Method for preparing absorbable and antibacterial guided tissue regeneration membrane for bone-like structure

A technology that guides tissue regeneration and manufacturing methods, applied in the field of biomedical materials, can solve the problems of no antibacterial properties, insufficient osteoinductive activity, poor mechanical properties and unable to maintain bone defect space, etc., to achieve convenient molding and operation, and facilitate bone repair space , the effect of inhibiting bone resorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

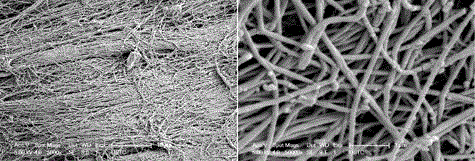

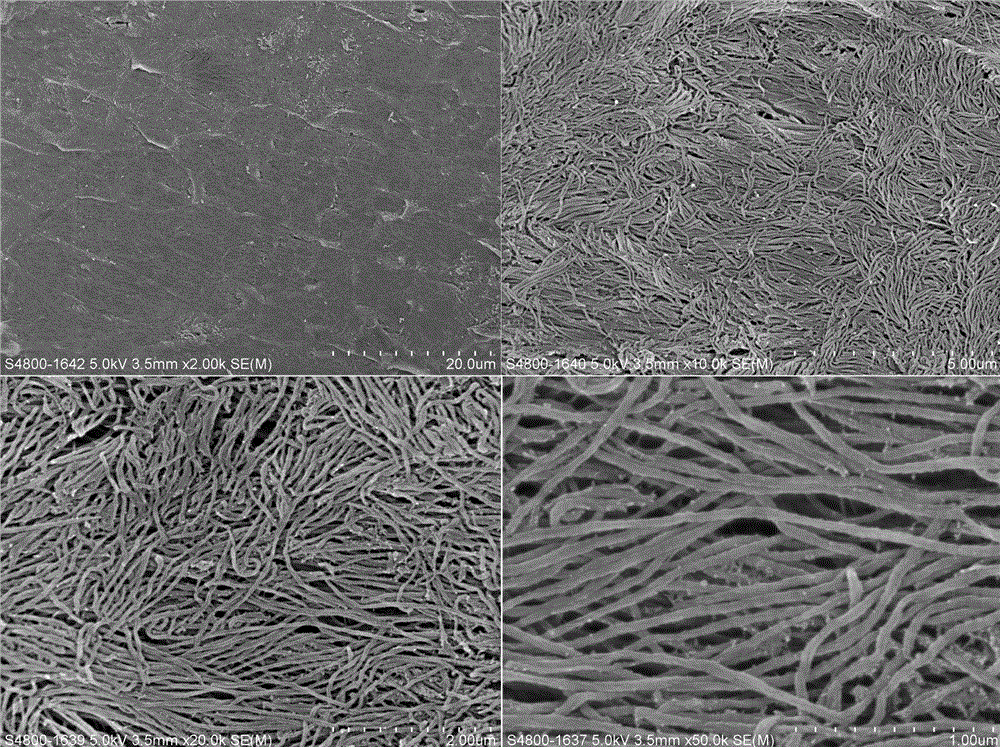

[0030] Example 1: Preparation of Decellularized Bovine Pericardium Collagen Fibrous Tissue Regeneration Guiding Membrane with Mineralized Osteoid Structure

[0031] A: Obtain fresh bovine pericardium, select a uniform anterior wall, remove fat tissue, wash with PBS buffer three times, and store in liquid nitrogen for later use;

[0032] B: Soak bovine pericardium trimmed to a certain size with PBS buffer, then place it in a -20°C refrigerator for 4 hours, and finally place it in a 37°C water bath for 30 minutes, then sonicate for 2 minutes, and freeze and thaw repeatedly 3 times;

[0033] C: Rinse the pericardium treated in step B with 100ml PBS solution for 24 hours, change the solution every 6 hours during this period, and shake it in a low-temperature shaker at 4°C;

[0034] D: Immerse the pericardium treated in step C in 0.25% TritonX-100 PBS solution, shake at 37°C for 24 hours, and sonicate for 2 minutes during the process;

[0035] E: The pericardium treated in step ...

Embodiment 2

[0042] Example 2: Preparation of decellularized bovine bovine pericardium collagen fibrous tissue regeneration guiding membrane with antibacterial mineralized bone-like structure

[0043] A: Obtain fresh bovine pericardium, select a uniform anterior wall, remove fat tissue, wash with PBS buffer three times, and store in liquid nitrogen for later use;

[0044] B: Soak bovine pericardium trimmed to a certain size with PBS buffer, then place it in a -20°C refrigerator for 4 hours, and finally place it in a 37°C water bath for 30 minutes, then sonicate for 2 minutes, and freeze and thaw repeatedly 3 times;

[0045] C: Rinse the pericardium treated in step B with 100ml PBS solution for 24 hours, change the solution every 6 hours during this period, and shake it in a low-temperature shaker at 4°C;

[0046] D: Immerse the pericardium treated in step C in 0.25% TritonX-100 PBS solution, shake at 37°C for 24 hours, and sonicate for 2 minutes during the process;

[0047] E: Rinse the...

Embodiment 3

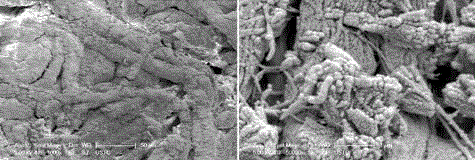

[0055] Example 3: Preparation of decellularized and demineralized bovine lamellar collagen fibrous tissue regeneration guiding membrane with mineralized bone-like structure

[0056] A: Obtain the tubular bones of fresh bovine limbs, remove the periosteum and other soft tissues, saw them into a certain size and shape under cooling conditions, remove the obvious bone marrow tissue, and store them in liquid nitrogen for later use;

[0057] B: Put a certain size of bone into 200mL of 0.5 M EDTA (pH 8.0) and 0.25% TritonX-100 mixed solution, decalcify for about 1 week under constant stirring at room temperature, until the bone becomes soft and can be easily pierced with a pin enter. The solution was changed once a day;

[0058] C: The demineralized bone slices treated in B were frozen in a -20°C refrigerator, and then cut into membranes about 200 μm thick with a frozen tissue slicer;

[0059] D: Immerse the demineralized bone treated in step C in PBS solution of 0.25% TritonX-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com