Mineralized collagen artificial periosteum and preparation method thereof

A technology for mineralizing collagen and artificial bone, applied in medical science, prosthesis, etc., can solve the problems of unfavorable bone defect healing, high immunogenicity, and fast degradation rate, and achieves beneficial repair, high bionic, broad The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1, Preparation of 30 mm × 25 mm × 0.25 mm artificial periosteum

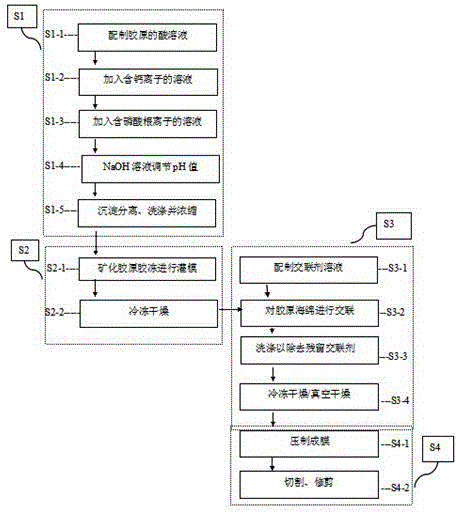

[0044] figure 1 Shown is the flow chart of the preparation method of the mineralized collagen artificial periosteum of the present invention. according to figure 1 As shown in the steps, the preparation steps of mineralized collagen artificial periosteum with a length of 30 mm, a width of 25 mm, and a thickness of 0.25 mm are as follows:

[0045] Step S1-1, dissolving 1 g of collagen in 2 L of 0.5 mol / L acetic acid solution to prepare a collagen acid solution;

[0046] Step S1-2, keep stirring the solution obtained in Step S1-1, slowly add 30 mL of CaCl with a concentration of 0.2 mol / L dropwise 2 solution;

[0047] Step S1-3, continue to stir the solution obtained in step S1-2, and slowly add 30 mL of Na with a concentration of 0.12 mol / L dropwise 2 HPO 4 solution;

[0048] Step S1-4, continuously stirring the solution obtained in step S1-3, slowly adding 0.5 mol / L NaOH solution dropwise...

Embodiment 2

[0062] Example 2, Preparation of 50 mm × 20 mm × 0.4 mm artificial periosteum

[0063] according to figure 1 The steps shown, the preparation steps of mineralized collagen artificial periosteum with a length of 50 mm, a width of 20 mm, and a thickness of 0.4 mm are as follows:

[0064] Step S1-1, dissolving 1 g of collagen in 1 L of acetic acid solution with a concentration of 1 mol / L to prepare an acid solution of collagen;

[0065] Step S1-2, keep stirring the solution obtained in Step S1-1, slowly add 100 mL of CaCl with a concentration of 0.05 mol / L dropwise 2 solution;

[0066] Step S1-3, continue to stir the solution obtained in step S1-2, slowly add 100 mL of Na with a concentration of 0.03 mol / L dropwise 2 HPO 4 solution;

[0067] Step S1-4, continuously stirring the solution obtained in step S1-3, slowly adding 0.5 mol / L NaOH solution dropwise until the pH of the mixed system = 7;

[0068] Step S1-5, let the mixed system obtained in step S1-4 stand for 60 hour...

Embodiment 3

[0078] Example 3, Preparation of 30 mm × 20 mm × 0.2 mm artificial periosteum

[0079] according to figure 1 The steps shown, the preparation steps of mineralized collagen artificial periosteum with a length of 30 mm, a width of 20 mm, and a thickness of 0.2 mm are as follows:

[0080] Step S1-1, dissolving 2 g of collagen in 5 L of acetic acid solution with a concentration of 0.25 mol / L to prepare a collagen acid solution;

[0081] Step S1-2, keep stirring the solution obtained in Step S1-1, slowly add 50 mL of CaCl with a concentration of 0.15 mol / L dropwise 2 solution;

[0082] Step S1-3, continue to stir the solution obtained in step S1-2, and slowly add 50 mL of Na with a concentration of 0.1 mol / L dropwise 2 HPO 4 solution;

[0083] Step S1-4, continuously stirring the solution obtained in step S1-3, slowly adding 0.5 mol / L NaOH solution dropwise until the pH of the mixed system = 7;

[0084] Step S1-5. Let the mixed system obtained in step S1-4 stand for 72 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com