Lightweight high-strength heat-insulation moisture-proof composite paper board

A high-strength, light-weight technology, applied in the direction of paper/cardboard layered products, synthetic resin layered products, packaging items, etc., can solve the problems of heavy weight and large volume, and achieve good cushioning properties and excellent barrier effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

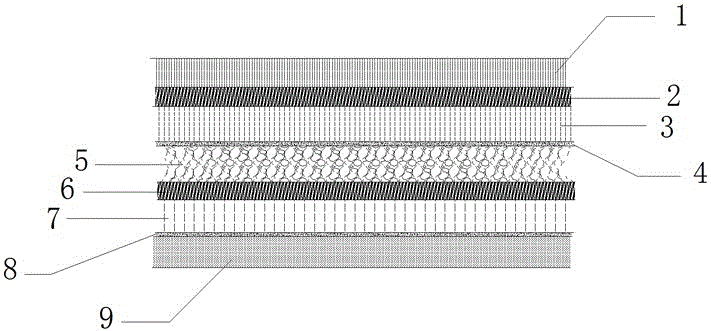

[0030] Reference figure 1, A light -quality high -intensity heat -heat insulation composite cardboard, which is compounded by multi -layer, includes elastic polystumin anti -rushing plates on the surface in turn 1. Anti -rushing fiber layer I2, honeycomb paper core 3 and bottom layer paper I4, environmental foam buffer buffer bufferLayer 5. Anti -rushing fiber layer II6, corrugated paper core 7 and bottom layer paper II8 and the bottom layer of polymapilic acid strength board 9.

[0031] The elastic polystumin anti -rushing plate 1 is the main raw material with polylactic acid, plant fiber, polycophactone, thermoplastic elastic body, and add a small amount of foam, compatible agent, plasticizer, waterproofing agent, antioxidant mixedAfter squeezing out the foaming.In the raw materials, the mass score of polymapilic acid is 45%, the mass score of plant fibers is 10%, the mass score of polycolins is 25%, and the mass score of the thermoplastic elastic body is 20%.

[0032] The mass ...

Embodiment 2

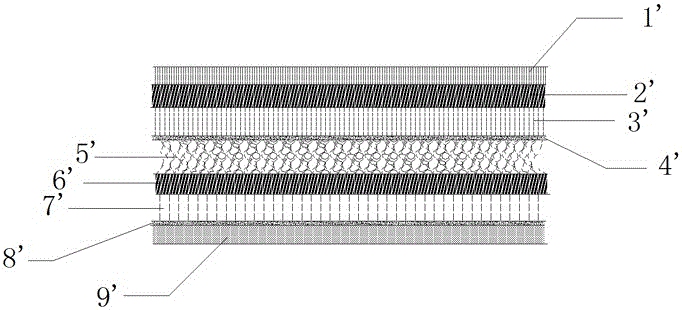

[0049] Reference figure 2 ., A light -quality high -intensity heat thermal insulation composite cardboard, which is compounded by multi -layer, includes the elastic polystraphic acid anti -rushing plate 1 'of the surface layer, I2' with anti -rushing fiber layer, honeycomb paper core 3 ', and bottom layer paper I4' i4 ', Environmental protection foam buffer layer 5, anti -rushing fiber layer II6 ', corrugated paper core 7', and bottom layer paper II8 'and the bottom layer of polymapilic acid strength board 9'.

[0050] The elastic polystumin anti -rushing plate 1 'is the main raw material with polylactic acid, plant fiber, polycophactone, and thermoplastic elastic body.After mixing, squeeze out the foam.In the raw materials, the mass score of polymapilic acid is 40%, the mass score of plant fibers is 15%, the mass score of polycolins is 25%, and the mass score of the thermoplastic elastic body is 20%.

[0051] The mass of the compatibility agent is 30%of the mass of polymapilic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com