Patents

Literature

56results about How to "Safeguard Resilience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High nickel steel for ultralow-temperature pressure vessel and manufacturing method thereof

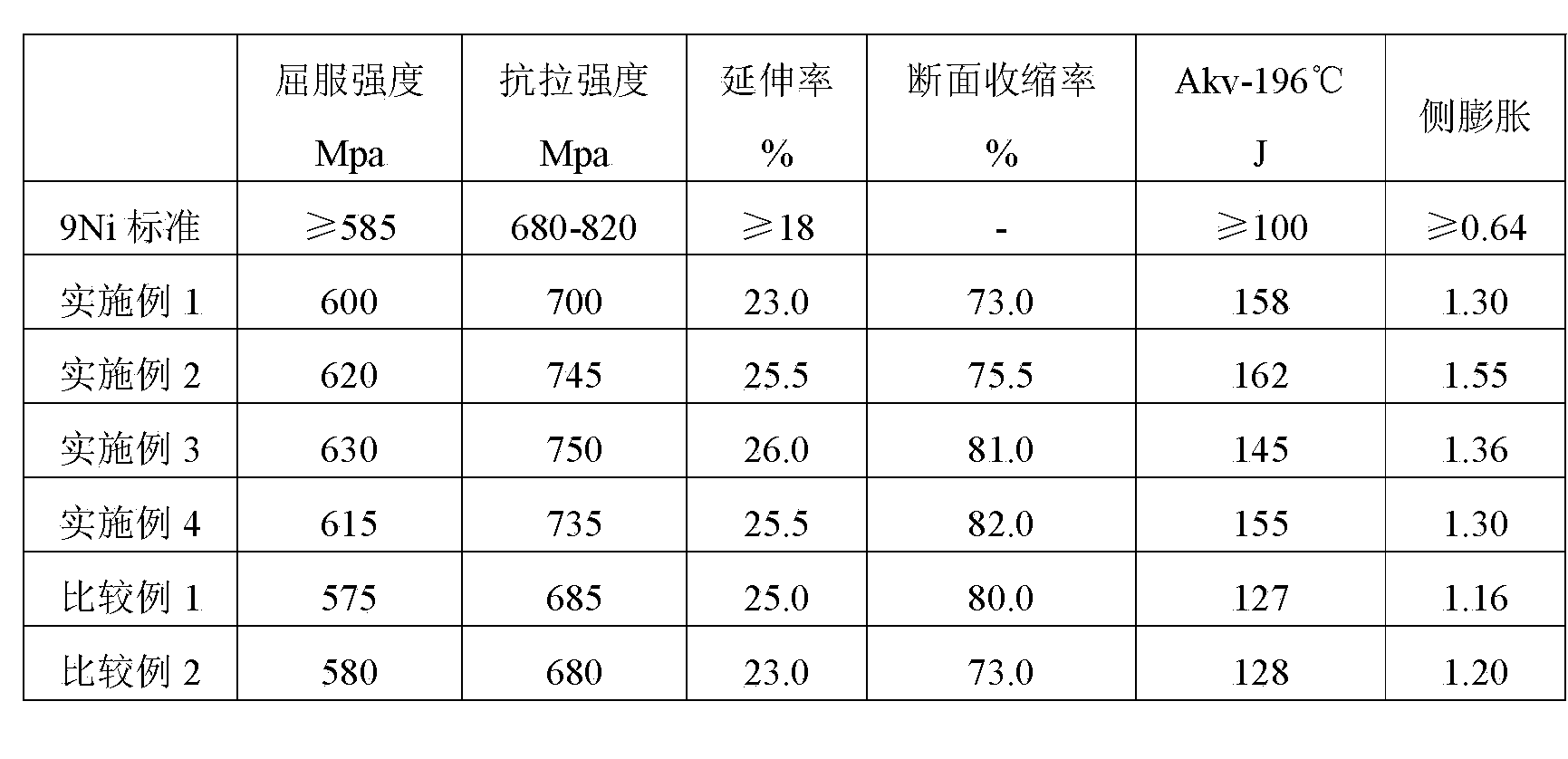

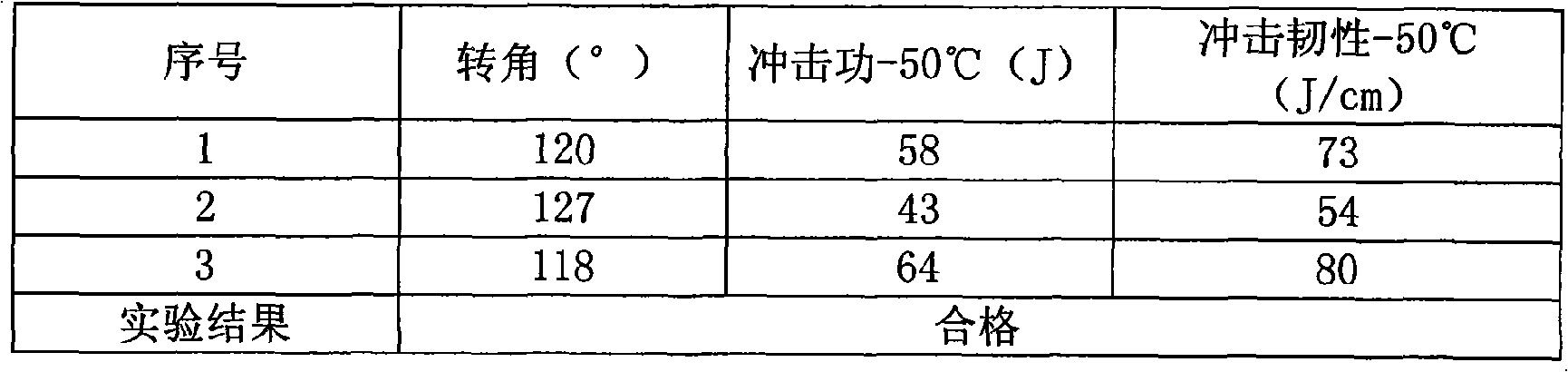

The invention discloses high nickel steel for an ultralow-temperature pressure vessel and a manufacturing method thereof. The high nickel steel comprises the following chemical components, by weight, 0.01-0.08% of C, Si being less than or equal to 0.05%, 0.90-1.20% of Mn, 7.00-7.50% of Ni, 0.05-0.10% of Mo, 0.30-0.60% of Cr, 0.01-0.03% of Ti, S being less than or equal to 0.005%, P being less than or equal to 0.008% and the balance Fe and impurities. Two-stage controlled rolling is adopted. First-stage rolling temperature is greater than or equal to 1050 DEG C, secondary-stage rolling temperature is greater than or equal to 850 DEG C, finish rolling temperature is 750+ / -20 DEG C, and air cooling is carried out after rolling; thermal insulation is carried out for 2min / mm at 800-850 DEG C and quenching is carried out, thermal insulation is carried out for 2min / mm at 630-700 DEG C and quenching is carried out, thermal insulation is carried out for 4min / mm at 550-600 DEG C and tempering is carried out, and air cooling is finally carried out. The high nickel steel for an ultralow-temperature pressure vessel can replace 9% Ni steel. Thus, manufacturing cost of steel for an LNG storage tank is reduced, and direct economic benefit can be created.

Owner:ANGANG STEEL CO LTD

Wind power flange steel and production process thereof

The invention discloses wind power flange steel and a production process thereof. The wind power flange steel comprises the following components in percentage by weight: C: 0.14-0.17, Si: 0.25-0.40, Mn: 1.35-1.50, P: smaller than or equal to 0.015, S: smaller than or equal to 0.003, V: smaller than or equal to 0.015-0.030, Nb: smaller than or equal to 0.025-0.040, Al: 0.030-0.045, N: smaller thanor equal to 0.004, H: smaller than or equal to 0.0001, O: smaller than or equal to 0.002, and As-Cu-Cu mixture: smaller than or equal to 0.1. The invention adopts a continuous-casting method to produce and manufacture the wind power flange steel. The integral process flows comprise the following steps: optimizing molten steel; pretreating KR molten steel; carrying out argon-stirring treatment in atop and bottom blowing converter of 120 tons; refining in an LF furnace; carrying out VD vacuum degassing treatment; continuously casting; cooling in pile; testing; and entering a warehouse. Comparedwith the prior art, the invention improves the manufacture yield of the wind power flange steel. Compared with a traditional forging ingot mold flange, a wind power flange forged by a continuous-casting blank improves the yield by more than 25 percent and greatly decreases the cost.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

High-toughness ultrahigh-temperature ceramic-based composite material and preparation method thereof

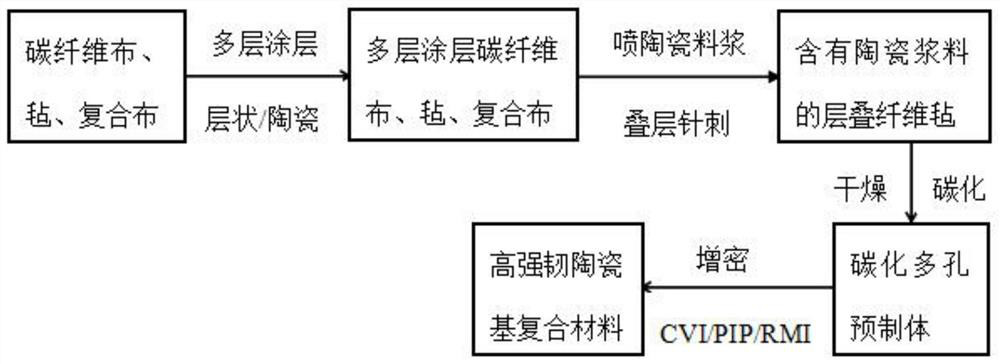

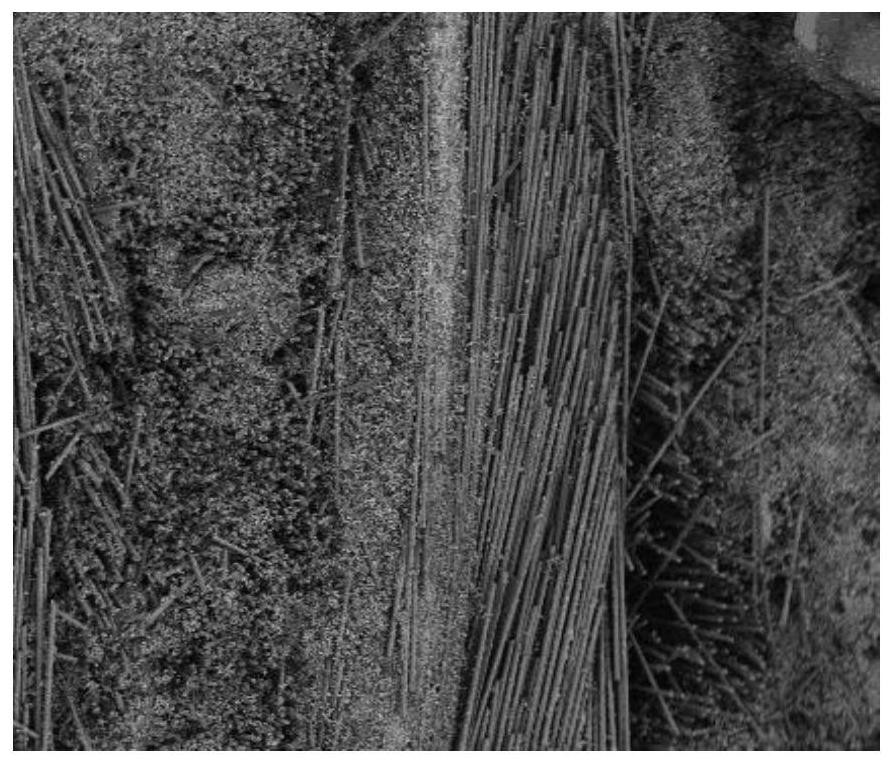

The invention belongs to the technical field of composite material preparation, and particularly relates to a high-strength and high-toughness ultrahigh-temperature ceramic matrix composite material and a preparation method thereof. The preparation method comprises the following steps: alternately depositing two coatings on the surface of the carbon fiber material by adopting a chemical vapor deposition method to obtain the carbon fiber material with the multilayer CVD composite coating, wherein the two coatings are one of a pyrolytic carbon layer or a layered ceramic coating and an ultrahigh-temperature ceramic coating; adopting a phenolic resin / epoxy resin solution and ceramic powder to form ceramic slurry, coating the CVD composite coating carbon fiber material with the ceramic slurry, performing alternately staggered stacking and needling to obtain a stacked fiber felt, and after vacuum drying, performing warm-pressing curing and carbonization treatment, and obtaining a porous prefabricated body; and finally, carrying out densification treatment to obtain the ceramic-based composite material. The material has high strength, high fracture toughness, oxidation resistance, ablation resistance and corrosion resistance, and can be applied to high-temperature and ultrahigh-temperature structural materials, oxidation-resistant and corrosion-resistant materials and aerospace ablation-resistant materials.

Owner:湖南兴晟新材料科技有限公司

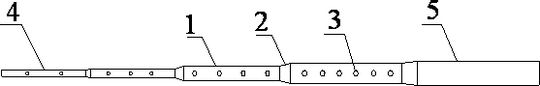

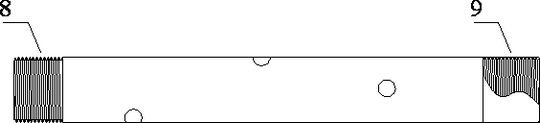

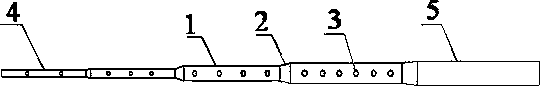

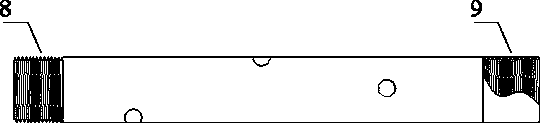

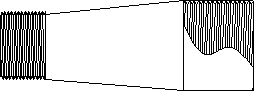

Pipe body structure of step type hole protecting pipe for gas extraction hole in soft coal bed

ActiveCN102619476AEasy to passConform to the gushing lawDrilling rodsGas removalPore diameterReducer

A pipe body structure of a step type hole protecting pipe for a gas extraction hole in a soft coal bed, and belongs to the hole protecting pipe. The hole protecting pipe comprises multiple groups of pipes, which are connected from the front end to the tail end in sequence; the diameters of the pipes in different groups are different, the diameters of the pipes in each group of pipes from the front end to the tail end of the hole protecting pipe are reduced in sequence, and every two adjacent pipes in different groups are connected through a reducer pipe; the whole profile of the hole supporting pipe is of a step type structure with a gradually changed diameter; the diameters of the pipes in the same group are the same, and the lengths of the pipes are the same; sieve pores are not formed in the pipe walls of one group of pipes at the most front end but are formed in the pipe walls of the rest groups of pipes, and the pore diameters of the sieve pores in the pipes in the same group are the same; the number of the sieve pores in each group is reduced from the front end to the tail end in sequence; the diameters of the sieve pores in each group are reduced from the front end to the tail end in sequence, the minimal diameter is 4 mm, and the maximal diameter is 10 mm; and the sieve pores are externally wound with gauzes. The pipe body structure has the advantages as follows: the structure is simple, the hole protecting pipe is not easily blocked and is more easily fed in a deflected drilled hole due to large flexibility, the hole protecting length is long, and the gas extraction efficiency is high at the same time. Therefore, the pipe body structure is suitable for the gas extraction hole in the soft easily-collapsed coal bed.

Owner:CHINA UNIV OF MINING & TECH

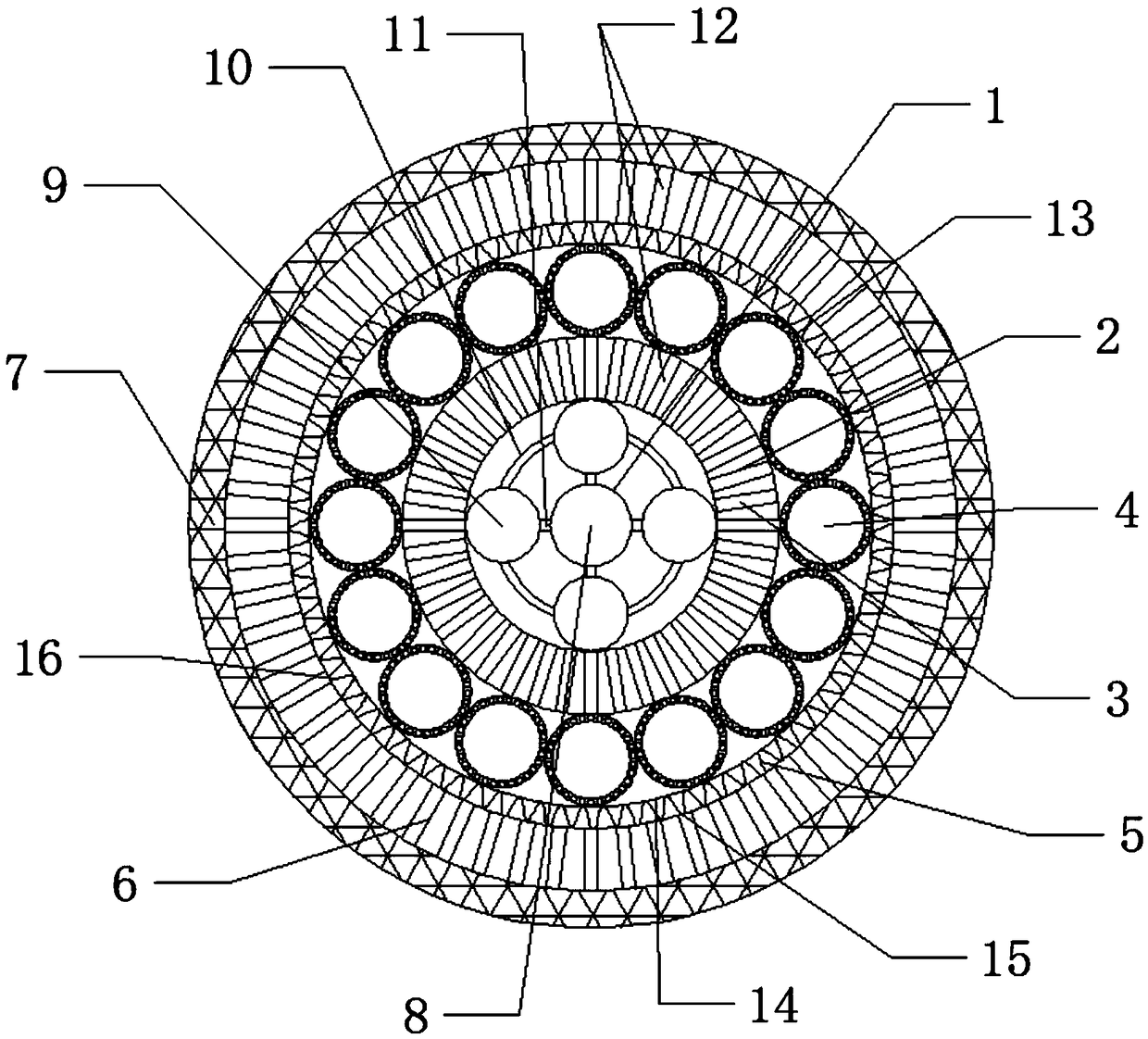

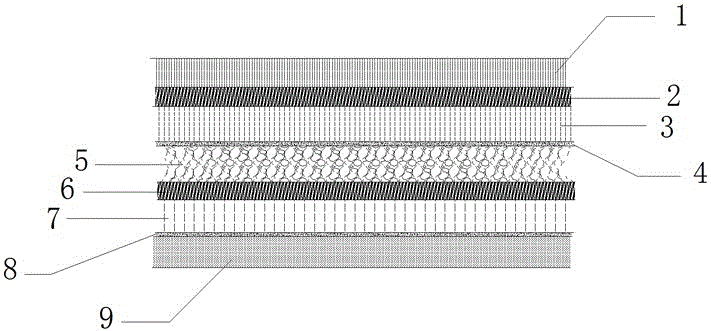

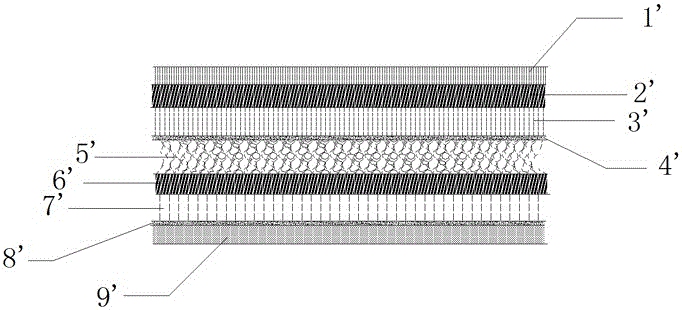

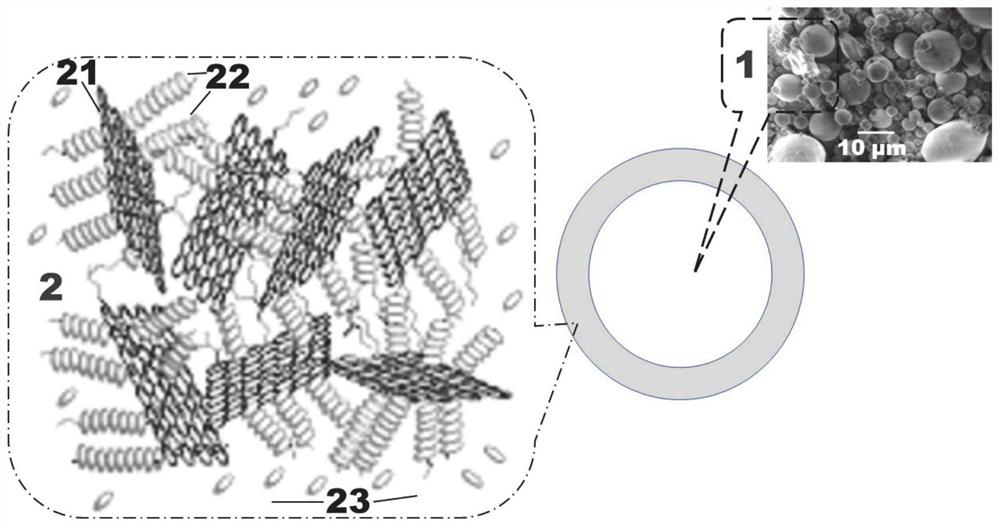

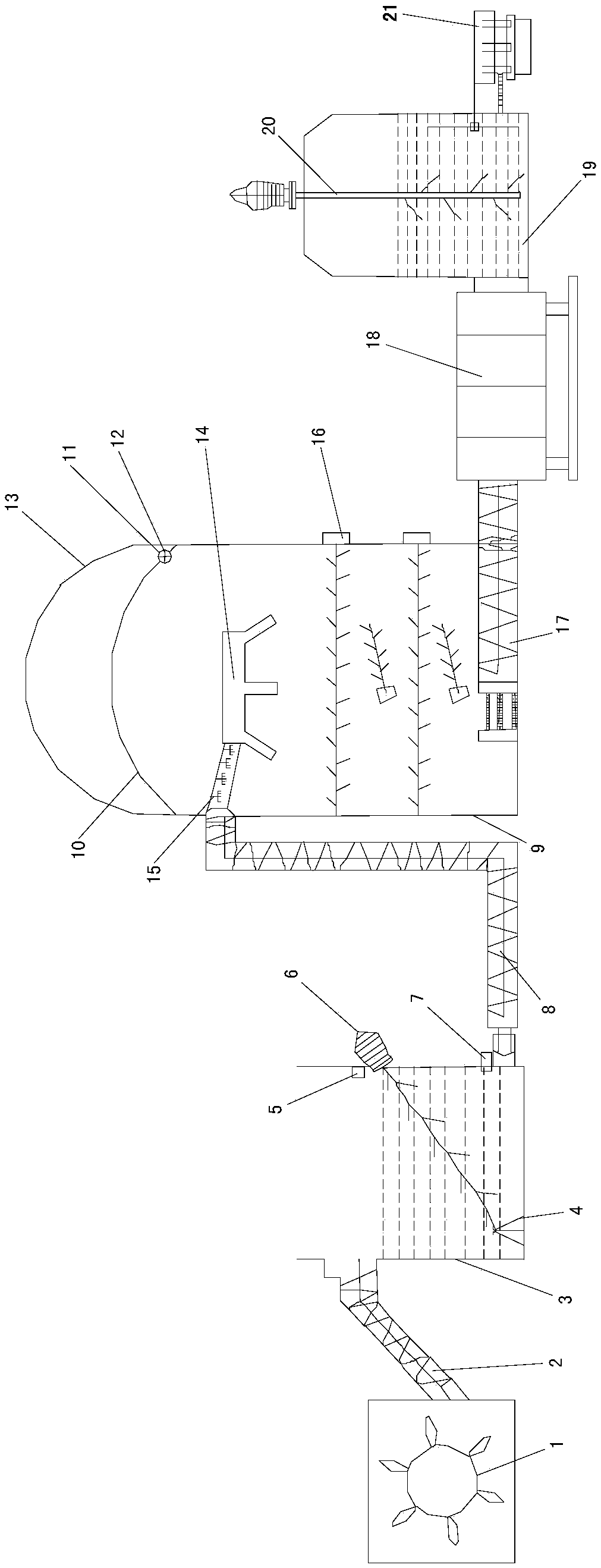

Flexible cable with heat dissipation effect

InactiveCN108735353ASafeguard ResilienceImprove toughnessFlexible cablesFlexible conductorsEngineeringElectric cables

The invention discloses a flexible cable with a heat dissipation effect, belongs to a multifunctional cable in the technical field of cables and aims at providing the flexible cable with the heat dissipation effect. According to the technical scheme, the flexible cable comprises a flexible cable core group arranged in the middle, wherein a first heat dissipation grid tube group is arranged outsidethe flexible cable core group; the length directions of grid tubes in the heat dissipation grid tube group are set along the radial direction of the flexible cable core group; a plurality of elasticcables are arranged outside the first heat dissipation grid tube group and are uniformly distributed along the external circumferential direction of the first heat dissipation grid tube group; a spring coil is arranged outside the elastic cables; a second heat dissipation grid tube group is arranged outside the spring coil; and a heat absorption layer is arranged outside the second heat dissipation grid tube group. The flexible cable with the heat dissipation effect has a good heat dissipation function while the flexibility of the cable is strengthened, and can be widely applied to a relatively harsh environment.

Owner:ZHENGZHOU JIZHI TECH CO LTD

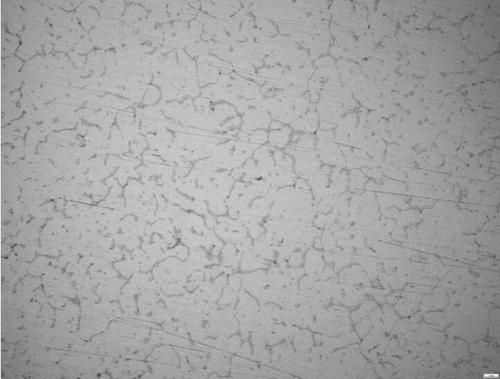

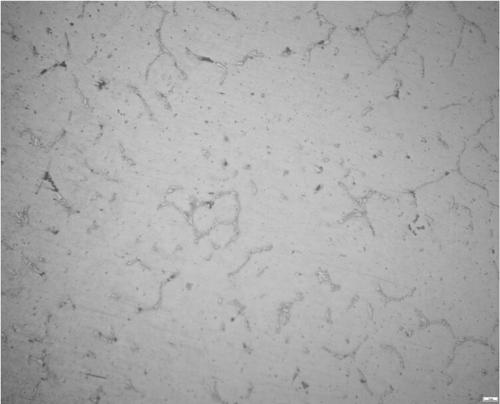

Low carbon, low boron, and high chromium alloy steel and preparation method thereof

InactiveCN108929983AGuaranteed wear resistanceImprove hardenabilityProcess efficiency improvementTungstenAluminium

The invention discloses low carbon, low boron, and high chromium alloy steel and a preparation method thereof which relates to the technical field of alloy steel. The low carbon, low boron, and high chromium alloy steel includes, by weight, 0.05-0.30% of carbon, 1-3.0% of silicon, 0.8-1.3% of manganese, <0.04% of phosphorus, <0.04% of sulfur, 8-13% of chromium, 0.5-2.5% of nickel, 0.1-0.8% of molybdenum, 0.03-0.25% of boron, 0.1-0.3% of aluminum, 0.05-0.2% of tin, 0.3-1.0% of vanadium, 0.1-1.5% of tungsten, 0.05-0.3% of copper, 0.005-0.015% of tantalum, 0.05-0.15% of cobalt, 0.05-0.25% of niobium, 0.8-2.0% of cerium, 0-0.08% of titanium, with the balance being iron and unavoidable impurities. The alloy steel of the invention enables high toughness and impact resistance performance to be ensured, enables wear resistance and hardness to be improved, is easy to control in process, and is suitable for civilian use and promotion.

Owner:LESHAN TAIGANG SUNKOS MACHINERY MFG

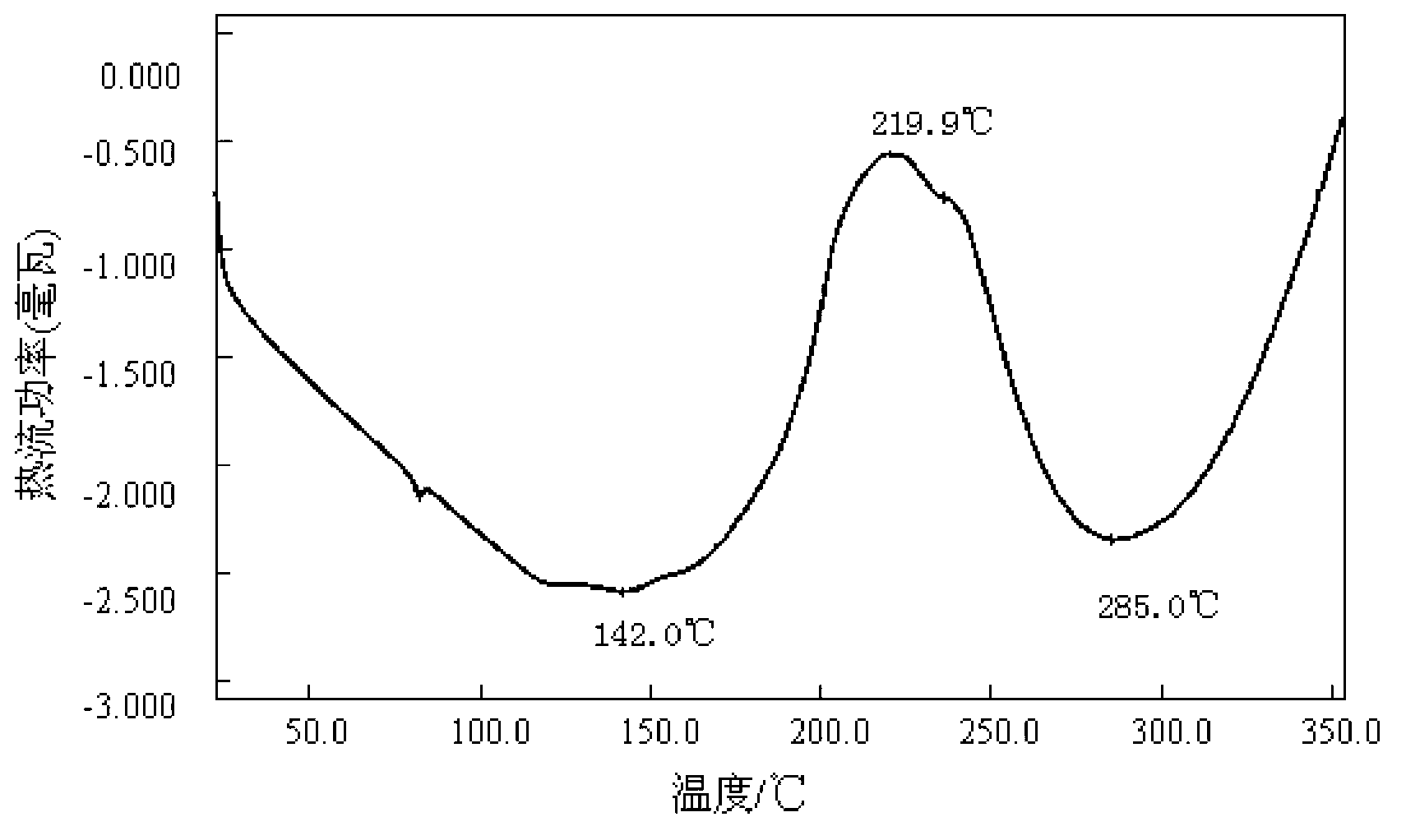

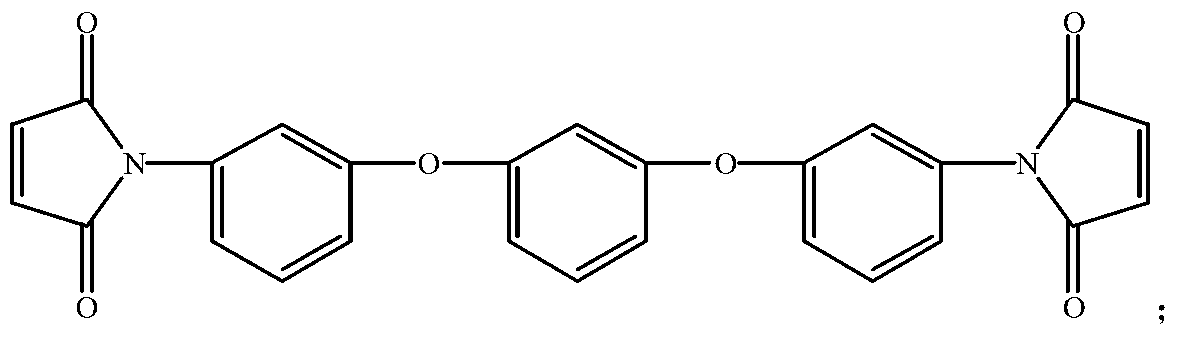

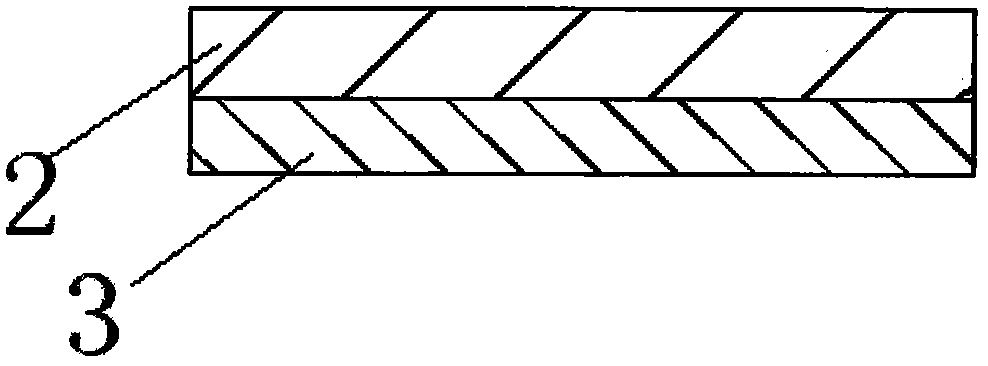

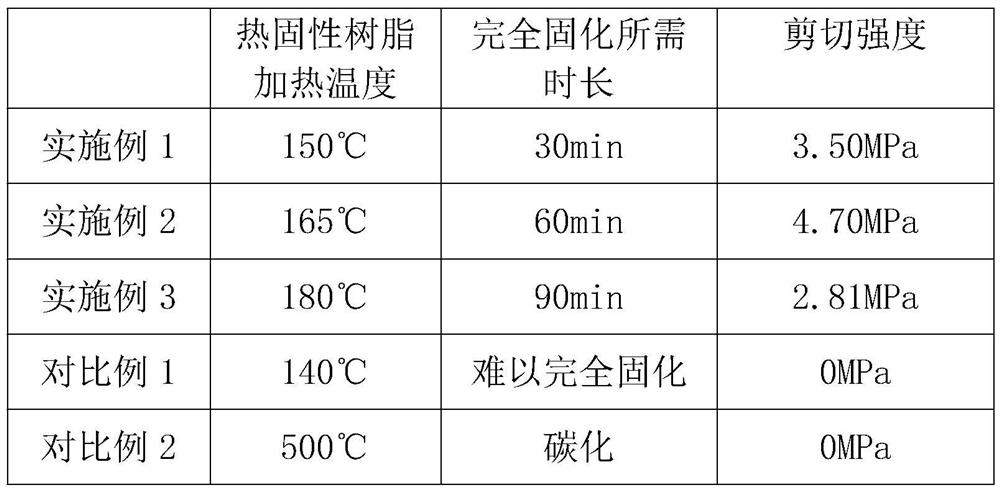

High-tenacity bismaleimide resin carrier structure adhesive film and preparation method thereof

The invention relates to a high-tenacity bismaleimide resin carrier structure adhesive film and a preparation method thereof. The invention aims at solving the problems of the existing bismaleimide adhesive that the tenacity is poor and the peel strength is low. The adhesive film is prepared from bismaleimide resin, a technical modifier, macromolecule blending alloy, a curing agent, a silane coupling agent and a carrier. The preparation method of the adhesive comprises the following steps of: firstly pre-polymerizing the bismaleimide resin and the copolymeric modifier so as to prepare bismaleimide resin prepolymer, then uniformly mixing the bismaleimide resin prepolymer, the macromolecule blending alloy, the silane coupling agent and the curing agent so as to prepare sizing material through a mechanical blending method, and taking braided fabric as the carrier and preparing the film adhesive through a dual-roller hot rolling manner. The adhesive has the characteristics of high strength, thermostability and high tenacity and can be used for cementing thermostability metal and resin-based compound material structural members in the field of aerospace.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Low-carbon low-boron medium-chromium alloy steel, and preparation method thereof

The invention discloses a low-carbon low-boron medium-chromium alloy steel, and a preparation method thereof, and belongs to the technical field of alloy steel manufacturing. The low-carbon low-boronmedium-chromium alloy steel comprises 0.05 to 0.30% of carbon, 1.0 to 3.0% of silicon, 0.8 to 1.3% of manganese, phosphor of 0.04% or lower, sulfur of 0.04% or lower, 3.5 to 7.9% of chromium, 0 to 0.08% of titanium, 0.3 to 2.0% of nickel, 0.1 to 0.5% of molybdenum, 0.03 to 0.25% of boron, 0.1 to 0.3% of aluminium, 0.5 to 1.5% of cerium, 0.02 to 0.1% of tin, 0.3 to 1.0% of vanadium, 0.1 to 1% of tungsten, 0.05 to 0.3% of copper, 0.005 to 0.015% of tantalum, 0.05 to 0.15% of cobalt, 0.05 to 0.25% of niobium, and the balance iron and unavoidable impurities. The hardness of the low-carbon low-boron medium-chromium alloy steel is HRC45-55, the impact energy is 8 to 15J / mm<2>. The preparation method is capable of guaranteeing the high toughness and impact resistance, and improving the wear resistance and hardness, is convenient to control, and is suitable for civil applications and popularization.

Owner:LESHAN TAIGANG SUNKOS MACHINERY MFG

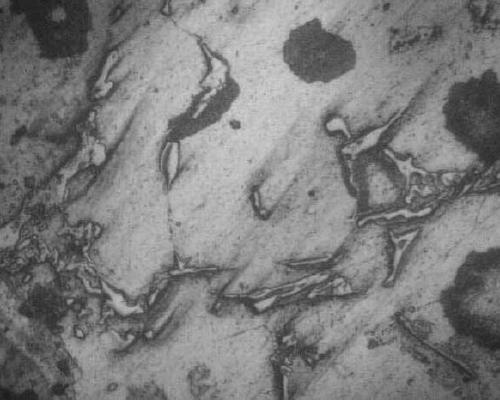

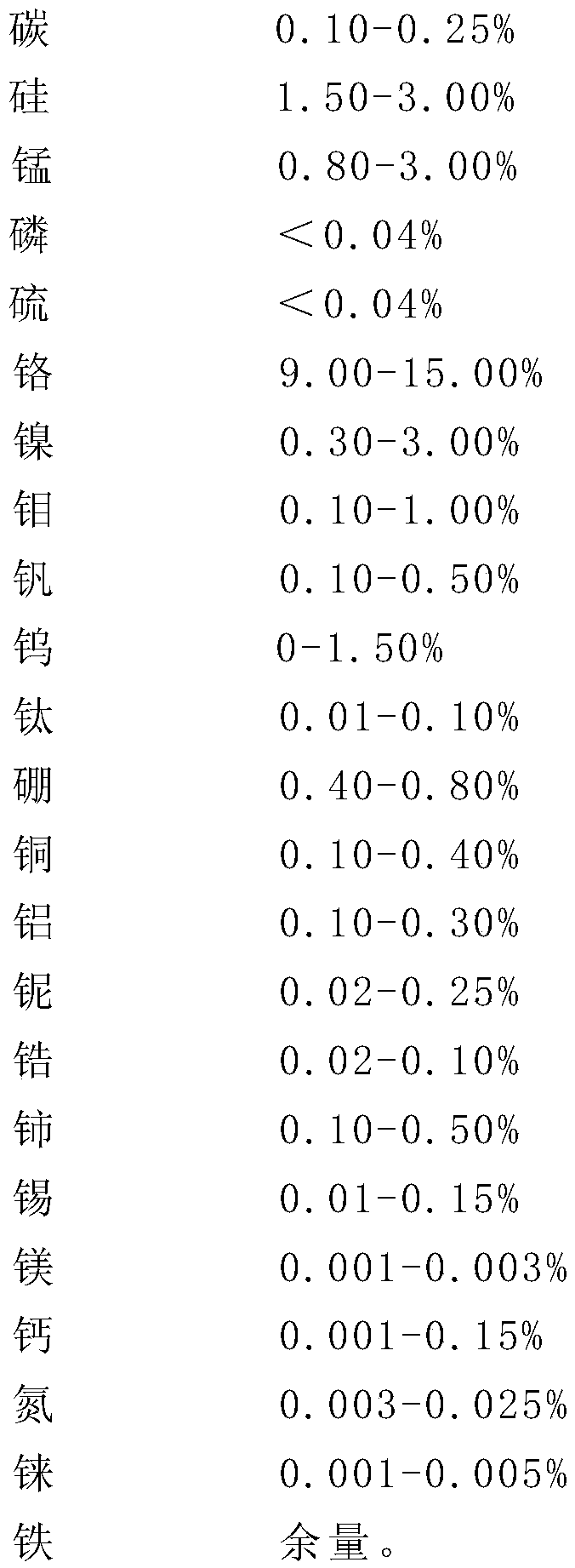

Micro-carbon high-chromium high-boron wear-resistant steel and preparation method thereof

InactiveCN109825778AHinder segregationAvoid hydrogen embrittlementProcess efficiency improvementWear resistantCerium

The invention discloses micro-carbon high-chromium high-boron wear-resistant steel and a preparation method thereof. The prepared wear-resistant steel comprises the following components of, in percentage by weight, 0.10-0.25% of carbon, 1.50-3.00% of silicon, 0.80-3.00% of manganese, less than 0.04% of phosphorus, less than 0.04% of sulfur, 9.00-15.00% of chromium, 0.30-3.00% of nickel, 0.10-1.00%of molybdenum, 0.10-0.50% of vanadium, 0-1.50% of tungsten, 0.01-0.10% of titanium, 0.40-0.80% of boron, 0.10-0.40% of copper, 0.10-0.30% of aluminum, 0.02-0.25% of niobium, 0.02-0.10% of zirconium,0.10-0.50% of cerium, 0.01-0.15% of tin, 0.001-0.003% of magnesium, 0.001-0.15% of calcium, 0.003-0.025% of nitrogen, 0.001-0.005% of rhenium, and the balance iron. The steel not only has the high hardness, also has the characteristics of certain toughness and high wear resistance at the same time.

Owner:陈章华

Vehicle transmission gear and manufacturing method thereof

The invention provides a vehicle transmission gear and a manufacturing method thereof. The manufacturing method comprises the steps of blank forming, preheating treatment, turning machining, final heat treatment and finish machining, wherein the final heat treatment step comprises multiple times of carburization, carbonitriding, quenching, tempering and the like. The vehicle transmission gear manufactured through the manufacturing method has the excellent comprehensive performance.

Owner:兴化市统一齿轮有限公司

Fan covering making process

A fan covering making process comprises the steps as follows: getting emulsion and water, evenly mixing emulsion and water according to the ratio of 1:2, and heating the mixture to obtain an emulsion adhesive; getting a piece of cloth or paper, hanging and drying the cloth or paper, and flattening the cloth or paper with a rolling log to obtain a fan covering raw material; cutting the fan covering raw material into sectors to obtain fan coverings, taking one fan covering and brushing the fan covering with the emulsion adhesive, covering the fan covering with an identical fan covering, and repeating the process 2-4 times to obtain a bonded fan covering; placing a plurality of hollow spaced paper slips on the bonded fan covering at equal intervals, and covering the hollow spaced paper slips with a fan covering; compressing the fan covering to obtain a finished fan covering, and drying the finished fan covering in the air for 48-60 hours to obtain a finished fan covering; and baking the finished fan covering in a baking room for 1-2 hours to obtain a fan covering. By adopting the fan covering making process of the invention, the fan covering can be of higher strength and toughness.

Owner:ANHUI GAOFENG DAILY ARTWARE CO LTD

Lightweight high-strength heat-insulation moisture-proof composite paper board

InactiveCN105015125ASafeguard ResilienceGood cushioning propertiesSynthetic resin layered productsPaper/cardboard layered productsFiberCellulose

The invention relates to a lightweight high-strength heat-insulation moisture-proof composite paper board composited by multiple layers of boards and successively including a surface elastic polylactic acid antishock board, an antishock fiber layer I, a honeycomb paper core and a bottom facial paper I, an environmental-protection foamed buffer layer, an antishock fiber layer II, a corrugated paper core and a bottom facial paper II and a bottom polylactic acid strength board. The composite paper board is also characterized in that the inner surface of a space formed by the corrugated paper core and the honeycomb paper core with the bottom facial papers is coated with an inorganic cellulose coating layer; the antishock fiber layer I and the antishock fiber layer II are formed by placing a nanoparticle suspension into multiple layers of fabrics and compositing. The composite paper board is light in mass, good in strength and good in shock resistance, and can be applied to buffer protection in the field of industrial and civil used board materials.

Owner:HUNAN UNIV OF TECH

Preparation technology of fan covering for fan

InactiveCN107736708AHigh strengthStrong toughnessUmbrellasMaterial gluingEngineeringCooking & baking

The invention discloses a preparation technology of a fan covering for a fan. The technology comprises the following steps that a fan covering raw material is prepared, a glue and alum solution is prepared, the fan covering raw material is cut into sectors to obtain fan covering bodies, one fan covering body is taken, brushed with the glue and alum solution and covered by one same fan covering body, and after multiple times of repetition, a bonded fan covering body is obtained; a plurality of hollow spacing paper slips are arranged on the bonded fan covering body at equal intervals, then the hollow spacing paper slips are covered by one fan covering body, and a primary fan-covering product is obtained after mounting, sleeving, folding and edge covering and bonding are conducted on the fancovering body; the primary fan-covering product is pressed, and then a finished fan-covering product is obtained through drying; the finished fan-covering product is put into a baking room for baking,and then the fan covering of the fan is obtained. By means of the technology, the strength and the toughness of the fan covering are higher; the fan covering produced through the production technology is not only suitable for a circular fan, but also suitable for a folding fan or a fan of other types after a folding working procedure; the application range of the fan covering is very wide, and meanwhile, the toughness and the strength of the fan covering are fully guaranteed.

Owner:苏州盛风文化创意发展有限公司

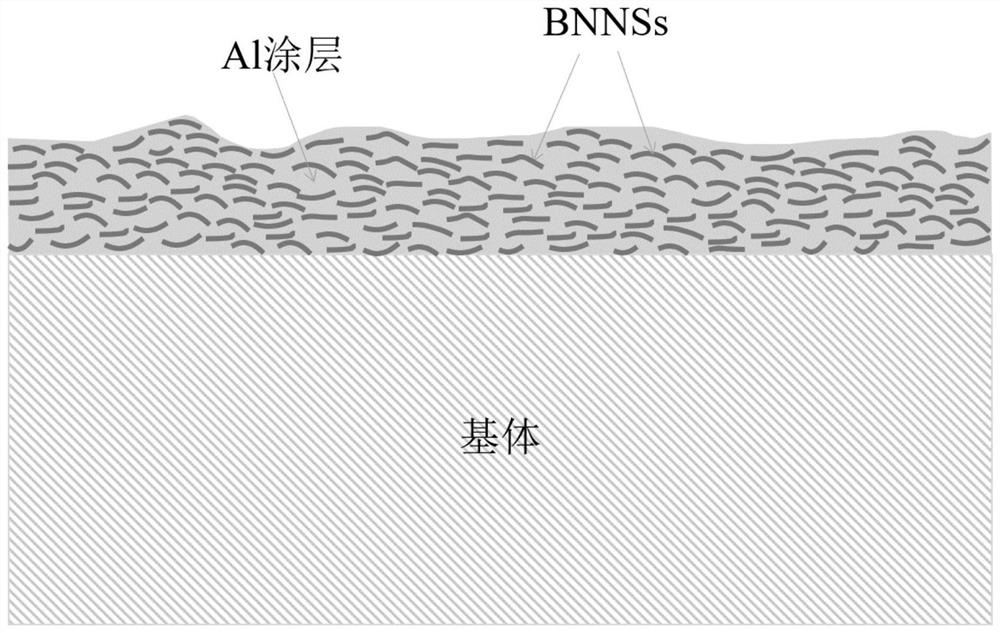

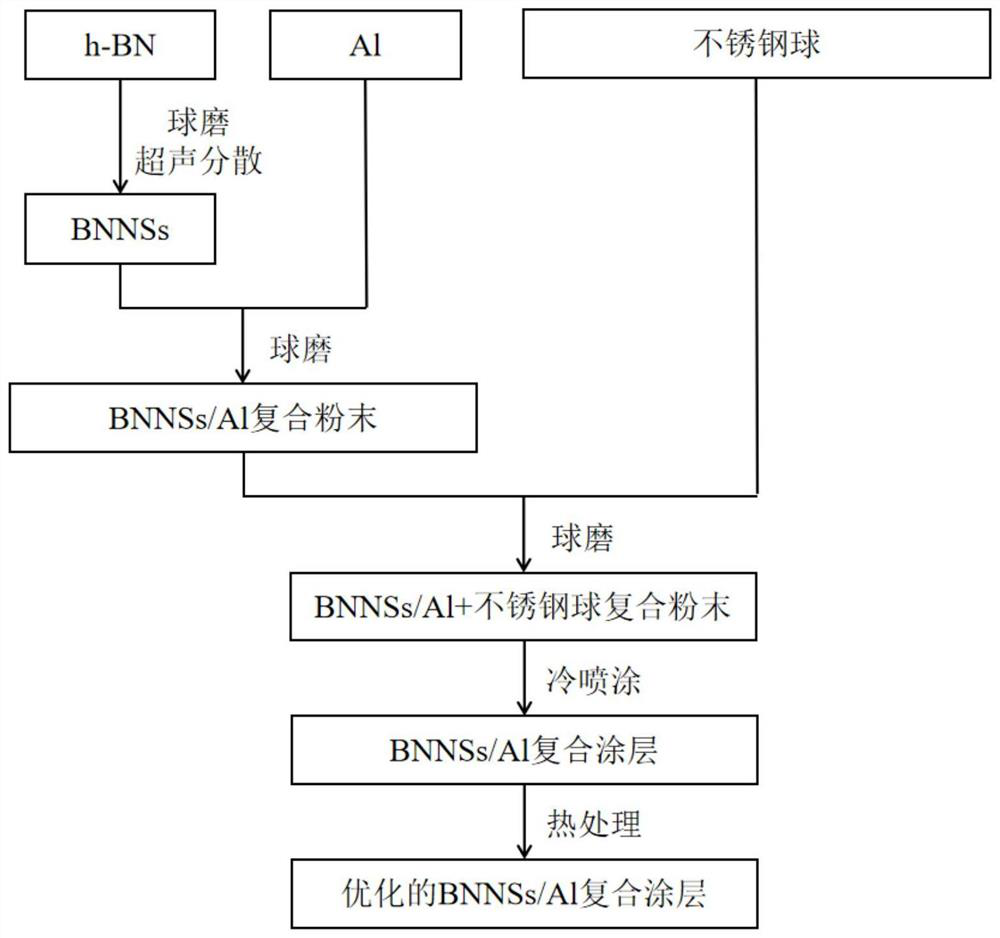

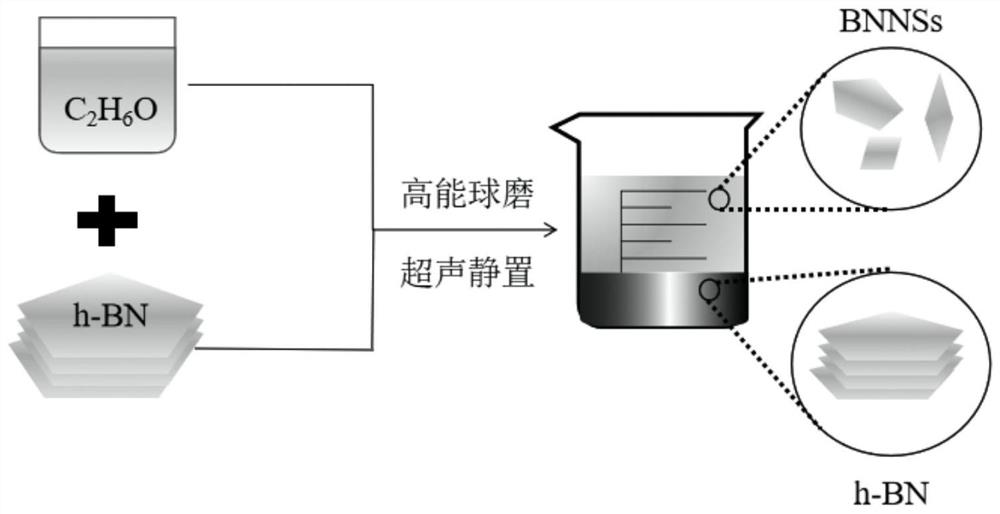

Aluminum-boron nitride nanosheet composite coating and preparation method thereof

PendingCN112376042AAccelerated corrosionImprove wear resistancePressure inorganic powder coatingAl powderHexagonal boron nitride

The invention discloses an aluminum-boron nitride nanosheet composite coating and a preparation method thereof, and belongs to the field of materials. The thickness of the coating is 0.5-2.0 mm, aluminum (Al) particles in the coating are lamellar, and two-dimensional boron nitride nanosheets (BNNSs) are uniformly distributed in an Al deposition body. The BNNSs have the characteristics of self-lubrication and high chemical stability and can be used as a physical barrier in the coating to prevent a corrosive medium from entering a matrix, and thus the wear resistance and corrosion resistance ofthe coating can be obviously enhanced. The preparation method of the coating mainly comprises the following steps that 1, hexagonal boron nitride (h-BN) is subjected to high-energy ball milling and then is subjected to ultrasonic dispersion to prepare BNNSs; 2, the spherical Al powder and BNNSs are subjected to ball-milling and mixing to obtain composite powder; 3, the composite powder is deposited on the matrix by using a cold spraying process to obtain an Al-BNNSs composite coating with uniformly distributed BNNSs; and 4, the coating is subjected to heat treatment to further improve the performance of the composite coating. The coating is wide in application range, simple in preparation method and capable of achieving large-scale preparation, and has great application value and market prospects.

Owner:JIANGSU UNIV

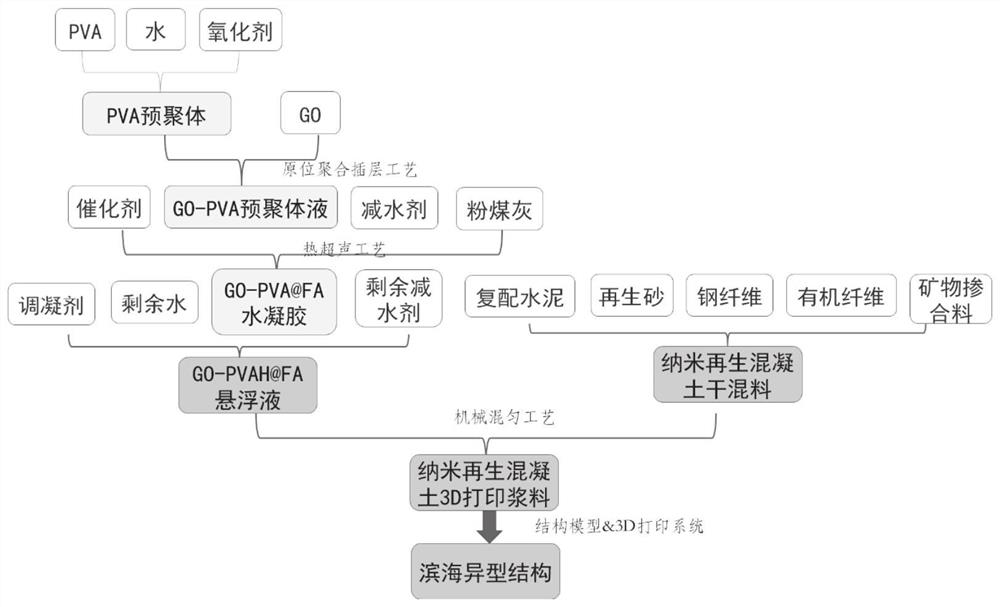

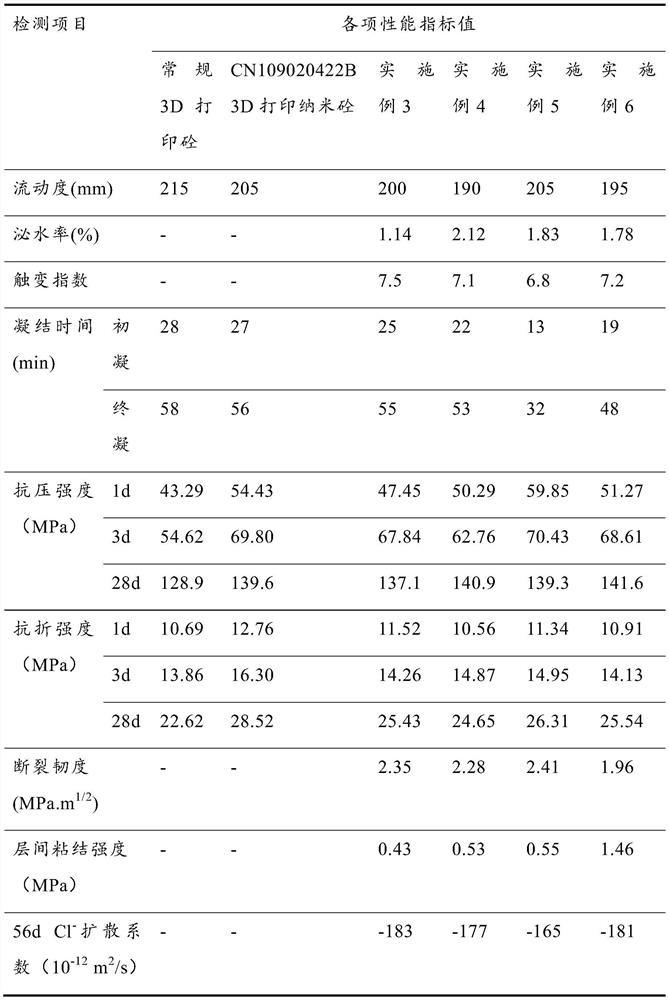

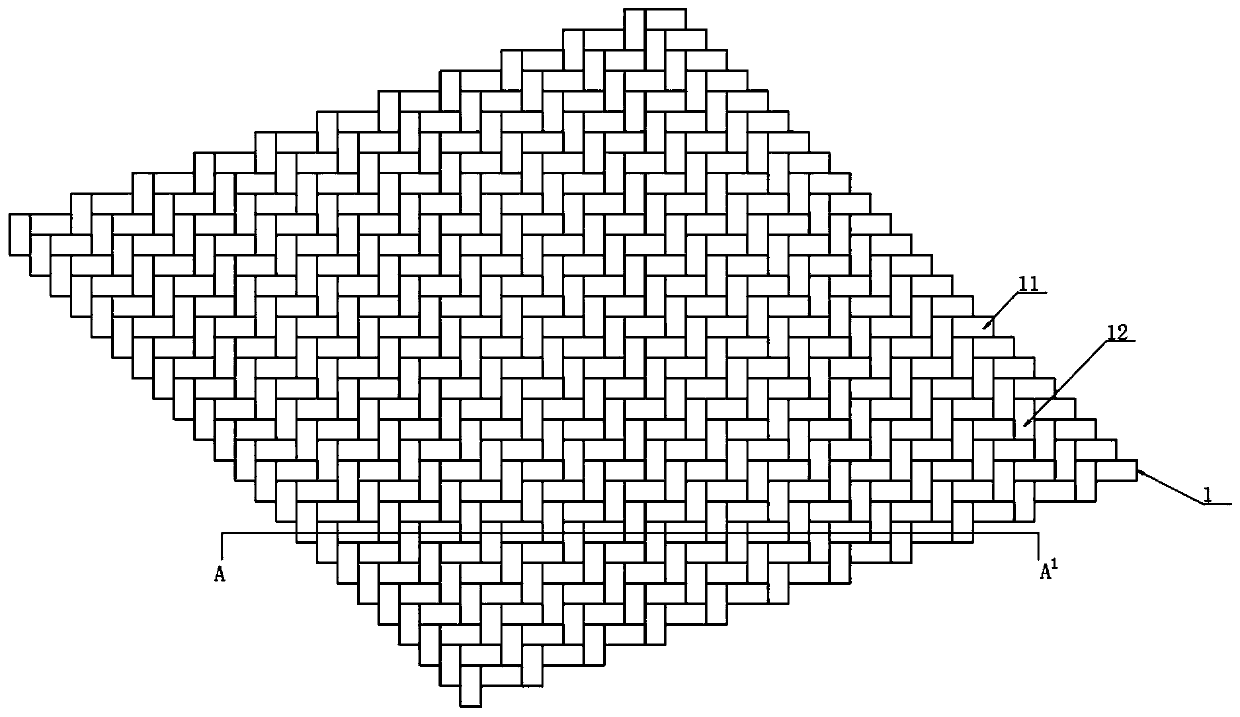

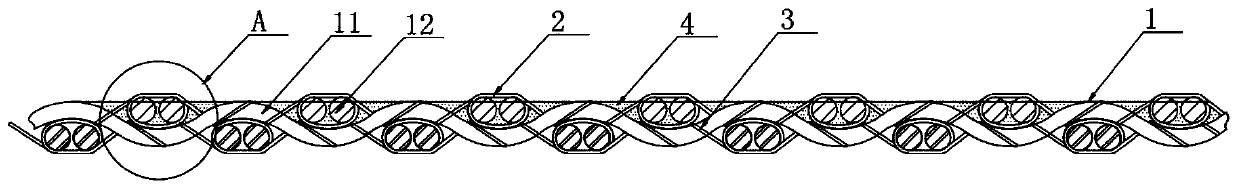

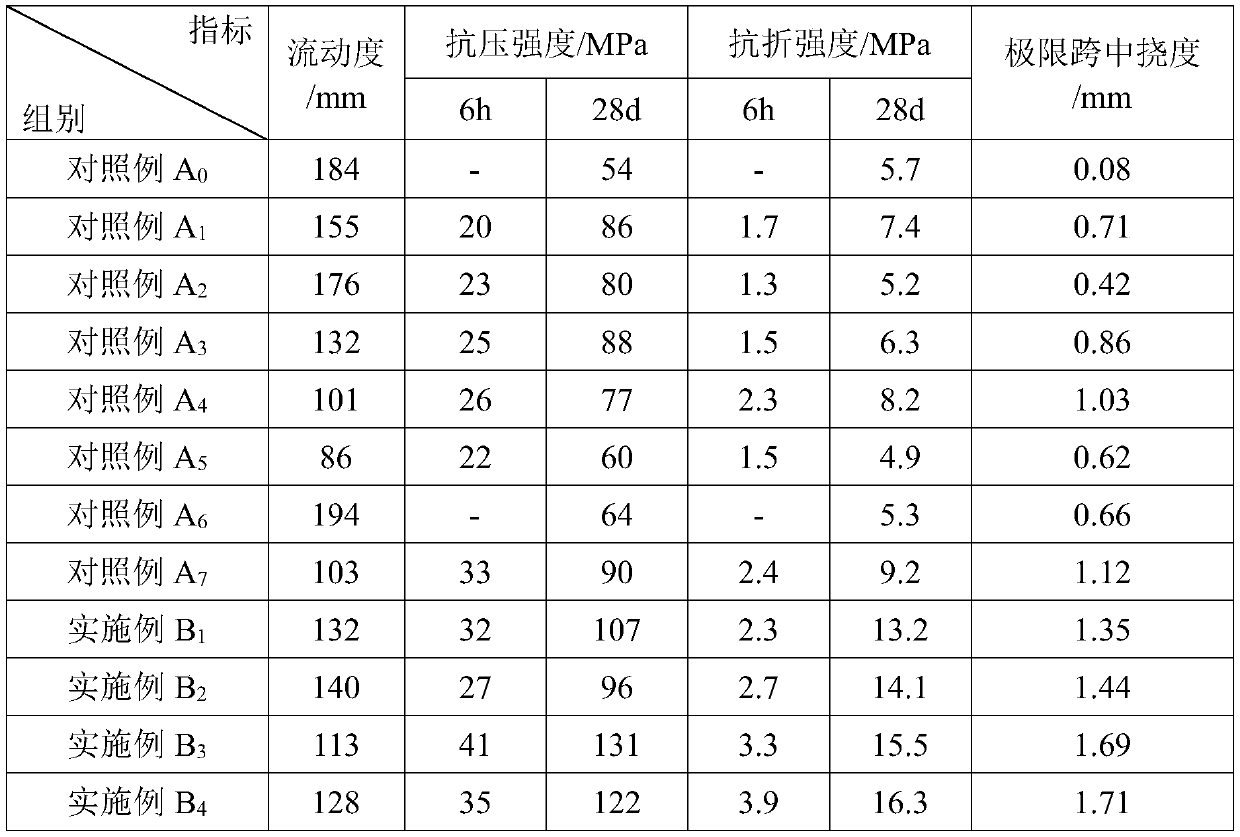

Nano recycled concrete, processing technology and application thereof

ActiveCN113307597ARealize water retention functionAids in water retentionAdditive manufacturing apparatusSolid waste managementElectrolytic agentPolyvinyl alcohol

The invention particularly relates to nano recycled concrete, a processing technology and an application thereof. The existing nano recycled concrete also has the following defects that the corrosion prevention effect is not ideal when a conventional marine corrosion prevention technology is applied to a coastal assembly structure for 3D printing, and in addition, interlayer interface bonding and thixotropy of a conventional 3D printing material are insufficient. The invention provides nano recycled concrete. The nano recycled concrete is prepared from the following raw materials: compound cement, recycled sand, fly ash, polyvinyl alcohol, graphene oxide, steel fibers, organic fibers, a water reducing agent, a thickening time control agent, a mineral admixture and water. The 3D printing concrete has good cohesive water-retaining property and adjacent thin layer interface cohesiveness, a micro-capacitor is formed through combination of GO and PVA electrolyte to avoid formation of a corrosion battery in a concrete thin layer, and the 3D printing concrete has good marine durability and has good application prospects when being applied to coastal assembly structure engineering.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Anti-pilling knitted fabric and preparation method thereof

ActiveCN111350082AImprove compactnessGuaranteed strength and toughnessSingeingFibre cleaning/openingFibre treatmentPolymer chemistry

The invention discloses an anti-pilling knitted fabric and a preparation method thereof. The anti-pilling knitted fabric comprises a base cloth layer, wherein a first reinforcing layer is arranged atthe top of the base cloth layer; a second reinforcing layer is arranged at the bottom of the base cloth layer; and an anti-pilling coating film is arranged at the top of the first reinforcing layer. Through weaving a herringbone twill weave structure with high integration degree, the density of the fabric is improved, wind prevention and warmth retention are achieved, and the toughness and the strength are ensured; through the arrangement of the anti-pilling coating film, the wear resistance is improved and pilling of the surface is avoided; the fabric is comfortable to wear and good in skin-friendly effect; fiber burrs are treated by using a fiber treatment agent before knitting, a blended yarn is dried by using a hot air blower and spool replacement through winding the blended yarn is completed, so that the strength, flexibility and cleanness of the blended yarn are enhanced, and the possibility of fiber breaking and pilling is reduced; and the burrs of the fabric are removed throughsurface treatment of a basic fabric, so that smooth and even spraying and adhesion of the coating film are facilitated, and the high-efficiency anti-pilling effect and the effect of reducing defectson the surface of the fabric are achieved.

Owner:潮州市乐欣服装有限公司

Production method and system for preparing seedling culture tray from straw

InactiveCN108410710AImprove the ecological environmentIncrease profitBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismEcological environment

The invention relates to a production method and a system for preparing seedling culture tray from straw. The system comprises a grinder, a pretreatment tank, a second screw conveyor, a dryer, a seedling culture tray mixing tank and a compression moulding press. The pretreatment tank comprises a pretreatment mixing tank, a first screw conveyor and a microorganism anaerobic fermentation tank. A methane monitoring alarm and a liquid level detection alarm are arranged on upper and lower portions of the wall of the pretreatment mixing tank respectively, and a stirrer is arranged in the pretreatment mixing tank. A biogas storage gas film is arranged above the microorganism anaerobic fermentation tank and provided with a gas hole, and a gas bag for biogas storage is arranged above the biogas storage gas film. A plurality of paddle agitators are arranged in the microorganism anaerobic fermentation tank, an outlet of the second screw conveyor is connected with an inlet of the dryer, an outletof the dryer is connected with an inlet of the seedling culture tray mixing tank, and an outlet of the seedling culture tray mixing tank is connected with the compression moulding press. A rural ecological environment can be improved to a great extent, and cleanness and harmlessness of the rural ecological environment are truly realized.

Owner:天津市天圣颐和科技有限公司

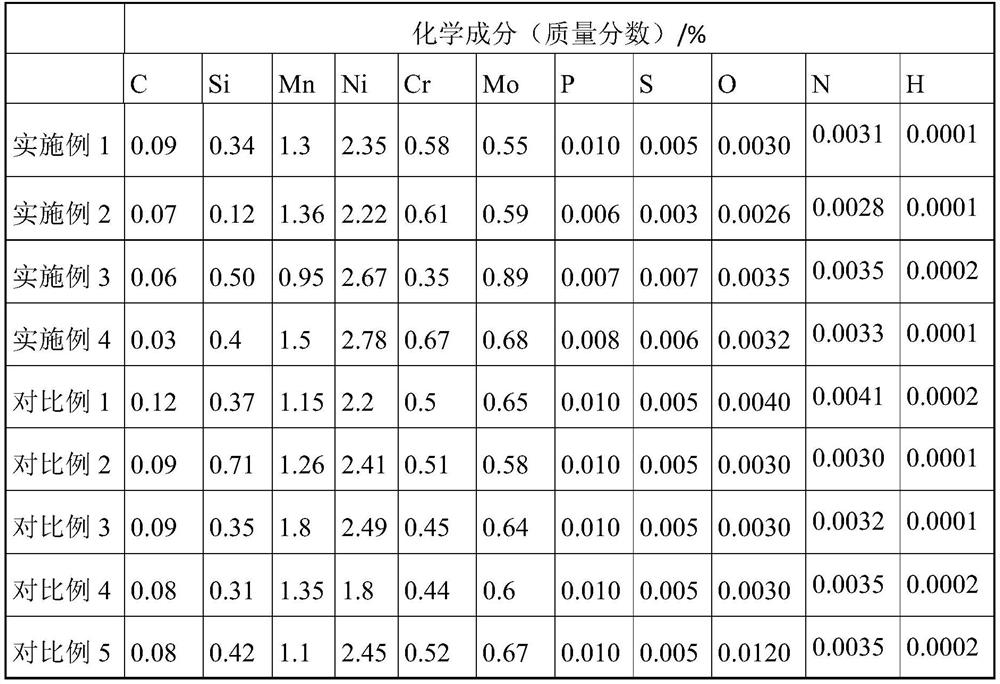

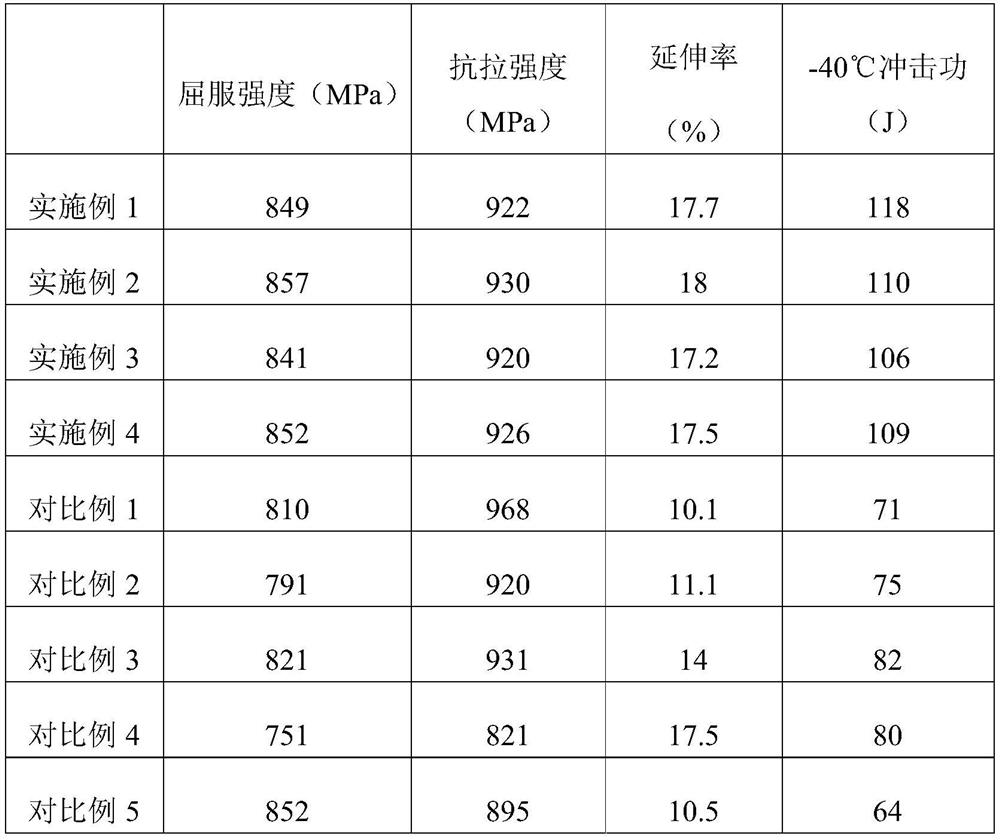

High-strength high-toughness low-alloy steel wire as well as preparation method and application thereof

InactiveCN112853216AHigh strengthHigh tensile strengthAdditive manufacturing apparatusFurnace typesWire rodIngot

The invention discloses a high-strength high-toughness low-alloy steel wire which comprises the following components in percentage by mass: 0.03-0.09% of C, 0.1-0.5% of Si, 0.9-1.5% of Mn, 0.5-0.9% of Mo, 2.2-2.8% of Ni, 0.3-0.7% of Cr, less than or equal to 0.01% of P, less than or equal to 0.01% of S and the balance of Fe and inevitable impurities. The invention also discloses a preparation method of the wire, which comprises the following steps: a, carrying out vacuum melting on the raw materials with a designed ratio to obtain a cast ingot; B, forging the cast ingot to obtain a bar; C, rolling the bar to obtain a wire rod; and d, annealing the wire rod, and then drawing the wire to obtain the wire . The high-strength high-toughness low-alloy steel wire can adapt to an inert gas environment in laser additive manufacturing, does not need special deoxidation and deslagging, can continuously work, does not need copper plating, and is environment-friendly.

Owner:ANSTEEL BEIJING RES INST

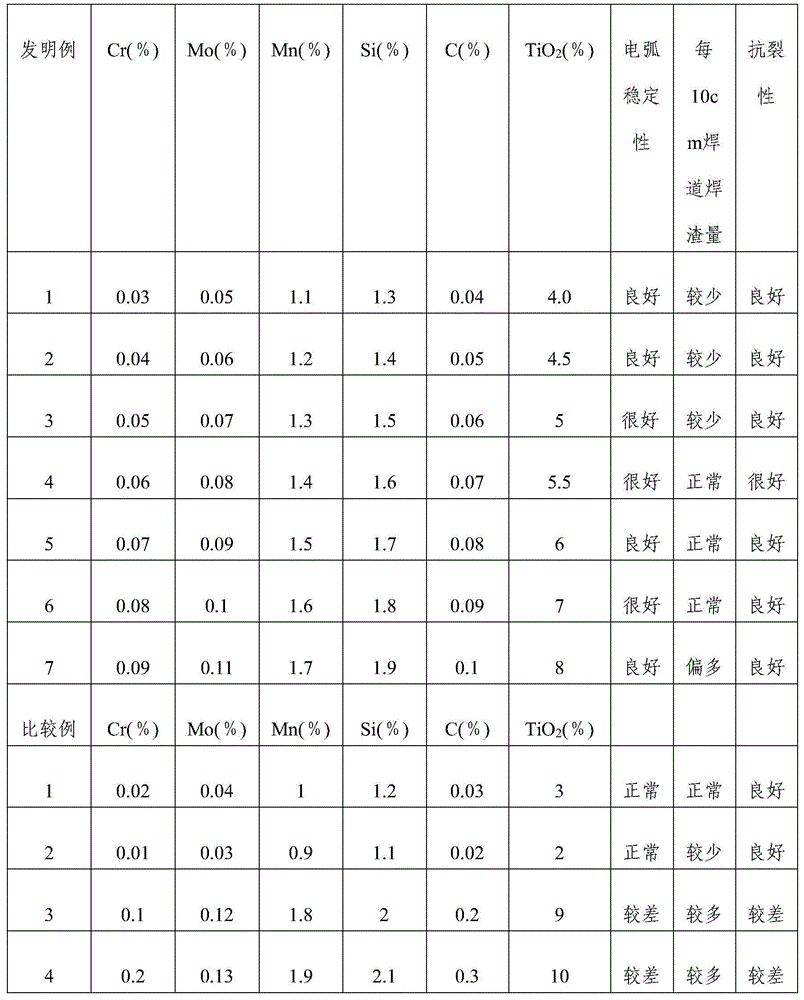

Heat-resistant flux-cored wire

InactiveCN104858562AGuaranteed StrengthQuality assuranceWelding/cutting media/materialsSoldering mediaMelting tankSlag

The invention discloses a heat-resistant flux-cored wire. The heat-resistant flux-cored wire comprises a carbon steel sheath and powder filled into the carbon steel sheath. The powder comprises 0.04 to 0.1% of Cr, 0.06 to 0.12% of Mo, 1.2 to 1.8% of Mn and 1.4 to 2% of Si, based on the total weight of the wire. The heat-resistant flux-cored wire has following beneficial effects: the flux-cored wire is added with C in order to ensure strength of welded metal and the flux-cored wire is added with Si in order to decrease the oxygen content of deposited metal; the mobility Mo of deposited metal is improved such that the welded metal structure becomes stable on the high-heat input welding high-level temperature condition and metal toughness and strength are guaranteed; the flux-cored wire is added with S in order to transfer molten pool flow from the exterior to the interior and welding slag is collected in the interior so that welding slag is eliminated much easily and tidiness of a weld pass is improved; and by adjusting components and content of power, the manufactured flux-cored wire has characteristics of high welding strength, a stable electric arc, easy slag removal, resistance to high temperature.

Owner:贵州凯宏汇达冷却系统有限公司

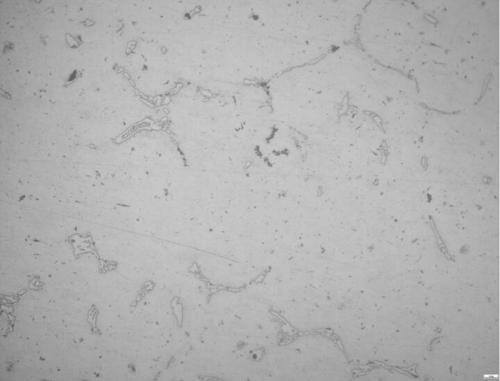

Low-carbon low-boron low-chromium alloy steel, and preparation method thereof

The invention discloses a low-carbon low-boron low-chromium alloy steel, and a preparation method thereof, and belongs to the technical field of alloy steel manufacturing. According to the preparationmethod, low-carbon low-boron low-chromium materials are combined with cerium rare earth, vanadium, tungsten, copper, tantalum, cobalt, niobium, and the like, technical target value determination, material preparation, melting, sampling adjusting, casting moulding, and heat treatment are carried out so as to obtain the low-carbon low-boron low-chromium alloy steel at last; the hardness is HRC42-52, the impact energy is as high as 11 to 20 joules. The preparation method is capable of guaranteeing the certain hardness of the alloy steel, and at the same time, improving the impact resistance, thetoughness, and the wear resistance greatly.

Owner:LESHAN TAIGANG SUNKOS MACHINERY MFG

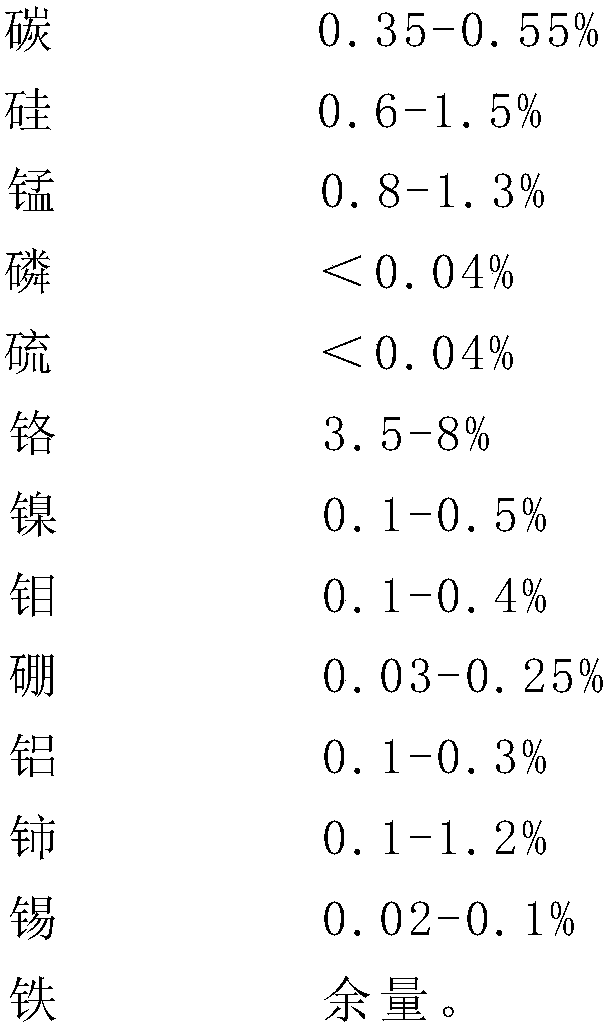

Low-chrome wear-resistant alloy steel, and preparation method thereof

The invention discloses a low-chrome wear-resistant alloy steel, and a preparation method thereof. The preparation method comprises following steps: technology target value determination, material preparation, melting, sampling and adjusting, casting and moulding, and hot treatment. The low-chrome wear-resistant alloy steel comprises, by weight, 0.25 to 0.35% of carbon, 0.6 to 1.5% of silicon, 0.8to 1.3% of manganese, phosphor<0.04%, sulfur<0.04%, 1 to 3.5% of chromium, 0.1 to 0.5% of nickel, 0.1 to 0.3% of molybdenum, 0.03 to 0.25% of boron, 0.1 to 0.3% of aluminium, 0.1 to 1.2% of cerium, 0.02 to 0.1% of tin, and the balance iron. According to the preparation method, both wear resistance and hardness requirements are satisfied, the toughness is increased greatly, impact resistance is excellent, impact energy is as high as 5 to 8 joules, and cobblestones can be crushed using the low-chrome wear-resistant alloy steel easily.

Owner:LESHAN TAIGANG SUNKOS MACHINERY MFG

Abrasion-resistant flux-cored wire

InactiveCN104858574AControl the amount of welding slagReduce the amount of welding slagWelding/cutting media/materialsSoldering mediaSlagOxygen content

The invention discloses an abrasion-resistant flux-cored wire. The abrasion-resistant flux-cored wire comprises a carbon steel sheath and powder filled into the carbon steel sheath. The powder comprises 0.03 to 0.09% of Cr, 0.05 to 0.11% of Mo, 1.1 to 1.7% of Mn and 1.3 to 1.9% of Si, based on the total weight of the wire.The abrasion-resistant flux-cored wire has following beneficial effects: by rigidly controlling components and the content of powder, an electric arc is stabilized and the amount of welding slag on the surface of a welding pass is greatly decreased, thereby effectively controlling the amount of welding slag; the flux-cored wire is added with C so that strength of welded metal is ensured and abrasion-resistant degree is further improved; the flux-cored wire is added with Si in order to decrease the oxygen content in deposited metal and improve mobility of deposited metal; and by utilizing the flux-cored wire, good stability is achieved and a welding surface becomes complete and neat.

Owner:GUIZHOU AEROSPACE KAIHONG SCI & TECH

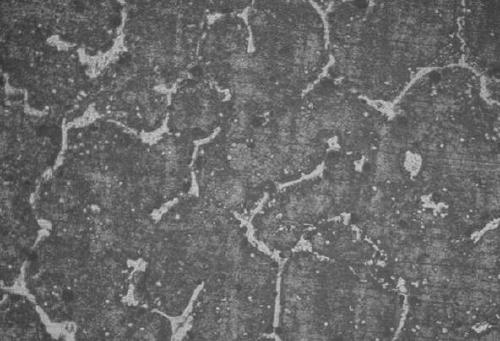

Medium-chromium wear-resistant alloy steel, and preparation method thereof

The invention discloses a medium-chromium wear-resistant alloy steel, and a preparation method thereof. The preparation method comprises steps of technology target value determination, material preparation, melting, sampling and adjusting, casting moulding, and thermal treatment. The medium-chromium wear-resistant alloy steel comprises, by weight, 0.35 to 0.55% of carbon, 0.6 to 1.5% of silicon, 0.8 to 1.3% of manganese, phosphor <0.04%, sulfur <0.04%, 3.5 to 8% of chromium, 0.1 to 0.5% of nickel, 0.1 to 0.4% of molybdenum, 0.03 to 0.25% of boron, 0.1 to 0.3% of aluminium, 0.1 to 1.2% of cerium, 0.02 to 0.1% of tin, and the balance iron. The relatively toughness and the impact resistance performance are ensured; the wear resistance and the hardness are improved; the technology is easy to control; and the medium-chromium wear-resistant alloy steel is suitable for civil applications and popularization.

Owner:LESHAN TAIGANG SUNKOS MACHINERY MFG

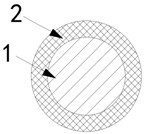

Composite electrode wire, and preparation method and application of composite electrode wire

PendingCN113823435ASolve the strength problemHigh strengthSingle bars/rods/wires/strips conductorsConductive materialComposite electrodeElectrically conductive

The invention relates to the technical field of electrode wire machining, and concretely relates to a composite electrode wire, and a preparation method and application of the composite electrode wire. A conductive alloy core material is directly sleeved with a brass tubular outer material, then pressure cold wrapping is conducted to make the conductive alloy core material and the brass outer material directly and concentrically wrapped into a whole, then drawing, annealing and wire drawing treatment are carried out to make the core material and the outer material form the final composite electrode wire, and a zinc material coating can be sprayed on the surface of the composite electrode wire, so the technical problems that the surface of an existing composite electrode wire is not glossy, and the overall strength is low are solved.

Owner:湖州金钛导体技术有限公司

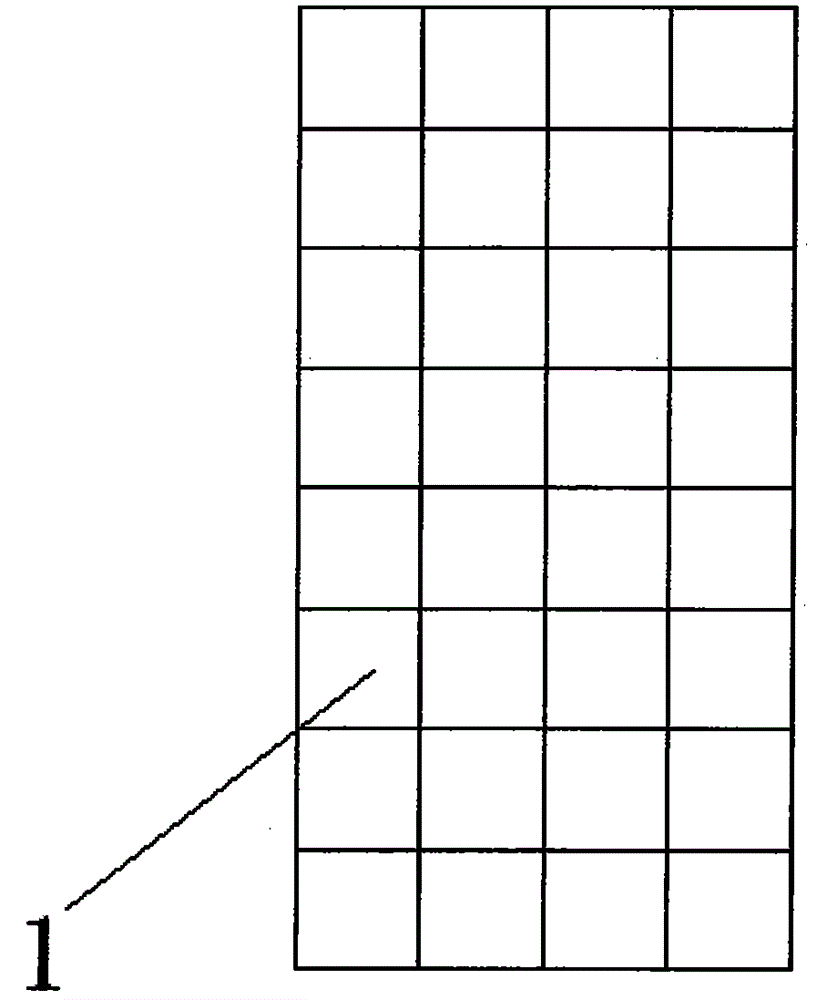

Mine protective net

The invention belongs to a protective net, and particularly relates to a mine protective net. The mine protective net comprises a device body which is mainly composed of steel wires and steel bars. The mine protective net is characterized in that a framework of the mine protective net is rectangular, the overall structure of the mine protective net includes square grids, the mine protective net is of a two-layer structure, the upper-layer structure is made of steel bars, the lower-layer structure is made of steel wires, and the two layers are combined together through a point welding process. The mine protective net is simple and reasonable in structure and low in cost. Compared with a mine protective net purely made of steel wires, the rigidity is increased, and the protective level is increased. Compared with a mine protective net purely made of steel bars, the rigidity and tenacity are guaranteed, and the production cost is reduced.

Owner:济源市乐享科技有限公司

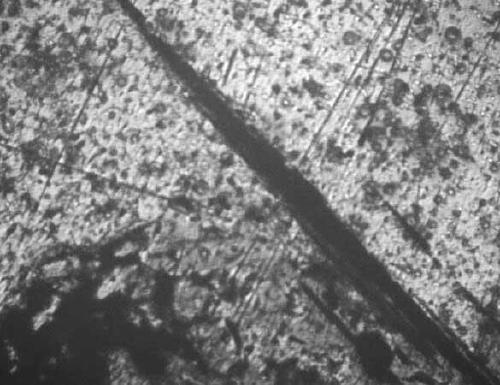

Chromium manganese tungsten molybdenum high alloy steel and manufacturing method

The invention discloses chromium manganese tungsten molybdenum high alloy steel and a manufacturing method thereof. The chromium manganese tungsten molybdenum high alloy steel comprises the followingcomponents in percentage by weight: 2-4% of carbon, 24-28% of chromium, 1-3% of silicon, 0.01-0.03% of phosphorus, 1.0-1.2% of manganese, 0.2-0.4% of nickel, 0.2-0.3% of tungsten, 0.1-0.3% of molybdenum, 0.1-0.3% of aluminum, 0.05-0.1% of tin, 0.05-0.06% of titanium, 0.1-0.15% of vanadium, 0.0005-0.0008% of antimony, and the balance of iron and impurities. The chromium manganese tungsten molybdenum high alloy steel has strict demands on the matching precision of all elements, so that the out-of-round rate and the breakage rate in the operation process are low; the preparation method is simplein process; a chilling process for aerospace science and technology is adopted in casting, so that grains of cast balls are finer, the structure is more compact, the wear resistance is improved, the electric energy loss is effectively reduced, and the effects of energy conservation and consumption reduction are achieved; after annealing, the alloy steel can eliminate the quenching stress; and remained austenite is converted to bainite to increase the hardness, so that the wear resistance, the hardness and the toughness of the alloy steel are guaranteed.

Owner:HUNAN CHANGJIANG WEARPROOF NEW MATERIAL CO LTD

Preparation process of metal wear-resistant alloy flange

The invention discloses a preparation process of a metal wear-resistant alloy flange, and particularly relates to the technical field of flange manufacturing. The preparation process comprises the following steps of raw material preparation and casting raw material preparation, specifically, raw materials comprise 0.8-1.2% of carbon, 0.6-0.8% of silicon, 18-22% of chromium, 2.2-3.2% of manganese,0.2-0.6% of vanadium, 0.01-0.03% of phosphorus, 0.4-0.8% of nickel, 0.2-0.5% of molybdenum, 0.2-0.4% of nitrogen, 0.06-0.08% of zinc and the balance copper, iron and inevitable impurities. According to the preparation process, an inner core layer and a high-chromium cast iron shell are arranged, so that the weight of the flange manufactured through the preparation process can be obviously reducedwithin a certain range on the premise that the hardness and the strength of the flange are not affected, moreover, carbon fibers can be selected from some leftover materials in a carbon fiber production workshop, and the material cost is low; and compared with a traditional metal flange preparation method at present, the flange prepared through the preparation process is formed by combining the high-chromium cast iron shell and the inner core layer, so that the flange has the advantages of being high in strength, toughness and wear resistance, low in manufacturing cost, small in weight and convenient to carry and transport.

Owner:湖北恩腾机械有限公司

Concrete tunnel lining material and preparation method thereof

The invention discloses a concrete tunnel lining material which is prepared from cement, fly ash, polyethylene chopped fibers, polypropylene profiled fibers, a fiber dispersion bonding aid, a hydration regulator, a polycarboxylate superplasticizer, water and sand, does not have reinforcing bars and can be constructed by virtue of 3D printing equipment. The invention also discloses a preparation method of the material. According to the material, construction of primary lining can be rapidly completed by means of 3D printing equipment after tunnel excavation, the lining concrete has the characteristics of no reinforcement, ultra-thinness, toughness, crack resistance and the like, the construction automation degree is high, the material variability is small, the inner contour surface is flatand smooth, the tunnel lining structure is compact in contact with an original excavation face of a tunnel and free of gaps, surrounding rock above the grade II or above can be directly used as a permanent lining, the surrounding rock of the grade II or below, a waterproof interlayer and a secondary lining can jointly form a composite lining, and therefore long-term safety and comfort of a tunneloperation space are guaranteed.

Owner:大悟海聚环境科技有限公司

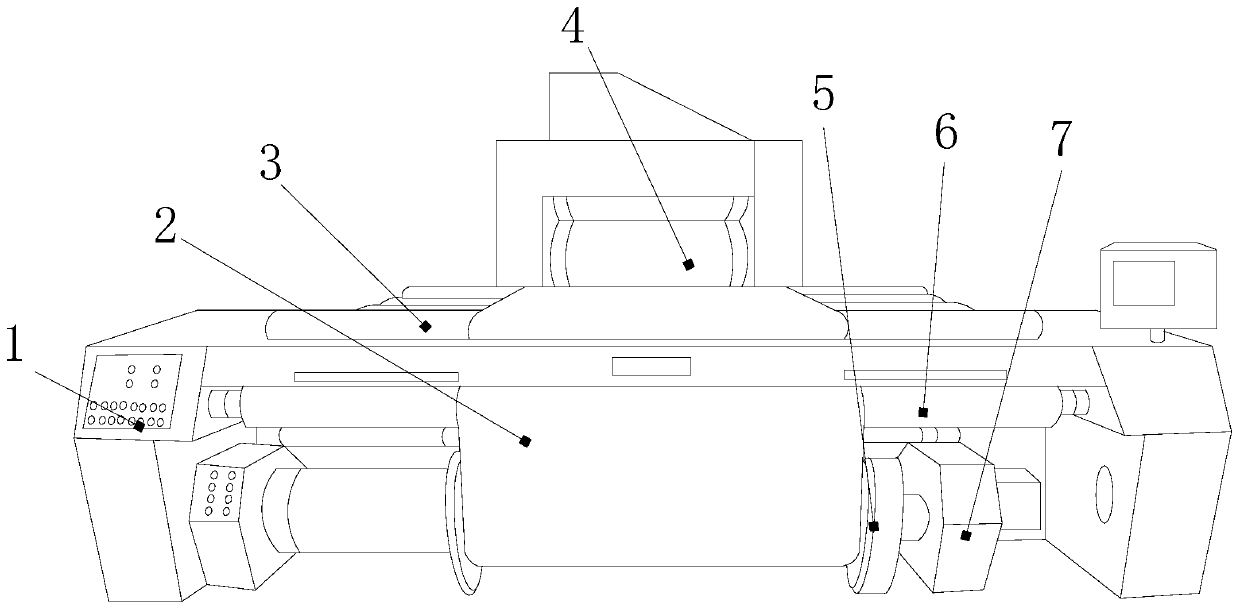

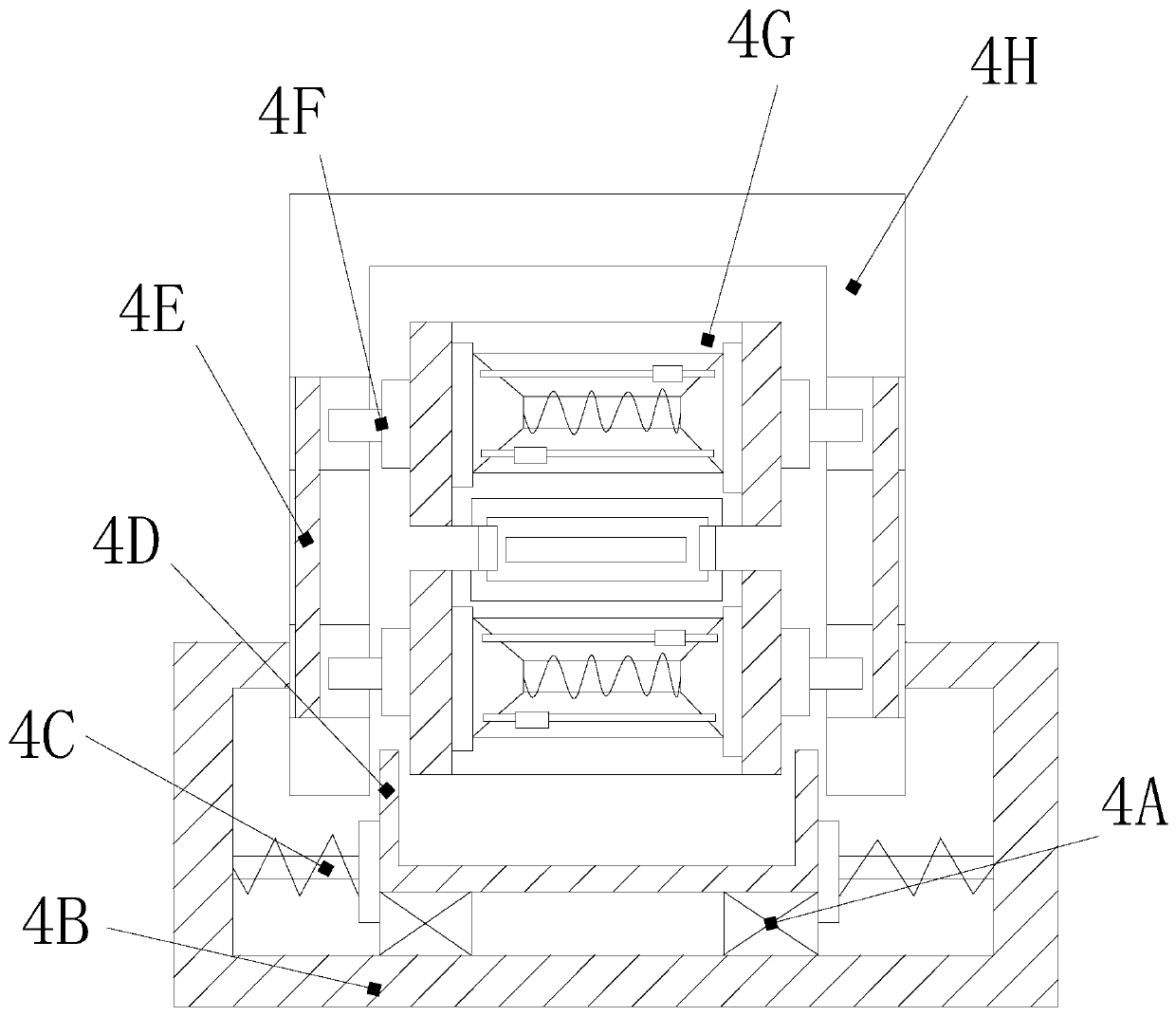

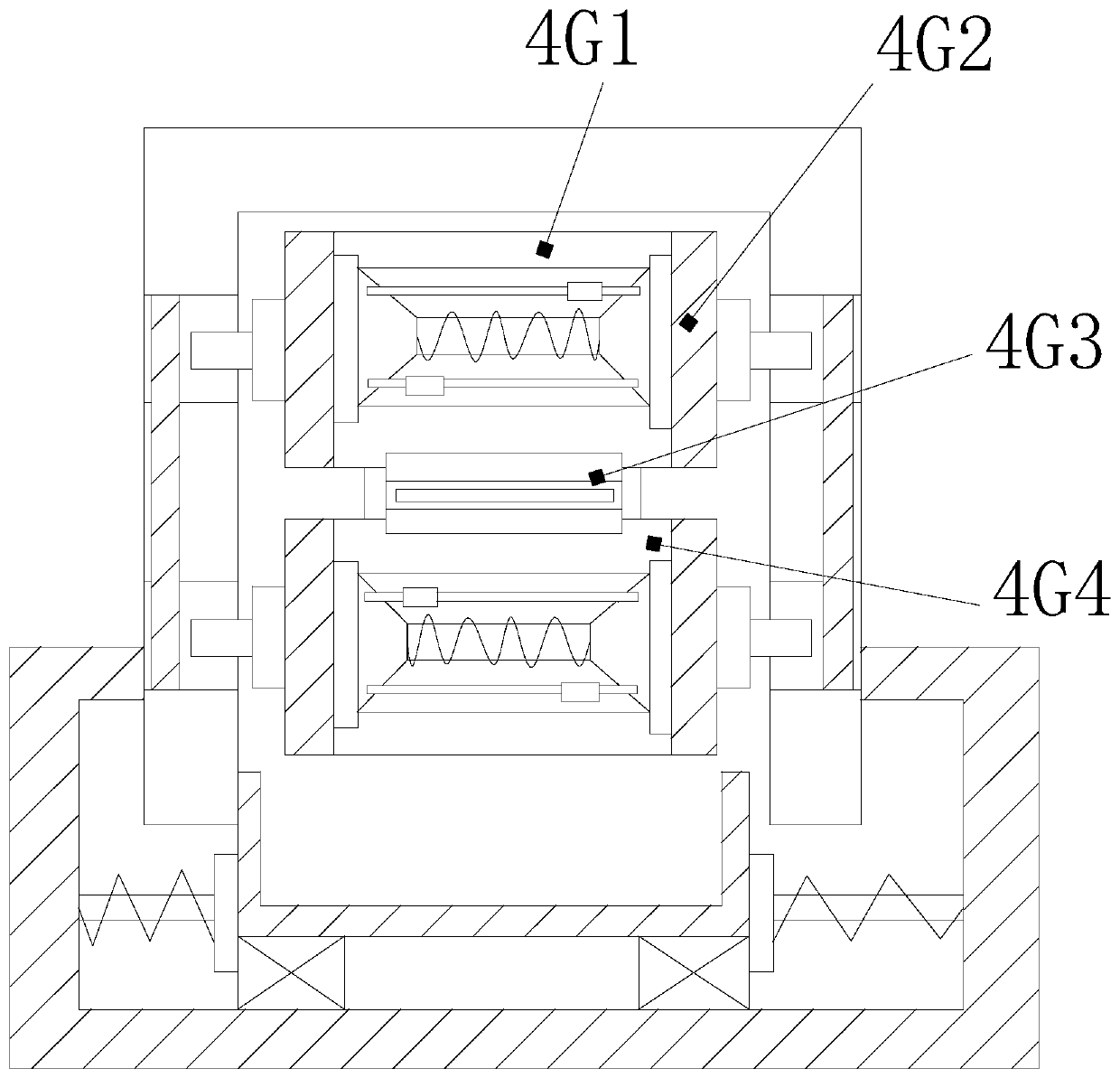

Slasher, with high drying performance, for performing double-dipping and quartic-pressing on wet slashed yarns through roller warp beams

InactiveCN110172793AOptimization of shaft movement trip rotation phenomenonHigh calorific valueLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsFlangingTar

The invention discloses a slasher, with high drying performance, for performing double-dipping and quartic-pressing on wet slashed yarns through roller warp beams. The slasher structurally comprises an industrial control base, a supporting cushion transporting platform, a roller rod group groove, a double-dipping and quartic-pressing oven, an I-shaped roller winding frame, an inner pressing revolving column and gearboxes. The slasher achieves the purpose that by the matching between the roller rod group groove and the double-dipping and quartic-pressing oven, the effect of upper-section, middle-section and lower-section four-layer desizing decrement is formed, sized hairiness is subjected to slurry infiltration to enable the fiber to be adhered and ensure the film toughness, the middle-section upper-surface lower-surface squeezing operation is performed, then filtering slurry falls and smoothly flows back to a large soaking groove tar, the recycling of materials is ensured, the interference on the yarn quality due to too much slurry is avoided, after a two-roller yarn pressing frame performs rolling, slashing and desizing, an oven housing is matched with a top electric heating roller to heat a baffle, the uniform heated surface under the drying matched revolving air pressure is reinforced, the roller rod group groove is connected after yarn discharging, and the flanging and hairiness of yarns are compacted and adhered, and the slasher has no impurity residuals, and the maintenance of warps is excellent.

Owner:褚晓婷

Pipe body structure of step type hole protecting pipe for gas extraction hole in soft coal bed

ActiveCN102619476BEasy to passConform to the gushing lawDrilling rodsGas removalEngineeringPore diameter

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com