Method for preparing collagen fiber through wet spinning

A wet spinning and collagen fiber technology, which is applied in the field of biomedical material preparation, can solve the problems of high dissolution temperature, collagen denaturation, ionic liquid toxicity, etc., and achieves the effects of mild conditions, controllable size and green process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

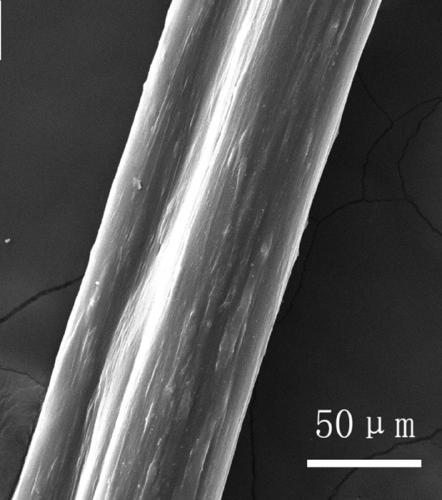

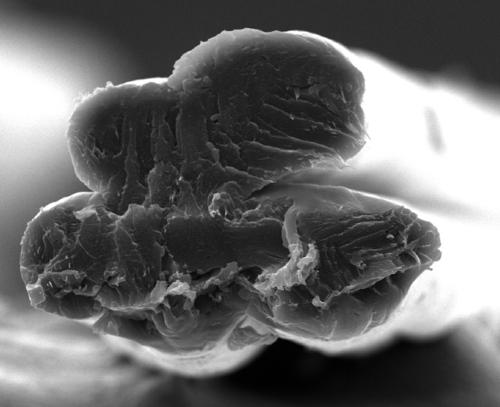

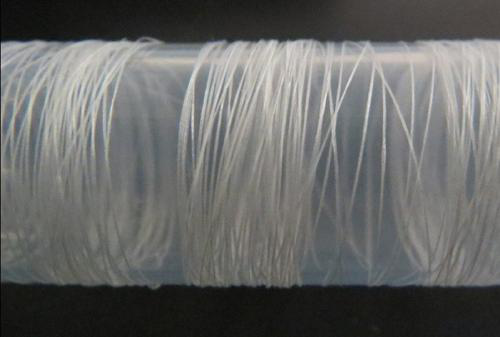

Image

Examples

Embodiment 1

[0027] A method for preparing collagen fibers by wet spinning, comprising the following steps:

[0028] (1) Dissolving type I collagen in NaAc / HAc buffer solution and stirring continuously at room temperature until type I collagen is completely dissolved to obtain a collagen solution;

[0029] (2) Vacuumizing and defoaming the collagen solution to obtain a collagen spinning solution;

[0030] (3) Wet spinning the collagen spinning solution, and after the fibers obtained by wet spinning are fully shaped, they are stretched and wound to obtain collagen fibers;

[0031] (4) After the above-mentioned collagen fibers are dried at room temperature, the cross-linking treatment is performed, and the above-mentioned cross-linked fibers are dried at room temperature to obtain the finished collagen fibers.

[0032] The coagulation bath used in the wet spinning process in the step (3) is absolute ethanol.

[0033] The cross-linking agent used in the step (4) cross-linking treatment is g...

Embodiment 2

[0041] A method for preparing collagen fibers by wet spinning, comprising the following steps:

[0042] (1) Dissolve type I collagen in NaAc / HAc buffer solution with a pH of 3.0, soak overnight and then stir in a water bath at 25°C until completely dissolved to obtain a collagen solution, in which the concentration of type I collagen is 100mg / mL;

[0043] (2) Filtrating and vacuuming the above-mentioned collagen spinning solution to obtain the collagen spinning solution;

[0044] (3) Add the defoamed collagen spinning solution into the wet spinning experimental device, push the spinning solution out of the needle at a speed of 5mL / h through a syringe pump, and enter it into the coagulation bath with absolute ethanol as the coagulation agent. In the coagulation bath, the fibers obtained by the wet spinning process were fully shaped and then stretched and wound to obtain collagen fibers; wherein, the inner diameter of the syringe needle was 0.08mm, and the spinning temperature w...

Embodiment 3

[0048] A method for preparing collagen fibers by wet spinning, comprising the following steps:

[0049] (1) Dissolve type I collagen in NaAc / HAc buffer solution with a pH of 2.8, and stir in a water bath at room temperature until completely dissolved to obtain a collagen solution, in which the concentration of type I collagen is 50 mg / mL;

[0050] (2) Filtrating and vacuuming the above-mentioned collagen spinning solution to obtain the collagen spinning solution;

[0051](3) Add the defoamed collagen spinning solution into the wet spinning experimental device, push the spinning solution out of the needle at a speed of 5mL / h through a syringe pump, and enter it into the coagulation bath with absolute ethanol as the coagulation agent. In the coagulation bath, the fibers obtained by the wet spinning process were fully shaped and then stretched and wound to obtain collagen fibers; wherein, the inner diameter of the syringe needle was 0.08mm, and the spinning temperature was 25°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com