factors or recombinant proteins.

Owner:北京恒泽博泰生物科技有限公司

Sheep leather acid swelling treatment method

ActiveCN103060489AThe overall thickness is thinSoft touchPre-tanning chemical treatmentFiberMuscle tissue

The invention discloses a sheep leather acid swelling treatment method. The method comprises a step of acid swelling and a step of de-swelling, wherein the acid swelling is carried out in an acidic swelling liquid, and the swelling is uniform and appropriate without hair dropping or excess leather loss; and the de-swelling is carried out in a de-swelling liquid, the de-swelling effect is very good, and a state before swelling can be completely recovered. Collagen fibers can be effectively loosened and elastic fibers and muscle tissues are digested to a certain degree through the acid swelling treatment. Compared with fur prepared through routine methods, fur prepared through the method disclosed in the invention has the advantages of obviously improved softness and fullness, elasticity, nearly 3-time improvement of the tensile strength, 20% reduction of the unit mass, obviously improved shrinkage temperature, and elimination of the sheep fur layering phenomenon. All the performance indexes of finished sheep fur accord with the Light Industry Standard of the PRC (QB / T1280-1991), and the finished sheep fur also has the characteristics of thinness, lightness, and softness.

Owner:SICHUAN UNIV +1

Emulsion capable of removing acne

InactiveCN106511218AIncrease elasticitySignificant anti-acne effectCosmetic preparationsToilet preparationsBletilla striataToxic material

The invention discloses an emulsion which contains bletilla striata root extract and is capable of removing acne. The emulsion comprises natural plant components such as the bletilla striata root extract, radix scutellariae extract and mentha haplocalyx extract. The emulsion has the advantages that the three components are complementarily and scientifically compounded to achieve effects such as clearing away heat and toxic materials, regulating skin grease balance, inhibiting bacteria and diminishing inflammation, eliminating free radicals, nourishing the skin, supplementing skin collagen and increasing skin elasticity, and the emulsion is evident in acne removing effect and has effects of whitening and resisting oxidation; the emulsion contains the bletilla striata root extract capable of repairing skin functions, is capable of promoting the synthesizing of wound surface cell DNA, increasing cell proliferation ability, providing nutrition for cell proliferation and increasing skin collagen fibers and is helpful to the repairing of damaged skin caused by the acne.

Owner:聚吉减肥塑形科学技术研究院(广州)有限公司

Use of collagen binding domains to deliver products to skin

PendingUS20210338558A1Improve bioavailabilityMinimize side effectsPolypeptide with localisation/targeting motifCosmetic preparationsSide effectCollagenan

The present invention addresses the need for an improved delivery system that is able to specifically target the skin for improved bioavailability and minimization of side effects resulting from administration of the active ingredient or ingredients. One aspect of the present invention is a targeting composition comprising: (1) a skin care agent or an agent that is a cosmeceutical agent; (2) an intermediate release linker bound to the skin care agent or cosmeceutical agent; (3) a targeting moiety bound to the intermediate release linker, the targeting moiety for binding the targeting composition to native collagen fibers; and (4) optionally, a carrier component to enhance delivery to the skin. The present invention also describes methods of use of these targeting compositions.

Owner:FABIUS BIOTECH

Medical suture and preparation method thereof

InactiveCN105963763ASimple preparation processPromote absorptionSuture equipmentsBiocompatibilitySaccharin

The invention relates to a medical suture and a preparation method thereof. The medical suture consists of the following ingredients in parts by mass: 35-55 parts of polyglycollide, 3-16 parts of chitin, 2-13 parts of collagen fibers, 1-8 parts of pigskin collagen, 0.5-4.5 parts of sodium alginate, 0.3-1.5 parts of glucose, 0.5-2.5parts of anisaldehyde, 0.1-0.4 parts of sodium polyacrylate, 0.1-0.4 parts of saccharin, 0.2-0.8 parts of nano cellulose, 0.1-0.5 parts of vinyl silicon oil, 0.1-0.4 parts of polytetrafluoroethylene and 0.1-0.4 parts of glutaraldehyde. The medical suture provided by the invention is excellent in degradation and absorption properties as well as biocompatibility; meanwhile, the medical suture can develop a bacteriostatic effect for a long time; and the medical suture, after being used for stitching wound, is free from the generation of inflammations and is not easy to cause scars.

Owner:SUZHOU COSMETIC MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com